Connecting the cylinder to consumption devices

As a rule, most gas cylinders are used to operate kitchen stoves. Therefore, within the framework of this review, attention will be focused on this type of operation. If you are interested in using gas cylinders as autonomous heating, you can read the article: autonomous gasification - gas cylinder installations.

Connecting gas cylinders to consumption devices

The device must be connected through a gearbox. Inside a conventional gas cylinder, the pressure is variable and depends on the ambient temperature. It can vary from 4 to 6 atm. The reducer is able to reduce and equalize the pressure to the optimal operating level of the stove.

A hose is connected to the reducer, and a plate is connected to it. The fixation point is secured with clamps, after which it is necessary to check the tightness of the connection with soap foam. Absolutely any foam will do. The fixation points must be covered with a soap solution: if bubbles form on the surface, then the connection is not airtight.

To eliminate the leak: further tighten the nut at the junction of the fitting with the gearbox. If a leak is detected in the sleeve area, then tighten the clamps. After adjustment, you need to check again with soap foam to finally make sure there is no leakage. This check is always carried out when a gas cylinder - this is the golden rule for safe use.

Correct connection of gas cylinders on the street, Figure 1

Correct connection of polymer-composite gas cylinders, Figure 2

IMPORTANT! You should not act like some particularly “experienced” gas technicians: under no circumstances check the tightness using lit paper. The result of this is small flames at the leak points. This is strictly prohibited by safety regulations. In addition, such flames are very small and in daylight can go unnoticed and lead to dire consequences.

Cylinder preparation

The most important thing is to work carefully with the cylinders, make sure that the gas has run out and only then do the preparation. To begin, unscrew the taps using an adjustable wrench. To make work easier, you can attach a metal tube to the key. This creates a powerful lever.

If the tap is stuck to the cylinder, then the following steps are performed: the tap is clamped in a vice, two holes are drilled at the opposite end opposite each other, into which bolts are inserted. A piece of steel chain is clamped between them, and a construction scrap is inserted behind it. This way the tap is unscrewed from the cylinder.

Gasoline remains at the bottom of the cylinders - a flammable substance that is poured out. Next, the neck is cut off from all specimens, and the bottom is removed from two more. To ensure the safety of the process, water is first filled into the cylinders. Always check for a film of gasoline on top of the water. To do this, paper is inserted into the neck and set on fire. If a wet leaf burns, the water needs to be changed.

The cylinder cap is cut off symmetrically. To do this, take a wire to which a white marker is tied. The other end is fixed to the top, and an improvised compass is obtained. Using a grinder, the neck is cut along the line; the bottom of two cylinders is removed along the lower weld seam.

Installation and operation of gas cylinders

The most important criterion for the safe operation of such devices is control over possible leaks and overheating. A seal failure can be detected by a characteristic odor. The gas, in principle, has neither color nor odor, but a special marker is added to SPBT - a mercaptan hydrocarbon. Thanks to this, a person can smell the smell when turning on the column of a gas stove or during a leak.

So, if you smell this smell, then you can conclude that the concentration of SPBT is 20 percent of the dangerous level. There is no reason to panic, that is, there is a reason to check the connection location according to the diagram described above.

Operation of gas cylinders, presented in table form

When the gas cylinder is in the room itself, it should be placed at a distance of 1 meter from the stove, which, when active, represents a source of heat. Also, you should not place any other heating devices nearby: heating radiators and autonomous heaters.

An acceptable option would be the “country” installation method - on the outer northern side of the structure, which eliminates the possibility of the cylinder overheating by the sun’s rays. In such a situation, the sleeve must be passed through a hole in the wall, previously “treated” with a metal sleeve. The cylinder is placed in a special metal cabinet equipped with ventilation holes in the lower part of the walls. Since the gas is somewhat heavier than air, in the event of a leak, it will accumulate from below, where there will be ventilation holes, so a light wind can eliminate the unwanted accumulation.

