How do solid fuel boilers behave in operation? What should you take care of if you decide to install a solid fuel boiler? They talk about the independence of wood-burning boilers and the cheapness of fuel. What will you have to pay for this? You won’t hear this from boiler equipment sellers. Reviews from people who have installed solid fuel boilers.

Let's turn to the reviews of those who heat their home with a solid fuel boiler

I am grateful to my clients for taking the time to share information.

You need to get used to a solid fuel boiler. It will take some time before the owner selects the appropriate fuel, determines how much it needs to be added, what temperature to set on the boiler, etc. Moreover, even family members living in the same house can heat differently. They are all similar in one thing: kindling is done once a day. Depending on the weather, you may or may not need to add more wood.

I interviewed four private home owners. Two of them installed conventional solid fuel boilers with simple piping. And the other two are pyrolysis boilers with buffer tanks.

Occupational safety instructions for a fireman driver in a solid fuel boiler room IOT-5

Occupational safety instructions for a fireman driver in a solid fuel boiler room

IOT-5

1. General safety requirements

1.1.Men at least 18 years of age may be allowed to work independently as a driver (stoker) in servicing a boiler installation after undergoing a medical examination in the prescribed manner, passing an exam according to the program for a driver (stoker) of a solid fuel boiler plant and receiving the appropriate certificate. Re-testing of this knowledge should be carried out at least once a year. 1.2.Upon entry to work and during work, each employee must be given the following briefings: introductory, initial at the workplace, repeated at the workplace (at least once every 6 months), and in case of production necessity and circumstances determined by regulatory According to labor protection acts, unscheduled and targeted briefings are carried out. 1.3. During work, the driver (fireman) is subject to the following harmful and dangerous factors: - physical severity of labor; — increased temperature, humidity and gas pollution in the boiler room; — electrical hazard; — fire hazard; — probability of explosion during operation of pressure vessels; — monotony of work 1.4. The driver (fireman) must be given the following personal protective equipment: — a suit (jacket, trousers) made of heat-resistant, non-thermal conductive fabric; - canvas mittens; — leather boots with thick soles; - respirator; - protective glasses; — protective helmet made of heat-resistant, non-thermal conductive fabric; — overalls and a helmet-mask with a hose of the required length in case of work in the furnace. 1.5. The driver (stoker) must comply with the work and rest schedule established in the educational institution, as well as fire safety rules. When operating a boiler installation using solid fuel, there must be one foam fire extinguisher for every two fireboxes in the boiler room. In addition - a box of sand, a shovel, a fire hydrant equipped with a fire hose (trunk). A special place must be allocated and designated for smoking. The driver (fireman) must be familiar with the fire safety instructions in force in the institution. 1.6. The head of an educational institution is obliged to obtain permission to operate boilers in accordance with the established procedure, promptly eliminate all defects in the boiler and piping system, check the control and measuring instruments of the boiler room equipment annually at a certain time, and also provide the driver (fireman) with the tools necessary for work ( shovel, scoop, containers, lantern with glass bulb in case of power outage). 1.7. A telephone or alarm system must be installed in the boiler room to communicate with the manager and representative of the institution’s administration. 1.8. The driver (fireman) must clearly know where the first aid kit with medicines and dressings is located in the boiler room, be able to provide first aid to victims of various types of damage to the body (bruises, wounds, thermal burns, etc.) using techniques and methods given in the instructions for first aid in force in the institution. 1.9. It is prohibited to instruct the driver (fireman) servicing the boiler to perform any work that is not related to boiler maintenance while on duty. 1.10. In the event of an accident, the victim must be immediately provided with first aid in accordance with the instructions for first aid. The situation at the scene of the accident must be preserved unchanged in order to conduct an objective investigation of the accident, unless this threatens the life and health of other persons and does not lead to an accident. 1.11.Knowledge and compliance with the requirements of these Instructions is the official responsibility of the driver (stoker), and failure to comply with them entails types of liability established by the legislation of the Russian Federation (disciplinary, material, criminal).

Get full text

2.Safety requirements before starting work

2.1. Before starting work, the driver (fireman) must put on the personal protective equipment required by the standards so that there are no hanging or flapping ends. 2.2. When starting work, the driver (fireman) must take over the boilers and boiler room equipment from the previous shift; personally inspect and check their serviceability (position of taps and valves, condition of safety devices, etc.). 2.3. When inspecting the boiler, electric lighting with a voltage of no higher than 12 V should be used. It is prohibited to use kerosene or other lamps with flammable liquids, as well as torches. 2.4. The driver (fireman) is obliged to record the reception of the shift in the logbook. During his duty, the driver (stoker) is responsible for the condition of the boiler room equipment and for the normal operation of the boilers. 2.5. The driver (stoker) must not allow unauthorized persons into the boiler room. 2.6. The boiler room must have a constant flow of air to maintain normal combustion and timely ventilation to avoid gas poisoning.

