Increasingly, warm floors are being installed in apartments and private houses. It makes it possible to heat the room evenly over the entire area, making the microclimate as comfortable as possible for residents. During the installation of such a system, waterproofing of the heated floor will be mandatory. The need for this measure is explained by the following reasons.

- Waterproofing under a warm water floor is a prerequisite when installing such a heating system, since if the seal of the pipes with the coolant is broken, the base will begin to collapse. This is especially true for an apartment that is not located on the ground floor, since there is a high risk of flooding of neighbors.

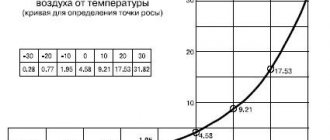

- Waterproofing a warm water or electric floor is needed to separate the insulation from the concrete base, since due to changes in low and high temperatures, condensation will occur, which will negatively affect building materials.

- Waterproofing the floor in a private house on the ground floor, between the soil and the screed, to create a protective layer that prevents capillary moisture from penetrating upward.

Do you need waterproofing for underfloor heating?

Do you need waterproofing for underfloor heating? This question is often asked by those who are making repairs for the first time, in particular, installing such a heating system. The answer in this case is simple - if you neglect insulation when laying a water floor, then there is a risk of leaks and subsequent corrosion and destruction of building materials. If the insulation procedure involves installing an electrical system in rooms with high humidity levels, then there is a risk of a short circuit. Therefore, for safety and comfort, experts recommend waterproofing under the heated floor.

Criteria for selecting waterproofing materials

According to the specific application, such materials are divided into different types, but their selection is subject to the same requirements:

- atomosphere resistance - protection from moisture must be distinguished by the ability to retain its original properties and quality characteristics for the longest possible period,

- moisture resistance and resistance to water is a very important criterion that determines the ability not to pass or absorb water,

- chemical resistance - this parameter is important to avoid damage from exposure to chemical elements during operation,

- resistance to temperature changes - this property helps maintain original performance at certain temperatures,

- biological stability - this characteristic allows you to prevent the penetration and impact of bacteria and microorganisms on the structure of the waterproofing material.

When deciding which waterproofing material to use for underfloor heating, it is recommended to pay attention to the following important aspects:

- price. As a rule, rolled materials are cheaper. Mastic materials and primers are more expensive, but they protect better from moisture,

- features of the premises - for rooms with a small area it is better to use mastic, but large rooms are easier to cover with roll materials,

- the possibility of installing waterproofing on your own - it is easiest to work with impregnating compounds, but difficulties may arise with the deposited layer.

In most cases, manufacturers of underfloor heating systems recommend types of waterproofing materials as recommendations. These include:

- polyethylene and polyvinyl chloride film materials. They are equipped with thermo-reflective layers. For ease of installation, the edges are heated and joined, insulation is performed with adhesive flax,

- cement-polymer - a freshly prepared elastic composition is applied to the surface using a roller or spatula, and a special tape is laid at the joints. The result is a durable and waterproof coating that is excellent for concrete surfaces. Many note its elasticity, which is very important during changes in temperature conditions and shrinkage of buildings recently put into operation,

- cast - the most reliable option. Today, liquid silicone membranes are used for this purpose, creating good adhesion and being elastic.

Liquid silicone membranes - a type of waterproofing for underfloor heating

Selection of materials for waterproofing underfloor heating

The selected floor waterproofing in a private house or apartment must meet the following parameters:

- heat resistance;

- the absence of components harmful to humans that will be released into the air when heated;

- waterproofness, which is especially important when waterproofing a heated floor with coolant;

- durability.

Let's consider the most effective materials that are used to insulate an electric or water floor.

Roll waterproofing

Rolled waterproofing is the most common material, especially when installing an electric floor. The simplest option is roofing felt or thick plastic film. In recent years, waterproofing membranes have become in great demand; the material is stronger and more durable than the usual roofing felt.

Fixation is carried out by gluing or fusing using a gas torch or a hair dryer.

Before laying the rolled product, the base is carefully leveled and treated with a primer. Next, a layer of waterproofing is laid, which in its own way provides some additional insulation. Only after fixing the insulation can you begin installing the heated floor.

Coating waterproofing

The simplest type of waterproofing that can be done under a warm water floor is to apply a coating composition to the concrete base, which makes the structure resistant to moisture. In this case, it is not recommended to use mixtures made on a bitumen basis. It is better to give preference to cement-polymer compositions, applied to the surface using a roller or spatula, at the joints, laying a special tape. An equally effective product is a cast silicone mixture, which, when hardened, forms a strong and elastic membrane, which is very important when shrinking buildings that have recently been put into operation.