Read also: At what angle to hold the electrode when welding

Selection of cylinder and materials

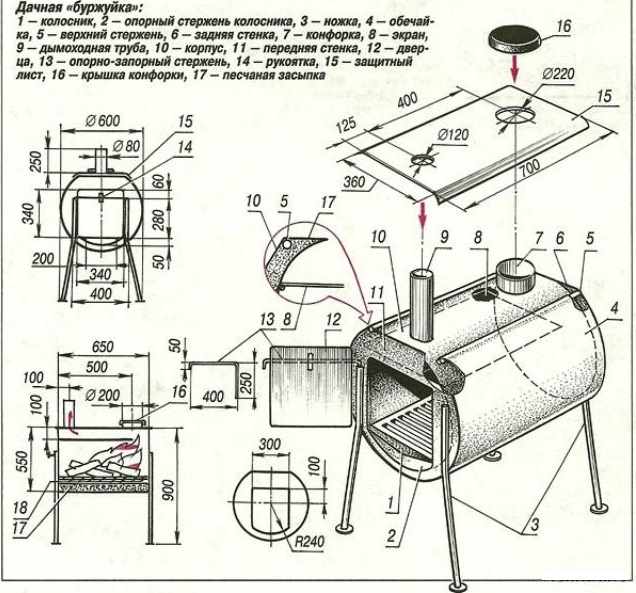

The furnace body is made from an old empty gas cylinder. For effective operation and high heat transfer of the structure, you need to decide on the size of the container. A small room can be heated using a five-liter cylinder. Small stoves with low power are constructed from containers ranging in size from 12 to 30 liters.

The industrial one (40 l volume) has thick walls, and the diameter of the inner surface is too small to accommodate a sufficient amount of fuel. The best option is a 50-liter propane container with a height of 85 cm and a diameter of 30 cm.

The cylinder is carefully prepared before work:

- unscrew the valve and leave the container for a day to allow the remaining gas to escape;

- then turn it over and drain the condensate into an unnecessary container;

- the balloon is filled with water and kept for several hours;

- pour out the water.

The remaining propane must be removed from the container, otherwise the cylinder may explode during welding. Additionally, you need to prepare some materials and tools:

- chimney pipe;

- steel sheets with a thickness of at least 3 mm;

- reinforcing bars;

- metal corners;

- pliers, chisel and hammer;

- welding machine;

- Sander;

- drill with drill bits.

Doors for the furnace are made from steel, and fittings are necessary to create grates. If it is not possible to make these parts for the stove from a gas cylinder with your own hands, then you can buy ready-made elements in specialized stores.

In this video, learn more about the potbelly stove from a cylinder:

Why do cylinders become covered with frost?

Here you can also debunk one of the most common misconceptions. It is generally accepted that if such a device “freezes,” it becomes covered with frost. Some even argue that such equipment should be insulated with blankets, old coats and other improvised items. So, the frost will disappear faster if you leave the gas container as is, without helping it “thaw” with warm things.

The bottom of a gas cylinder that is covered with frost

The appearance of frost can be explained by a number of physical processes that occur inside the structure when it is connected to stoves or burners. At such moments, active fuel consumption is observed, therefore, large volumes of gas liquid turn into a vapor fraction. And this phenomenon is always accompanied by high heat consumption, which is why the surface of the cylinder becomes much colder than the temperature in the surrounding space. Moisture in the air space begins to appear in the form of condensation on the walls of the installation, subsequently turning into frost. This is an absolutely natural phenomenon that you don’t need to do anything about.

Moreover, all attempts to use artificial “insulation” violate safety standards during operation, and also affect the deterioration of heat exchange between the device and the environment and affect the gas supply conditions. If your burner did not delight you with a grandiose flame, then after your “maneuvers” with the blanket, it may stop working altogether.

Do not insulate gas cylinders with anything!

In general, when connecting high-power gas devices, you need to be aware that the gas cylinder has limitations on the speed of release. This means that the liquid fuel turns into the vapor stage gradually. For example, a 50-liter cylinder can provide about 500 grams of gas in 60 minutes. This is equivalent to a power of 6-7 kW. In the cold season, this figure is halved if the equipment is located outside. In summer the situation is reversed: the maximum flow rate increases.

