Gas is, without a doubt, the most popular fuel for heating boilers. There is no need to constantly worry about reserves, as is the case with coal. To use gas as fuel, you just need to connect to the mains. Therefore, a huge number of individual autonomous heating systems are designed for this fuel. One of the options for autonomous heating is a parapet boiler. These units can be used even in city apartments.

These devices were created as an alternative to wall-mounted boilers. The latter had many advantages, but were characterized by operational difficulties. In order for the wall-mounted boiler to operate stably, it was necessary to ensure stable pressure in the pipeline. And the gas must only be of high quality. For the operation of such boilers, soft water and uninterrupted power supply are also required. Therefore, they often fail and require constant maintenance.

Over time, this equipment, sensitive to operating conditions, was replaced by a parapet gas boiler. These units have lower operating requirements and provide greater stability of the heating system.

How are they arranged?

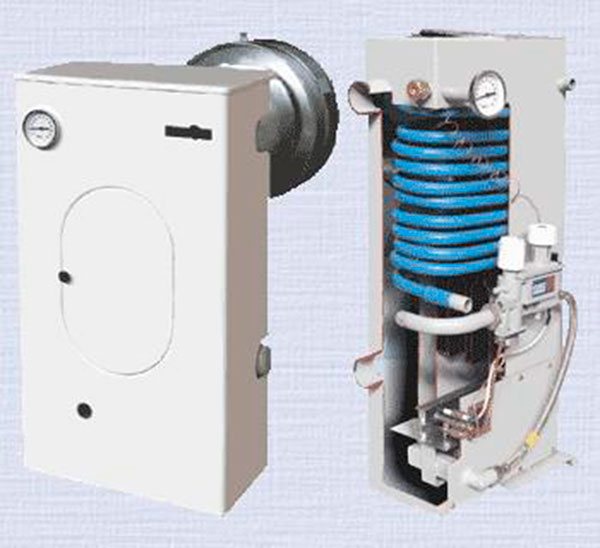

The parapet boiler has a closed combustion chamber. It does not contact the room. The equipment does not emit combustion products into the atmosphere, which is very important for small areas with poor ventilation. Therefore, these devices do not require traditional chimneys. The side two-pipe design is sufficient for operation. The main task of these pipes is the intake of air and the removal of exhaust gases. Due to the presence of a hole in the unit body, additional radiators are not needed. If you correctly perform all the calculations and select the device, then one unit will be enough for a complete heating system.

Installation of parapet boilers is carried out according to the principle of convectors. Due to the pipes, the system is connected to the gas main (and water supply in the case of double-circuit boilers). Next, the unit is mounted on the wall using brackets. The chimney for the boiler is of the coaxial type. It has a small diameter. The reader can see what a coaxial type chimney looks like in the photo below.

It can be laid directly in the outer wall on which the unit itself is installed. It is more efficient to remove the pipe through a window to make it more convenient to control the operation of the equipment.

Boiler installation

Installing the boiler is quite simple, so it can be done by hand; the main thing is not to forget to once again look at the installation instructions, which are included in the documentation for the unit. You also need to know the principles of using gas equipment.

All work must be done in stages. Stages include:

- Coordination of the installation diagram with the gas service (if necessary).

- Unpacking the equipment, checking the contents and removing packaging elements. It is not recommended to immediately connect the boiler, especially if it was brought in from the cold; the temperature should be equal to room temperature.

- Familiarity with the attached documentation, a thorough study of the installation and operating instructions; it must be in Russian or have a proper translation.

- Marking the location for installing the boiler and placing the outlet pipe; it is also important to check the presence of a water supply (for a double-circuit boiler).

- Installing fasteners and making holes for the pipe, the location should be as convenient as possible for subsequent maintenance and repair.

- Installation of the first chimney pipe, securing it.

- Preparation and installation of pipes for water supply.

- Mounting the boiler to the wall or floor.

- Installation of the second chimney pipe (at an angle).

- Installation of protection and adjustment of individual parts of the boiler.

- Installation of pipes, heating radiators and water tank.

Main advantages

The main advantage of a parapet boiler is the presence of a closed combustion chamber. Due to such a device, there is no need to install a full-fledged chimney system. A boiler of this type can be installed in any room where at least one wall is external.

