PR

Every car enthusiast in Kharkov is ready to deny himself a lot, just so that everything is always in order with his “iron horse”.

One of the most basic problems that can happen to a car is metal corrosion. And if in the open air there is no way to protect it from precipitation, then at least in the garage all conditions should be created so that nothing drips from above on the car. This means that reliable waterproofing must be installed on the roof.

Insulation of the ceiling in the garage

If the garage is equipped with a single or double slope roof, then it is much easier to ensure that the roof does not leak.

But what to do if the roof is flat and made of a concrete slab? But there are a lot of such roofs on garages. And often when buying a garage you don’t have to choose, since if you refuse it, the car will have to “sleep” on the street all the time.

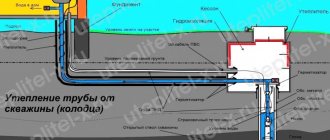

When starting to waterproof a flat roof, it is better to combine this process with insulating the ceiling.

The roof and ceiling here will form one whole. It is better to choose extruded foam as insulation, as it has good mechanical strength and is very resistant to compression. And for the roof above you can buy Kharkov roofing felt or even Euro roofing felt.

When the concrete slab below is prepared and cleaned of dust and dirt, a frost-resistant primer is first applied to it. But it should only be of deep penetration.

The foam is attached with a special glue and fixed using a device called an “umbrella”. There should be a small gap between all sheets of foam on all sides, which is subsequently filled with polyurethane foam. Due to this, thermal insulation will become more reliable.

A cement-sand screed should be applied on top of this insulation, the thickness of which should be 3-4 cm, and only after this can you begin waterproofing the roof.

To do this, the top of the concrete surface should be thoroughly cleaned and coated with a primer, or a special bitumen-polymer mastic should be used. This mastic is sold in construction stores. But before use, you should read the instructions, since it is applied to different materials differently.

Stages of thermal insulation of walls and garage doors

The instructions for thermal insulation of a metal garage suggest carrying it out in several stages:

- The lathing for the thermal insulator is installed.

- Thermal insulation is installed.

- The inner surface is covered with decorating material.

Wooden sheathing is necessary to create a space between the trim and the walls of the garage, which is then filled with insulation.

Tip: The sheathing should be fixed to the walls of a metal garage with bolts, and the dimensions of its niches should be adjusted to the dimensions of the plates of the purchased material: mineral wool, polystyrene foam or glass wool.

After making the sheathing, thermal insulator material is placed, which is placed in the niches of the sheathing. Insulating a garage is possible without making sheathing.

This option involves simply gluing foam sheets to a metal surface. At the end of this process, you can perform decorative finishing with facing materials. For this you can use PVC boards, fiberboard or lining.

Roof waterproofing from above

After the bitumen mastic hardens, roofing material is placed on top of it.

It is best to use built-up roofing felt, since in this case the waterproofing of the garage roof will be more reliable. But first the roll rolls out and it needs to be given a certain time to level out and rest. It is better to do such work in the summer on a sunny day, since in this case the roofing material will level out faster.

Waterproofing should be carried out using a gas torch.

In this case, it is necessary to take into account one very important nuance: the roofing felt has an indicator coating, which looks like polyethylene, on which factory markings are applied. Therefore, roofing felt should be heated until this coating disappears, but no more. If you overheat roofing felt, it will simply lose all its insulating qualities, and waterproofing will turn out to be unreliable.

It is better to do this work together: one person gradually rolls out the roll and warms it up, and the second person walks behind with a hand roller and presses the roofing felt to the base of the roof. Roofing felt should be laid on top of each other with an overlap of at least 10 cm. If there are chimneys or ventilation holes in the garage that lead to the roof, then it is necessary to use a master flush so that rain or melt water does not leak inside through the cracks.

Click and read on Facebook and subscribe to our Telegram!

If you find a typo on the site, highlight it and press Ctrl+Enter

Whether to insulate the garage roof or not is up to each motorist to decide for himself. But, you see, in comfortable conditions, car repairs and maintenance are faster and of better quality.

Repair work in the cold, in a cold garage, can have a detrimental effect on the health of the car owner. If we take into account the amount of time that a true car enthusiast spends in his garage, then the need for insulation becomes obvious. Thermal insulation of the garage roof, along with insulation of the gates, floors, walls, as well as a heating device, makes it possible to work on your car with pleasure, without compromising your health.

