What is foil insulation for walls

Foil insulation has had great success. It's hard to believe, but this brilliant material has only recently appeared on the construction markets. However, thanks to its advantages over other materials, it has already won the hearts of many ordinary consumers.

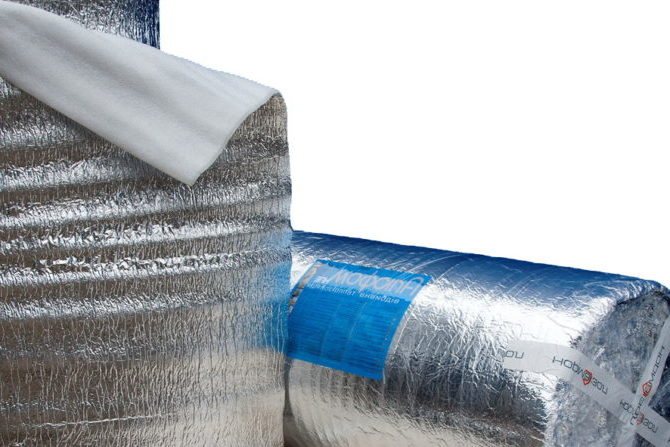

The silvery material for arranging walls is correctly called “foil insulation.” It is a sheet of warm layer, which is covered with foil on top.

This insulation has many advantages over other materials used for walls and floors. It is thanks to them that it is so often used to insulate a wide variety of buildings.

Advantages of foil insulation:

- Thanks to the reflective surface, foil insulation has a small thickness. At the same time, it is not inferior in quality to the thickest insulating materials.

- This thermal insulation is easy to install. In addition, it has low weight and high strength. Thanks to this, such insulation can be installed without the help of professionals.

- Foil thermal insulation is supplied to the market in the form of small rolls. Thanks to this, you can easily buy the amount of insulation you need without overpaying for unnecessary material.

This material has excellent thermal insulation, sound insulation and waterproof qualities. That's why more and more people are choosing them for their homes. However, in addition to its advantages, such insulation also has its disadvantages.

Disadvantages of foil insulation:

- The shiny elephant of foil insulation can be subject to corrosion. Therefore, its use in places of high humidity is possible only with high-quality waterproofing.

- In hot weather, foil insulation becomes very hot, giving off its heat to the wall. Therefore, very often rooms with such insulation are hotter in the summer. However, this problem can be avoided if the insulation is installed correctly.

These are, perhaps, all the disadvantages of this insulation. However, if the material is laid correctly, they do not appear. Therefore, more and more people are choosing this type of insulation.

Thermal insulation with foil: technical characteristics

The insulation contains foamed polyethylene with foil. It is thanks to the foil that it has a property called reflective thermal insulation (it is almost 97% effective). Insulation with foil - called penofol.

Insulation provides protection for the room from cold and wind. And its water-repellent property will prevent surfaces from becoming damp.

Foil and polyethylene together form a high-quality insulation that has the following advantages:

- High heat and sound insulation.

- Light weight and elastic for easy installation.

- Eco-friendly material without toxic compounds.

- Good waterproofing.

- Foil insulation can be used for a long time without rotting.

Types of foil thermal insulation

Foil insulation, as you already know, is a warm base and a shiny layer. Depending on the material from which the base is made, foil insulation is divided into types.

Types of foil insulation:

- Polyethylene foam with a foil layer is one of the most popular insulation materials. Thanks to its porous synthetic structure, it retains heat perfectly and is not afraid of moisture. When ignited, it goes out on its own.

- Insulation with a basalt base is an environmentally friendly material. It is not afraid of fire and can withstand various aggressive environments.

- Foil-coated adhesive-based isolon is thin, but at the same time meets all the necessary qualities. Excellent heat reflection and easy to use.

- Foil-coated mineral wool combines all the advantages of the two materials from which it is composed. In addition to being environmentally friendly and having excellent insulation ability, this material has excellent moisture insulation.

These types of insulation have all the qualities of their base, plus the beneficial properties of foil. Which type is right for you depends on the problem you want to solve with it.

Adhesive polystyrene has excellent thermal insulation properties. However, we do not recommend using it for residential use as it may release toxins into the air.

Thanks to this variety, you can find the material that perfectly suits your requirements. However, when purchasing, you must remember that the seller must have all the quality certificates for her product.