Convection holes on the body provide heat to the entire room. There is no longer any need to install additional convectors, since these boilers are both a heating stove and a battery. Devices of this type combine all the advantages of this equipment.

Another important advantage is that the unit can be installed even in city apartments. All you need is gas and access to electricity. In a city apartment, a parapet boiler is most often located in the space under the window in kitchens. If there is no such place, then the structure can be installed near the walls.

A wide selection of models makes it possible to choose the most optimal option for rooms of any size and area. As for power, it can range from 15 to 40 kW, depending on the specific model.

Another important advantage is versatility. The model range includes different options. On sale you can find a parapet double-circuit boiler, which allows you not only to heat the room, but also heats the water if there is no hot water supply.

For individual heating systems, these units are the best choice for the price. Devices are available to most people of any income level. The cases are made in a modern design that does not spoil the interior. Modern residents of cities and private cottages choose a parapet gas boiler as a heating system. Reviews about them are positive. The equipment has a lot of serious advantages.

Operating principle of parapet gas equipment

- The burner device is ignited with a wick or igniter.

- Gas, when burned, releases heat, which heats the boiler.

- Network water, using a circulation pump or with natural circulation, heats up, leaves the boiler and enters heating devices located in residential, public or industrial premises.

- The gas combustion process will continue until the water in the heating circuit heats up to a predetermined level, after which it will be automatically turned off by a gas valve installed in front of the boiler.

- The wick continues to function and will re-ignite the burner when the mains water temperature drops.

Pros and cons of parapet boilers:

- Possibility of indoor use.

- Affordable prices.

- Small geometric dimensions of the installation.

- Speed and ease of installation work.

- Possibility of use without installing additional radiators.

- Large power range.

There is only one drawback - energy dependence.

The basic rules for installing a wall-mounted gas boiler in a wooden house cover three important areas:

- Standards stipulating the minimum requirements for a boiler room.

- Rules for connecting smoke removal and ventilation systems.

- Existing fire safety regulations.

Acceptable standards for the arrangement of a gas boiler room inside a wooden building stipulate the types and types of interior decoration, the security system, the presence of a fire alarm and fire extinguishing equipment.

To install a boiler in a wooden house, strict compliance with existing requirements is necessary. A gas boiler room is a place of increased fire danger, which will need to be taken into account during the arrangement.

The requirements for installing a floor-standing gas heating boiler in a wooden house take into account the operating features and the increased fire hazard associated with the structural material of the building. In this regard, the standards indicate the need to comply with the following requirements:

- The volume of the boiler room is calculated based on the overall performance of the heating equipment. Gas boiler up to 30 kW, installed in an isolated room of at least 9 m³. Provided that the ceiling height is at least 2.5 m.

- It is allowed to locate a gas boiler in any technical room of a wooden house. Sanitary standards prohibit the installation of heating equipment in living rooms, as well as kitchens and living rooms. Some restrictions affect the location of the boiler in the house. PPB standards prohibit the installation of a boiler room in the basement, but allow, with several reservations, the installation of a gas boiler in the basement.

- The boiler room is fenced off from the living rooms by a wall. To increase fire resistance, the walls are coated with special impregnations. In the boiler room, a door leaf with a minimum width of 80 cm is installed, not adjacent to the frame at the bottom, for a constant flow of fresh air.

- It is necessary to have natural lighting, as well as windows for ventilation.

If you agree on the design of the future house with representatives of the gas industry at the stage of preparing working diagrams, you can avoid unnecessary material costs for remodeling the building.

In a wooden house, special attention is paid to the installation of supply and exhaust ventilation and the correct connection of the smoke exhaust system. Minimum requirements applicable to the boiler room:

- Exhaust device - the diameter of the ventilation duct, calculated based on the boiler productivity - 8 cm² for each kilowatt of power.

- The installation of the smoke exhaust pipe is carried out in compliance with fire distances and gaps. The height of the chimney is calculated depending on the distance from the roof canopy. The pipe head must not be covered with decorative elements. To increase traction characteristics, it is recommended to install a deflector.

