Most common systems require connection to communications - electrical or central heating networks.

The ability to use network resources is a big plus, since the use of modern heating methods, such as underfloor heating, becomes available. This method allows you to make almost the entire free surface of the floor a heat source. Constant contact of the inhabitants of the house with a heated surface helps to create a comfortable environment in the room, making living in the house cozy and comfortable.

general information

Warm floor is a complex system, the design of which includes:

- Preparatory layers.

- Heating source.

- Cement screed (as an option - sheet materials such as OSB, chipboard and the like).

- Flooring.

The most common coating is universally recognized as linoleum. In combination with a warm floor, it experiences an increased temperature load, which changes its technical characteristics (in particular, rigidity and strength) and linear dimensions, and unevenly.

Laying heated floor elements under furniture or household appliances is prohibited, so some parts of the coating heat up, while others remain cold, which can cause deformation of the canvas and disruption of the plane - the appearance of waves, wrinkling, etc. In addition, linoleum - soft material, it is extremely demanding on the quality of the substrate, which does not allow it to be laid directly on a heat source, as is done when using more rigid coatings.

Therefore, a cement screed or a leveling layer made of sheet materials such as OSB, chipboard, MLF and the like is required. At the same time, the presence of a leveling layer will remove the excessive thermal load on the coating, thereby reducing the possibility of deformation.

Finish coating for heated floors

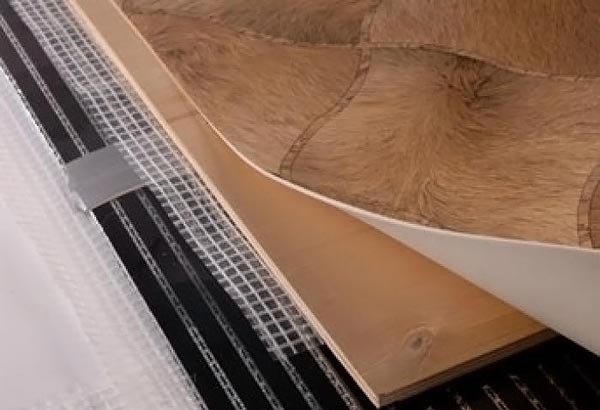

If testing is completed successfully, installation work can continue. Thermal film must have a protective coating against exposure to water. For these purposes, you can use special modern waterproofing (expensive option) or ordinary polyethylene film (recommended option). The effect will be the same, and the savings will be significant. Spread the film with an overlap of about ten centimeters, the joints must be taped. Work carefully, do not leave gaps or loose joints.

Linoleum is a flexible coating material; it cannot be placed directly on thermal film. Manufacturers recommend protecting the heating layer with sheets of plywood approximately one centimeter thick.

Lay plywood and linoleum on top of the film

The sheets are attached to the base with small nails. They must be driven in very carefully so as not to damage the conductive elements. Check the exact location of the nail before hammering it in. Nails should be driven only along the perimeter of the sheet, this makes it possible to accurately control their position. Before fixing, it is strongly recommended to dry the plywood thoroughly in a warm, ventilated area. In this way, you can prevent the appearance of cracks during the operation of the heated floor.

Application

To achieve maximum effect, it is necessary that the heat generated by the source reaches the surface with minimal losses.

If linoleum, which has a small thickness and relatively high thermal conductivity, is used as a coating, then successful functioning of the system can be expected.

Use will be most successful if the following conditions are met::

- Possibility of temperature control to avoid fabric deformation.

- The presence of a high-quality, durable base - a substrate that ensures an even surface of the coating.

- The quality of linoleum must correspond to operating conditions and withstand work at elevated temperatures.

- The ceiling and subfloor must withstand the load from the screed and underfloor heating.

If these requirements are met, the service of the floor heating system can be stable and reliable.

For more information about whether it is possible to lay linoleum on a heated floor, read this article.

Premises

So, some types of substrate do not tolerate moisture - these are OSB, chipboard and similar boards. Therefore, for bathrooms, kitchens or toilets, you should choose a cement screed with a waterproofing layer as a substrate.

For rooms with a lot of furniture, especially chairs, which are often moved from place to place, the use of heated linoleum is fraught with the appearance of many marks from the legs. In addition, if the material is of poor quality, exposure to heat may result in a strong release of volatile substances that have a noticeable chemical odor, which can cause discomfort or headaches.

Heating system testing

To do this, set the heating indicator on the thermostat at 20 - 25 degrees and wait a few minutes. Check with your hand whether the mounted film heaters have warmed up. Then the power is turned off completely to see how the electrical connections heat up.