Types of insulation with foil

There are several types of insulation that contain foil. Each of them has several characteristic features.

Foamed polyethylene with foil

Available in roll form. Due to its high insulating properties, it can be used on any surface.

The foil on the material can be on one or both sides. Sometimes one of them has a self-adhesive tape, which greatly facilitates installation. Such insulation can be found behind batteries. This is done so that the heat does not escape from them. For the most creative ones: the soles of shoes can be insulated with foil insulation.

Sold in the form of massive slabs. Recommended for use in floor coverings only.

The material has increased strength (density about 45 kg/m³) and resistance to fungus and mold. It can retain its thermal insulation properties at temperatures up to 200˚C.

Mineral wool with foil

Mineral wool with foil is produced in the form of rolls. It can also be used to insulate any surface. Including bathhouse foundations and chimneys.

The thickness of the mineral wool slab reaches up to 10 cm. There are some varieties: glass wool and foil-coated stone wool. It is preferable to choose the last option, because... it is safer, and its heat-saving properties are the same. The material is well suited for stoves or chimneys because it is resistant to high temperatures. And thanks to its excellent waterproofing properties, mineral wool is suitable for showers, saunas and other places with high humidity.

Basalt wool with foil (basalt insulation with foil)

Foil basalt material is used in all areas. Its combustion temperature is from 300˚C, so the material often protects the room from fire. Foil basalt thermal insulation is often used in wooden buildings, such as a bathhouse. Foil basalt wool in rolls is much more convenient than in slabs.

Using shiny insulation

Foil insulation is an excellent option for rooms with high humidity. However, it can also be used under standard conditions. Let's look at the scope of application of the material.

Areas of application of the material:

- This material will be an excellent solution for insulating baths and saunas;

- Insulating the floor with foil material will ensure comfort in the house without hiding extra centimeters;

- Open gazebos and attics will become much warmer if they are supplemented with foil insulation.

- The wall behind the radiator can be insulated with such material, then all the heat coming out of the device will be reflected into the room.

- This material is also suitable for insulating pipes, ventilation, roofs and air conditioning systems;

- Foil insulation can be glued to any surface, wall, ceiling or floor;

- You can place shiny material in unheated rooms, on heating pipes and external sewers.

As you can see, the scope of application of foil insulation is quite large. It's all about its availability and a large list of positive qualities.

Area of use of foil insulation

There are many places in the room that need insulation, this is not only a layer of insulation of the main walls. And since the products are affordable, everyone can implement thermal insulation.

Insulation of balconies and loggias

For this purpose, insulation with polyethylene (penofol) is most often used. Maximum thickness – 10 mm. The surface of the foil is selected smooth or corrugated. If you live in a region with a cold climate, such a thin layer will not be enough for complete insulation. Ideally, isover insulation is supplemented with ordinary mineral wool or polystyrene foam.

Advice! It is better to use polystyrene foam. It is not only cheaper, but also not afraid of moisture (unlike cotton wool). And the balcony is a damp place. The slabs are fixed using foam adhesive.

- Preparing the base, cleaning, removing old coating, if any.

- Fixing polystyrene foam with adhesive foam. You can use another option - creating a wooden frame and laying polystyrene foam in the cells.

- Foiled penofol is glued on top of the foam.

- Installation of wooden or metal sheathing to create a ventilation gap and a backing for finishing material.

- The finishing can be siding, lining, plastic panels, block house, drywall.

The foil layer cannot be laid overlapping. Everything is done end-to-end and taped with special aluminum tape.

Pipe insulation

Foil pipe insulation is used for pipelines, communications underground or outside. The process is very easy and does not require a professional approach. You need to buy insulation of the required diameter, put it on the required place, removing the film from the adhesive layer. Thanks to the outer foil layer, the pipes will be protected from heating. And if the foil is on the inside, then the heat will be transferred back into the pipe.

Mineral wool is used as insulation if the pipes are located outside, sometimes it is foil penofol.

Bath insulation

Rolled materials are suitable for this purpose. They are easier to work with. Foamed polyfol or mineral wool of medium thickness is suitable. Installation of insulation begins from the ceiling, then the walls are insulated, and then the floor is treated. In addition to mineral wool, it is important to buy parchment, it is fixed to the ceiling.

The insulation scheme is as follows:

- A wooden sheathing is created. The insulation is placed there with glue.