- It is not allowed for the horizontal section of the chimney to have a total length of more than 3 meters. It is allowed to install no more than 2 rotary couplings on the entire smoke exhaust system.

Some requirements for chimneys and supply ventilation are specified in fire safety rules.

Fire regulations cover: placement of the boiler, arrangement of the boiler room and installation of the smoke exhaust system:

- Placement of the boiler - optimal use for the needs of a boiler room, a separate building made of non-combustible materials: ceramic or silicate bricks, foam blocks, aerated concrete, etc. It is allowed to install a boiler room in the house, provided that the conditions of the safety regulations are met.

- The floor and walls of the boiler room are lined with non-combustible materials. If this is not possible, fire safety requirements stipulate the need for partial protection of surfaces at the location of the boiler and the chimney. The walls and floor are protected with non-flammable basalt insulation. Additional protection is provided by special fire-fighting compounds. Preliminary preparation of walls, ceilings, and floors will be required by treating them with mastics or impregnations with a high degree of fire resistance.

- When the chimney passes through the floor slabs and roof, a special fire-resistant cutting is used.

Fire-resistant materials for walls that are recommended for covering the surface are plaster plaster mortars, gypsum fiber boards, etc.

The floor-mounted turbocharged boiler has a closed combustion chamber, therefore it is safe and does not require a separate room

The product was created in the early nineties of the last century, when mass private construction began and people abandoned central heating. The universal stoves used at that time could operate on any fuel, but they had an open-type burner installed. Since domestic enterprises were closing en masse, and foreign products were unavailable, it was decided to develop and put into production a boiler of our own production that meets all power and safety requirements.

The work was carried out in Ukraine and Luch Russia. In 1996, the first two-circuit samples went on sale, with a compact design, a power of 10 kW, an efficiency of 0.92 and a closed combustion chamber. These boilers became the prototypes of units that are still manufactured today.

Since a gas boiler is purchased for decades, its choice must be taken as responsibly as possible.

For single-circuit boilers it is necessary to install a hot water boiler

When purchasing, you should pay attention to the following criteria:

- Heat exchanger steel thickness. It should not be less than 3 mm, preferably made of non-ferrous metal or stainless steel.

- Product design and effectiveness. To save money, it is better to take dual-circuit devices with an efficiency of 0.92 and higher.

- Dimensions and dimensions. If the space of the room allows, it is advisable to choose a floor-standing option. This type of boiler is more reliable and unpretentious.

- Location of connectors for connection. Depending on the installation location, a type of product with side or rear connection is selected.

- Power. You should purchase a unit at the rate of 1 kW per 10 m² of total area of the house with a reserve of 15% for extremely cold periods.

- Chimney material. The pipe must be made of thick stainless steel, resistant to high temperatures and the formation of soot inside the channel.

- Ease of installation. The cost, duration and labor intensity of the installation of a heating system depends on this.

- Functionality. A single-circuit boiler is smaller and cheaper, but does not solve the DHW problem.

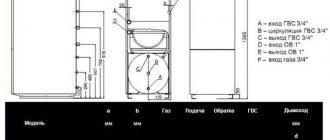

Layout of the main components of a parapet boiler

The operating principle of an autonomous boiler is quite simple:

- The wick ignites the burner, which heats the heat exchanger.

- Water moves along the circuit by natural current or under the influence of a pump.

- After heating the working fluid to the set temperature, the thermocouple closes the gas valve and combustion stops.

- When the coolant cools down to the set value, the valve opens and the constantly working wick ignites the gas.

A coaxial chimney is connected to the boiler. It is a structure of two pipes. The internal one removes smoke, and the external one supplies fresh air into the combustion chamber.

Installation of a boiler in a house: SNiP standards

Before installation work, you must obtain all permits. Self-installation is not only illegal, but also unsafe (especially if the device will be used in a high-rise building).

The basic requirements and standards for gas equipment are written in SNiP 42-01-2002 “Gas distribution systems”. Also, many requirements can be read in SNiP “Gas Supply” 2.04.08-87. This document is no longer relevant today, but it still contains useful information.

Types of gas heating boilers

There are two main types of devices - floor-mounted and wall-mounted boilers. The latter is less powerful, cheaper and more suitable for installation in an apartment.

