Design and how a pellet boiler works

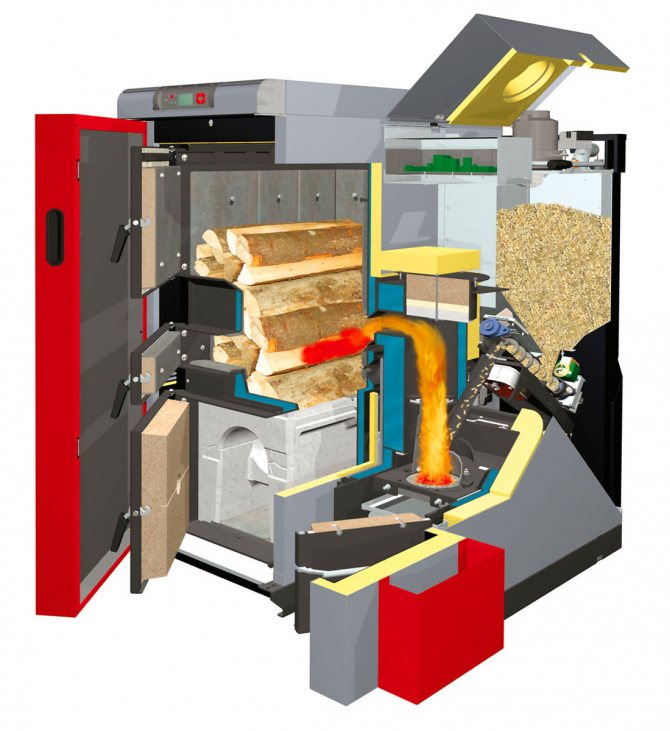

This equipment includes units:

- The firebox is the chamber where the combustion of pellets actually occurs. Equipped with a torch or retort burner.

- The convective zone is a cavity where the main heat is removed from the gases formed during the combustion process. Equipped with a plate or tubular heat exchanger.

- The ash pan is the part of the unit where waste is received after the combustion of pellets.

- A bunker is a container with pellets from where they enter the firebox.

- Auger – a device for portion feeding of granules from the hopper into the firebox.

- Fan – to create artificial draft in order to maintain the required combustion parameters.

- Automation system – controls the operation of the unit.

The operating principle of pellet boilers is as follows. The granules are fed portionwise (periodically) into the furnace via a screw, where they are burned. Hot gases rise upward, enter the convective zone, where they heat the heat exchanger, inside which water or another coolant circulates. This water then enters the heating devices (radiators, radiators) of the home heating system.

To maintain the required combustion parameters, the control system controller controls the operation of the fan and auger. The portioned method of fuel supply in combination with fan control provides an effective ratio between the mass of pellets and the air pumped for their combustion. In addition, it becomes possible to precisely regulate the power of the device. For example, reduce combustion at night or at other appropriate times.

Choosing a long-burning pellet boiler

Factors to consider:

- Burner type. Retort burners produce a vertical flame ; the quality of the pellets is not important to them. Stoker burners are demanding on the quality of pellets (with low ash content); they must be cleaned frequently, otherwise the device will stop working.

- Level of automation. Modern models have different levels of automation. The functions of turning off, turning on, changing the operating mode, and adjusting the temperature are available.

- Auger type. The device can be equipped with a rigid screw, its price will be lower and the design is simple, and the length is limited to two meters. The hopper is tied to the burner, its position is fixed. The flexible auger is connected to an electric motor; it does not have the disadvantages of a rigid design: the hopper can be installed at a distance of up to 12 m, has a backfire prevention system, and more.

- Heat exchanger design. A pellet heating device for home heating can have different types of heat exchangers. The vertical type is considered the best, since it has the greatest energy transfer to the coolant; the ash falls down and does not settle on the walls.