Requirements for thermal insulation materials for garage roofs

First of all, you should decide on the choice of thermal insulation material that best suits the roof structure, taking into account regional climatic characteristics. The insulation material must have a high fire resistance rating, because...

There is a high risk of an accidental spark from the exhaust pipe during repair work. The insulation should be easy to install. Water resistance is one of the main criteria when choosing.

The decision about what kind of thermal insulation - internal or external - will be made depends on the stage of “readiness” of the garage. If the roof is just being erected, then it is better to do external insulation, and if the building is already in use, then it will have to be insulated from the inside.

Types of thermal insulation materials

Modern insulation allows you to avoid heat loss, maintain a comfortable temperature in the garage, and also protect others from excessive noise. The following groups of materials can be distinguished:

- mineral wool, fiberglass, polymer.

Mineral wool has excellent technical characteristics, but there is an urgent need for mandatory protection from moisture (vapor and waterproofing), with a “breathing” gap.

Mineral fiber is flexible and ductile when compared to fiberglass material. It is less susceptible to destruction, has low thermal conductivity, and its sound insulation properties are also used. Subject to installation technology and proper protection from moisture, this type of thermal insulation will last for quite a long time.

Glass wool, which is produced in rolls or slabs, is often used as insulation.

The width of such material is equal to the rafter pitch, which is very convenient during installation. When choosing fiberglass materials, special attention is paid to the thermal conductivity coefficient. A higher level of thermal insulation will be where this indicator is lower.

The light weight of the material contributes to a faster installation process. The cost of such insulation is relatively low. Resistance to various kinds of negative influences and a fairly long service life make this material one of the most suitable for insulating a garage roof.

Sprayed polyurethane foam insulation is very effective. This method of insulation is characterized by high moisture resistance, durability and fire resistance. Among all thermal insulation materials, polyurethane foam has the lowest thermal conductivity.

Applied to the surface, the heat insulator is able to fill all voids firmly and hermetically. A significant advantage is that there is no need to use additional vapor barrier. After spraying, almost immediately, you can begin constructing a frame system for the cladding.

Stages of insulating a flat garage roof

If the base of the roof is reinforced concrete slabs, then external insulation of the structure is carried out. The best option in this case is foam plastic, on top of which there is a concrete screed.

The first step is to carry out preparatory work, which includes cleaning the slabs from various irregularities, dust, and dirt. Particular attention is paid to the joints between the slabs and the junctions with the external walls. All this is filled with polyurethane foam or filled with fiberglass.

For thermal insulation purposes, high-strength foam is used.

It is laid in two layers on the prepared surface. The insulation is placed staggered, i.e.

with a shift of one row relative to the adjacent one, moreover, the joints of the layers should not coincide. Waterproofing is laid on top of the foam. More often they use roofing felt or under-roofing film.

Next, they are engaged in constructing a concrete screed.

It is mounted on a waterproofing layer. Here either reinforcement is used or special plastic additives are used. To prevent cracking of the coating, it is a good idea to add frost-resistant additives to the concrete solution, which increase plasticity and frost resistance.

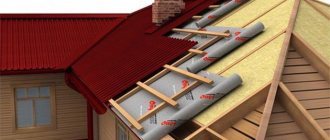

Thermal insulation of a pitched roof

Shed roofs are considered easier to install and subsequently operate; in addition, this is the most economical option. The structure is a wooden frame system constructed from beams that rest on a mauerlat.

It is more expedient to carry out high-quality thermal insulation of the roof at the stage of its construction. In this case, the insulation becomes an element of the roofing pie, which will be a barrier that protects the room from overheating in the summer and from cold in the winter. And it will not allow condensation to form during significant changes in humidity and temperature.

To insulate a garage roof, you should prepare:

- vapor barrier; fiberglass insulation (Ursa, Isover) or mineral wool; waterproofing; adhesive tape; construction buttons, nails; carpentry tools.

More often, the rafter pitch is 50-60 cm. This distance corresponds to the traditional width of the insulation - within 50-61 cm. Using the technological reserve, a tight, gap-free fit of the material between the beams is ensured.

They start by attaching a vapor barrier between the rafters, on the inside of the garage.

It is fixed using buttons or construction brackets. It is important to achieve absolute tightness of the vapor barrier layers. This is achieved by gluing the joints of the material with adhesive tape.

Subsequently, the vapor barrier from inside the building will be covered with any type of finishing. For these purposes, fiberboard, panels, plasterboard, lining and other materials are used.