Wall-mounted parapet gas boiler

Gas floor-standing boiler systems are characterized by high power, most often installed according to the “cascade” principle and include several boilers. This system can be called a mini-boiler room; it is capable of heating areas exceeding 1000 sq.m.

Floor design

Project

When there are technical conditions, you should start developing an installation plan.

The project represents an installation diagram, as well as laying a gas main from the point of connection to the city gas communication network. For the private sector, a drawing of the passage of gas communications throughout the entire site is additionally required. The entry point to the house must be marked. The project will be developed by engineers. In this case, all provisions of the GOS are taken into account. The design company must have a license for this type of service.

The lineup

Today, parapet boiler models are presented on the market with a wide variety of models from different manufacturers.

In the product line you can find boilers with different capacities, which are designed for heating houses and apartments.

Boilers are also classified according to the type of installation, number of circuits and operational characteristics. These parameters determine how much a gas boiler costs and how it will perform in the heating system. Discerning buyers who want to find the best heater option before choosing a specific model should study the products from the main manufacturers operating in the home heating equipment market.

Boilers from the Termotechnik brand - reliability and affordable price

Consumers who want to find a reliable and high-quality source of heating should pay attention to parapet boilers from the Termotechnik brand. These devices are assembled in Russia and have an affordable price due to the absence of manufacturer costs for paying export costs and customs duties.

Despite the availability and simplicity of design, Thermotechnik gas boilers, reviews of which speak about the stability and durability of the devices, have all the qualities of a functional and reliable heater.

Specific differences between Termotechnik boilers:

- high maintainability;

- availability of spare parts and repair kits;

- inexpensive price;

- adaptability to work in difficult conditions;

- ease of maintenance.

The Taiga gas boiler, whose power range is from 5 to 20 kW, deserves special attention in the line of this brand. The Taiga parapet gas boiler, reviews of which can be found online, is a well-designed and well-assembled device with an efficiency of 90%

The boiler is equipped with Italian automatic equipment, so its use as a basic heating device guarantees the stability and reliability of the circuit.

Helios boilers - excellent price and solid warranty from the manufacturer

The Ukrainian brand "Helios" produces parapet boilers of decent quality. These devices are also characterized by reasonable cost, ease of installation and ease of operation. In addition, the Helios gas boiler, the price of which can vary from 180 to 250 dollars depending on the power, has a number of competitive advantages.

Advantages of the Helios parapet boiler:

- high efficiency;

- wide range of models;

- possibility of installation in open and closed heating systems;

- availability of reliable Italian automatic equipment;

- high level of security.

Boilers from the Luch brand - functionality and reliability

The Luch parapet gas boiler is produced in Taganrog. This boiler differs from analogues in its compact body, simple installation procedure and inexpensive price. Various boiler models can be used to heat houses with an area of 80 to 180 square meters. When selecting the power of the boiler, it is worth considering that the device should not wear out. Experts recommend selecting the power of the device in accordance with the requirements of the heating scheme developed by competent heating engineers.

The specifics of the operation of parapet models from the Luch brand are presented in the following list:

- rational gas consumption;

- complete combustion of the energy carrier in a sealed chamber;

- convenient location of pipes for connecting the gas supply line;

- low heat loss;

- the presence of a tubular heat exchanger that ensures maximum boiler performance.

Installation Requirements

If the basic installation requirements are not met, this may result in complaints from the neighbor. Combustion products have a special odor and are harmful to human health. Also, violation of the requirements may affect the stability of the equipment - the unit may regularly go out, not light up, or smoke. These shortcomings are corrected by re-installation with the involvement of professionals.

Boilers should be placed on the external walls of the house. The distance from the facade is from 0.3 to 3.0 meters (the indicator depends on the power of the boiler). The chimney is installed only in open rooms. The wall intended for installation should be treated with non-flammable and fire-resistant materials.

Boilers should never be installed dangerously close to upholstered furniture, curtains or other flammable materials. The room where the equipment will be installed must be equipped with a high-quality ventilation system. The power of the unit is selected according to the size of the house that needs to be heated.

