Classification of boiler houses

According to their purpose, boiler rooms are divided into:

- heating - to provide heat to heating, ventilation and hot water supply systems;

- heating and industrial – to provide heat for heating, ventilation, hot water supply and process heat supply systems;

- industrial – for process heat supply;

- energy - generating superheated steam to generate electricity in turbine units (SNiP II-35–76 “Boiler Installations” does not apply to such boiler houses).

Based on their location, boiler rooms are divided into:

- free-standing;

- attached to buildings for other purposes;

- built into buildings for other purposes, regardless of the floor of placement;

- roof-mounted, located (placed) on the building’s roof directly or on a specially constructed base above the roof.

According to the reliability of heat supply to consumers, boiler houses include:

- to the first category - boiler houses, which are the only source of heat for the heating supply system and provide consumers of the first category who do not have individual backup heat sources;

- the second category includes the remaining boiler houses.

Heat consumers in terms of heat supply reliability include:

- the first category includes consumers whose heat supply disruption is associated with a danger to human life or significant damage to the national economy (damage to technological equipment, mass defects of products);

- the second category includes the remaining heat consumers.

Boiler classification

According to the nature (type) of the generated coolant:

- steam,

- hot water,

- steam-water-heating.

According to coolant parameters:

- steam boilers with a working steam pressure pp of more than 0.7 kgf/cm2 and hot water boilers with a water heating temperature tb above 115 °C are subject to boiler inspection (Rostechnadzor of Russia); they are subject to PB 10-574–03 “Rules for the design and safe operation of steam and hot water boilers” - “supervisory” boilers;

- steam boilers with a working steam pressure pp of no more than 0.7 kgf/cm2 and hot water boilers with a water heating temperature tw of no higher than 115 °C are “non-supervisory” boilers; they are subject to the “Rules for the design and safe operation of steam boilers with a steam pressure of not more than 0.07 MPa (0.7 kgf/cm2), hot water boilers and water heaters with a water heating temperature not exceeding 388 K (115 °C)”, approved Ministry of Construction of Russia.

According to the material used:

- steel,

- cast iron

According to the principle of heat exchange:

- surface (recuperative), in which heat transfer from combustion products to boiler water occurs through a dividing wall (heating surface);

- contact, in which heat transfer occurs through direct contact (mixing) of gases and water.

Based on the movement of combustion products and water, surface boilers are divided into:

- water-tube, in which boiler water moves through pipes, and combustion products move outside the pipes;

- gas-tube (with a flame tube (furnace) and a bundle of smoke tubes), in which combustion products move inside pipes washed externally with water;

- water-tube-gas-tube (boiler VK-32, in which the combustion part is water-tube, and the convective part is gas-tube).

On the organization of the combustion process (method of air supply and removal of combustion products):

- working under vacuum; can have draft and air supply natural or forced. In the gas path (and in the furnace) the pressure is below atmospheric (draft);

- operating with back pressure (supercharged); the firebox and flues are under excess pressure relative to the surrounding air. Air supply and combustion products removal are carried out forcibly from a blower fan.

According to the nature of the movement of boiler water (steam-water mixture):

- with natural circulation (Fig. 1, a);

- with forced circulation, when water moves due to the pressure created by pumps: with multiple forced circulation (Fig. 1, b; not widely used);

- straight-through (without drums). Large power boilers at thermal power plants operate according to this scheme (Dp = 3950 t/h, rp = 255 kgf/cm2, tpp = 560 °C) and almost all hot water boilers (Fig. 1, c).

Rice. 1. Water circulation patterns in steam boilers: a – natural; b – forced multiple; c – forced direct flow; 1 – evaporative rise pipes; 2 – upper drum of the boiler; 3 – steam superheater; 4 – lowering pipes; 5 – water economizer; 6 – feed pump; 7 – evaporation pipes; 8 – collectors; 9 – incentive circulation pump

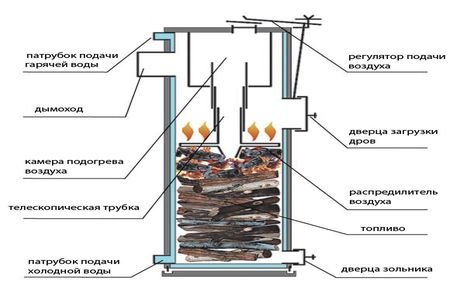

Design features of a long-burning boiler

The thermally insulated body consists of two steel cylinders of different sizes, one of which is located inside the other. In the space between them there is a coolant, which heats up during the combustion of fuel. The housing is equipped with a door for loading firewood, removing ash and a hole for removing smoke. Pipes for connecting the heating system and a thermometer are also connected to it.

