What does boiler piping mean?

If a person has never before encountered the need to arrange a heating system, he is not familiar with the term “piping”. This concept means the use of a specific installation scheme that will protect the equipment from possible overheating.

According to experts, correctly installed piping of a gas heating boiler or an appliance operating on a different type of fuel allows the heating system to operate more economically and efficiently.

Heating boiler piping elements

Knowing what elements a gas heating boiler piping diagram contains will help you connect heating equipment to the system without any problems:

- Heating boiler

. It is one of the main components of the heating structure; its choice largely determines the connection method and piping diagram of the heating boiler. The heating boiler must not be placed at the top of the pipeline distribution. The heating circuit rod must be capable of venting air. To avoid air pockets, if the boiler does not have an air vent, the pipe should be positioned vertically. - Pipes

. This element has gas wall-mounted and electric appliances designed for heating liquid coolant (pro

Boiler equipment

Types of heating boilers

In almost every heating boiler piping video, special attention is paid to the pipe layout and the general organization of heating. It is these factors that determine the required functionality of the boiler, as well as the safety of its operation.

At the first stage, you need to decide on the boiler model, type of fuel used and design. They will determine which piping of a diesel heating boiler will be optimal for a particular scheme. In addition, you need to take into account the following heat supply parameters:

- Type of system – single-pipe, two-pipe or manifold. The method of connecting the boiler, as well as the list of additional components for its operation, depends on this;

- Equipment . Proper piping of an electric heating boiler may include a protective bypass and shut-off valves. If the device does not include a circulation pump, an expansion tank and a safety group, these elements must be installed for water heating;

- Pipeline material . Thus, the correct piping of a heating boiler with polypropylene may differ depending on its design - solid fuel, gas or diesel. In some cases, the primary pipe must be made of metal.

In practice, you can simplify the solution to this problem by reading the instructions from the manufacturer of a specific boiler model. It provides a complete list of materials and shows a wiring diagram for an electric heating boiler or its solid fuel analogue. But besides this, there are general recommendations for additional equipment for heating a home, depending on the type of boiler.

Before purchasing a boiler, you need to familiarize yourself not only with its functionality, but also with its equipment. It will determine the optimal piping scheme for the heating device.

Gas boiler piping

Gas boiler wiring diagram

This is the most widely used type of heating equipment for heating the coolant. There are many models that differ not only in appearance, but also in functional features and equipment.

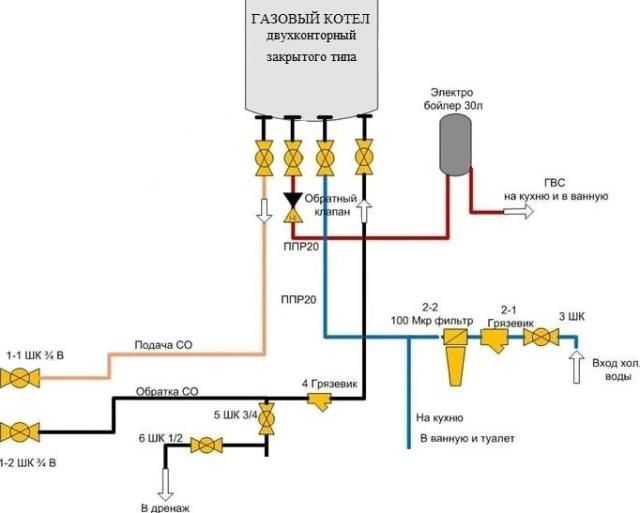

To wire a double-circuit heating boiler, it is actually necessary to adapt it to the operating conditions of a certain heat supply scheme. If the device equipment already includes a safety group, a circulation pump, an expansion tank, additional installation of the following components will be required:

- Shut-off valves – mounted on all pipes. It is best to use ball valves in the heating boiler piping scheme, since with their help you can quickly shut off the coolant flow;

- Thermometers and pressure gauges . If the boiler does not include these measuring instruments, installation on the supply and return pipes is mandatory. If available, you can limit yourself to piping the heating boiler with your own hands by mounting a thermometer and pressure gauge on the return pipe;

- Mixing unit . Necessary for optimizing coolant flow. If, according to temperature sensor readings, the degree of cooling of the return flow of coolant is low, it can be mixed with hot water.