On the outside, thermal insulation (mineral wool or fiberglass) with a thickness of at least 15 cm is placed between the rafters. The main thing is to ensure a tight fit of the material. If there is a need to cut the insulation, you can use a special construction knife.

The edges of the heat insulator must be aligned with the vertical plane of the outer part of the walls. A board (150 mm) is nailed between the rafters, which will become a limiter for the insulation.

Its upper edge should be flush with the rafters, i.e. in such a way that the wood protects the thermal insulation on all sides.

Between the layer of waterproofing, which is laid on the insulation, and the sheathing under the roofing, be sure to leave a ventilation gap of two to three centimeters.

How to insulate a roof from the inside

In order to insulate the roof from the inside as efficiently as possible, it is necessary to lay three layers of insulating material: hydro-, heat- and vapor barrier. This “layer cake” is suitable for both wooden beam structures and reinforced concrete slabs. Initially, the beams from the inside of the garage should be covered with sheet material, and then the above layers of insulation should be laid.

Let's take a closer look at foam insulation.

The method of fastening the sheets depends on the design of the floor. If it is made of timber or boards, this insulation is secured with umbrella dowels or nails. Then the heat insulator is covered with sheet material, which is fixed to a wooden base using long screws.

If the floor is made of concrete slabs, then a frame is needed to install thermal insulation. To attach the frame to the slabs, metal corners and self-tapping screws are used. Polystyrene foam is laid over the frame, “grabbed” with tape, and pressed with sheets of sheathing, secured.

Insulation with foam plastic does not require hydro- and vapor barrier, because...

the material does not allow moisture to pass through. If a fiber heat insulator is used, you should definitely take care of additional protection from moisture. Waterproofing is laid on the roof side, and vapor barrier on the room side.

Any garage owner can insulate the roof on his own. A variety of modern materials allows even a person who does not have special skills in construction to cope with this task.

Share the article on social networksComments

Since four-wheeled friends require not only high-quality fuel and timely care, but also comfortable living conditions, each car enthusiast is sure to think about how to insulate the garage roof and how to install it correctly. However, the convenience of machine maintenance and timely repairs also depend on the air temperature in the room.

Preparing the work surface

The main requirement for effective heat conservation concerns the use of waterproofing and vapor-proof layers. They contribute to the long-term operation of the insulation materials themselves, protecting against the accumulation of moisture or condensation, both under the roof and from inside the room itself.

In the process of how to insulate a garage roof, the roof itself deserves special attention. All existing cracks and holes must be closed and processed before all work begins. For this, new sheets of slate and metal profiles or special seals, polyurethane foam, or cement mortar can be used.

How to insulate a garage roof yourself?

With the onset of winter, motorists begin to wonder how to insulate the garage roof so that the heat does not escape from the room. Car maintenance and repair in the cold season is a real challenge. Therefore, it is necessary to think about how to insulate the garage roof from the inside, so that later you can work in comfortable conditions and so that the car body does not suffer from temperature changes.

The method of insulation largely depends on the design features of the roof.

For this, you can use various thermal insulation materials. Each of them has certain advantages.

Garage roof structures

After making sure that the roof is completely closed and there are no flaws in it, you can proceed to choosing insulation that matches the existing structure of the building. They can be:

- single-pitch; gable; attic.

If for a single-pitched type of roof metal or wooden slats can be used, between which sheets of foam plastic or mineral wool are attached, then work on attic and gable options involves the creation of a stable frame. Professionals can best advise you on how to insulate a garage roof. Especially if the attic space is planned to be actively used, for example, for storing tools or seasonal tires.

Even before purchasing materials, it is worth calculating the permissible thickness of the insulation along with the structure itself. Separately, it is worth considering the functioning of the ventilation system, as well as ensuring absolute waterproofing of the roof.

External garage roof insulation technology

Since the room itself is not always heated, it is extremely important that the material itself retains its insulating abilities at any room temperature. An equally important point concerns machine exhausts and vapors from fuels and lubricants, which accumulate on roofing insulation over time and can reduce their fire resistance.

That is why it is worth choosing mineral wool or fiberglass as insulation. If the installation of the insulating layer will be carried out in the garage with your own hands, it is worth considering the option of foam insulation or polystyrene foam, which are easy to use. These same materials are resistant to possible deformation and retain their original elasticity throughout their entire service life.