The bi-thermal draft regulator, located on the housing, changes the position of the damper due to thermal expansion of the heat generator housing. When the temperature rises, the damper closes or closes completely, and when it drops, it opens. At the top of the combustion chamber there is a compartment for heating the air, which improves the efficiency of fuel combustion and the transfer of thermal energy.

To supply air to the long-term combustion chamber, a folding tube with a distributor is used. At the top of this chamber there is a damper that regulates air access.

The air supply mechanism is controlled by a chain with a ring and a fixed hook. The umbrella-shaped air distributor rests on the firewood with its sides and moves down as the fuel burns.

Since long-burning boilers have a large height, the ceiling in the boiler room should not be lower than 195 cm. The recommended room area is at least 4 m2. Be sure to have a ventilation duct or window for air intake. The heat generator is installed on a concrete floor base. If this is not possible, you can order a concrete pallet.

A chimney must be connected to the boiler, the diameter of which depends on the model. If the draft in the chimney is insufficient, an electric fan is connected to pump air.

Advice! A long-burning solid fuel boiler must be connected to the heating circuit by a professionally trained specialist who is familiar with the manufacturer’s requirements. This will allow you to get high-quality installation and a guarantee.

The procedure for starting and operating the boiler

Long-burning boilers are divided into wood-burning and universal boilers, which can operate on other solid fuels. Maximum fuel economy is achieved when the furnace is fully loaded:

- When using firewood, the damper must be lowered, and when using coal, the damper must be raised.

- You need to lift the air distributor by pulling the ring on the cable and putting it on the hook below.

- The firewood is stacked horizontally, placing the short ones closer to the edges and the long ones towards the center.

- The space remaining between the logs is filled with sawdust.

- When burning coal or peat, a grate must be used. Large coal is preferable.

- The top layer of wood is ignited. In this case, the door should be slightly open by 2-5 cm.

- When the fuel has ignited well, the door is closed and the ring with the lifting chain is removed from the hook.

- During operation of the boiler, air must flow freely into the boiler room through a window or ventilation duct.

- When using insufficiently dried firewood, coal or peat, turn on the blower fan.

Advice! It is not recommended to mix coal with other types of fuel. Firewood is placed on top of the coal only for lighting. Moreover, fine coal gives 50-70% less combustion power.

Main technical characteristics of steam and hot water boilers

The design parameters characterizing the operation of the boiler are indicated in the boiler passport, drawn up by the manufacturer in the prescribed form (Appendix 4 to PB 10-574–03) and kept by the owner for the entire period of operation.

Each boiler must be affixed with a nameplate containing the nameplate data, printed in a manner that ensures clarity and durability of the image.

The following data must be written on the steam boiler plate:

- name, trademark of the manufacturer;

- boiler designation;

- boiler number according to the numbering system of the manufacturer;

- Year of manufacture;

- nominal steam output Dp in t/h;

- working pressure at the outlet in MPa (kgf/cm2);

- nominal steam outlet temperature in °C.

The following data must be written on the boiler plate:

- name, trademark of the manufacturer;

- boiler designation;

- boiler number according to the numbering system of the manufacturer;

- Year of manufacture;

- nominal heating capacity Q in MW (Gcal/h); working pressure at the outlet in MPa (kgf/cm2);

- nominal outlet water temperature in °C.

The designation of the steam boiler includes:

- type,

- steam capacity (t/h),

- absolute (excess) steam pressure pp, (MPa or kgf/cm2),

- type of fuel (G – gas, M – fuel oil);

- Pressurized boilers are designated by the letter N.

For example: DKVR-10/13; E-25-2.4 GM; DE-6.5/14-225 GM; E-1/9-G.

The designation of the hot water boiler includes:

- type – KV (hot water boiler);

- type of fuel (G – gas, M (F) – fuel oil, diesel fuel);

- type of firebox (H – pressurized);

- rated thermal power (MW or Gcal/h);

- nominal water temperature at the boiler outlet, °C;

- gas pressure (Gn – low; Gs – average);

- an automated boiler is designated by the letter “a”;

- C – steel.

For example: KV-GM-10-50; KSVa-2.5-Gs; KVA-3-95; KVA-0.75Zh-115.

On each boiler put into operation and after technical inspections have been carried out, a plate with a format of at least 300×200 mm indicating the following data must be attached in a visible place:

- registration number;

- permitted pressure;

- date, month and year of the next internal inspection and hydraulic test.