The mastic is applied with a brush or roller in several layers. You can also use the airless spraying method. The components of the composition penetrate into the structure of the building material, creating a protective hydrophobic layer. As a rule, waterproofing mastics are used in bathrooms, toilets and kitchens; if we are talking about a room on the ground floor, then insulation will also be a mandatory procedure.

Floor coating compounds

This group of materials includes various types of mastics. The most common is bitumen mastic; it has been known since ancient times, but in modern construction oxidized bitumen with various polymer additives is more often used.

Some mastic compositions are specially made in a bright color so that when applied they do not leave the area without waterproofing

Bituminous mastic was known in the states of Ancient Mesopotamia. Residents of Mesopotamia used bitumen, which naturally came to the surface.

Some manufacturers produce latex, cement and cement-polymer mastics. Compared to bitumen, they are more durable and easier to apply.

- Method of application: mastic is applied using a brush, roller or spatula; in a liquid state it fills small cracks. After hardening, a water-protected coating is formed on the surface. Bitumen mastics are heated before use; polymer and cement-polymer compositions can be applied without heating.

- Advantages of coating compositions: mastics are easy to apply: with their help you can easily process joints and seams. This type of material is suitable for local waterproofing. They can also be used in combination with roll materials. Coating compositions allow you to obtain a seamless water-repellent coating. Polymer and bitumen compositions have good elasticity.

- Disadvantages of floor coatings: Cement waterproofing materials have low elasticity, so they are not recommended for use in regions with high seismic activity. The process of applying mastic over a large area will take a lot of time.

Technology for applying waterproofing under heated floors

If you need waterproofing of a room located above the ground, then initially a protective layer is laid under the screed, so to speak, preliminary insulation. As a rule, rolled materials are used for this (roofing felt, glass insulation, etc.).

The next stage is to pour the screed, after which it has completely dried it can directly waterproof the heated floor. If we are talking about an existing screed, then you first need to remove the remnants of the old insulation from it and clean it of dirt.

Rolled insulation is rolled out over the floor surface and pressed as much as possible against the base. In this case, it is necessary to extend the waterproofing material about 20 centimeters onto the walls. The panels are fixed with an overlap, the joints are carefully glued or welded.

If waterproofing the floor is carried out using coating compounds, then during work you must strictly follow the manufacturer’s instructions. Mastics are applied in several layers, and after each treatment you need to wait for the composition to dry completely.

The heated floor is installed only after the last layer of insulation has dried.

If necessary, you can waterproof the insulation on top, for example, using a waterproof underlay. Whatever waterproofing under a water floor or electric heating is chosen, it is very important to follow all the steps in order to achieve the desired result. Of course, you can do everything yourself, but each material and technology has its own nuances that need to be taken into account. There is another option for solving this problem - to entrust the arrangement process to specialists who have experience in such work.

Floor construction

When you have already decided what kind of insulation is needed for a warm water floor, you can begin work. The level base has already been prepared, which means the differences do not exceed 7 mm per 2 m. If there are uneven spots, they are covered with sand. Some people lay waterproofing under the insulation, while others do the opposite.

Extruded polystyrene foam, for example, requires almost no waterproofing, so the position of the waterproofing is not critical. At the next stage, you can lay the damper tape. It can be ready-made or made independently. If you decide to use sheet insulation, then it is laid with offset joints so that the material is tightly connected.

It is important to reinforce the floor. A mesh that is tied together with wire is perfect for this. Nylon clamps are attached to the mesh, which will strengthen the pipes. Now you know what pipes are needed for a warm water floor, this was discussed above. At the next stage, you can start laying them. To do this, you need to step back from the wall about 20 cm.

Next, the circuits are connected and crimped. The final stage will be pouring the screed and laying the finishing coating. When the materials and pipes for warm water floors have been laid, you should not immediately turn on the system at full power. She needs to be allowed to work at medium intensity for some time.

Types of waterproofing under a water floor

Several types of waterproofing materials are known, differing in composition, principle of operation, and efficiency.

Roll

Inexpensive and most common option for insulation. For this type of protection, roofing felt, a thick polyethylene film, is used. Fused waterproofing materials are applied using the gluing method with pre-heating with a gas burner or a hair dryer.

Water based mastic

Creates maximum surface protection from moisture penetration. Recommended for use in multi-storey buildings for maximum protection against water leakage if the water circuit has lost its integrity. In order to prevent leaks, the water circuits of heating systems are placed in special corrugations as an additional measure. This measure ensures that if the integrity of the pipes is compromised, water will not flood the lower floor.

Water-based mastic is one of the options for waterproofing under heated floors