Advantages of pellet boilers

- High efficiency. The best pellet boilers have this figure of 95%! This is already comparable to the characteristics of gas similar devices. This is achieved through the use of pellets. Having a developed surface (much higher than that of coal or firewood), they have excellent heat transfer, while burning almost completely. That is, the entire purchased mass of fuel is used. You don't pay for the ash. The calorific value of these granules reaches 5 kW/h per kilogram of such fuel.

- High degree of automation and ease of use. In this indicator, a pellet boiler is much superior to other varieties of its solid fuel counterparts and is closer to a gas and electric boiler. Depending on the capacity of the bunker, such units operate autonomously from several days to several weeks, or even months. Since pellets practically do not pollute the environment (unlike coal with its dust or firewood with its sawdust and chips), the pellet device can even work in apartment buildings. A separate boiler room is not required.

- Minimum amount of ash. You won’t have to take it out in buckets a day. Compared to other options for solid fuel devices, you simply won't do anything at all!

The only drawback of such units is the high price. This is due to a complex design to ensure maximum automation and autonomy, as well as high efficiency. However, taking into account the latter, as well as the long service life, all costs will be recouped. But you can enjoy the simple, comfortable operation of such a unit, which will cause a minimum of hassle.

Advantages and disadvantages

Pros:

- Full autonomy, you can adjust the equipment according to your preferences.

- High efficiency, this parameter reaches 86-93%, which practically coincides with the parameters of gas equipment.

- Low power consumption. A low-power fan and electronics that ensure the operation of the boiler consume about 60-70 watts.

- A small amount of ash. When the boiler operates regularly, cleaning is carried out every 5-7 days. In addition, there are already options on sale with self-cleaning of ash residues.

- Increased heat transfer. Due to their denser structure, the combustion process of pellets is more efficient than that of conventional firewood.

- High degree of fire safety. External metal parts do not heat up, except for those surfaces that are heated according to the technological scheme.

- Automation. Equipment with this function can operate autonomously for up to 5 days.

- Environmentally friendly, when burning pellets, the emission of carbon dioxide into the atmosphere is very small.

- No permits or approvals are required for installation.

Minuses:

- The main drawback is predictably the cost. This limits the distribution of such equipment. In addition, compared to conventional wood, heating with pellets is more expensive. And the dependence of equipment on electric current also does not contribute to its popularization.

- Significant cost of equipment;

- Increased operating cost compared to other solid fuel boilers. The cost of pellets is quite high, despite the low cost of the source material.

- High cost of thermal energy from pellets.

- Pellets require specially equipped storage.

Which is the best pellet boiler to choose?

It is necessary to select a pellet boiler model, adhering to the following algorithm.

- Availability of the required thermal power. The method for calculating the required heat for heating a house or apartment is outlined on the Internet, and it is not difficult to find it. Our advice is to choose a model whose rated power is 15-20% more than necessary.

- What fuel do you intend to run on? There are models that operate only on pellets, and there are those that also allow operation on coal or wood. They cost more, but you have to pay for universalism.

- With this unit, do you intend to only heat the house or also heat water? That is, is a single-circuit or double-circuit model necessary?

- Degree of automation of the device. There are models:

- Automatic - you just need to periodically add fuel to the bunker and set the temperature parameters that need to be maintained.

- Semi-automatic - thermal power is set by a mechanical regulator. Subsequently, the volume of supplied fuel for a given power level is maintained automatically. The optimal choice in terms of price and quality

- With manual fuel supply. The most affordable option, but during the heating season you become a fireman.

Types of pellet boilers by degree of automation

On the market you can buy a number of ready-made solutions, partially or fully automated pellet boilers. May be offered:

- granule control and screw feeding system;

- a storage hopper, the volume of which is designed for several days of boiler operation, a pellet supply system, automatic control of parameters and notifications;

- a complete set of automatic tools, which include remote control, diagnostic, monitoring, warning and ash removal systems.

Important: solid fuel heating units based on wood pellets (except for a separate segment of models with fireplace combustion chambers) require power supply for electronic components, the blower and the fuel supply system. The problem of uninterrupted power supply is easily solved by purchasing special UPSs, which are offered by both the manufacturer of pellet boilers and many other companies.