When piping a heating boiler with polypropylene, you should avoid installing adapter corrugated hoses. This is a prerequisite for installing wall-mounted double-circuit models.

Some sources recommend organizing a small auxiliary circuit to preheat water. After this, it should supposedly be fed into the main one. This should not be done, since a large temperature difference can lead to thermal shock, which will cause failure of pipes, radiators and even the boiler.

For better DHW operation, it is recommended to install an auxiliary storage tank. Its capacity can be from 50 to 200 liters.

Components for solid fuel and diesel boilers

Solid fuel boiler piping

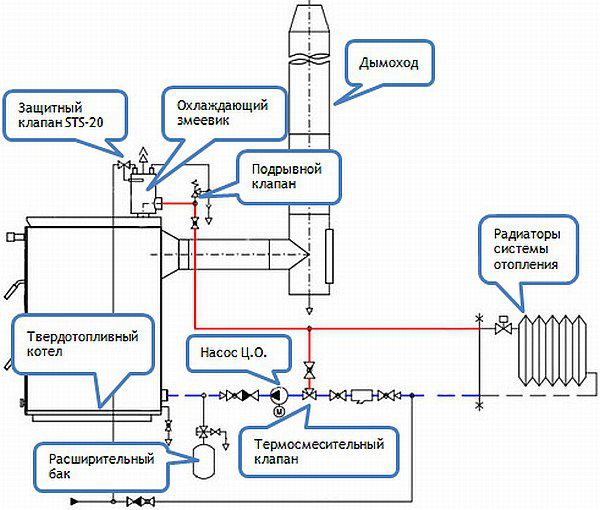

When piping a diesel heating boiler or its solid fuel analogue, the high inertia of this type of equipment should be taken into account. Those. the rate of temperature change is significantly lower than that of gas models. This is especially true for boilers operating on solid fuel.

Analyzing the video of heating boiler piping, we can conclude that special attention is paid to the safety group. This is due to the above-described factor of adjusting the intensity of fuel combustion. Therefore, in addition to installing the elements necessary for piping a floor-standing gas-type heating boiler, the following components must be installed:

- Air vent . With its help, accumulated air resulting from overheating of the coolant is released;

- Drain valve . It is equipped with each piping of a floor heating boiler. It performs the same functions as an air vent, but for the coolant - water. As a result of overheating, it expands, which leads to an increase in pressure. To stabilize the system, it is necessary to forcefully remove some of the liquid, which the drain valve successfully copes with.

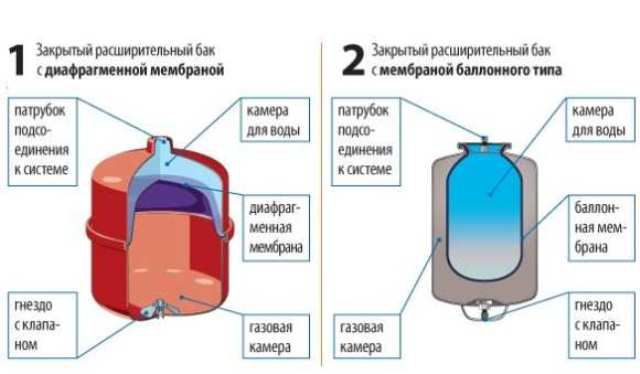

In addition to these components, an expansion tank must be present in the heating boiler piping circuit. Its design and installation location depend on the type of system - open or closed.