In any case, we can conclude that frost is evidence that the cylinder cannot cope with high fuel consumption. This may cause a temporary drop in gas pressure and equipment failure. If this happens, it is better to stop consumption and wait until there is a sufficient vapor cap.

Making a potbelly stove with your own hands

To make your own stove, the easiest way is to use a 50-liter cylinder designed for storing a propane-butane mixture or propane. Such cylinders are often used in everyday life and industry , so finding them is not difficult.

Preparing the gas cylinder

First, the gas is released. To do this, open the valve and wait until the hissing stops. This procedure must be performed outdoors.

Then you need to get rid of the specific smell. It is produced by a mercaptan fragrance, which is used to detect gas leaks. The container oxygen-based bleach solution Most often it is persol. Then the sediment is washed off with a solution of soda ash. After this washing, the cylinder is ready for use.

Choosing a potbelly stove design

Do-it-yourself ovens can be horizontal or vertical. In the first case, the structure lies with the valve to the side and rests on welded legs, and in the second it is located with the valve up. In this case, a ring stand is used as a support.

It is worth noting that creating a horizontal oven will take less time, but this design will be larger. Many people prefer the vertical option, since it can be placed even in the tiniest room. In this case, the traction will be even better.

Why is there a “splash” of water in the container?

This can be heard in winter. Please know that this is not water, but the butane component of SPBT. At the slightest frost, butane stops being converted into a vapor fraction. It is this that “splashes” in the form of liquid inside.

Butane component of SPBT in a gas cylinder

In the warm season, this problem does not arise: almost all of the propane-butane mixture is used. In order to avoid this in cold weather, it is recommended that when filling the container, ask the gas station attendant about the availability of a passport for the SPBT used. This document must contain information that the mixture contains at least 80 percent propane, which changes from liquid to vapor in cold weather. If you use such a gas station, then there should be no problems.

Selecting the design of a wood stove

Outdated and inefficient heating equipment is gradually becoming a thing of the past, which also affects homemade stoves. Nowadays, no one needs primitive iron boxes with a pipe and doors that devour firewood without good heat transfer. A modern potbelly stove should be economical and heat the room well. Therefore, advanced craftsmen are constantly working to improve steel furnaces.

To achieve the most efficient operation of a wood-burning heater, it is necessary to solve 2 questions: how to increase the efficiency of a potbelly stove and the burning time from one load, without increasing the quantity and price of the materials used. We present 3 homemade options where these tasks were successfully solved and implemented:

- three-pass stove made of two propane cylinders;

- pyrolysis stove with an air-fire-tube heat exchanger and a secondary chamber;

- A very popular design is “Bubafonya” with top burning of wood from a gas cylinder.

For reference. The first 2 units were developed, made and tested by our expert Vitaly Dashko, who kindly provided his photos and video materials.

If you are comfortable with a welding machine and have the necessary tools, then there will be no technical problems with production. Below we will present drawings and explain the technology of how to make a potbelly stove from a gas cylinder using all three options. But first, make your choice by reading the review of these stoves.

To make a stove you need a welding machine, a grinder, plumbing and measuring tools. You will need several clamps, at least 2 pieces

How much gas is enough?

Here you can use primitive mathematical rules. If we take into account the power of a kitchen stove, where 4 burners work at once, then 8 kWh of energy is used in 60 minutes. If you burn 1 kg of gas, you can get 12.8 kWh of energy. The first result must be divided by the second digit, resulting in the amount of “liquid” fuel required for full operation of the kitchen stove for an hour. This figure is 0.625 kilograms of gas. Therefore, a 50 liter container with 21 kilograms of gas will be used to operate the cooker for 33.6 hours. If the passport of your equipment indicates the power in kg of fuel burned, then the calculations are greatly simplified.

In the future, everything greatly depends on the intensity of use of the stove. If you often cook jellied meat, then the level of consumption will be one, if you are content with only brewing morning coffee, then another. Based on practical experience, we can say that 12 liters of gas, which will be used by a small family on weekends at the dacha, will be enough for the whole summer. You will find more detailed information about autonomous gasification in this section.

How to refill a gas cylinder?

Such devices are refueled at special points, which can be located autonomously and be part of a gas station. In the latter conditions, it is possible to refuel with gas engine fuel.