Let's consider the features and capabilities of equipment options with varying degrees of automation.

Rating of pellet boilers

Here is a brief description of the most popular models of 2018.

The best pellet boilers:

- Cooper 30 is a single-circuit model with automatic fuel loading with a very competitive price. Power 30 kW (for heating 250-300 m2).

- Roteks 70 Lux is a powerful (for heating 500 m2) model with automatic loading.

- Termal-20 is an excellent device with two circuits and efficiency up to 92%. Power 20 kW.

- Kiturami KRP 20PA is also a dual-circuit model with a power of 24 kW. Heats more than 8 liters of water per minute.

- Buderus Logano G221 A is a highly efficient device with two circuits. Works on pellets and coal. Power 25 kW.

Wood and pellet boiler

In case of interruptions in the supply of pellets, it is worth considering alternative heating options. There is solid fuel equipment into which you can load firewood or briquettes.

Device

Units that can be heated with wood or briquettes for some time do not differ in design from conventional ones. Only the shape and size of the firebox differs.

Principle of operation

The operating principle is almost the same as the basic model, but there are several differences:

- Firewood or briquettes are loaded manually and last for several hours; you have to frequently load fuel into the firebox.

- There is no automated loading of fuel into the firebox.

- Firewood and briquettes do not burn completely.

- More ash and soot are formed.

The principle of operation of a boiler using pellets and wood

This heating option is temporary, as a last resort.

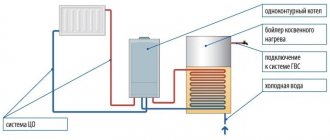

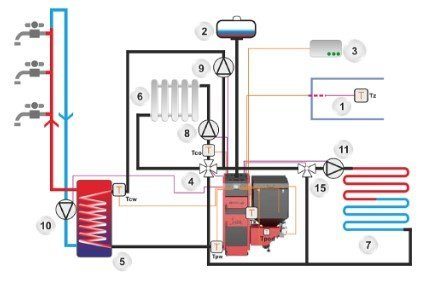

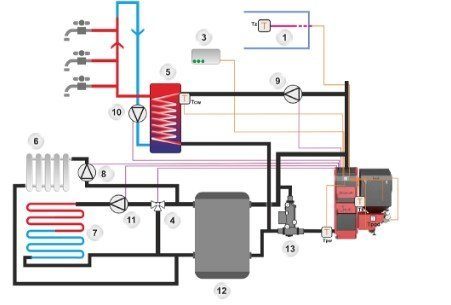

Connection diagram

Connecting pellet boilers is no fundamentally different from connecting other units with similar functions. If this is a single-circuit model, then the discharge pipe cuts into the supply, and the suction pipe into the return. The double-circuit model also needs to be connected to the hot water supply system in the same way.

In most cases, these devices do not have a circulation pump. Therefore, the heating scheme of the house should be based on natural circulation (due to changes in the density of hot and cold water). Or it is necessary to additionally install a circulation pump. Of course, the cost of the system increases, but the efficiency and speed of heating the room increases significantly.

Below are schematic diagrams of heating with natural (Fig. 1) and forced circulation (Fig. 2).

Rice. 1 Heating scheme with natural coolant circulation

Fig.2 Heating diagram with forced circulation of coolant

Best lists

A few more top models that we simply couldn’t miss:

- Best price – Stropuva S30P.

- Reliable – Buderus Logano S181-25 E.

- For a large house - ACV TKAN 1.

Let's take a closer look at them.