In open heating, the installation of the expansion tank is carried out at the highest point of the accelerating riser. Closed - before supplying cooled coolant to the boiler. In the latter case, it is necessary to correctly calculate the volume of the tank, as well as follow the rules for its installation.

When piping a solid fuel heating boiler with polypropylene, steel pipes are first installed, and then polymer lines are attached to them. This is necessary to prevent overheating of the polypropylene.

Wiring of electric heating boilers

Electric boiler wiring

The operation of electric boilers is based on a different principle than that of solid fuel or gas boilers. The effect on water occurs due to heating of the heating element or indirectly. Regardless of this, all wiring diagrams for an electric heating boiler must have one component - a power connection unit.

It includes an RCD, an uninterruptible power supply device, and an automatic power regulator. All further equipment depends on the boiler model and its design. The easiest way to wire a heating boiler yourself is if it already has automatic operation control devices, an expansion tank and a circulation pump. But this does not always happen.

Heating expansion tank

There is a special category of electrical heating equipment that does not have these components. These include electrode and induction models. In fact, they are only a heating element without additional operation control devices. In this case, the correct piping of electric heating boilers should be carried out according to the following rules:

- The size of the supply pipes is taken into account. The diameter of the pipes must match their cross-section. Otherwise, additional hydraulic resistance will arise;

- To control the temperature level, a thermometer must be installed. The same applies to measuring pressure, which requires a pressure gauge;

- The piping of a double-circuit electric heating boiler is equipped with an additional filtration system for hot water supply.

In addition to these components, it is recommended to purchase a voltage stabilizer. Almost all types of alternative electric boilers are sensitive to voltage drops in the network.

It is necessary to include a heating pump in the piping only if the thermal expansion of the coolant cannot provide the required level of circulation.

Features of gas boiler piping

There are several ways to tie a gas boiler. The most popular option is lining the heating boiler with polypropylene. Working with pipes made of this material is low cost and simple. Plaque and solid particles do not collect on the walls of polypropylene products. When such pipes are used, piping a gas boiler with your own hands is not difficult; any property owner can handle such work.

Piping of boilers, including double-circuit models, is carried out by soldering. This method allows you to avoid leaks during operation, in contrast to the use of fittings, when, if they are not fastened accurately, there are places through which the coolant liquid flows (pro

The simplest automation for solid fuel boilers

In fact, the only way to regulate the intensity of fuel combustion in a solid fuel boiler is to open/close the firebox or ash door. In order not to have to do this themselves, visiting the boiler room every now and then, the craftsmen came up with a very simple device. This device is screwed into the boiler body. You can call this device a thermostat, because, like other thermostats, it has a graduation and the ability to set the desired coolant temperature using it:

As you can see in the photo above and below, the device has a lever to which a chain is attached, the second end of the chain is connected to the blower door:

When the coolant temperature reaches the set temperature, the thermostat lever turns, pulls/releases the chain - the ash door closes/opens slightly. In accordance with the degree of “openness” of the door, more or less air enters, and the fire burns stronger or weaker, causing the coolant to heat up more or less.

How does the thermostat of a solid fuel boiler work?

Use the handle on the thermostat body to set the desired coolant temperature. Connected to the thermostat is a temperature sensor placed in the coolant in the boiler. When the coolant temperature deviates from the set value, the mechanism connected to the lever rotates inside the thermostat housing. A chain is attached to the lever, connected to the door of the plenum. As you can see, the design and operation of such automation is not very tricky.

Connecting double-circuit gas boilers

A double-circuit boiler, unlike a single-circuit heating device, has a universal purpose.

Such a unit for domestic needs heats water and at the same time maintains the required temperature in a dual-circuit heating system. The peculiarity of double-circuit boilers is that in the process of consuming hot water, parallel operation of both circuits does not occur. This means that the piping of a wall-mounted double-circuit gas boiler does not depend on the type of heating and is always the same. Due to the large size of the pipes, radiators and coolant take quite a long time to cool.