Main technical characteristics of steam boilers:

- rated steam output, Dp, t/h – the maximum working amount of steam produced by the boiler for 1 hour;

- parameters of the resulting steam:

- operating (calculated or permitted) steam pressure, rp, MPa (kgf/cm2);

- test pressure, rtest, MPa (kgf/cm2);

- type of steam (saturated, superheated);

- saturated steam temperature, tsat, °C (at operating steam pressure pp or superheated steam temperature, tpp, °C);

- feed water temperature, °C;

- steam and water volume of the boiler, m3;

- volume of water, m3;

- evaporation time of this volume, min.

Main technical characteristics of hot water boilers:

rated heating capacity (thermal power), Q, Gcal/hour (MW) – the maximum working amount of heat absorbed by water for 1 hour of operation; 1 Gcal/h = 1.163 MW;

water parameters:

- working water pressure, MPa (kgf/cm2);

- minimum permissible water pressure pv at nominal temperature tb;

- test pressure, rtest, MPa (kgf/cm2);

- minimum permissible water temperature at the boiler inlet, °C;

- nominal water temperature at the boiler outlet, °C;

- nominal water flow through the boiler, Gw, m3/h, as well as the minimum and maximum permissible;

- hydraulic resistance, no more than, MPa.

General parameters characterizing steam and hot water boilers:

- type of fuel and its characteristics;

- burner type;

- boiler heating surface: radiation, convective, total, S, m2;

- calculated efficiency, gross, % when burning gas and fuel oil;

- resistance of gas and air paths, Pa (mm water column);

- temperature of combustion products at the exit from the furnace, behind the boiler, temperature of flue gases - when burning gas and fuel oil;

- content of O2, CO, NOX in flue gases;

- design indicators: internal diameter of the drums, drum wall thickness, length of the cylindrical part of the upper and lower drums; diameters of downcomers, screen and convective pipes; pitch of screen pipes, their number; boiler dimensions.

Coaxial and collective chimneys in apartment heating

Market situation

In the mid-1990s, apartment heating came to our country - decentralized individual provision of heat and hot water to each apartment in a residential building. According to experts in the construction industry, the transition to individual heat supply is primarily due to the fact that in many regions heat communications are severely worn out or overloaded, and the pace of their modernization does not keep pace with the pace of multi-apartment construction. It is in this case that the question of the economic rationality of using centralized heating systems becomes more relevant than ever.

In one of the Russian cities, a large manufacturer of gas boilers launched a project to introduce apartment heating, the results of which showed a reduction in utility costs.

According to the project concept, 5,000 apartments were equipped with boilers that operated autonomously, without connection to the central heating main. Analysis of the results showed a significant reduction in heating and hot water supply costs, namely five times.

Such indicators were explained by the high efficiency of heating equipment and the absence of energy losses (30-70%) during the transportation of heat and hot water to residential premises, characteristic of traditional heating systems.

Manufacturers of gas boilers currently estimate the market share of apartment heating at 20%.

Despite noticeable growth compared to previous years, a number of difficulties are visible in this segment. Firstly, when delivering most individual heating projects, developers are faced with the main inhibitory factor - the administrative barrier.

Lobbying of their interests by energy companies operating in the field of centralized heating, as a rule, blocks each apartment heating project at the initial stage. Due to the imperfection of the legislative framework, many problems arise that designers of such systems face.

These difficulties are more likely not of a technical, but of a municipal nature. In many regions of the Russian Federation, there are certain administrative restrictions on the installation of individual heating systems, and they are associated primarily with the aforementioned lobbying of energy workers.

According to the concept of the project, implemented in one of the Russian cities, 5,000 apartments were equipped with boilers that operated autonomously, without connecting to the central heating main. Analysis of the results showed a significant reduction in heating and hot water supply costs, namely five times

Secondly, many market participants are still faced with an acute shortage of specialists in the design, installation and maintenance of apartment heating systems, which undoubtedly harms the active dissemination of these technical solutions.

Thirdly, it should be noted that the regulatory documentation is weak and contradictory.

Issues that arise when designing apartment heating systems and are not regulated by regulatory documentation, as a rule, are resolved by developing special technical specifications (abbreviated as STU).

STU - technical standards for a specific capital construction project, containing additional to the established or missing technical requirements in the field of safety. This document is also required in cases where it is not possible to comply with applicable regulatory requirements during the design process.

For example, these include the problem of removing condensate from chimneys operating in wet conditions. In general, issues related to smoke removal and combustion air intake, especially for the northern regions, are extremely poorly regulated. In practice, everything that can be agreed upon with local supervisory organizations is implemented.

