To improve the insulation parameters of a structure, special technologies are used. Insulating aerated concrete walls from the outside protects load-bearing structures from natural influences and reduces the cost of maintaining a comfortable temperature in the rooms.

Modernization can be carried out without interrupting the operation of a residential building.

House made of gas blocks.

Characteristics of gas blocks

To make these building materials, a mixture of gypsum (quartz sand, lime, cement) is used. By adding waste from metallurgical production, the cost of finished products is reduced.

Aluminum powder activates the process of gas formation. After solidification, the bubbles form a porous structure with a low thermal conductivity coefficient.

Durable, lightweight aerated concrete blocks are used for the construction of three-story buildings without additional reinforcement. At a height of more than 10 meters, a reinforced concrete or metal load-bearing frame is installed.

Technical and consumer features of standard products:

- the weight of the gas block (D500, 30x60x25 cm) is 30 kg, which is equivalent in volume to a masonry of 22 bricks (100 kg);

- thermal conductivity (0.12 W/m*°C) is slightly higher compared to laminated timber (0.1 W/m*°C);

- sound insulation characteristics are 9-10 times better than those of a brick wall;

- aerated concrete is resistant to open flames.

High-quality materials in this category maintain their integrity and functional parameters for 100 years. The blocks are processed without excessive labor using standard cutting tools. The dimensional accuracy allows the use of a small amount of adhesive solution for the construction of reliable structures.

The porous layer allows steam to pass through, providing natural micro-ventilation of the premises. The mixture contains no components harmful to human health.

The blocks are used to create environmentally friendly buildings that, in terms of basic parameters, are no worse than their wood counterparts. However, concrete structures are not damaged by rotting and retain their shape and structure over a wide temperature range.

Should I insulate my house? Calculation and analysis

The following are factors that may determine the need to insulate a house made of gas silicate blocks:

- The house is built from foam blocks with a density higher than D500 or a thickness of less than 30 cm.

- The load-bearing frames of the building are filled with aerated concrete.

- Poor-quality laying of blocks and other errors during the construction of walls.

To make accurate calculations and make sure whether it is really necessary to insulate the house, determine the heat transfer resistance coefficient and compare it with the standards according to the climate zone. Let's give an example: D500 blocks with a thickness of 0.375 m were used to build a house. Their thermal conductivity index is 0.14. To find out what the heat transfer resistance is, divide 0.375 by 0.14. We get 2.67. It remains to compare with the SNiP II-3-79 indicator. For the Moscow region, the norm is considered to be a heat transfer resistance of 3.2.

The resulting number is less than normal. However, it is worth taking into account the cladding materials - both external and internal - and adding their indicators to the resulting number. If the number is still less than the norm, you should seriously think about how and with what to insulate a house made of aerated concrete.

Is it necessary to insulate a house made of aerated concrete?

Good thermal insulation characteristics are a reason to doubt the advisability of special measures. To find out whether it is necessary to insulate a house made of aerated concrete, you should carefully study the operation process.

The porous material allows moisture to pass through along with air. The direction of movement is towards the side with lower temperature. Water accumulated in the pores expands when freezing, destroying durable aerated concrete blocks. In a liquid state, it worsens thermal conductivity.

The noted features determine the specific requirements for the project of insulation of external walls. The passage of water and steam should be maintained in order to naturally remove moisture from building structures and create a comfortable microclimate in the rooms.

Installing an additional layer provides the following advantages:

- prevent the negative effects of moisture on walls;

- extend the life of the building without major repairs;

- cover seams, jumpers, and other cold bridges;

- reduce heating (air conditioning) costs;

- improve the appearance of the building.

Insulating the facade allows you to reduce the thickness of the aerated block.

Insulation of external walls with polystyrene foam.