Device for refilling gas cylinders

The most important nuance in this process is the fact that you need to refuel not by volume, but by weight. If you are guided by safety precautions, gas containers should be filled to a maximum of 85 percent of the total volume to avoid excessive pressure.

In order to follow safety precautions and its standards, such a device with any volume is marked with a number with a maximum permissible weight, thereby corresponding to the permissible 85 percent. The containers are placed on the scales, including fuel injection. The process stops after reaching the required mass.

Refilling point for household gas cylinders

But even when filling relative to the mass, overflows are not excluded, which is especially important for small-volume containers - 5 or 12. They should be filled with 2 and 6 kilograms, respectively. A high filling speed sometimes makes it impossible to see that the maximum limit has been reached. If this happens to you, be sure to ask for the excess gas to be drained. In the future, it is better to choose another place for refueling.

Read also: Starter for stihl chainsaw

To avoid such problems, it is better to refuel in places where not mechanical scales are used, but electronic ones equipped with a cut-off device. Such devices can automatically stop refueling when needed, eliminating human error and related errors. Our filling points are equipped with such scales. So you can refill your cylinder with us. You can view information on prices and delivery by following the link https://www.propangaz.ru/? >

In general, the basic criterion for choosing a tanker is whether it has licensing documents for the use of fire and explosive objects. If the documents are present, then we can conclude that you are being served by qualified specialists who undergo special certification annually.

Conveyor for refilling gas cylinders

In other cases, you take responsibility for the operation of the refilled container. And you risk not only your money, but also the safety of your home and life. In addition, an unlicensed gas station is a violation of the law and may entail not only administrative, but also criminal liability under the article on illegal business activity.

The information provided in the review does not claim to be accurate encyclopedic data and is largely dictated by our experience. But we are confident that it can help you save a lot of time and money.

With the onset of cold weather, a caring car owner is looking for an opportunity to warm up his “iron horse”. Being left without a means of transportation due to low temperatures is an unpleasant pleasure. The room intended for parking a car must have a stable temperature all year round. Otherwise, the equipment may simply rust. Today we will talk about how to make a stove for a garage from a gas cylinder.

Furnace in production

A waste oil furnace operates as follows: a supply of oil is poured into the fuel compartment, it is ignited, and more or less air flow is supplied through the air damper, thus controlling the power of the furnace. Combustion products rise through a vertical perforated pipe and carry with them vapors of evaporating oil.

This mixture is burned along the entire length of the pipe and enters the afterburner chamber, divided into two parts. In the first, oil vapors are burned, in the second, with a lack of oxygen, nitrogen compounds are split into oxygen and nitrogen. The resulting oxygen promotes afterburning of combustion products, ensuring constant temperature and energy efficiency.

Pyrolysis oil furnace

A pyrolysis oil furnace made from a gas cylinder has a very high efficiency - about 80%. The disadvantage of such a pyrolysis device is harmful fumes and an unpleasant odor. This stove is not suitable for residential premises or areas where animals are kept.

Features, types and functionality

There are several ways to achieve an optimal climate in a car box - from basic thermal insulation in the walls, ceiling, roof and floor to installing a central and natural heating system. An average option in terms of labor intensity and budget would be an autonomous heater - a stove made from a used gas cylinder.

Particularly handy car owners have long thought through the design of such stoves down to the smallest detail. The idea of this garage heating itself is not new, but it has a number of features, which are described in detail below.

Garage heaters made from gas (usually propane) cylinders are much more economical and functional than other homemade stoves. Their main advantage is that they are convenient for thermal decomposition of fuel. The elongated shape of the gas cylinder is optimal, therefore it meets the basic requirements of the firebox without additional modifications. Only two holes are enough - for the access of oxygen and the release of carbon dioxide into the chimney.

Such “potbelly stoves” are usually divided into two types – vertical and horizontal. If desired, they can be combined.

Types of oil furnaces

Using waste oil, you can make the already discussed pyrolysis furnace. Another type of oil stove made from a gas cylinder is a dripper or long-burning stove. There is a brick at the bottom of the combustion chamber. Above it there is a tube supplying oil (or diesel fuel).