It is important to understand that each apartment heating project is largely individual. Design organizations use already adopted regulatory documentation for their purposes. If problems arise at the design stage, then, as a rule, they are resolved locally exclusively within the framework of the law, otherwise the project will not go through the approval process.

The fastest solution to this problem is the adoption of uniform federal standards and regulations for apartment heating.

Standards and rules

Today, the rules for apartment heating systems in residential buildings are regulated by local branches of gas utilities and Rostechnadzor.

The coordination mechanism looks like this. Before drawing up a project involving apartment heating, the contractor obtains technical specifications from the gas distribution organization.

Then the plan is developed by designers taking into account the specified conditions and again agreed upon by the same gas distribution organization.

Today, there is no specific body regulating the rules of apartment heating in the constituent entities of the Russian Federation. Now these functions have been taken over by several organizations such as the non-profit partnership ABOK and a number of others. They have the necessary specialists on their staff, as well as the legal potential to resolve many issues related to apartment heating.

This allows them to introduce their own developments in this area into the existing legislative framework after they have been agreed upon by all authorities.

Today, for apartment heating, the documentation of clause 6.3 of SP 41-108-2004 is used.

If we consider the list of standards currently in force in our country, it is certainly incomplete. The recommendations and requirements given in regulatory documents do not regulate all issues related to apartment heating, and sometimes contradict each other.

First of all, it is necessary to make changes to the current SNiP regarding the number of storeys. For example, if an apartment building has more than nine floors, apartment heating systems cannot be officially installed in it. Although the apartment segment could show significant growth if it became possible to install individual heating in multi-storey buildings.

It all starts with the boiler

All gas equipment (including gas heating boilers) supplied to Russia undergoes certification, during which its compliance with the standards required in our country is checked. One of the features is the adaptation of the boiler to operate at low gas inlet pressure (up to 5 mbar). When choosing, you need to pay attention to the power of the wall-mounted boiler directly for the specific apartment. The main thing is that the boiler does not have excess power, otherwise it will constantly “tick”, that is, turn on and off, which will lead to increased wear and tear on the equipment, and, as a consequence, to its rapid failure.

The recommendations and requirements given in regulatory documents do not regulate all issues related to apartment heating, and sometimes contradict each other. First of all, it is necessary to make changes to the current Russian SNiP regarding the “number of storeys”. Let's give a clear example - if an apartment building has more than nine floors, apartment heating systems cannot be officially installed in it.

You should also remember about good burner modulation. Usually for a small apartment there is no need for high power.

Let's briefly consider what types of boilers exist.

Heat generator with open combustion chamber

Gas boilers with an open combustion chamber consume the air required for combustion directly from the room in which the heat generator is installed. They are also called “natural draft boilers”. To remove exhaust gases, a chimney connected to the device is used. Despite the relatively low cost of such boilers, their main disadvantage is that the air is taken directly from the room in which the heat generator is located. If there is insufficient ventilation in the room, there may be a lack of oxygen, resulting in a risk of carbon monoxide poisoning. Therefore, for safety reasons, it is recommended to install such a boiler in a separate room - the furnace room. It must meet all the necessary requirements of heating equipment, be suitable in area and comply with the necessary safety standards.

In this case, combustion products must be removed using a chimney, and the ventilation system must provide three times air exchange.

Boilers with an open combustion chamber have one advantage - in this product line, manufacturers offer heat generators that operate independently of the electrical network.

Heat generator with a closed combustion chamber

Boilers recommended by experts for apartment heating systems must have a closed combustion chamber and the ability to produce hot water for domestic needs, that is, be double-circuit.

For boilers with a closed combustion chamber, forced air supply to the firebox is required. Using a special fan or cooler, air is taken from the street, passes through an external pipe, heating up along the way, and enters the firebox. Combustion products are removed from the heat generator through the internal pipe, thereby heating the entire structure and increasing the efficiency of the boiler.

As a result, wall-mounted double-circuit boilers with a power of up to 35 kW, with a closed combustion chamber and a separate smoke removal and air intake system, have gained popularity.

It is also important that such a heat generator must be resistant to: use with untreated water, low gas pressure, power surges.

A gas boiler with a closed chamber is more expensive than an open one and cannot operate without electricity, but it is very important that it can be installed in a residential area. It does not take up much space and does not require specially equipped premises.

Flue gas removal

There are a lot of solutions for smoke removal systems from boilers for apartment heating. However, taking into account our regulatory framework and the requirements of regulatory organizations, it is necessary to use collective smoke removal systems. It is also important to take into account the climate zone.