We recommend: Wall-mounted and other radiators, convectors for the bathroom

Their temperature should be the same as that of the film. In the case when it is much higher, this means that the contacts are unreliable. They must be checked, and the cause of excessive heating must be identified and eliminated.

Kinds

There are two types of heated floors:

- Water.

- Electric.

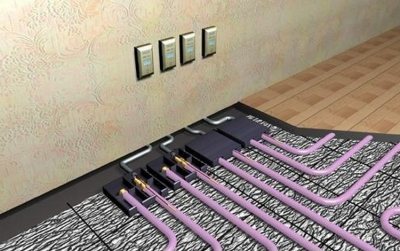

The difference lies in the type of heat source - in the first case, it is a system of flexible pipelines laid on the heated area in a “snake” or spiral (“snail”), in which hot water circulates.

In the second case, the heater is a cable or cable mat, as well as infrared devices - rod or film.

Using water

At the same time, water heated floors can have different options for the structure of the pie:

- using concrete screed;

- floor (dry) type, laid on a wooden subfloor or on insulation - polystyrene.

Concrete screed is a strong and level substrate that evenly distributes heat from the piping system throughout the entire volume. At the same time, it is quite heavy and requires a concrete floor, which is not typical for a frame house.

The flooring system is a method of laying layers without the use of “wet” compounds - cement mixtures, etc. The subfloor is used as a base, and a grid of bars is made to protect the pipes, carrying the base slabs. The system is much lighter and easier to install, but is less durable and requires protection from pipeline leaks or accidental water spills.

Read more about the water system for linoleum in this article.

Electric heating

Electric underfloor heating has two main types of design:

- Cable type. A heating cable or a more modern system is used - a cable mat, a structure consisting of a fiberglass mesh with a cable attached to it in a zigzag pattern. Cable mats are much more convenient to install - you just need to spread them over an area, while a separate cable needs to be rolled up in a certain way and secured to a mesh or mounting tape. Installation is possible both under the screed and in the “dry” method.

- Infrared type (rod or film). The most successful design is film; it is a flat film with built-in radiating elements. It does not tolerate moisture, so installation is possible only in a “dry” way, using a backing made of sheet materials.

Attention! Attempts to lay linoleum directly on a film emitter lead to rapid failure of the coating. The presence of a substrate is mandatory, although it causes unproductive consumption of heat and electricity.

Read more about the electrical system under linoleum in this article.

How to choose?

The ability to connect to a central heating system makes water heated floors more profitable, which in this case will not require electricity consumption.

However, sometimes it is more profitable to use an electric heated floor - for example, if you often have to leave for several days, you can simply turn it off, and the water system must work constantly, which requires costs. Therefore, if living in a house is not permanent, then using an electric heated floor is much more effective and convenient. Reaching a comfortable temperature when using an electric heater is much faster, and it can also be adjusted.

Types of linoleum

The surface of linoleum can be made from the following materials :

- PVC.

- Glypthal.

- Rubber (relin).

- Colloxinaceae.

- Natural.

The most preferred coating for heated floors is considered to be PVC linoleum, as it is more durable and rigid, less “flowing” from heating.

Linoleum can have the following types of backing:

- Baseless.

- On a warm basis.

- On a foam basis.

- Multilayer.

The use of coatings on a soft base is irrational, since the heated canvas becomes completely pliable, and dents from furniture legs, heels, etc. remain on it. Experts recommend choosing natural types as more rigid and able to withstand increased temperatures during operation, in particular, marmoleum. Typically, linoleum suitable for use in conjunction with heated floors has a special marking on the reverse side.

Choosing linoleum for film heated floors

Linoleum is a very cheap and therefore popular material. However, its low cost suggests that it lags far behind new materials in terms of its technological characteristics.

To decide whether this type of linoleum can be used in combination with heated floors, you can consult with a sales consultant, or look at the pictograms on the packaging.

Very often, unscrupulous manufacturers add harmful substances to linoleum. Because of this, when heated, such materials begin to release compounds hazardous to health. To avoid becoming a victim of deception, always ask the seller for a quality certificate before purchasing linoleum, and also make sure that this type of material is suitable for use in combination with heated floors.

When choosing linoleum for a heated film floor, you need to take into account its quality and main characteristics

Types of linoleum and their interaction with heated floors:

- Rubber linoleum is perhaps one of the cheapest types. They have a not very aesthetic appearance and low quality indicators, which is why they are rarely used for finishing houses and apartments. However, laying such material on a warm floor is quite possible.