Materials for thermal insulation of aerated concrete facades

Most often, mineral wool or expanded polystyrene are used as insulation for plastering the facade of aerated concrete houses. Let's try to figure out which material for facade insulation is best to choose in a particular case:

- Expanded polystyrene (foam plastic) and mineral wool are identical in terms of thermal parameters, durability and mechanical properties;

- polystyrene foam is an insulation material that is attractive to rodents, and mineral wool (basalt) repels them;

- working with polystyrene foam is easier than with other materials, its slabs are easy to cut, gaps can be easily eliminated using polyurethane foam;

- mineral wool material has high fire safety parameters, polystyrene foam does not burn, but when heated to high temperatures it releases poisonous and toxic substances;

- polystyrene foam provides reliable thermal insulation protection;

- polystyrene foam is a more financially accessible material compared to mineral wool.

If you need to save money

If your budget is limited, choose polystyrene foam for insulation. A comparison of characteristics shows the advantages of mineral wool, but not significantly.

When should thermal insulation work be carried out?

Experienced specialists do not recommend insulating aerated concrete without interruption during the construction process of the building. Ensure that the walls are completely dry.

Depending on climatic conditions (initial moisture concentration in the blocks), the duration of this process is up to 5-6 months.

However, this rule can be excluded if you leave ventilation gaps in the structure or choose a material with good vapor-permeable characteristics.

Where is a warm water floor not installed?

- It is technically impossible to carry out installation on monolithic interfloor stairs and turning platforms. Therefore, for comfort and safety, it is recommended to trim concrete stairs with wood.

- In the boiler room, because the room is heated sufficiently due to heat transfer from the boiler equipment.

- There is a misconception that a warm water floor can be avoided under cabinets and beds in order to save money. This solution will save you linear meters of pipe, but will increase heating costs. Warm water floors first warm the concrete screed, which then transfers heat through the floor covering into the room. If you do not lay contours under large furniture, then the system must spend additional energy to warm up the entire volume of the screed without the contours of a heated floor, and only then release heat into the room.

- In the “pie” of the floor there is EPS - it prevents downward heat loss. The lower the thermal conductivity of the floor covering, the larger the thermal insulation layer should be. The thermal conductivity of parquet and laminate is lower than that of porcelain stoneware. Contours of a warm water floor.

- There are 2 main ways of laying contours: “snake” and “snail”. My opinion is that both methods work. One or the other can be determined depending on the configuration of the room. From my experience, it has been concluded that when laying the contours of a warm water floor with a “snake”, the pipe consumption is approximately 10% less in comparison with the “snail”.

Before laying the concrete screed, hydraulic tests of the system are carried out to check its tightness. After checking, the system should remain under pressure.

What criteria should you use to choose a heat insulator?

In addition to the cost of materials, you should consider costs for the following items:

- delivery;

- performing installation work;

- acquisition of tools, fasteners, decorative structural elements.

Suitable technical parameters are determined taking into account climatic conditions, characteristics of load-bearing walls and other building components.

Optimal material thickness

To make the correct calculation, you need to find out the regional standard for the thermal resistance of walls (Rst, measured in sq. m * °C/W):

- Voronezh - 3.12;

- Kazan - 3.45;

- Sochi - 1.79;

- Irkutsk - 4.05.

Data for another city can be obtained from the architectural office of the local municipality or found in the reference tables of the information site.

High-density aerated concrete (D500) 400 mm thick creates a resistance Rgb = 2.6 m2*°C/W. This is more than enough for southern Sochi. However, when constructing a building in Irkutsk, additional insulation of an aerated concrete house will be required.

Aerated concrete D500.

The parameters of insulation suitable for a northern city are calculated using the formula: Ri = 4.05 - 2.6 = 1.45 sq. m * °C/W. With a thermal conductivity of mineral wool of 0.04 W/m*K, the layer thickness will be: 1.45*0.04 = 0.058 m.

To shift the dew point outward, it is recommended to change this size. In the example under consideration, two standard 50 mm slabs can be used.

Information on the thermal resistance (m2*°C/W) of an aerated concrete wall made of D 400 blocks of different thicknesses:

- 200 mm - 1.86;

- 300 mm - 2.8;

- 375 mm - 3.5.

For accurate calculations, use the official data of the building materials manufacturer.