3.Safety requirements during operation

3.1. During operation of the boilers, the doors of the boiler room, if there are people in it, should not be closed. The exit from the boiler room in winter must be cleared of snow and ice. 3.2. The boiler should be fired up only with the permission of the head of the educational institution. 3.3. If the boiler is re-lit, it is necessary: - before closing the boiler manholes and hatches, you must make sure that there are no people or foreign objects inside the boiler and gas ducts; - check the condition of the boiler lining, the presence and serviceability of fittings, instrumentation, make-up, feed and circulation pumps, as well as explosion valves of the furnace and gas ducts; - check the presence of the required pressure in the supply water main using a pressure gauge, the serviceability of the make-up valve and the check valve on the make-up line. 3.4. Repair of boiler room equipment and delivery of fuel may be allowed to an employee only if there are two or more drivers (stokers) in the shift. 3.5. The heating of the hot water boiler should be done with the valves between the boiler and the system open, gradually with the circulation pump turned on, while observing the readings of control instruments (thermometers, pressure gauges). 3.6. The driver (stoker) should not leave the boiler unattended if there is a fire in the firebox. Every time leaving the boiler room, the driver (stoker) is obliged to stop the blower fans and smoke exhausters. 3.7. When operating a hot water boiler, the driver (stoker) is obliged to: - constantly maintain the required water temperature in the heating system; — monitor the filling of the system with water; — check the operation of safety valves at least once per shift, monitor the operation of circulation pumps, motors, fans; — if malfunctions are detected, try to restore normal operation while observing personal safety measures. If this is not possible, inform the person responsible for ensuring the safety of the boiler room. 3.8. During work, the driver (stoker) must comply with the following basic safety requirements: - do not turn on electrical equipment in the absence of protective equipment (insulating stands, protective grounding, etc.); - do not operate the boiler room equipment in the absence of guards for moving and rotating parts (belts, couplings, shafts, etc.) - beware of burns when removing slag and coal from the furnace, when pouring hot slag and when throwing flames out of the furnace; - if smoke passes from the boiler into the boiler room, stop the boiler operation, ventilate the room and find out the reason for the cessation of draft. 3.9. If it is necessary to stop the boiler as soon as possible after the combustion of fuel (coal) in the furnace has stopped, remove the heat from the grate, leaving the damper and combustion doors open. Carefully pour water over the heat and ash removed from the firebox; 3.10. It is prohibited to carry out kindling if the measuring and safety devices are faulty; 3.11. Work on internal cleaning of boilers and chimneys should be carried out only by two people, to assist each other. The admission of people into the boiler, furnace, chimneys, installation and removal of plugs, opening of valves must be carried out with the permission of the person responsible for the operation of the boiler room, with entry in the logbook. 3.12.Before opening the firebox door, stop blowing enough so that the flame does not eject from the firebox; 3.13.If the power supply is interrupted, immediately turn on the emergency lighting and turn off all electric motors. 3.14. The driver (stoker) is obliged to immediately stop the boilers and notify the person responsible for work in the boiler room in cases specifically specified in the job description.

4.Safety requirements in emergency situations

4.1. In the event of an emergency in the boiler room or another emergency outside the boiler room, but in the immediate vicinity of it, the driver (fireman) is obliged to report it to the immediate supervisor or a representative of the administration of the institution, in the event of a fire - to the fire department. The driver (stoker) himself must remain at his post and not leave the boiler room. 4.2. If the emergency situation is related to the boiler room, then after sending messages (see above), the personnel must take measures to extinguish the fire using available fire extinguishing means, without stopping monitoring the boilers. 4.3. For the most possible types of emergency situations in the boiler room, emergency action plans must be developed and studied by the staff in advance. 4.4. If it is impossible to quickly extinguish the fire and it threatens the boilers, it is necessary to stop the boilers in an emergency, in this case it is necessary to intensively water the boilers with water, drain the water from the hydraulic seal, while simultaneously directing the steam into the atmosphere, release water into the water heating boiler system and take extinguishing measures source of fire. 4.5. Boiler room personnel must know the location of property and fire extinguishing equipment in the boiler room and be able to use them. 4.6. The driver (fireman) must be able to provide first aid to victims in emergency situations; The type of assistance and methods of delivery depend on the nature of the injury to the victims.

4.7. The sequence and rules for performing medical care must comply with the instructions for first aid in force in the educational institution. 4.8. In case of various types of injuries, victims, as a rule, are taken to medical institutions. The exception is cases of complete preservation of the normal functioning of the human body, without loss of ability to work.