There is one more feature: if you are piping a double-circuit gas boiler, then you cannot use natural circulation of water. Many models are equipped with a special pump, because without it, after the generator stops heating, the movement of the coolant stops and the installation begins to reheat, which takes much more time and, as a result, the radiators begin to heat the room unevenly (read: “Correct diagram for connecting a double-circuit gas boiler").

Wiring diagrams for floor-standing boilers

As the wiring diagram for a floor-standing gas boiler suggests, when creating a heating system, the installation of a circular electric pump is required (read: “Connection diagram for a gas heating boiler with examples”).

Forced-type devices are easy to operate and are considered more comfortable to use.

The heating unit is controlled automatically. Among the advantages, it should be noted that a certain temperature can be set for individual rooms, thanks to the presence of sensors that control the heating process.

At the same time, the piping scheme of a wall-mounted gas boiler has negative aspects, including:

- high price for components;

- the difficulty of implementing the strapping, which can only be done by a professional;

- the need for constant balancing of parts;

- high cost of service.

If the house has a complex heating system, for example, there is a “warm floor” and radiators, then you may notice some inconsistency in the movement of the coolant.

Therefore, to solve the problem, a hydraulic decoupling is included in the piping circuit, forming several circuits for the movement of coolants - a common circuit and a boiler circuit. To waterproof each circuit, an additional heat exchanger is installed. This will be required to combine open and closed systems. Installations belonging to the separate type must be equipped with circular pumps, a safety system and taps (drain and feed). How to connect a gas boiler, see details in the video:

What is included in the boiler safety group

The safety group of a solid fuel boiler includes three elements:

- A pressure gauge showing the pressure in the system at the boiler outlet.

- Emergency pressure relief valve, set to the upper value of the permissible pressure in the CO.

- Automatic air vent.

For ease of use, the safety group pressure gauge has an additional manually installed arrow, which shows the limit of permissible coolant pressure in the heating system.

The emergency pressure relief valve is configured to release the coolant when the set pressure limit is exceeded. Typically, the operating pressure in the heating system is 1.5-2 atm, the relief valve is set to 3 atm.

The air vent removes air when the heating system is filled with coolant. When the pressure in the heating system rises to the operating level, the air vent valve closes.

Next, the air can be released through the upper air vent valve in the system or through the Mayevsky valves in each individual radiator.

The safety group of a solid fuel boiler should be installed at the outlet of the boiler heater, at the hot water supply to the heating system. Only such a scheme for piping a solid fuel boiler using a safety group is correct.

It happened that the safety group of a solid fuel boiler was installed on the return line of the heating system. In this case, the boiler could explode, the pipes of the heating system will melt, and the safety group will still not work.

Wiring diagrams for wall-mounted boilers

The piping of a floor-standing gas boiler and other types of heating devices can be simplified if you use primary-secondary rings.

There will be fewer all kinds of devices designed to control the operation of the system if you make several rings of the heating system and install its own circulation pump for each of them. Thanks to such measures, a uniform supply of hot coolant to the end consumer is ensured. The wiring diagram for a dual-circuit device is complex. A reasonable solution is to contact a specialized gas organization. Its employees will quickly connect the equipment to the gas supply system.

Piping a solid fuel boiler without an auxiliary boiler

In the following scheme the auxiliary boiler is not used:

I believe that using the explanations for the previous diagram, you can understand how this one works. I will simply list what is there and under what number: 2 – safety valve; 4 – two-way valve connected by a temperature sensor to a circulation pump; this sensor works on a warm floor, controlling the temperature in it; 5 – three-way valve, from which a wire goes to the sensor; this valve controls the returning temperature; if it is high, the valve does not allow the coolant to return, but directs it back into the supply; 6 – balancing valve; BR – expansion tank.

Here is a photo of the same circuit:

It is clear that it is easy to exclude warm floors from the scheme, then the whole scheme will be even simpler.