Insulating the garage roof from the outside

Consists of the following steps:

Preparing the existing work surface.

We are talking about cleaning the outer part of the roof from accumulated debris, dust, dirt and foreign objects. Installation of sheathing. Pre-measured wooden planks or beams are attached to the roof vertically and then horizontally. Installation of a vapor barrier layer made of a special film material. It prevents the appearance of secondary condensation and prevents drips on the walls. Laying insulation boards. Installing a hydrobarrier coating. Installing a second layer of sheathing. Laying new roofing material.

The easiest way to insulate a garage roof is with polystyrene foam, due to its ease of installation and relative ease, especially on a flat roof.

During the work, it is important to remember that the first layer of the sheathing must be treated with antiseptic agents. This technology will significantly increase the service life of the material and protect the object itself from mold and fungal damage due to accumulated condensation. The plates are overlapped by at least 10 cm, which are additionally glued with special tape.

Another important point concerns the air gap between the sheathing and the protective film.

It must be at least 5 cm. That is why bars with a thickness of at least 5 cm are first nailed to the rafters, and then the film itself is mounted. To install the vapor barrier layer, a special membrane or durable polyethylene film can be used. The waterproofing layer can be roofing felt sheets or geotextiles.

The outer roof covering can be made of metal profiles. Similar requirements apply to the process of insulating a garage with polystyrene foam. If there are gaps between the insulation boards, they must be closed with polyurethane foam.

How to insulate a garage roof with your own hands

When insulating the roof internally, we advise you to pay attention to mineral insulation. This insulation does not support combustion, but requires additional protection with a vapor barrier film. The best option for roof insulation is thermal insulation of the garage roof with mineral wool at the construction stage, as in the case of independently insulating an attic with mineral wool from the inside.

How to insulate a pitched garage roof

Technoruf is a modern material that is used as a top layer for thermal insulation of pitched roofs. The material is not flammable, it can be used without loss of characteristics at temperatures from -60 to +400°C. The use of waterproofing when laying Tekhnoruf mineral wool is mandatory. All brands of Tekhnoruf mineral wool are characterized by high density and low thermal conductivity.

How to insulate a garage roof from the outside

It is quite difficult to insulate a garage roof from the street so that it lasts for a long time. Therefore, manufacturers offer different solutions to this problem every year. A layer of polystyrene foam or mineral wool insulation for external thermal insulation is located between the roofing and the reinforced concrete slab, but the material should be protected from mechanical damage and moisture.

Photo. Insulating the garage roof with expanded clay from the outside

When insulating a garage roof, you should strictly follow the sequence of laying materials. To begin with, a hydrobarrier, a heat-insulating layer and a vapor barrier are laid. If the ceiling is a reinforced concrete slab, then the thermal insulation materials are attached directly to the roof. Mineral wool is characterized by fire safety and high heat-saving ability and sound absorption.

Expanded polystyrene can be fixed to a flat roof from the outside or inside using dowels. The seams between slabs of foam plastic or extruded polystyrene foam should be foamed. It is advisable to lay expanded polystyrene slabs in two layers in a checkerboard pattern so that the second layer overlaps the seams of the previous layer. Thus, you will reduce the risk of cold bridges in the thermal insulation layer.

How to insulate a garage roof from the inside

When laying thermal insulation internally, you should first treat the wooden floors with an antiseptic and the reinforced concrete slab with mastic. Installation of polystyrene foam on a concrete roof slab is carried out using mounting foam with additional fastening using disc dowels. For single-pitch and gable roofs made of wood, slab insulation is laid between the rafters, and all seams are foamed.

Photo. Insulating a garage roof with foam plastic from the inside

To lay mineral wool, a frame should be built on the ceiling. Many manufacturers produce slabs of increased rigidity that are easily inserted between the rafters. If rolls or slabs of low-density mineral wool are used, then insulation should be laid on the roof lining. After laying the mineral wool, it should be protected with a vapor barrier membrane from moisture penetration.

How to insulate a garage roof from the inside

Internal insulation of the garage roof is carried out in 3 mandatory layers:

- waterproofing; thermal insulation; vapor barrier.

This option is relevant for wooden beam structures, as well as for reinforced concrete slabs. Even before the installation of the first layer, the roof with wooden beams is sheathed from the inside with sheet material. For reinforced concrete structures, a frame is first prepared, attached using metal corners and self-tapping screws. It is extremely important that there are no cracks or holes on the surface.