- If the insulation layer is torn during installation, this can be repaired with aluminum tape.

- A counter-lattice is fixed to the sheathing for finishing and creating a ventilation gap.

- All that's left is the finishing touches.

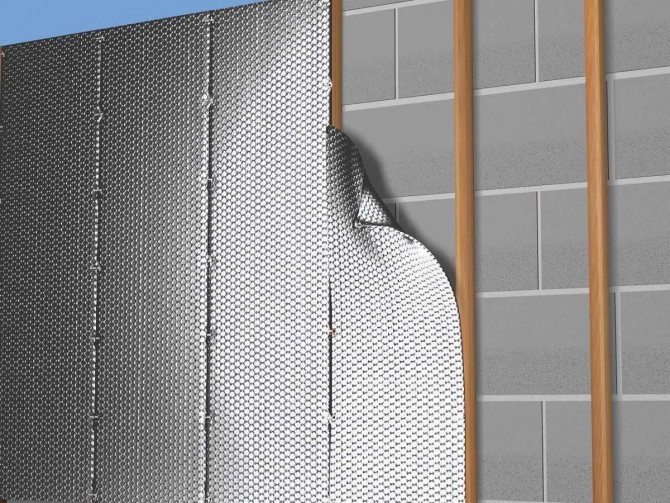

External insulation

It is better to carry out thermal insulation work outside. But when this cannot be done, it is permissible to insulate the house inside. Foil mineral wool of medium thickness is used. To work you need glue, a construction gun, dowels, and windproof film.

The thermal insulation process is as follows:

- The starting strip is fixed with dowels around the perimeter. The first layer of mineral wool will rest on it.

- Glue is applied to the inside of the insulation and pressed against the wall. For better fixation, you can use plastic dowels with an umbrella.

- A wind barrier is mounted on top of the made layer.

- At the end there is a finishing touch.

Roof insulation

It is best to buy basalt foil slabs for the roof. Insulation is performed as follows:

- All cracks and crevices on the roof are sealed. Tow or polyurethane foam is suitable for this.

- A vapor barrier layer is created. It is enough to buy glassine fixed to a stapler.

- Then the formwork is done and everything is done according to the standard scheme: laying basalt wool and finishing.

If everything is done correctly, the house will be warm and cozy. Foil insulation is a good solution for thermal insulation. It has many advantages, and most importantly, it can be used to finish pipes and places with bends. The aluminum layer protects the insulation from negative influences, extending the service life of the insulating layer.

How to lay foil insulation on walls

Laying foil insulation is easy. With a little practice, you can install it yourself. Therefore, by choosing this insulation, you can save on the services of a specialist.

Many people advise using foam rubber for insulation in a wooden house or country house. However, this insulation is practically no longer used, since there are other, better materials.

Since this material weighs little, it is easy to lay. However, it is very important to know how to do it correctly. Otherwise, the material will show its negative properties.

How to properly insulate walls with foil materials:

- First of all, you need to clean the insulated surface from the old finish, as well as dust and dirt. If this is not done, the material will not sit tightly on the wall.

- To prevent insects, mold, mildew or mice from infesting the insulation, you need to treat the wall with antiseptic agents.

- Next, the insulation can be mounted on the wall. Thanks to the self-adhesive layer, this is easy to do. You need to stick it to the wall with one side (not foil), and the shiny surface will look into the room. The insulation must be glued end to end, and the joints must be sealed with foil tape.

- After this, the sheathing is erected. This is necessary so that the section does not adhere to the insulation. In this case, one of its negative effects will not appear.

Attaching insulation with foil to the wall is quite simple. Here you don't even need the hand of an experienced craftsman. The only thing that may be difficult is the sheathing.

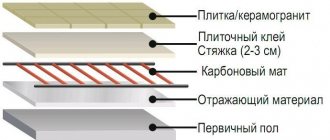

Additional thermal insulation for floors

Scheme for laying penofol on the floor

Considering that penofol, in addition to thermal insulation, also has vapor barrier properties, it is actively used when arranging floors. At the same time, the protective tape can be installed both from the basement side and directly from below the floor.

To insulate the floor with penofol in a wooden house, two installation options are used:

- with one-way reflection towards the ground;

- with two-way reflection.