Using a valve with a poppet valve, the oil supply is adjusted so that approximately one drop drips per minute. To start the furnace, a small puddle of oil is poured onto the brick and set on fire, the brick becomes hot, and the next drops burst into flames upon contact with it. Combustion products rise to the top of the stove and heat it.

Advantages and disadvantages

The positive aspects of homemade stoves include:

- excellent thermal conductivity (provided by the thick metal walls of the cylinder);

- convenient dimensions (can be made to fit your garage);

- ease of manufacture and maintenance;

- availability of consumables and fuel.

Among the few disadvantages, one can highlight only the ability to use a limited number of types of fuel (wood, coal, fuel briquettes), and with a vertical design, there is also the need to adjust the size of the logs to the length of the firebox.

Design features and operating principle

The “potbelly stove” does not have any special design differences from its relatives in terms of solid fuel. It consists of three departments:

- direct fireboxes with a grate (fuel burns in it);

- blower (provides access to oxygen and space for ash);

- chimney.

To make the operation of the stove convenient and safe, the firebox and vent are equipped with doors with a bolt. These additional design elements improve ignition, reduce the risk of coal falling out and unintentional combustion, and by adjusting the size of the gap in the door, you can reduce or increase the intensity of oxygen supply to the oven.

Doors can be of absolutely any shape. It is only important to take into account the standard size of the logs, as well as the convenience of their placement.

An important element of a homemade stove made from a gas cylinder is the grate. Its function is to retain firewood, as well as to conveniently sift through loose pyrolysis elements. Wood is burning on the grate. Consequently, the material from which the grate will be made must be as durable and heat-resistant as possible. For manufacturing, fittings with a diameter greater than 10 mm are ideal. The rods are connected by welding.

You can install a potbelly stove where there are no problems with the convenience of leading the chimney pipe to the street. For fire safety purposes, it is better to line the adjacent wooden walls with sheets of metal so that when heated, a fire does not occur. This type of stove heats the room very quickly, so they are convenient in emergency situations that require instant heating.

Features and types of homemade stoves from a gas cylinder

All solid fuel stoves made from a gas cylinder have common design elements:

- A housing in which holes are cut for the door, vent and exhaust pipe.

- Blower.

- Exhaust pipe equipped with a throttle valve.

- A grate located low above the bottom of the stove. Fuel is placed on it and its combustion occurs.

- Internal walls that form the flow of combustion products.

- Legs.

Through the door, fuel is loaded and ash and slag are removed from the grate space. An air flow enters the combustion chamber through the blower and the combustion mode is adjusted. The blower is made as a structural part of the door or is made in the form of a separate hole with a damper. A throttle-type damper is installed into the exhaust pipe, which also regulates the combustion mode. Gas cylinder stoves are available in vertical and horizontal versions. A horizontal oven is easier to implement, but takes up a lot of space. The vertical one can be placed in any corner of the room; it has significantly better draft and fuel combustion efficiency.

In liquid fuel furnaces (they are also called oil or drip furnaces), instead of a grate, a burner of one design or another is fixed and a fuel supply pipeline is installed. The door is much smaller - it is not needed for loading fuel and removing ash and slag, but only for adjusting the air flow, as well as for installing and servicing the burner.

To the basic configuration of a gas cylinder stove, a home craftsman can add various improvements: a burn-protection guard, burners for heating and preparing food and drinks, hangers for drying clothes and shoes, etc.

Materials for production

In addition to a propane cylinder (it is better to choose an all-metal cylinder of fifty liters and three decimeters in diameter - this volume is enough for waste-free pyrolysis), you will definitely need corner stands as legs, a grate for the grate, steel sheets (4 mm), a door and a chimney pipe of optimal length . Of the necessary tools you will need to purchase:

- grinder;

- welding;

- metal scissors;

- Screwdriver Set;

- hammer drill

Read also: How is thread pitch measured?

Gas cylinder stove: pros and cons

There are many other options: welded from sheet iron, made of brick, and so on. But today we are interested in the most common and functional option - a stove converted from a gas cylinder, since the price tag of a ready-made cast iron or steel stove in a store is not suitable for everyone.