Foam boards can be used as insulation. If a wooden roof is insulated, then the foam is secured with nails or dowels in the shape of an umbrella. The heat-insulating layer is covered with additional material, for example, plasterboard.

It is necessarily attached to a wooden base through the use of long screws. The main advantage of using polystyrene foam is the ability not to use additional waterproofing and vapor-proof materials, since its structure does not allow moisture to pass through. For insulation with a fiber structure, for example, mineral wool, both protective layers are necessary. This also applies to fiberglass.

The advantage of the first material is additional noise insulation of the room, as well as increased elasticity of the material. Glass wool is distinguished by a thicker layer and pliability. The layer of such insulation should have a thickness of about 15 - 30 cm.

Insulating a garage roof from the inside

We have already learned about the main materials that are used to insulate the roof. And now it’s time to figure out how to insulate the garage roof from the inside.

Before you begin work on roof insulation, it is worth preparing the surface. Particular attention should be paid to the presence of depressions and potholes. If possible, they should be equalized. This is done to ensure that the insulation fits tightly to the surface. Otherwise, air pockets will form, in which condensation will inevitably begin to accumulate.

Foam insulation

Polystyrene foam is distributed in the form of slabs with a thickness between 20 and 1000 mm and dimensions:

- 1000x500 mm;

- 1000x1000 mm;

- 2000x1000 mm.

Installation of polystyrene foam is simple. Lightweight slabs are cut into pieces and then attached to the ceiling. To do this, it is recommended to use glue or nail it to the sheathing. It should be remembered that a thin layer of polystyrene foam will not cope with the insulation task. Therefore, they use thick blocks or thin ones in several layers. For good thermal insulation, the joints of the blocks must be foamed.

Insulation with mineral wool

Installation of mineral wool is carried out using lathing and bars. The bars should be nailed in a strict order, taking into account the width of the mineral wool roll. On the room side, in order to avoid moisture saturation, the structure is covered with foil or some other material that does not allow moisture to pass through. If the insulation is carried out correctly in accordance with the standards, the result will please you for many years.

Glass wool insulation

It can be in a roll or in the form of a pressed slab. In the first case, the installation is similar to the installation of foam plastic, with the only exception that bars are packed onto the sheathing. All joints must be foamed. In the case of a roll, installation is no different from installing mineral wool.

When working with glass wool, remember safety precautions. Do not carry out installation without gloves and goggles; to prevent glass particles from entering the respiratory tract, use a respirator.

Insulation with a pensaw

Perhaps the simplest way to insulate a roof today is to use a pensaw. Foam insulation is applied to the inner surface of the roof. Due to its composition, which expands when it dries, the foam saw reliably fills all the cracks and plugs the holes that you missed during the preparatory work. Today this is, without a doubt, the highest quality insulation.

It does not contain substances that have a sharp and negative effect on the respiratory tract or optic nerves. The chemical composition is such that no mold will grow on it. It also does not attract insects and rodents. Its cost, of course, is high, but the 70 years of operation declared by the manufacturer speaks in its favor.

Let's sum it up

If you want to insulate the roof in the garage, you should take into account what stage of construction the structure itself is at.

If the garage is just being built, then it is recommended to insulate the structure from the outside, preserving more free space inside. If the garage is already completely ready, then internal thermal insulation of the roof will be more economical and affordable.

As for choosing a suitable insulation, it should be easy to install, durable, and have maximum fire resistance. Water resistance is a prerequisite for successful insulation of a room, which is not always heated and provokes condensation, in particular this applies to garages.

How to properly insulate a garage roof from the inside

In each individual case, the insulation of a garage roof can differ significantly: in the features of the location of the layers of insulation, the material with which you are going to insulate your garage, and the features of the roof structure to which the insulation will need to be “adjusted.”

The only thing that should remain unchanged and on which the quality of insulation largely depends is the presence of waterproofing and vapor barrier layers in the roof structure.

If there are none, then all further work on insulating the garage will turn into a Sisyphean task.

Make sure that the roof is equipped with effective vapor and waterproofing and only then begin the insulation process.

If there is no insulation, then you will have to first deal with the insulation issue, and then the insulation issue. And all this - overnight.

First, prepare a set of tools needed for work:

- direct insulation; waterproofing material; film to provide vapor barrier; self-adhesive tape; special buttons; carpentry tools.