Best price – Stropuva S30P

Among many options for high-quality pellet boilers, it is Stropuva S30P that has one of the lowest prices with fairly good technical parameters. It is allowed to use several types of fuel at once; the device operates on one load for up to 3 days, heating a house with an area of up to 300 m². Excellent value for money and quality! In addition, the unit does not look bulky, despite its rather large size, and its pleasant ergonomic design will fit into any home interior.

| P (kW) | 30 |

| Efficiency % | 85 |

| S heating (m²) | 300 |

| Weight, kg) | 259 |

Price: from 95,500 to 96,000 rub.

heating boiler Stropuva S30P

Reliable – Buderus Logano S181-25 E

The most reliable pellet boiler is Buderus Logano S181-25 E. How has it earned such trust? Firstly, the duration of operation - one download is enough for 50 hours. Secondly, built-in sensors for monitoring the operation of the firebox and bunker, which ensures safe operation of the device. And finally, thirdly, the presence of an automatic fire extinguishing system. This model truly has the maximum level of reliability and safety, coping well with the main task - heating the house.

| P (kW) | 27 |

| Efficiency % | 88 |

| S heating (m²) | 270 |

| Weight, kg) | 274 |

Cost: from 224558 to 272640 rubles.

heating boiler Buderus Logano S181-25 E

For a large house – ACV TKAN 1

If you are the owner of a large house, then be sure to pay attention to the ACV TKAN 1 - this model is designed for an area of up to 300 m². The main advantage of the device is its efficiency - even during the most intensive work, 8 kg of pellets will be enough for a whole hour of work. If the average temperature parameters are set, then the fuel consumed is half as much.

| Power, kWt) | 35 |

| Coef. useful actions | 90 |

| S heating (m²) | 300 |

| Weight (kg) | 560 |

Cost: from 289,750 to 290,450 rubles.

heating boiler ACV TKAN 1

Features of installing pellet boilers

Thanks to the design (the high-temperature zone is concentrated in a relatively small-volume firebox), there is no need to make the body of this unit from massive cast iron. Relatively light sheet steel is quite suitable. Therefore, the mass of these devices with a power of 25-30 kW (for home use) does not exceed 150-300 kg. Therefore, they do not require a special foundation for installation.

But if the piping of pellet boilers involves connecting to it a pellet hopper with a capacity of 0.5-1.5 tons, then a foundation is necessary. Of course, this option requires a separate boiler room.

Principle of operation

So, to properly understand the operating principle of a pellet device, you should understand its design. It is quite simple and consists of 3 main parts: the boiler itself with a burner, a conveyor for feeding pellets and a fuel hopper. The functioning of the boiler is ensured as follows:

- Pellets are loaded into the fuel bunker.

- The pellets are supplied by a screw conveyor.

- In the process of burning pellets, they heat up the coolant.

The principle of combustion occurs “from top to bottom”. Such combustion occurs more slowly than when the fuel burns “from the bottom up,” so that the circulating gas flows involve the upper layers of the fuel in the combustion process. The rate of fuel combustion can be controlled by moving the fire zone downward. Thus, soot and ash are formed in minimal quantities, and efficiency increases up to 96%. Pellet boilers can operate on one bed for more than a day - quite convenient for use in domestic conditions.

Installation of pellet boilers in Moscow

We said above that these units are expensive heating equipment. In order for it to work with maximum efficiency and for many years, it must be installed and tied by professionals. This is an axiom. Especially if these are expensive automatic models.

In Moscow, we recommend contacting our. Our advantages:

- We will develop a project for a heating and water supply system based on a pellet boiler, which will have high characteristics of efficiency and ease of use.

- We will promptly carry out high-quality installation and commissioning work.

- We will provide warranty service.

- We will offer competitive prices for our services.

Pellet boilers are one of the most advanced heating devices. And in many cases they are the best option for heating a home. You do not need to connect to the gas or electric network, which means that the troublesome and lengthy process of approval with municipal authorities is eliminated. As a result, you will enjoy the comfort and coziness of your home without making much effort.