Making your own “potbelly stove” from a gas cylinder is the most economical and effective means of heating a garage.

There can be many fuel options for “bourgeois”: coal, mining, combustible mixtures, but they mainly use natural materials – wood.

Do-it-yourself long-burning stove from a gas cylinder

Although “slow” boilers contain a pyrolysis process, they are still not pyrolysis (the latter are 10 percent more efficient than them, have a different structure, complete combustion of fuel, are more environmentally friendly and cost).

But the Bubafonya stove does not need turbocharging with a fan and can be made from a gas cylinder with your own hands.

Ready-made stove Bubafonya

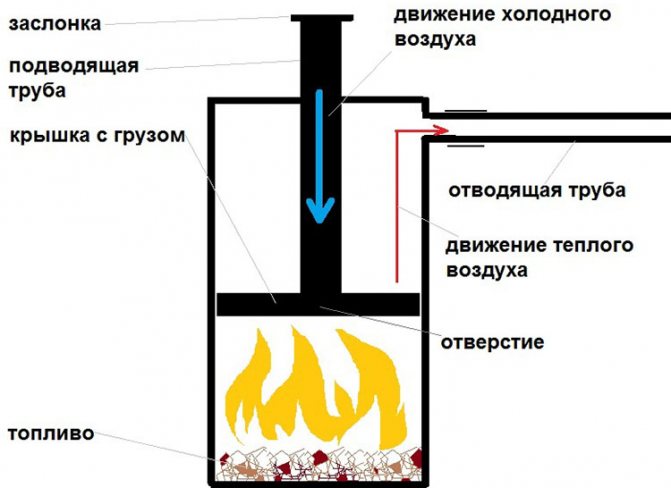

Principle of operation

Let's look at how a gas stove for a summer residence with a cylinder (on a cylinder) works.

The entire lower part of such units is densely filled with fuel. Combustion occurs in a thin top layer. Efficiency is achieved through afterburning of pyrolysis gases. In Bubafon, pyrolysis takes place under pressure, which presses the fuel and lowers as it burns.

Through a pipe welded to this pancake, oxygen is supplied for the combustion process. The oppression plate has ribs, the curved shape of which distributes air.

Scheme of operation of the Bubafonya stove

The diameter of the tank for loading Bubafoni fuel must be from 30 to 80 cm! It turns out that the balloon, with its 30 cm, is the minimum limit.

The efficiency of a potbelly stove does not reach 40%, but the stove is very easy to assemble, which is why it is still popular. Wood stove made from a gas cylinder - design features and assembly instructions.

For recommendations on making a decorative fireplace from plasterboard, read this topic.

Assembly

Procedure for making a furnace:

- With a diameter of 30 cm, the height of the boiler is 90 cm, but the entire cylinder is 85. There are two options for solving the problem. Firstly, you can cut off the entire vaulted part and add the missing height with a fragment from another cylinder. Secondly, you can turn this vaulted part into a lid. The top cut is made where the straight part of the body begins.

- A press is being made. A circle with a diameter of 27 cm is cut out of metal (6-10 mm thick). A hole is made in the center to the size of the air duct pipe.

- The ribs are made 4 cm high. They are slightly bent and welded onto the pancake so that the bend goes clockwise.

- A door is cut into the lower part of the body - an ash pan 17 cm wide.

- Grate bars. The grate can be welded separately from metal rods. The legs welded to it will help you place the grill at the desired height. Their height is taken based on the height at which the ash door ends.

- Air duct pipe. Diameter 7.5 - 8 cm. Its lower edge should protrude from the pressure sheet (reach the edge of the ribs). The top edge is 15 cm above the collar welded onto the lid. The pipe is welded to a round press with ribs.

- A damper is made on the upper edge of the air supply pipe, with the help of which the intensity of the air supply is regulated. A bolt is welded along the outer wall of the pipe along the axis, and a hole is drilled in the damper. The damper turns out to be rotary.

- Lid. Must dress tightly. To do this, you can weld a bead ring along the outer edge of the body. It will be convenient if the lid and body are equipped with handles.