- PVC linoleum is also inexpensive and looks good in the interior of an apartment. When heated above 28 degrees Celsius, it begins to release harmful compounds, so it is absolutely unsuitable for installation together with a heated floor.

- Single-layer linoleum is a thin and short-lived material. It can, of course, be laid on a warm floor, but it requires frequent replacement.

- Insulated linoleum is a high-quality thick material with low thermal conductivity. However, it can only be placed in a room where there is no underfloor heating system.

- Glyphthalic linoleum is covered with a thick layer of varnish. It meets all modern technological requirements. This is an ideal option for laying heated floors.

Related article: Where can you decorate walls with laminate?

In addition to the above qualities of linoleum, you need to pay attention to what the back side of the material is made of. If its back layer consists of fabric, then such linoleum is not suitable for a warm floor.

Device

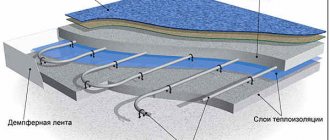

A warm floor under linoleum is a layered structure (pie).

Water

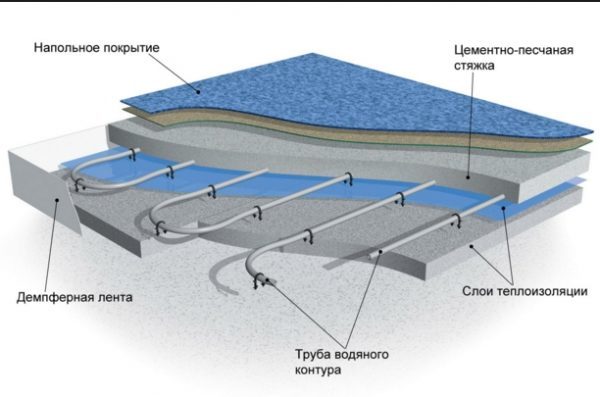

The composition of the water floor cake.

For concrete subfloor:

- rough floor;

- waterproofing;

- insulation layer;

- fiberglass mesh (or MAC mesh);

- water pipes;

- layer of screed (50 mm recommended);

- linoleum.

Warm floor under linoleum on a wooden floor:

- subfloor flooring;

- a grid that protects pipes from mechanical stress and carries the substrate;

- substrate made of OSB, chipboard, MDF, plywood, etc.;

- linoleum.

Electric

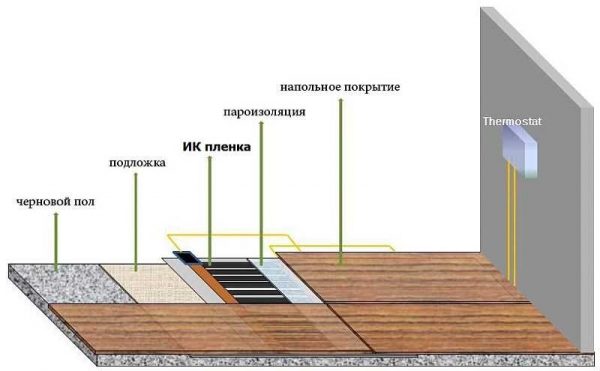

Composition of an electric heated floor cake.

Warm floor under linoleum on concrete floor:

- waterproofing;

- insulation layer;

- screed that protects the insulation from heat;

- heating element (cable or mats);

- screed layer;

- linoleum.

Wooden floor:

- fiberglass mesh or mounting tape (not required when using cable mats);

- cable protection grid;

- a heating element;

- substrate made of sheet materials;

- linoleum.

Attention! There is no insulation in the latter version, since it does not play any role in this case - the wooden floor itself is insulated with high quality.

Infrared heated floor under linoleum

More recently, a heated floor system required a lengthy and labor-intensive installation, during which it was necessary to deal with concrete work. However, now that the construction industry is rapidly developing, there are simpler and more convenient options.

Infrared film heated floor is a modern material that in appearance resembles a black thick plate, it bends well and is light in weight. In some respects, this film is inferior to more traditional types of heated floors, but it also has plenty of advantages.

Quite popular today is infrared heated flooring under linoleum.

Advantages of infrared heated floors:

- The cost of all elements of such a design is lower than, for example, a water-heated floor.

- Installation of film heated floors is so simple that you can handle it yourself.

- Such a system is not afraid of frost and cannot crack and flood the rooms underneath.

- When you turn on such a device, the floor heats up instantly. In this case, only objects in contact with the floor are heated, and the air does not lose moisture.

- Heated floor film can be laid only in those places where heating is needed. This way you save material.

The list of advantages of infrared flooring is quite long. However, unfortunately, such tape heating can hardly be called ideal. It has quite significant disadvantages.