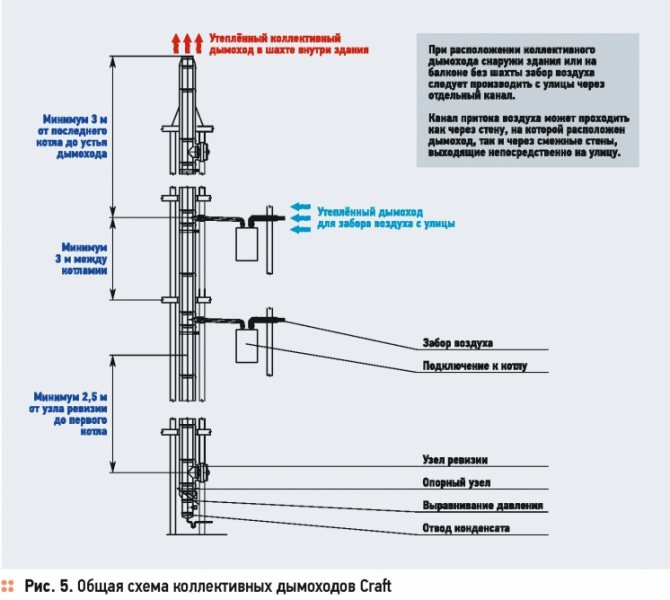

In central Russia, and even more so in the northern regions, taking combustion air from the street for each individual boiler is not the best solution. Therefore, in such cases, a collective insulated air supply system should be used. In this situation, collective coaxial LAS systems (Luft-Abgas-System - a combined system for supplying air and removing combustion products), made of acid-resistant stainless steel to withstand the harmful effects of condensate, are optimal.

In central Russia, and even more so in the northern regions, taking combustion air from the street for each individual boiler is not the best solution. Therefore, in such cases, a collective insulated air supply system should be used

Optimal removal of flue gases is carried out through a chimney, which must be provided in the apartment. The implementation of chimneys can be very different. For example, a chimney is initially provided for during the construction of a residential building. In addition, the organization of a collective chimney can be done externally, that is, when the chimney is installed directly on the outer wall of the building.

In multi-apartment residential buildings, flue gas emissions should be provided through collective smoke ducts (pipes) above the roof of the building. The installation of smoke exhausts from each heat generator through external walls (including through windows, under balconies and loggias) in residential multi-apartment buildings is not allowed. Also, chimneys cannot be laid through residential premises.

Flue gas removal, according to paragraph 6.3 of SP 41-108-2004, is carried out as follows. Modern air supply and combustion product removal systems can be designed according to the following schemes:

- with a coaxial (combined) device for air supply and removal of combustion products;

- built-in or attached collective air ducts and chimneys;

- with a separate device for air supply and removal of combustion products through built-in or attached collective air ducts and chimneys;

- with an individual air duct that ensures air intake through the wall and supply it individually to each heat generator, and removal of flue gases through a collective chimney.

The installation of smoke exhausts from each heat generator individually through the facade wall of a multi-story residential building is prohibited.

Steel grade for smoke exhaust systems

There are several large companies on the market that design and manufacture modular smoke removal systems made of stainless steel. When working with them, you need to take into account that the reliability and service life of the chimney depend on the correct choice of the quality of the material for the smoke exhaust system and the professionalism of installation when designing apartment heating.

The service life of smoke exhaust systems for apartment heating must be designed for the entire period of operation of the building, since eliminating malfunctions of the chimney during its operation will leave the residential building without heat for an indefinite period, and outside the heating season will create a lot of inconvenience for residents associated with construction work.

Installation of a smoke removal system occurs during construction or in an already built residential building. It is almost impossible to make any changes to the design later or replace failed elements after the heating system has begun operation. That is why experts recommend paying special attention to the quality of steel and insulation for the chimney, as well as to the design of the elements. In the future, this will help eliminate a lot of problems for builders and future residents of an apartment building.

Coaxial chimneys of the LAS (air-gas) system are a “pipe-in-pipe” design. An internal circuit of a certain diameter is designed to remove combustion products. Combustion air is supplied through the external circuit (larger diameter), called the “inlet”

AISI 316L series steel is used in the production of collective and coaxial chimney systems. It belongs to the class of austenitic acid-resistant steels. Alloying the alloy with molybdenum and nickel increases its corrosion resistance. This ability of the material is fully manifested in the process of processing natural gas inside the chimney pipe. The fuel in boilers with a closed combustion chamber is saturated with hydrogen and, as a result, is characterized by high “dew point” temperatures. Under such operating conditions, the risk of condensation and an aggressive acidic environment is significantly high. Therefore, AISI 316L series steel is indispensable for operation in a wide temperature range and is resistant to a large number of concentrated acids. This feature makes this steel grade indispensable in the production of smoke removal systems for apartment heating.