Vapor and water permeability

These parameters are assessed taking into account the characteristics of the insulating material. If a tight junction is expected, the permeability of the outer layer should be better compared to the wall.

This design will absorb water in the additional part, preventing the blocks from getting wet. A suitable option is mineral wool slabs.

Polystyrene foam does not allow steam to pass through well. Condensation forms on the inside of the stove during operation. To prevent water from penetrating into the aerated concrete block, create a ventilation gap.

If the walls are made of dense brick, it is permissible to attach the insulation directly to the supporting structure without gaps.

Vapor permeability of the material in mg/(m/h*Pa):

- gas block - 0.11;

- mineral wool - 0.6;

- polyurethane foam, polystyrene foam - 0.05;

- polystyrene foam - 0.015.

The parameters under consideration should be taken into account when modernizing a house in the northern region. In warm climates, there is less difference in temperature outside and indoors, so moisture movement processes do not have a significant impact on the integrity of the building. However, in this case, one should not forget about preserving the beneficial properties of “breathing” walls.

Other options

External placement of the insulating layer reduces environmental requirements. All high-quality materials in this category do not emit harmful and dangerous substances during normal operation.

For a thorough comparative analysis, the following parameters are checked:

- fire resistance, smoke formation, toxicity of combustion products;

- compressive strength (bending, tensile);

- preservation of shape (integrity) in the expected temperature conditions.

When working with fiber materials, it is necessary to prevent small particles from getting into the lungs, skin and mucous membranes using personal protective equipment.

Technological operations can be performed with polymer boards without special precautions. The complexity of installation operations should be taken into account when creating an insulating layer on a wall with a relief surface.

Floors in aerated concrete houses

The installation of floors in houses made of aerated concrete depends on the type of flooring chosen. There are no special technologies here, except for taking into account the characteristics of aerated concrete itself. If the house uses wood beam floors, the floor construction in the house is similar to that of standard wood floors. When using porous concrete slabs, it is important to avoid installing wet concrete screeds due to their weight and consider a lighter floor structure. Withstand load 600 kg per meter.

- Floors made of aerated concrete slabs do not require insulation.

- Aerated concrete absorbs water well, so it requires reusable, or better yet, polymer priming before using solutions in floor finishing.

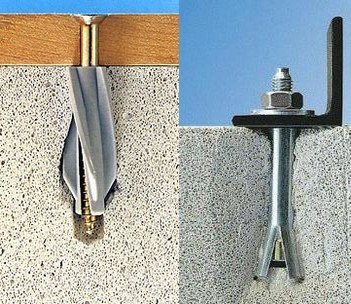

- Aerated concrete is poorly suited for holding fasteners. Therefore, when attaching structures to aerated concrete, you need to use special dowels and fasteners.

How to calculate the dew point for your building

This term refers to a place in a wall structure with favorable conditions for the formation of condensation. The position of the dew point depends on the temperature (humidity level) indoors and outdoors.

Simplified calculations do not take into account:

- wind force;

- Atmosphere pressure.

To calculate the location of the point, the temperature outside (T1) and inside the building (T2) is measured. Next, apply the formula K = (Hc/Tc)/(Hi/Ti), where:

- K is the thermal resistance coefficient;

- Hc (Hi) - thickness of the wall (insulation);

- Tc (Ti) is the thermal conductivity of the corresponding parts of the structure.

The resulting value is used to calculate the temperature difference T = (T1-T2)*K. To construct a graph, use tabular data with the conditions for dew formation:

| Temperature, °C | Relative humidity, % | ||

| 35 | 50 | 70 | |

| 14 | -1 | 3,7 | 8,6 |

| 20 | 4,1 | 9,3 | 14,4 |

| 28 | 11,1 | 16,6 | 22 |

To simplify the calculation, use a specialized calculator. The initial data indicates the thickness and materials of the layers. The result of automated calculations is a line showing the movement of the dew point at different values of humidity (temperature).