Disadvantages of film-based heated floors:

- Possibility of electric shock to people walking on it. And although such a probability is very small, because the device is well grounded, such cases have still happened.

- High energy consumption. Maintenance of such a system is several times more expensive than floor heating with a water device.

- Dependence on the availability of electricity. When there is a power outage, floor heating stops immediately.

Related article: How to calculate the thickness of brick walls?

As you can see, infrared heated floors also have disadvantages. If they seem too significant to you. Then you can choose a different system, but each type has its own disadvantages.

Installation

Water

Installation of a heated floor under linoleum differs little from the usual scheme:

- Insulation (optimally EPS) is laid on the prepared subfloor.

- A heating element - water pipelines - is laid on top of the insulation.

- The pipeline is completely installed and pressure tested.

- A layer of screed (50 mm) is poured. Attention! At this time, the pipes are under operating pressure!

- The screed is kept until it hardens completely, after which the linoleum is laid.

This is the procedure for installing a water heated floor.

Electric

When installing an electric floor, the stages of work are as follows::

- Laying waterproofing and insulation.

- Thin protective layer of screed.

- Laying and connecting cables or mats, test connection, checking the operation of all sections of the system.

- Filling screed, laying linoleum.

Procedure for installation on a wooden floor:

- Installation of a grid protecting pipes or cables. (when using mats or infrared film, this step is not needed).

- Laying the heating system.

- Installation of the substrate - OSB, chipboard, plywood, etc.

- Linoleum is being laid.

Read more about the installation process in this article.

Laying heated floors under linoleum

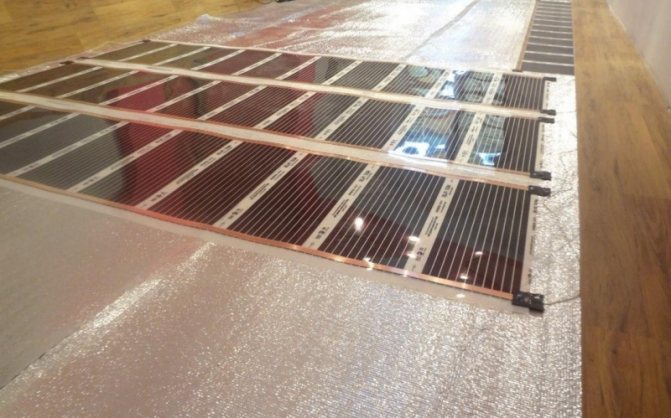

Once you have decided on the type of floor heating, you can proceed directly to its installation. We will look at how to properly install an infrared floor on a film base. This is the easiest system to make, and you can definitely handle it.

Related article: Do-it-yourself overhaul of a balcony in a panel house: the right recommendations

It is quite possible to lay a heated floor under linoleum yourself, the main thing is to familiarize yourself with all the nuances of this process in advance

Instructions on how to lay film heated floors:

- The preparatory stage includes leveling the floor using screed or cement plaster (this depends on how uneven the base is).

- Waterproofing protection is glued on top of the leveled floor. This can be a film or bitumen glue (mastic).

- The waterproofing film is covered with sheets of plywood or chipboard.

- Now you can draw up a diagram according to which the thermal film will be placed. It does not need to be laid in a continuous line. It is better to leave the places where sofas and wardrobes will be without heating.

- A heat-insulating material containing a layer of reflective aluminum foil is laid on top of the plywood base. To fasten the sheets of thermal insulation together, use tape and a construction stapler.

- Now, according to the previously drawn up diagram, the infrared film is laid. In this case, it should lie with its underside on the thermal film. The heated floor panels are fastened together with tape.

- Next, the cut site of the wide copper busbar is covered with bitumen insulation. Copper clamps are installed where the film will be connected to the wires. And the entire structure is connected according to the manufacturer's instructions.

Before assembling the heated floor, be sure to read the instructions on the package. You will also need to consult with an electrician to see if your wiring can handle the loads of such a system.

Advantages and disadvantages

Advantages of heated floors:

- uniform heating of the entire usable floor area;

- lack of visible heating devices;

- comfortable and cozy environment, the ability to adjust the temperature as desired.

Minuses:

- linoleum is not very suitable for such specific use; it changes size, deforms and warps;

- short-lived coating life;

- the need to have a substrate causes waste of heat and electricity;

- The heating mode setting is limited for fear of ruining the linoleum.

Other types of heated floor coverings presented on our website: under laminate (general information, whether it can be installed and the installation process), under tiles (general information, selection and installation), under parquet boards, under carpet.