Types of heating devices

To heat a private house or city apartment, boilers can be used, which differ:

- at the installation site

- by power

- according to the method of removing combustion products

- by functionality

- by cost

- by burner type

- by type of coolant

- depending on electricity

- by the presence of automation and many other parameters

Depending on the installation site, gas heating boilers can be floor-mounted or wall-mounted. Floor-standing devices are usually more powerful and are capable of heating rooms up to several thousand square meters.

Wall-mounted ones are used more in private houses and apartments, since their power does not exceed 30 kW. Naturally, there are wall-mounted boilers with greater power, but here we are talking about mini-boiler houses that combine several devices like a cascade.

Type of chimney

Aton 7-16 kW

Based on the method of removing combustion products, units with natural draft and forced draft are distinguished. In the first case, gases are discharged through chimneys in the form of a pipe that exits through the roof to the outside. In the second case, combustion products are removed through special coaxial chimneys passing through the outer wall.

In some information materials you can find mention of turbocharged devices. Essentially, these are wall-mounted parapet boilers, from which combustion products are removed using built-in fans through a coaxial chimney.

Natural draft boilers use an open burner, and the air for combustion of fuel is taken directly from the living room. With coaxial exhaust, oxygen comes from the street. Such a chimney consists of two pipes of different diameters located one inside the other. A pipe of a smaller cross-section serves to remove combustion products, and through the space between the walls of the pipes, outside air, necessary for burning the gas, enters.

It is the parapet gas boiler that is equipped with such a chimney, which has a positive effect on the environmental situation in the house. Indeed, in this case, oxygen is not consumed from living quarters, but taken from the street.

Boiler functionality

Boiler functionality

Wall-mounted heating devices, like floor-mounted ones, can have one or two circuits. With one circuit, only the house is heated; with a second circuit, it becomes possible to also obtain hot water for domestic needs.

In parapet boilers, the built-in flow-through hot water heater is usually made of copper, since this metal has the best thermal conductivity qualities.

Parapet devices can be connected to the heating system on the right, left or both sides at the same time, which simplifies the heating installation.

These units are designed to operate on natural gas, but when changing burners they also function well on liquefied gas.

Coolant

Wall-mounted gas condensing boiler

Many people do not know that they cannot use hot water from the city heating system for domestic needs. And this often happens when the supply of hot or cold water is turned off for a while. Some residents, without thinking twice, open the tap on the radiator and drain the hot water to use it, for example, for washing the floor.

This is strictly forbidden, because there are special additives in the water. They prevent the formation of scale and other deposits on the walls of pipes and radiators. The use of such “water” can have a very negative impact on human health precisely because of these additives.

When installing a gas boiler in a city apartment, you need to carefully study this issue, because not all devices are designed for a similar coolant composition. It’s a different matter in a private house, where the water quality is controlled by the homeowner himself, and any heating units can be installed without regard to the coolant.

DIY installation

The bulk of the work on assembling and installing the boiler can be done independently. But some steps are best left to professionals - mistakes can be very expensive. This applies to the installation of chimney pipes for coaxial chimneys, as well as the first start-up. The exact installation process varies depending on the specific model. Each boiler comes with detailed instructions, where the manufacturer describes all installation steps:

- The first thing to do is to arrange a channel where the chimney and air pipes will be routed. What should the dimensions be? The holes must match the diameter of the pipe.

- A suitable place for the chimney is next to the window. In the future, this element will need to be serviced and its condition checked.

- Next, install the first duct pipe. It is fixed to prevent displacement. Then the section for the water supply is installed.

- On the surface where it is planned to install a parapet double-circuit gas boiler, studs are fixed. The unit body is secured with nuts.

- The pipes and chimney are installed in the same way, and the fasteners are fixed. In this case, you need to try to achieve maximum compaction between all elements. It is better to place the chimney at an angle. This way condensate is removed more efficiently.

- The chimney section is connected to the pipe, and protection is installed. The gaps should be adjusted so that the burner fire burns evenly and there are no tears.

- Then radiators and pipes are connected using standard technology. It is also worth installing an expansion tank.

- After installation, the equipment is checked by gas industry specialists. Then instructions are given. Only then can operation begin.

Boiler structure

The heating device is small in size, which makes it possible to install it in the kitchen, bathroom or basement level. The presence of convection openings in the body allows the unit to be used as an oven, which makes it possible to avoid installing piping and batteries indoors.