Why you can’t insulate aerated concrete with foam plastic

Let's say you built a house from aerated concrete and invested a lot of money, nerves and time in this structure. It would seem that you can move in and live, but not everything is so simple. Now you need to insulate the gas block. But what material should be used to insulate a house? Is it possible to use polystyrene foam as insulation, or do you need to choose a special material?

Polystyrene foam is excellent as insulation for buildings made of concrete and brick. However, such insulation is not suitable for a material such as aerated concrete. If you still decide to use foam plastic as insulation, then get ready for possible problems.

The thing is that in buildings of this type, thermal insulation materials must be used that have greater thermal conductivity, heat capacity, and also a higher vapor permeability resistance.

This means that the outside of the room is insulated with higher quality and warmer materials, but inside these indicators may differ. This is necessary so that the outer layers dry quickly and push the accumulated moisture out.

What happens if the outer layer has low vapor permeability? The insulation will not have time to dry completely over the summer and autumn, and will begin to accumulate moisture inside. Because of this, its service life will be reduced by half, or even three. As for our aerated concrete house. The integrity of aerated concrete directly depends on air humidity. Thermal resistance also depends on humidity. And under unsuitable conditions, this figure drops. In turn, the foam will accumulate moisture in the layer. Accordingly, after some time the walls will gradually begin to crumble. Usually, this takes from 3 to 5 years.

In general, the dew point will move inward and remain between the insulation and the wall. Next, condensation will begin to accumulate, causing fungus to spread throughout the wall. That is why, if the room is built of aerated concrete, then for insulation you need to select a special material with a certain vapor permeability parameter. One such material is mineral wool.

In any case, the use of aerated concrete as a material for building a house is justified. It is lightweight and environmentally friendly. With the right technology, the material can last for many years. In addition, it is easy to install, which makes it very popular.

New publications are published daily on our channel in Yandex.Zen

Go to Yandex.Zen.

Preparing walls for work

To create high-quality thermal insulation for a home, you must first eliminate cracks, cracks, and other defects. The walls are cleaned of dirt and leveled. The primer is used for gluing slabs.

The list of operations is adjusted taking into account the selected insulation technology. When preparing the project, special attention is paid to the areas of joints with window (door) blocks. For a heavy ventilated façade, a separate solid base is created.

Plastering walls.

What methods of attaching insulation are considered correct?

As an example, this section discusses the features of working with mineral wool.

This material is different:

- low thermal conductivity;

- resistance to high temperature influences;

- good vapor permeability;

- long service life (50 years or more).

Soft mats can be installed tightly into cells of complex shape. Fastening and other structural elements should be calculated taking into account the large weight of the material - from 40 kg/m3.

Mineral wool in facade insulation.

Wet facade technology with and without reinforcement

The specific name denotes the use of aqueous solutions and mixtures in the technological process. To reproduce this technique, dense mats with a specific gravity of 120 kg/m3 are purchased.

Algorithm of actions:

- clean the surface;

- apply an even layer of primer;

- the slabs are glued to the wall;

- after 2-3 days, dowels with plastic “umbrellas” are used for reliable fixation;

- reinforce the outer surface with a painting mesh made of fiberglass threads;

- A decorative protective coating is created with a layer of plaster followed by painting.

The technology is adjusted if it is necessary to attach ceramic tiles or other heavy cladding. In this situation, metal anchors of complex shape are used, which fix the slabs together with the steel reinforcing mesh in the desired position. Eliminate the glue layer. The thickness of the plaster on such a base can be made up to 40-50 mm.

Wet facade application technology.

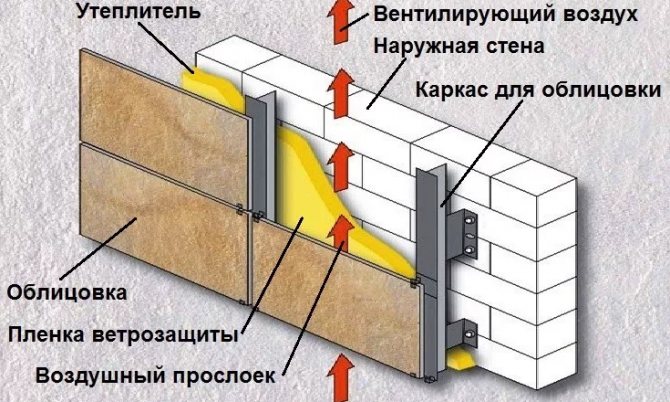

Ventilated facade

The lattice structure is created from wooden boards or metal guides. Leave a gap for ventilation. Mineral wool slabs are inserted into the frame cells with pre-compression.