Types of chimneys for organizing apartment heating

Let's look at how a project for a smoke exhaust system for apartment heating is implemented based on materials provided by the manufacturer of Craft chimneys. The following two types of chimneys are used in apartment heating.

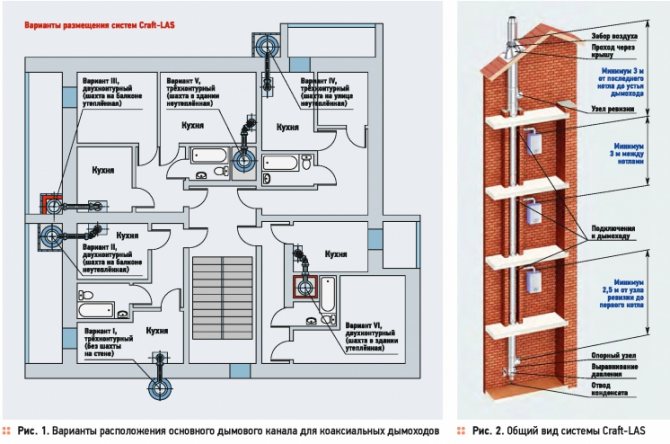

Coaxial chimneys of the LAS (air-gas) system are a “pipe-in-pipe” design (Fig. 1 and 2). An internal circuit of a certain diameter is designed to remove combustion products. Through the external circuit (larger diameter) an air supply is carried out, called the “inlet”.

The air channel for supplying air to the firebox is integrated directly into the chimney itself. The air necessary to support the combustion process is taken from the atmosphere in countercurrent to the flue gases. Combustion products are removed from the firebox to the mouth of the chimney along the internal contour.

In connection with this, there is no need to organize an additional supply air shaft connected to the boiler by visible elements.

The uniqueness of the LAS system is that it is designed taking into account an increase in boiler efficiency. This process works like this: the combustion air is preheated by passing between the internal and external contours of the chimney, thereby eliminating heat loss in the ventilation shaft.

The smoke exhaust system must always be designed in such a way that the pressure in the inner pipe is lower than in the supply air shaft and in adjacent rooms. Thanks to this pressure difference, combustion products are removed using a thermal lift force that occurs in the inner pipe.

Using the example of connecting a Craft-LAS chimney to a heat generator with a closed combustion chamber, a closed structure is obtained - this guarantees safety from smoke in the room, complete combustion of fuel, optimal use of energy and reliability of the entire smoke removal system. Another advantage of such tightness is that air is not drawn out of the room, unlike boilers with an open combustion chamber, which means that the kitchen hood can work simultaneously with the heat generator.

The combustion chambers in closed-type heat generators are well soundproofed. In turn, closed smoke removal systems do not require additional air flow from other rooms. The spread of noise through chimneys between adjacent apartments is also excluded, which creates ideal soundproofing of the apartment.

It is also important that more heat generators can be connected to one chimney of the LAS system than in systems operating using room air.

In addition, the LAS system, made of stainless steel, has a number of advantages over ceramic and brick chimneys:

- can be installed in an already built house at any time of the year;

- has a modular structure, which simplifies assembly and allows you to create a configuration of any complexity;

- It is lightweight and does not require laying a foundation;

- withstands large temperature changes;

- prevents soot deposition due to the smooth inner surface of the smoke channel;

- prevents the formation of condensation using the “sandwich” chimneys included in the system.

It is important to note that air ducts and chimneys where they pass through walls, partitions and ceilings should be enclosed in cases.

The gaps between the building structure and the casing should be carefully sealed to the full thickness of the structure being crossed with non-combustible materials or mortar that does not reduce the required fire resistance limits.

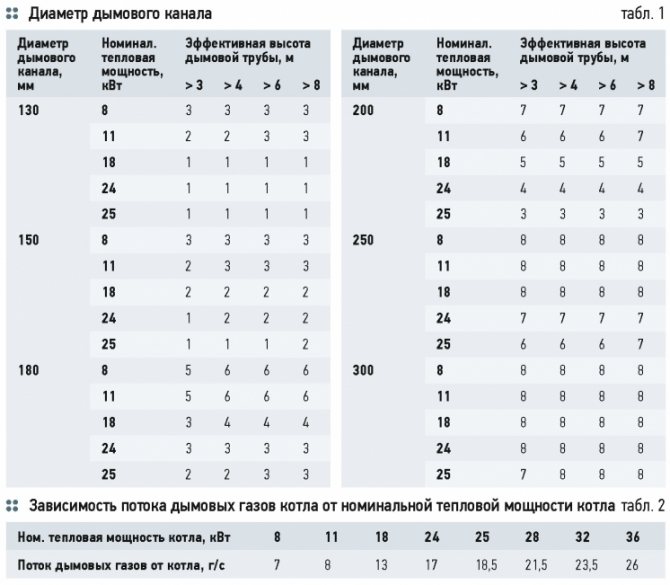

Calculation of the cross section of the smoke exhaust system

Accurate calculation of the cross-section of the smoke channel according to the table. 1 allows you to significantly simplify the design task and select a chimney in accordance with the rated thermal power of the connected devices.