How to insulate a garage roof with your own hands

How to insulate the roof in a garage correctly, from the inside or outside - this question interests every garage owner. Even in the summer, many car owners think about thermal insulation and improvement of the garage so that they can repair and maintain the car in comfortable conditions. The roof protects any building from precipitation, but you need to take care of the insulation of the single-pitched and double-pitched garage roofs. Read on to learn how to do this correctly.

With the onset of cold weather, many car owners want to insulate their concrete garage roof to make car repairs much more comfortable in winter. To understand which insulation to choose for the roof, how best to insulate the garage roof - from the outside or from the inside, you should first find out all the technical characteristics of modern thermal insulation and the technology for laying materials.

Foam insulation

Foam sheets have long proven themselves to be a favorite and convenient insulation material.

In order for garage roof insulation using polystyrene foam to be as effective as possible, you need to know the nuances of installing this material:

- The slabs are fastened only with glue; installing sheathing is unnecessary and undesirable, since holes for bolts can disrupt the tightness of the roof and become an additional cause of heat leakage; foam sheets can be used for both decorative and functional purposes. After insulation, you can build something like a false ceiling from the remains, which can be used: as an attic for storing spare parts; as an additional thermal insulation layer; as a decorative element.

Glass wool insulation

Glass wool is a good option for insulating material. Thick, but soft and pliable, the insulation can be placed without problems in the most inconvenient places for other insulation materials: cotton wool will fit everywhere.

But when working with such a flexible material, you need to take into account some features:

- if the sheathing is solid, then it is better to attach the insulation from the bottom of the structure - this will be both more convenient and effective; if the sheathing is discharged, the wool should be placed between the rafters, and the waterproofing should be installed on top of the insulation; pay attention to the features of the roof structure and place insulation depending on how the roof requires it; The waterproofing film should not be placed in such a way that it is in close contact with the insulation, unless you have chosen a coating with a superdiffusion membrane as the insulating material.

To ensure high-quality fastening of glass wool (or mineral wool), you will have to work hard and build wooden beams on the ceiling in order to place layers of insulation between them.

This method is simpler and more accessible than others. When using penoizol in the process of insulating a garage roof, there is no need to worry too much and spend a lot of time: the material is simply applied to the surface by spraying, and it itself penetrates into all the cracks and cracks, quickly hardens, forming a neat, even layer.

Penoizol does not require any protection from moisture and is designed for long-term operation.

As a rule, external insulation of a garage roof is carried out during the construction process, since it is not very convenient to pick apart an already finished building in order to correct omissions.

The first thing you need to pay attention to when insulating a garage roof from the outside is the presence of a vapor barrier on the room side, in order to subsequently avoid secondary condensation of vapors and unpleasant leaks on the walls.

The outer roofing “layer” is the same as the inner one:

- waterproofing; insulation; vapor barrier; lower decorative finishing (or not very decorative).

Now let's look at how to make external insulation in stages:

Lay the first layer of vapor barrier; it will serve as the main protection against moisture getting on the insulation and guarantee the operation of the insulation for as long as possible.

Attach a layer of insulating material. Make sure there are as few gaps as possible. If the sheets do not fit tightly together, fill the cracks with foam (this advice applies if you are insulating the roof with polystyrene foam).

The last layer is a hydrobarrier. It will be more reliable and effective if the film in the area of the joints is also sealed with adhesive tape. Roofing materials can be laid on the finished hydrobarrier.

Insulation from outside

As a rule, external insulation of a garage roof is carried out during the construction process, since it is not very convenient to pick apart an already finished building in order to correct omissions.

The outer roofing layer is the same as the inner one:

- waterproofing;

- insulation;

- vapor barrier;

- lower decorative trim (or not very decorative).

Now let's look at how to make external insulation step by step :

- Lay the first layer of vapor barrier; it will serve as the main protection against moisture getting on the insulation and guarantee the operation of the insulation for as long as possible.

- Attach a layer of insulating material. Make sure there are as few gaps as possible. If the sheets do not fit tightly together, fill the cracks with foam (this advice applies if you are insulating the roof with polystyrene foam).

- The last layer is a hydrobarrier. It will be more reliable and efficient if the film in the area of the joints is also sealed with adhesive tape.

- Roofing materials can be laid on the finished hydrobarrier.

And here is an article about choosing a roof for a garage.

This section of our website https://ru-house.net/postrojki/garazh/ contains all the most important and necessary things for building a garage.