A polymer membrane is fixed to the outer surface with slats to protect it from wind and moisture.

The film is mounted with an overlap of 20 mm. The seams are sealed with tape.

Scheme of a ventilated façade wall.

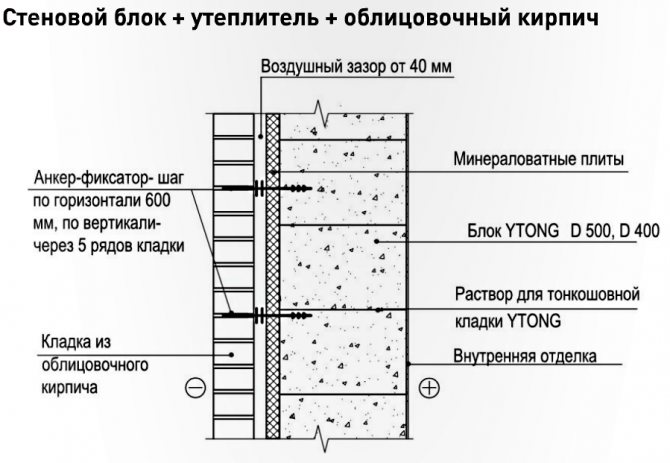

Thermal insulation for brick finishing

Using this method, you can use inexpensive mats with a lower density - 50-80 kg/m3. The slabs are fixed using flexible connections and protected with film waterproofing.

A gap of 40±5 mm is left between the mineral wool and the outer wall of the facing brick. To create a reliable structure, a strip foundation is first poured under the outer part.

Brick cladding scheme.

Types of floors in aerated concrete houses

One may come across the opinion that aerated concrete construction technology requires the installation of wooden floors. Traditional wooden beams, with the construction of a rough wooden floor using traditional technologies. However, the use of D600 aerated concrete blocks for external walls in the construction involves the use of aerated concrete slabs, as well as hollow-core concrete floor slabs.

You need to understand that the desire to use floor slabs instead of wooden beams changes and increases the cost of construction technology. In this option, it is necessary to install a reinforced concrete ring belt along the outer walls.

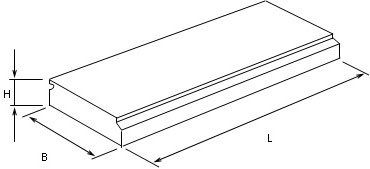

Aerated concrete floor slabs are considered universal and preferable in aerated concrete houses. They are warm, do not require additional insulation, and create a smooth base floor surface.

Hollow-core concrete slabs are used for distances greater than 6 meters. The slab rests on a concrete belt, which is poured from monolithic concrete or sand-lime brick masonry.

It is worth noting that reinforced floor slabs made of aerated concrete have appeared on the market. They are laid using the tongue-and-groove method, using a dry method. They are distinguished by their low weight, allowing them to work without the use of heavy lifting equipment.

Description of installation of various insulation materials

Detailed descriptions of technological processes will help you figure out how to properly use insulating materials. If a product is cheap, the overall costs will not necessarily be low. Economic parameters are assessed as a whole, taking into account the estimated service life.

Using polystyrene foam or polystyrene foam

This material is supplied in standard size slabs. If the load-bearing wall is made of high quality “autoclaved” foam blocks, no additional leveling is required.

If necessary, apply plaster mortar according to the level of the vertically fixed guides.

Next, apply the considered scheme of working operations to create the following structure (layer-by-layer):

- glue;

- Styrofoam;

- reinforcing mesh;

- primer;

- adhesive composition;

- plaster;

- facade paint.