5.Safety requirements after completion of work

5.1. At the end of the shift, if the shiftman does not show up for work, the driver (fireman) must continue to work, notifying the immediate supervisor or a representative of the administration of the institution about the absence of the shiftman. .2.When handing over a shift, the driver (fireman) is obliged to inform the shift worker about all malfunctions noticed while working in the boiler room. The handover of the shift must be recorded in the logbook. 5.3. When accepting and handing over a shift, both drivers (stokers) sign in the logbook, and the condition of the equipment must be especially noted. 5.4.After this, the driver (stoker) must take a shower with the obligatory use of neutral detergents. 5.5.Personal protective equipment must be processed and placed in a locker for special clothing.

Operating a conventional wood-burning boiler

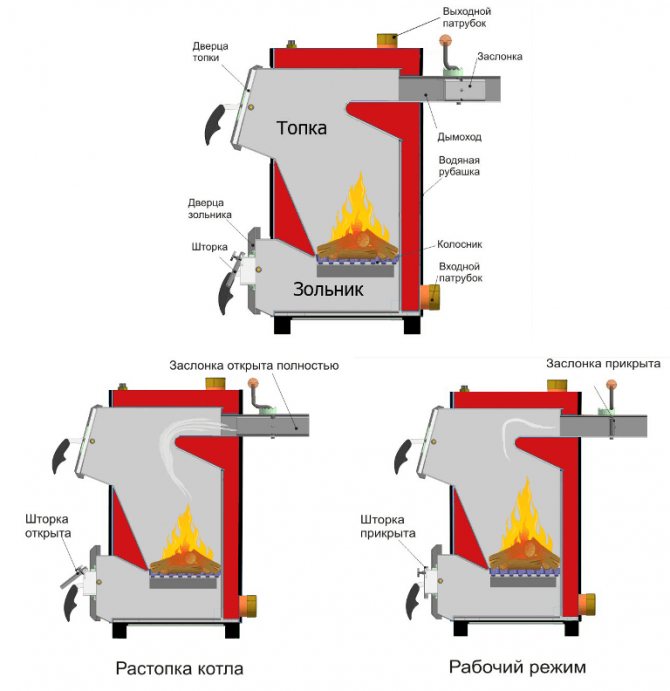

Firewood burns out quickly. In order to prolong the combustion process, it is necessary to achieve smoldering. Briquettes are more suitable for this purpose. In a simple boiler, one load can be smoldered for up to 4 hours.

Without a heat accumulator, it is impossible to maintain an even air temperature in the house throughout the day. And during the night the house cools down to 15-18oC. Owners of houses with a conventional solid fuel boiler resort to electricians. To maintain a comfortable temperature, turn on an electric boiler or electric heated floors.

Operation of a pyrolysis boiler with a heat accumulator

The owners of the houses with whom I spoke use only firewood. Who chooses which breeds based on the supply in their locality. The automation of the pyrolysis boiler performs well. You can throw a full firebox of wood into such a boiler, and it will burn for up to 4 hours.

However, the combustion process is not completely controllable. The danger lies in a sharp decrease in the home's need for heat. In this case, the automation will not be able to reduce the combustion sharply enough. It’s good that these houses have heat accumulators installed in the boiler room. They take on peak loads.

In addition to safety, the buffer tank ensures uniform heating of the house. In houses where a buffer tank is used, the rooms have a comfortable temperature even in the morning. I just ended up in these houses for the morning kindling. And I could personally verify that the thermometers showed more than 20 degrees. In this case, the temperature in the container itself completely cools down to 25-30oC overnight.

Reviews from owners of wood-burning boilers show: modern boilers are quite easy to use. Automation almost completely handles the combustion process. But this is when it is turned on.

Rules for the safe operation of boilers

A hot water heating device, no matter what type of fuel it operates on, can pose a potential danger if handled incorrectly. This is due to many factors and situations that may accompany the operation of boilers. Manufacturers of modern boiler equipment are trying to equip their products with increasingly advanced automation, which, without a doubt, greatly increases the safety of such products during their operation. However, no automation can guarantee absolute safety if the established rules are not followed during the installation of water heating equipment and, especially, during its operation.

Representatives of the relevant organizations monitor the rules for installing only gas water heating appliances. Boilers operating on other types of fuel are installed by the owners themselves. Often the only source of information (instructions) is the instruction manual that accompanies the product upon purchase. In theory, each instruction should also describe the rules for handling the device, compliance with which can guarantee the owner a certain degree of safety. It also indicates the period during which this product can be safely used.

In order to systematize the information available in different sources regarding the safe use of boiler equipment using various energy sources, it is worth considering these types of boilers and understanding what exactly in each of them can pose a real danger.