The double-sided option is used on cold foundations, but in this case the air gap must be present on both sides of the insulating tape.

accepts orders for all types of work performed during the finishing of log and timber houses to the level of readiness for finishing, including work on external and internal thermal insulation of wooden log houses. To clarify the details of cooperation, as well as find out the timing and cost of order fulfillment, go to the “Contacts” page and contact us in any way indicated there.

Calculate the cost of painting and insulating your home right now

Content:

Wooden houses built more than 40 years ago had thick and massive walls. It was necessary to pour a massive foundation, and hire a whole construction team to install the walls. But even with sufficient thickness, the walls had to be insulated with the help of: moss, tow or straw with clay. Modern materials make it possible to insulate a wooden house from the inside quickly and without much physical exertion. Mineral wool, polystyrene foam and polyester began to be used more than 20 years ago, but modern markets offer lighter and more practical materials. One of these is penofol. How to insulate a wooden house from the inside with penofol, design features and installation in one article.

Tips: how to lay insulation on a wall

You already know how to lay insulation, but a few practical tips will help you do this job better. These little nuances are the fruit of the labors of many installers, so you can use them without fear.

Tips for insulating your home:

- The foil layer on such insulation should always face outward. Otherwise, the qualities of the material will not be revealed.

- It is better to insulate pipes with foil zone. In this case, the shiny layer should also face outward.

- Do not use foil-coated polystyrene foam to insulate residential premises. This material is more expensive, but tends to emit substances harmful to health.

- It is better to choose materials where the foil layer decorates not one, but two sides. In this case, the reflectivity of the material will be higher.

- Choose insulation with a layer of foil rather than aluminum plating. The latter is unable to fully reflect heat and rays.

By following these tips, you can insulate your home better. At the same time, you need to be careful not to spoil the expensive material.

Technical characteristics and price issue

It is impossible to name the general characteristics of all foil-type insulation - different materials have different properties. But you can consider the characteristics of the most popular and affordable insulation materials.

Insulator made of foil and polyethylene foam

In most cases, the material is sold in the form of compact rolls. The thickness of the insulation varies from 2 millimeters to 1 centimeter. Foamed polyethylene can be coated on both sides or on one. In addition, self-adhesive material is available on sale, when one of its surfaces is covered with an adhesive layer and a protective film.

The scope of use of polyethylene foil insulation for walls is, as a rule, not limited: they are used for insulation of floors and walls, roofs, ventilation, refrigerators or pipelines. Also quite often, this type of heat insulator is used for installing heated floors, for insulating baths, and as a finishing coating for linoleum or laminate.

To prevent heat from escaping through wall structures, a layer of insulation based on polyethylene and foil is secured behind the heating radiator so that there is about two centimeters of free space between the insulation and it.

Foil-coated polyethylene is often used in shoe production - good shoe insoles are made from this material.

In building materials stores you often find such names of materials as Ecofol, Izolon and Penofol. The price of one roll is directly dependent on the thickness of the material. For example, a roll of thermal insulation with foil 2 millimeters thick will cost about 1,700 rubles. With a thickness of 1 centimeter, the cost will be about 3,500 rubles.

Mineral wool with foil

In this type of heat insulator, only one side is often covered with foil. It is sold in two different formats: rolls and slabs. The thickness of the thermal insulation layer is from 4 to 10 centimeters. It is made on the basis of basalt wool or fiberglass.

The use of foil mineral wool is limited, since the material is harmful to human health, it causes lung diseases and releases phenol into the surrounding space. It is mainly used for external insulation of buildings and non-residential premises. Basalt wool is not subject to combustion; it is installed if resistance to high temperatures is required: on fireplaces, stove pipes, etc.

Properties such as moisture absorption, density and others depend on the brand and type of wool, as well as the characteristics that were included in the material by the manufacturer. The good waterproofing properties of this insulation make it possible to use it in showers, saunas and baths.

The most popular brands are Izover, Parok, Ursa and Rockwool. The cost of the material is approximately 1,300 rubles per 0.25 cubic meters.

Foiled polystyrene foam insulator

This is a high-strength thermoplastic, which is obtained by melting polystyrene granules. Produced only in the form of individual slabs. Such material can be used in places that are subject to significant mechanical stress and moisture - strong polystyrene with foil is not susceptible to rotting and mold or mildew. Therefore, it is often used when installing a warm water floor. The average cost is 90 rubles per slab.