The structure of the products is quite simple:

- durable body covered with heat-resistant enamel;

- closed combustion chamber;

- gas-burner;

- wick;

- heat exchangers (coils made of copper or brass);

- chimney with wind protection.

Rating of the best manufacturers

Gas double-circuit parapet boiler, which manufacturer is better, what to focus on. It is necessary to analyze the rating of parapet gas boilers and read reviews.

Imported parapet gas boilers. Among them, it is worth highlighting equipment with cast iron heat exchangers, their advantage is reliability, with a power of 12 to 60 W. They will be able to heat larger houses and apartments. A distinctive feature of this kind of heat exchangers is their resistance to temperature changes and mechanical deformation. Thus, the Electrolux company produces equipment that can withstand critical temperatures above 90 degrees.

It should be noted the high-quality products of such companies: Italian - Fondital, Beretta; Slovak – Alphatherm Beta, Attack; Hungarian - Alphatherm Delta.

Russian parapet gas boilers. Domestic manufacturers often use components from the CIS and EU countries to manufacture equipment. These are cast iron heat exchangers, sensors, controllers. Thus, while maintaining quality characteristics, the final cost is reduced to approximately 15%.

This type of product includes: “Titan N” boilers (Ryazan); Lemax Leader GGU-ch (Taganrog); Siberia KCHGO (ZAO Rostovgazoapparat). These models are distinguished by a wide range of equipment power. Manufacturers offer single-circuit and double-circuit boilers of various types.

It is worth noting the high-quality products of Russian companies Helios, Danko, Conord.

We can conclude that parapet gas boilers are universal equipment for heating a home, which combines high quality indicators (efficiency 93-95%) and optimal prices. They compare favorably with chimney models with an open gas chamber in that they do not require a separate room for a boiler room. At the same time, compared to turbocharged models, it is easier to operate. The advantageous aspect of this type of equipment is its independence from the power supply system. This makes it possible to install the boiler in areas where there is a risk of power outages.

Installation rules

A parapet boiler, the price of which ranges from 12-65 thousand rubles, is a source of increased danger, so to install it you need to obtain permission from the fire inspection authorities, gas service and others (if necessary). In addition, the installation of the device is carried out in compliance with certain rules:

- The installation can be located in any room, but only near an external wall in which it is possible to make a hole for the chimney. The inside should be treated with special non-flammable materials - steel plates.

- Those objects that can quickly catch fire (furniture, curtains) should be kept at a distance of 30 cm from the boiler. Otherwise, a fire may occur.

- The distance between the device and the facade can vary between 0.3-2.5 m.

- The boiler can only be installed in a room with good ventilation.

- The chimney of the device must be vented only to the street. You cannot install it on closed balconies or porches.

Choosing a location for installing parapet units

Parapet gas boilers are installed in the same way as conventional ones in non-residential premises: kitchen, hall, corridor. They are placed only on the external wall of the house. If the walls are built from flammable material, then the distance from them to the pipe must be at least 20 cm. The surface on the side of the boiler and pipe must be protected with fireproof materials.

The coaxial chimney should not be located next to other facade elements or objects. The permissible distance to the chimney is about 30 cm. The chimney must not go out onto a balcony, loggia or under a canopy.

All about parapet gas boilers here

The pipe should not interfere with people passing by the wall or smoke out the window of neighbors.

For units with a power of up to 7 kW, it is allowed to place the pipe at a distance of 25 cm from the window. If the boiler is more powerful, then 50 cm.

When the gas boiler is located on the ground floor, the installation height of the pipe cannot be less than 0.5 m. And if there is a passage for people at the chimney outlet, the height of its placement should be from 2.2 m.

From balconies and other elements protruding more than 40 cm, it is allowed to place the pipe no closer than 2 m (for a unit power over 7 kW - 3 m).

The chimney should be placed so as to provide free access to it, which is necessary for the care and maintenance of the pipe.

There should be no flammable objects near the gas boiler indoors; the permissible distance to them is 30 cm.

Near the unit panel and its shut-off valves, free access of 1 m is required for control, operation and repair.