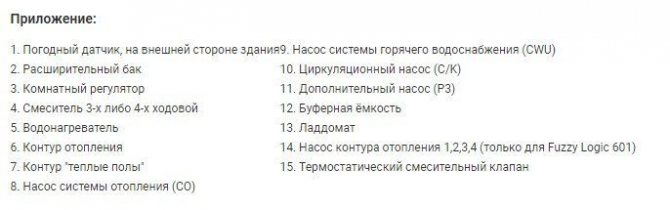

Power and consumption of a pellet boiler

A simple table for calculating the power of heating equipment.

The most decisive factor is the power of the pellet boiler, which is calculated based on the area of the private house. For every 10 sq. m of living space we need 1 kW of thermal energy . If the area of your private house is 100 sq. m, you will need a 10 kW pellet boiler. We add here a margin of 10-20% - we get the equipment power of 11-12 kW.

Next, we calculate the approximate costs of heating a private home. Pellet fuel has good heat release - 1 kg of pellets releases 5 kW of thermal energy. For the above house heated by a 10 kW pellet boiler, the pellet consumption will be 2 kg per hour. Daily consumption will be about 48 kg. In order to reduce fuel costs, it is necessary to purchase it in bulk, in large quantities at once. It is also recommended to deal with heat losses.

To eliminate heat losses, pay attention to the design of windows, the presence of insulation of walls, floors and attic space. It is also recommended to reduce the window area and install normal insulated doors in a private house.

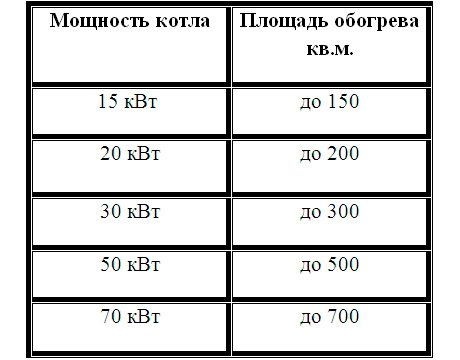

"Obschemash" pellet boilers: prices and characteristics

The manufacturer of boiler equipment, Obshchemash, is located in Russia and today produces two main lines of pellet stoves: Valdai and Peresvet. Both of these lines are distinguished by a high level of automation and reasonable cost.

Helpful information! Valdai ovens are produced with different powers (from 15 to 200 kW). Such units are used to organize heating in residential buildings or small industries.

Let's look at the main functions that are built into this equipment:

- auto ignition;

- automatic delivery of granulated fuel;

- self-cleaning;

- controller.

If necessary, the operation of the Valdai kiln can be monitored via GSM. Peresvet boiler equipment has several differences from Valdai, including:

- possibility of control via the Internet;

Valdai pellet boilers are equipped with a fire-tube multi-pass heat exchanger, a cast-iron collapsible burner and automatic ignition

- larger hopper;

- work not only on pellets, but also on other types of fuel (for example, firewood).

Prices for pellet stoves start at 150,000 rubles. At the same time, as a rule, Valdai devices cost about 10,000 rubles more than Peresvet.

Features of the design and operation of installations

The design of pellet heating boilers includes a hopper, automation and burner. The fuel is supplied to the pre-firing department via an internal auger, and after pre-firing, the fuel is transferred via an external auger to the burner nozzle. When the pellets fall on the nozzle, automated ignition is performed, which promotes complete combustion of the fuel. In terms of thermal performance, burning 1 kg of solid fuel is equivalent to 0.5 liters of diesel, which provides heating with a power of 5 kW/h.

Pellet boilers with automatic fuel supply require installation in a separate room with sufficient space. Installation is carried out on a solid base in the form of tiles or concrete. The room should be as dry as possible and have the possibility of ventilation. The efficiency of the models varies between 86-93%, which exceeds the performance of competing analogues.