Types of hot water boilers

Despite the fact that the function of various boilers is identical and is to provide water heating systems with hot coolant, there are enough varieties of such devices. They vary in shape, size, power, warranty periods of use and other criteria. But the main difference is in the type of heat source, that is, the energy carrier, which is used to heat the circulating fluid. Today, if we take the type of energy source as a basis for classification, there are the following types of boilers:

- gas;

- solid fuel;

- electrical;

- diesel;

- combined.

The first type of devices is designed to extract thermal energy from natural (supplied through pipes) or liquefied (in cylinders) gas when it is burned in a furnace. Here, the main danger is represented by both the gas itself, the leakage of which can lead to an explosion, and combustion products that can cause poisoning. Therefore, the rules described in the relevant instructions are aimed at preventing precisely such situations.

Equipment operating on any type of solid fuel (coal, firewood, pallets) can cause a fire or carbon monoxide poisoning if handled incorrectly.

Electric water heating devices do not have fireboxes, and combustion does not occur in them. However, in certain situations where basic safety rules are not followed, they can cause electric shock or short circuit due to network overload.

Modern diesel boilers have a perfect automation system, thanks to which their operation is almost autonomous. In addition, their level of security is quite high. But even when servicing such high-tech equipment, you should not lose vigilance, that is, you should do everything according to the rules from the instructions.

Combined water heating devices are usually designed to use two types of fuel. Models are common where solid fuel energy and electricity or, for example, gas and diesel fuel can be used simultaneously. Precautionary measures for the operation of such devices must correspond to the type of energy carrier used at a given time.

Now let’s take a closer look at the rules, compliance with which will significantly increase the safety of using certain types of boiler equipment.

Safe operation of gas boilers

Safer in terms of operation are gas devices equipped with a closed firebox, the cavity of which does not communicate with the air environment of the room where the boiler is located. However, such thermal energy generators are limited in maximum power. Therefore, it is often necessary to install boilers with an open combustion chamber in private households. For the installation and subsequent operation of this type of water heating equipment, there are certain rules that must be observed.

A list of them can be presented as the following list:

- the presence of a separate room (boiler room);

- the boiler room must be at least 4 m2 in area with a ceiling height of 2.5 m or more;

- the boiler must be located at a distance of at least 20 cm from the nearest walls, the surface of which must be protected with fire-resistant material;

- it is imperative to equip the room with a ventilation hole of sufficient area;

- it is necessary to have natural lighting at the rate of at least 0.3 m2 per 10 m2 of boiler room area;

- the width of the entrance doors is made at least 80 cm;

- the chimney must be made of acid-resistant and heat-resistant material;

- the upper edge of the chimney (head) must be raised above the level of the roof ridge by at least half a meter;

- horizontal sections of the chimney pipe should not exceed 1 m in length.

The above conditions can be called instructions for installing gas water heating equipment, although the listed rules are precisely aimed at the possibility of safe operation.

On modern boiler equipment, additional protection against possible unforeseen situations is provided by an automatic control system.

Thanks to automation, the gas supply is shut off when the burner goes out spontaneously or, for example, the coolant is maintained within certain temperature limits, which prevents overheating of the liquid. The degree of safety when operating gas appliances is greatly increased by installing a gas analyzer - a device that not only signals the presence of gas in the room, but is also capable of stopping the gas supply.

Safe use of solid fuel boilers

Second after gas ones (in terms of potential danger) are units operating on solid fuel. The installation of such equipment in private homes is not regulated. That is, here the safety of using the boiler directly depends solely on the correct actions of the owner.

In this case, the danger may be the lack of necessary draft, when carbon monoxide may be released into the room. To prevent this from happening, you should properly arrange the chimney and promptly clean it of accumulated soot.

Also, hot coals that fall out of the firebox can pose a certain danger. Therefore, it is worth making sure that the area in front of the boiler is made of fire-resistant material.

In addition, it is advisable to place the boiler equipment in a separate room that is not connected to living rooms.

Safe use of electric boilers

In such a situation, the risk of electric shock comes first. To avoid such an incident, it is necessary to take care of the grounding of electric boilers, especially the hydrolysis type.

To eliminate the possibility of a short circuit, an electric water heating device should be connected to the network through an automatic safety switch. The use of RCD is also effective.

Boiler service life

It is known that any units, including water heating units, have limitations on their service life. Typically, manufacturers must indicate in the accompanying instructions the safe use period for each product. It is advisable not to exceed the specified periods, since after their expiration the safety of operation of water heating equipment is significantly reduced.

Reading the instructions before using boiler equipment is very helpful. By following the rules listed there, the risk of unforeseen situations that pose a danger is significantly reduced. In addition, do not forget about such concepts as logic and common sense. Then the safety of using heating boilers will be fully realized.