The efficiency of the LAS system directly depends on the cross-section of the smoke duct. In turn, the cross-section diameter depends on: the rated thermal power of the heat generator; number of connected heat generators; total effective height of the chimney (height between the last heat generator and the elevation of the chimney mouth).

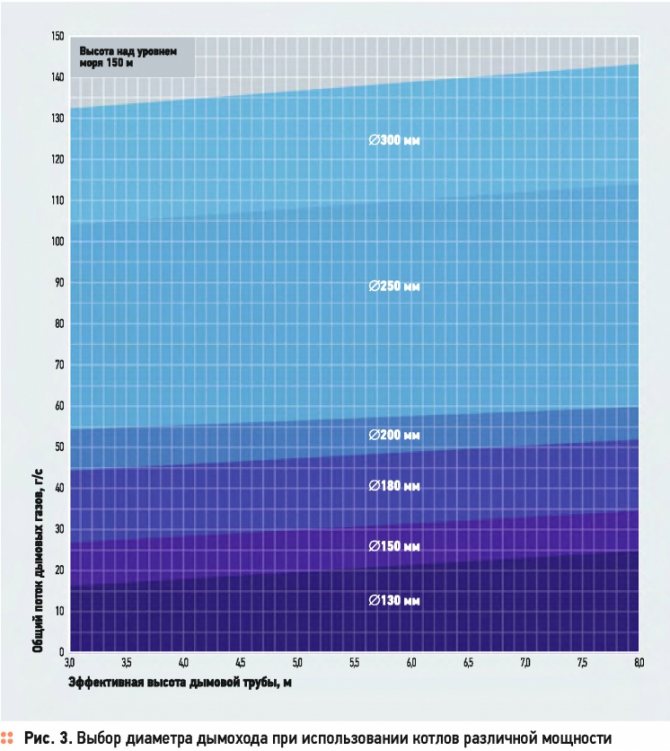

For different power heat generators, the concept of total flue gas flow is introduced. Its value is determined as the sum of flue gas flows from each heat generator (Table 2, Fig. 3).

In the case of using units of various capacities for apartment heating systems, only those devices whose rated power is lower by no more than 30% in comparison with the unit of maximum heating capacity can be connected to the coaxial chimney.

Craft-LAS System Design Guidelines

Designing chimneys includes several points: determining the exit location and configuration of the smoke channel, calculating the cross-section depending on the maximum power of the connected boiler. After this, the chimney route is determined from the point of connection to the heat generator to the mouth of the chimney on the roof. The last stage is the selection of specific elements of a certain diameter for the project. It is important to note that the chimney can be placed in a free room along the walls or in a construction shaft. If the chimney is located on the outside of the building, it must be protected from mechanical and temperature influences of the environment.

Designing chimneys includes several points: determining the exit location and configuration of the smoke channel, calculating the cross-section depending on the maximum power of the connected boiler. After this, the chimney route is determined

The requirements for the heat generator are as follows: it must have a closed combustion chamber and forced air intake; The air supply and gas removal channels must be hermetically sealed; the device must be certified; atmospheric burner power - up to 25 kW; the maximum temperature of combustion products in the smoke duct should not exceed 220 °C; the design of the device must include a safety valve that shuts off the gas supply within 10 seconds; The heat generator must be securely attached to the wall in the room, and hanging the device on the chimney is prohibited.