Advantages of pellet boilers:

- automated control - granules are stored in a special department, and automation allows you to set the mode of fuel supply to the firebox;

- a fuel bunker with a capacity of 200-300 liters is capable of ensuring continuous operation of the unit for 3 days;

- the fuel resource used is environmentally friendly for humans and animals, and the design of the heating device is made in such a way that oxygen in the room will not be “burned”;

These are the main advantages of automatic pellet boilers. But there are some drawbacks here. The disadvantages of the units are as follows:

- compared to wood-burning boiler equipment, the equipment in question is slightly more expensive;

- fuel must be stored strictly in a dry room, otherwise it will lose its properties;

- To ensure autonomous operation, it is necessary to purchase a generator and additional accessories, which increases the overall costs of the equipment.

Taking into account all of the above aspects, we can safely say that a unit operating on pellets is not inferior in characteristics to its analogues, and in some parameters even surpasses them. But if the consumer does not have experience in choosing such equipment, it is recommended to use the rating presented below. It is compiled based on user reviews.

Features of the pellet stove device

The unit, operating on fuel pellets, includes three main sections:

- furnace;

- convective;

- ash pit.

Furnace department. It is represented by a chamber in which solid fuel pellets are burned. It is equipped with a torch or retort gas burner and has two doors (inspection and cleaning).

Convective department. Has a built-in heat exchanger. Depending on the location, there are three types of heat exchangers: vertical, horizontal, and combined. In this department, the coolant (water) is heated with hot air, which is released during the processing of fuel pellets. The design of the heat exchanger can be either tubular or plate.

Pellet boilers are in most cases used only for heating purposes and have one circuit. However, there are units on the market with two circuits: heating and water heating.

Standard pellet boiler design

Ash pan. This section of the furnace is necessary to collect waste that is generated during the processing of pellets. After this, they are removed through the cleaning door.

The above structural elements of a pellet solid fuel boiler

represent its main part. But for the stove to operate, another important component is needed, namely: the APT attachment (automatic fuel supply).

Let's look at what devices are included in the APT set-top box:

- bunker;

- screw;

- fan.

A bunker is a metal container into which fuel is poured for processing. From this container, fuel flows in parts into the combustion section. Depending on the location, there are two types of bunkers: internal (built-in) and external. The auger is an important element of the APT and is necessary for portion feeding of pellets. It is driven by a special device - a gearbox.

Diagram of a pellet boiler with a hopper

Note! The fan is needed so that in the absence of natural draft the fuel does not stop burning.

The pellet stove also includes a control panel. It is necessary in order to set the parameters of the solid fuel processing process and maintain the required temperature.

Selection options

Manufacturers produce a large number of different models of pellet boilers. You can buy them in specialized or online stores.

When choosing the optimal model for yourself, you need to pay attention to factors such as:

- unit power;

- efficiency;

- functionality;

- fuel consumption;

- number of circuits.

Double-circuit boilers can be connected to heating and hot water systems. When choosing a pellet stove, be sure to take into account what type of room it will heat: residential or industrial. For domestic needs, a small power boiler is sufficient.

The best pellet boiler with automatic loading

The operating principle of automatic pellet feeding depends on which drive is used in the device. There are certain installation requirements - the minimum distance from the boiler to the bunker is at least 1 m, a fireproof partition between the storage and the unit, etc.

Cooper OK 30

The Kupper combined pellet boiler is designed for heating rooms with an area of up to 250 m2. Automated operation at maximum load ensures continuous operation for 5 days. The main type of fuel is pellets; if necessary, you can switch to gas by changing the burner.

Cooper OK 30

Specifications:

| Heating area, m2 | 300 |

| Power indicator, kW | 30 |

| Maximum burning time, days | Up to 5 |

| Fuel length, mm | 6-12 |

| Weight, kg | 193 |

| Bunker capacity, m3 | 0,2 |

| Efficiency | 95% |

The cost of the model is 87,300 rubles.

Operating instructions Cupper OK 30

Roteks 70 Lux

The Chelyabinsk-made model operates on a granular type of fuel in the form of pressed wood and other types of combustible materials. The device is manufactured in accordance with GOSTs 20548-47 and 30735-2001. The main distinctive features of this unit are the presence of an option for remote shutdown or activation, as well as a module that regularly sends messages to the phone about the operation of the boiler equipment.

Roteks 70 Lux

The operating temperature is 70-90°C, and the efficiency is 85-90%, depending on the cleanliness of the unit. The device weighs 735 kg, the fuel bunker can hold up to 100 liters. The storage compartment for fuel granules has a volume of 500 liters.

Here it is possible to connect to a heating system with a parameter of 50 DN. When operating, the model consumes up to 7 kg per hour, taking into account the minimum heating mode setting, and during operation at maximum power, consumption will vary within 15.5 kg/h. Equipment with dimensions 1965x1800x1870 mm costs 260,000 rubles.

Operating instructions Roteks 70 Lux

Pros of the device

The advantages of pellet boilers are due to the qualities of the energy carrier they process. Solid fuel boilers are advantageous in operation and are not demanding on the quality of heated water and the cleanliness of the surrounding air.

Solid fuel is made by the equipment working with it:

- independent from centralized energy sources (including their availability);

- explosion-proof and flame-retardant;

- does not require the cost of connections or a tank for liquid fuel.

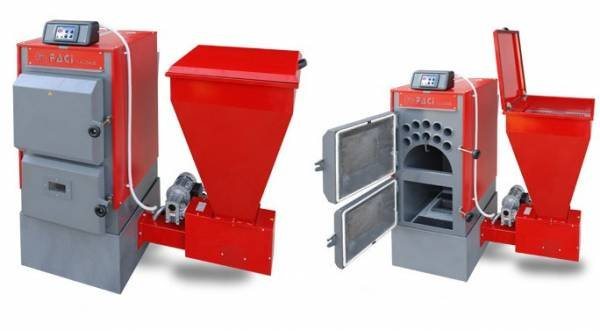

Photo 3. Pellet boiler with a closed (left) and open firebox (right). At the top of the device there is a control panel.

The woody nature of the fuel gives pellet boilers their positive features:

- environmental safety;

- the ability to use ash to deoxidize and enrich the soil;

- aesthetic value - places where firewood and pellets are stored and used remain clean, only the smell of wood gives them away.

Environmental friendliness

The form of existence of the raw material (dense, homogeneous granules) and the technology of its production give pellet boilers new qualities that distinguish them favorably from heat generators using traditional types of fuel. Like lump wood, pellets are environmentally friendly and hypoallergenic (no binders or modifiers).

Flue gases from coal contain from 1 to 3% sulfur , smoke from wood pellets - 0.1% . There are practically no carbon dioxide in the combustion products of pellets (only the amount that the plant absorbed during growth), which cannot be said about other types of fuel:

- hard coal - 60 kg/GJ;

- fuel oil - 78;

- gas - 57;

- peat-based biofuel - 70.

Efficiency

The calorific value of wood pellets is more than one and a half times higher than that of firewood and is comparable to the specific heat of combustion of coal.

The efficiency of a pellet boiler is higher than a wood boiler - 8.5-9.5. The temperature of the flue gases of the first is only 120-140 °C , the rest of the heat is “absorbed” by the flues.

Convenience

The ash content of wood pellets ( 0.5-1% by weight ) is lower than firewood, and 10-60 times less than coal. The ash content of straw and peat pellets is slightly higher: 4 and 20% , respectively. The ash pan of a 25 kW is cleaned twice a month.

Attention! Ash removal begins only after the burner has cooled.

Granulated and packaged material is convenient to transport, unload, and store. The constancy of the specified physical, mechanical and metric parameters of the fuel filling elements guarantees long-lasting combustion at a constant temperature. When burning, pellets do not “shoot” or spark.

Classification

Most models of pellet boilers are intended only for heating buildings, but there are designs that can also provide hot water. The units produced by manufacturers are classified according to various criteria.

Boilers are classified according to the method of fuel supply:

- automatic;

- semi-automatic;

- mechanical.

Automated models work according to a given program. When servicing semi-automatic boilers, you have to perform some functions manually. Mechanical units are fully human-serviced.