The plates are installed in a checkerboard pattern. For reliable fixation, use umbrella dowels - 5 pcs. on the element in the corners and in the center.

When choosing extruded polystyrene foam, a similar installation technology is used. In these slabs, at the production stage, a uniform porous structure with closed cells is formed.

Unlike standard foam plastic, this material does not allow steam to pass through. This feature should be taken into account when designing.

Expanded polystyrene does not absorb moisture. High density (up to 40 kg/m) provides sufficient strength to create a reliable structure without additional reinforcement. Expensive modifications of slabs add special fillers that inhibit combustion and smoke emission during a fire.

Expanded polystyrene boards for wall insulation.

Mineral wool insulation scheme

When working with materials of this category, a set of measures is used to prevent the accumulation of condensate in the insulating layer:

- do not create a plaster coating from acrylic-based compounds;

- large damage in the walls is repaired with a mixture that, after hardening, allows moisture to pass through;

- the adhesive composition is applied to a limited area - along the perimeter of the element and in the central part.

The installation of the slabs is carried out in a checkerboard pattern to prevent displacement in the area of cross-shaped joints. Corner joints are covered with special perforated corners.

Laying mineral wool for wall insulation.

Thermal insulation with stone wool

The insulation of aerated concrete walls does not differ from the installation method of other fiber boards. When constructing the outer wall, the brickwork is connected to the blocks with a polymer anchor. Such binders perform their functions without compromising thermal conductivity.

The siding is installed on a sheathing with an intermediate film layer for moisture and wind protection. The air gap in this design facilitates the rapid removal of condensate.

Decorative plaster can be fixed to a stone wool slab through a mounting mesh. For this solution, a dense insulating material is chosen to ensure sufficient strength of the created structure.

Insulation with stone wool.

Insulation using polyurethane foam

This material is created directly on the construction site. An experienced specialist using productive equipment can insulate aerated concrete walls at a rate of up to 550 sq. m per shift.

The characteristic advantages of polyurethane foam should be taken into account when comparing with other methods of insulation:

- excellent adhesive characteristics eliminate the need for preliminary preparation of walls;

- a solid layer without cold bridges is created on surfaces with complex shapes;

- durable insulation does not need to be reinforced additionally.

The material is breathable and does not support combustion. To decompose by heating, the temperature must be increased to +500°C. Moisture absorption does not exceed 5%.

The following data confirms the superior thermal conductivity indicators (W/m*°C):

- polyurethane foam - 0.023;

- polystyrene foam - 0.038;

- extruded polystyrene foam - 0.031;

- mineral wool - 0.056.

The only significant drawback is the need to turn to professionals. To insulate aerated concrete walls with polyurethane foam yourself, you will have to purchase technological equipment and master special skills.

But for an objective comparison, it is necessary to take into account official quality guarantees under an agreement with a specialized company. A pre-agreed estimate will prevent additional costs.

Wall finishing with polyurethane foam.

Electric heated floor

It is possible to order heating installation at gaston.com.ua. Arrangement nuances:

- It is laid over the entire area of the house if the warm floor is used as a heating system.

- Initially, a floor heating system is installed, and then a concrete screed is made.

- Such a system can be used in any home, including those made of aerated concrete.

- But to install a heated floor, it is necessary to create a separate electrical wiring with a power cable for it.

Each system has its own design nuances. Most often, the first option is chosen for heating a house made of aerated concrete. But if there is no gas pipeline in the village, then preference should be given to an electric heating system.

Recommendations for insulating aerated concrete facades

A correct integrated approach at the preparatory stage will prevent erroneous actions and excessive costs. To find out how to insulate the walls, you need to collect the correct initial data.

Calculations of thermal conductivity are made with a margin to shift the dew point in the desired direction in the most unfavorable weather conditions.

When choosing materials, in addition to general technical parameters and cost, the service life is assessed. If your own knowledge is not enough to design or perform work operations, then turn to professionals for help.