Collective or separate chimneys

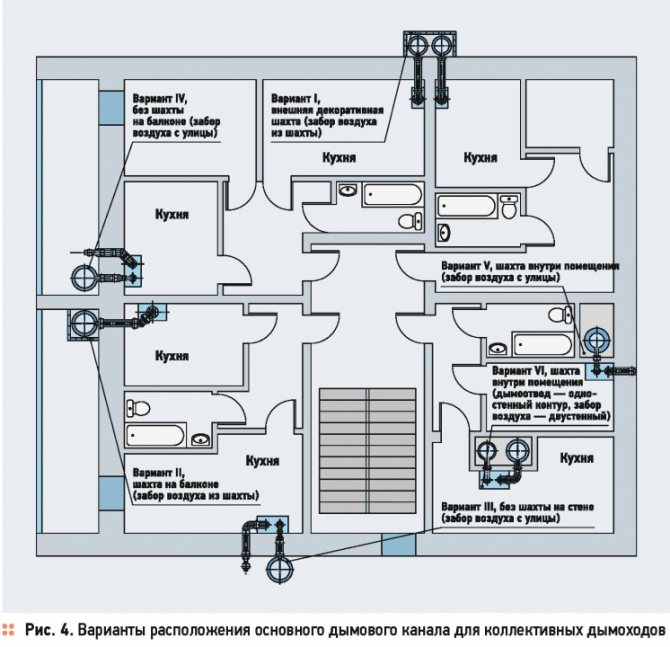

This chimney consists of two separate pipes with diameters of 80 mm or more. One of them is intended for supplying air to the combustion chamber, and the second is for removing flue gases (Fig. 4 and 5). In terms of design, there are no differences between the “inlet” and “outlet” pipe parts. When the collective chimney is located outside the building or on a balcony without a shaft, air should be taken from the street through a separate channel. The air supply channel can pass both through the wall on which the chimney is located, and through adjacent walls facing the street.

Clear benefits

Today, in addition to the many existing successful examples of apartment heating, there is also the necessary technical arsenal for the large-scale implementation of new projects in this area. The presence on the market of high-quality gas equipment and highly reliable chimney systems makes it possible to cover small towns or settlements with apartment heating. As for smoke removal systems, now in new construction it is permissible to install chimneys in the walls, and in the reconstruction of buildings, the installation of a chimney is decided based on specific conditions, for example, they can be laid in the area of a flight of stairs or along a wall.

Design of chimneys includes: determination of the exit location and configuration of the smoke channel, calculation of the cross-section depending on the maximum power of the connected boiler. Next, the chimney route is determined

The economic feasibility of introducing apartment heating systems has been repeatedly confirmed by the results of technical and economic calculations over several years. It is obvious that capital investments and operating costs for apartment heating are significantly lower than for centralized heating.

As for the costs associated with the operation and payment of heat by residents, due to a sharp decrease in the amount of fuel consumed per unit of heat generated, emissions into the atmosphere are reduced, thereby improving the environmental situation. On top of that, residents of houses with apartment heating pay five to seven times less for heating and hot water than their neighbors with centralized heating.

The use of energy-efficient technologies such as apartment heating will immediately solve the problem of heat metering, raising the question of the need for a service in the housing and communal services sector related to the operation of heating networks. And in the future, if a reasonable tariff policy in the field of apartment heating is maintained, the housing and communal services sector will be able to turn from a subsidized industry into a profitable one.

Steam boilers with natural circulation of water

The simplest circuit of natural water circulation (Fig. 2) consists of an upper drum 1 and a lower collector 2, connected to each other by a lower unheated (or weakly heated) pipe 3 and a rising heated pipe 4, forming a closed loop.

Rice. 2. The simplest circuit of natural water circulation: 1 – upper drum of the boiler; 2 – lower collector; 3 – downpipe; 4 – riser pipe; 5 – boiler lining

Natural circulation occurs due to the difference in the densities of boiler water in unheated lower pipes and the steam-water mixture in heated rising pipes.

The total amount of steam generated in the riser pipes is many times less than the amount of circulating water, which ensures intensive cooling of the pipe walls.

The ratio of the mass of water entering the circulation circuit to the mass of steam formed in it over the same period of time is called the circulation ratio.

The multiplicity of natural circulation is always greater than 1 and ranges from 8 to 50.

The pressure created during natural circulation is spent to ensure speed and overcome resistance in the circuit during the movement of water and steam.

The speed at which water enters the riser pipes is called the circulation speed and is 0.5–1.5 m/s.

In modern boiler designs, evaporative heating surfaces are made of separate bundles of pipes connected to drums and collectors, which form a rather complex system of closed circulation circuits.

For reliable and safe operation of a steam boiler, the circulation in it must be stable, that is, the movement of flows of water and steam-water mixture in the circulation circuits must be continuous and at the required speed. Otherwise, steam pockets may appear in the riser pipes, leading to local overheating and destruction of the pipe walls.

In this case, the phenomenon of stagnation or overturning of the circulation is possible, when the steam-water mixture in the riser pipes begins to move downwards.

The reliability of circulation is affected by sudden changes in load, pressure and water level in the boiler drum, and scale deposits on heating surfaces, leading to a decrease in the cross-section of the pipes.