- In the center of the straight lid and at the top point of the vaulted one, a hole is made through which the air duct will exit. Its diameter is equal to the outer diameter of the air duct + the minimum gap that will ensure the free passage of the pipe (no more than 2 mm).

- A collar is placed around the perimeter of the hole. Its height is the size of the gap increased by 80 times.

- Chimney. A piece of pipe (40 cm or more in length) will be positioned horizontally and connected to a vertical chimney pipe (10 - 12 cm in diameter). Stepping 1 - 2 cm down from the cover, a hole equal to the diameter of the chimney is cut out, and a short pipe is welded to it. This is the final stage of making a stove in a workshop. Further work is carried out after installation on site.

- Part of the chimney is lowered below the junction with the pipe and a device is made in it to collect and drain condensate, which is inevitable in such stoves.

- The chimney is routed through the roof and welded to the stove.

Calculation of parameters: drawings and recommendations

You should start with the selection of source material. A 50-liter gas cylinder is ideal.

Its dimensions: 300 mm in diameter, 850 mm in height with a 4 mm metal wall.

These cylinders are commonly used in a variety of applications, from stove fuel to industrial applications.

Main parameters and features of stove manufacturing:

- the chimney is usually made of a pipe with a cross-section of 100–125 mm with a wall of 3-4 mm;

- place it vertically, perhaps with a slight deviation, 25-350;

- the firebox and ash pan are equipped with doors, which must be locked to improve heat transfer during fuel combustion and for fire safety purposes; in addition, the doors are used to regulate the air supply;

- it is important that the firebox must have sufficient depth for firewood of a convenient size;

- grates are needed for storing fuel and separating ash and coals during the combustion process;

- It is better to weld them from the most durable and heat-resistant material, for example from reinforcing bars with a thickness of 12-15 mm;

- their length must correspond to the inner diameter of the cylinder body; this grid usually has a mesh or a gap with a pitch of 10–15 mm;

- In order for your wood-burning “potbelly stove” to heat and fire properly, it is built according to the principle of a conventional wood-burning stove.

Vertical oven assembly process

A vertical oven is more difficult to manufacture, but requires less space for its installation and has better user qualities. The volume of the cylinder is used more rationally. The principle of operation of the furnace does not change, but is implemented with greater efficiency. In the vertical version, two doors are made - for loading fuel and for the ash tray. Grate bars made of reinforcement are welded between these doors.

In principle, the entire upper part of the furnace can be dedicated to loading fuel, which will ensure long-term operation on one load. However, the volume of the combustion chamber is often reduced to accommodate additional heat exchangers in the upper part. One of the interesting options is through metal pipes welded into the upper part of the gas cylinder, through which air is driven by a fan (necessarily heat-resistant).

DIY construction

Let's look at an approximate diagram.

- The firebox and ash pan are separated by a grate made of refractory material.

- Wood is placed on it and set on fire. As combustion proceeds, soot and coals are poured into the ash pan.

- The blower is an important element of the furnace. For better combustion of wood, the firebox requires a constant supply of air, for which holes are made.

- An alternative way to provide oxygen to the combustion process is to open the firebox door from time to time.

- Combustion products are removed using a chimney. If it is laid incorrectly, you can achieve the opposite effect - instead of smoke, a significant part of the heat will escape through the pipe, and smoke will be created in the room. Consequently, an unreasonably large amount of firewood will be wasted, which will lead to low efficiency.

Recommendations for masters

When making a stove from a cylinder with your own hands, you need to take into account several nuances. It is necessary to adhere to the basic recommendations and operating rules:

- the chimney should consist of broken sections, since all the heat will quickly escape through a short pipe;

- fuel can be anything - coal, firewood, wood waste, household waste;

- the efficiency increases with increasing chimney length, but straight and downward sections must be avoided;

- heat transfer increases if another container is placed inside the main body, but of a smaller size. This way you can increase draft and prevent smoke from entering the room.

At home, you can make a stove from a gas cylinder for heating small spaces. This is an economical design that allows you to heat a small country house or quickly prepare food in a few hours.

More information about a wood-burning stove made from a gas cylinder: