Pros and cons of using corrugated sheets

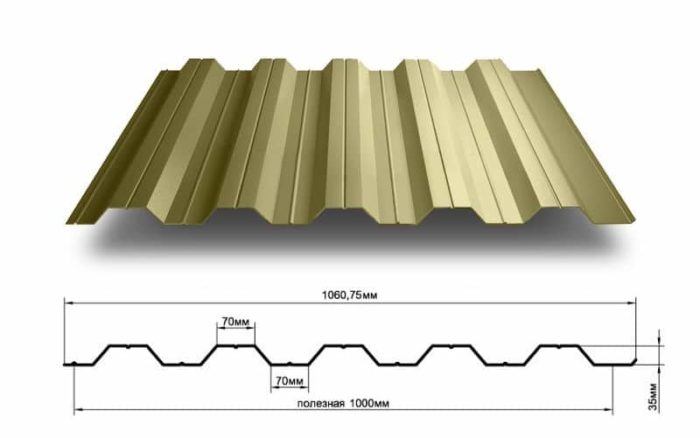

The appearance of this material is very attractive. A roof covered with it looks solid and expensive. This is one of the factors that makes the material so popular among builders.

In addition to aesthetic appeal, corrugated sheeting has other advantages:

- low cost. Whatever the design of the roof - single-pitch or gable - it will be quite affordable in cost. It is worth considering that doing the work yourself will further reduce the cost of the process. It will not be possible to save on hired workers. This point should not frighten a novice master, since the process of working with corrugated sheets is not difficult;

- This material is easy not only to install, but also to transport. It does not require special conditions of transportation and storage;

- ease of use allows for high speed of construction work. Even beginners in construction can cope with fastening corrugated sheets. An important factor is the lack of special equipment for fastening. A grinder, drill or screwdriver is enough;

- the sheet weighs little, it is convenient to lift it onto the roof;

- Corrugated sheets are successfully used in regions with snowy winters. The material has proven high resistance to snow loads. With a correctly designed roofing system, a roof made of corrugated sheets does not bend or sag under the cover of snow;

- high level of waterproofing. To be completely sure that moisture will not penetrate into the house, you need to pay special attention to the processing of joints and fastenings. An additional layer of waterproofing is often used;

- proven long service life, in all weather conditions;

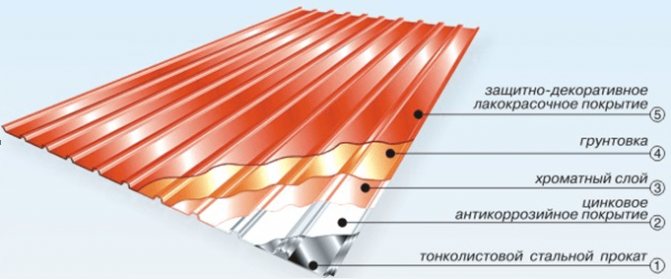

- It is not susceptible to rust or fading under ultraviolet rays. This means that the new roof will delight its owner with its original color for a long time;

- high level of fire safety, since the material is not flammable;

- well-fixed corrugated sheeting is not exposed to even the strongest gust of wind;

- Due to the strength of the metal, sparse lathing can be used. This item saves money on building materials;

- wide range of colors available. There is one suitable for any building.

Like all building materials, corrugated sheeting has not only advantages, but also disadvantages. Among the most significant are:

- high thermal conductivity. At any negative temperature outside, the surface of the metal will be even colder, which means that all the heat from the house will quickly go outside. For this reason, corrugated roofing is additionally insulated;

- in hot weather the material becomes very hot, which precludes the use of the attic for residential purposes. It will be hot there;

- low sound insulation. Due to their thinness, metal sheets completely transmit, and often resonate, all sounds from the outside. Drops of rain or the sound of a branch hitting the roof will be clearly audible in the attic. However, some owners of corrugated roofs claim that such a noise effect, on the contrary, has a calming effect on them;

How to insulate a corrugated roof from the inside. Summing up

Insulation of a finished roof made of corrugated sheets without removing the roofing material is only possible from the inside of the attic space. There are several methods, the effectiveness of which depends on:

- choosing a quality material with the necessary thermal insulation properties;

- correct calculation of the thickness of the insulation layer;

- ensuring reliable vapor and waterproofing;

- absence of discontinuities - cracks (cold bridges) at the joints.

Insulation of a roof made of corrugated sheets is a responsible operation that requires strict adherence to technology when performed independently.

Selecting insulation for a pitched roof Roof insulation based on "Ursa - pitched roof" Roof insulation technology "Ursoy" Insulation with "Penoplex" Installation of Penoplex slabs on top of the rafters Laying Penoplex under the rafters Thermal insulation of the attic with Penoplex Insulation for a pitched roof in the form of polystyrene foam

The installation of a pitched roof is considered one of the most labor-intensive, most expensive and most important stages of any construction. This is especially true when constructing a private house. If everything is calculated incorrectly, then soon the roof will have to be redone. Below we will talk about what measures need to be taken to insulate a pitched roof in order to ultimately ensure the necessary temperature conditions inside the attic, as well as in the house as a whole.

Poor quality or improper installation of thermal insulation material can cause rotting of wooden structures. As a result, you will have to re-equip the roof of the house, which will entail additional costs of effort and money. In order for the roof to perform its functions for a long time, it is necessary to take the stage of insulation of the pitched roof seriously.

Mandatory layer of waterproofing membrane

This is a necessary step when working with a corrugated roof. Its installation must be approached carefully, avoiding free spaces and unprotected joints.

The entire rafter system is pre-treated with an antiseptic solution. Next, the waterproofing membrane is fixed over the entire surface of the rafter system. The most convenient way to work with the membrane is to secure it with a construction stapler. The overlap of the material is at least 10 cm. The seams must be additionally taped with tape for this material, or with universal rubber tape.

The procedure for insulating a corrugated roof in an attic

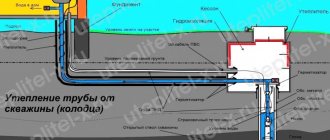

- Waterproofing material is laid in the plane of the rafters under the corrugated sheeting attached to the wooden frame. In this case, a gap of 4-5 cm, the so-called air cushion, must be maintained. A high-tech Tyvek Solid (Soft) waterproofing membrane or a layer of thick polyethylene (depending on the developer’s ability to pay) can be used as waterproofing. The Tyvek Solid membrane is laid with the markings facing out; for Tyvek Soft this is not important.

Rolls of waterproofing are rolled out directly at the installation site, from top to bottom along the entire valley. Sagging of the main waterproofing material is unacceptable. The rolls are rolled out horizontally, placed in the spaces between the lags. The waterproofing is fastened between the rafters “in space”. At the joints, the material is laid with an overlap of 150 mm, and the joints should be located on the rafters.

Attic insulation scheme.

The waterproofing material should not have gaps, holes, or poor-quality joints, otherwise the insulation of the entire roof will suffer. All seams must be sealed for high-quality insulation.

If for some reason the air cushion is not maintained, a so-called “cold triangle” is constructed under the ridge in the roof cavity, providing ventilation of the under-roof space. In this case, ventilation passages are created at intervals of 2-3 spans, but in no case in each one. Such a ventilation system will significantly reduce the formation and accumulation of condensation in the roof space, which may result in damage to the roof insulation.

- Under the waterproofing layer, again in the plane of the rafters, insulation is laid closely. This can be mineral wool or glass wool. For the attic, it is better to take the maximum thickness available in construction stores (up to 100 mm). If the insulation is laid in several layers, then each layer must overlap the previous joints. A special knife is used to cut the thermal insulation material.

- Next, the heat-insulating layer is sheathed with another layer of waterproofing - a vapor filler. Typically, H96 Silver or H110 Standard film is used. The vapor filler is installed from the side of the living room using a construction stapler, and the seams are overlapped. Its surface, like the waterproofing, must be sealed - all seams are duplicated with SP1 connecting tape and glued.

- The roofing pie is completed with wood cladding on the attic side. The material can be wood, lining, OSB boards, plywood - in a word, it all depends on the thickness of the wallet and the design of the interior. For the interior cladding of the attic, moisture-resistant materials with a thickness of 9-12 mm are recommended.

When installing particle boards, they are laid across the rafters.

Important: each slab must have at least two supports.

The slabs are fastened with 50-70 mm self-tapping screws at intervals of 20-30 cm to the supports of the rafter system, and the distance from the edge of the slab must be at least 10 mm.

This completes the insulation of the attic. Now you can begin finishing and other construction and installation work, after which you can move into the attic

Choice of insulation

The process for working with different species is different. Therefore, before starting work, it is necessary to take into account all the nuances and choose one of the insulation materials existing on the market. For example, expanded polystyrene sheets are easier to install than all other options. They are placed tightly between the rafters or glued directly to the ceilings. The operating principle is simple and does not require additional instructions.

Polyurethane foam insulation is sprayed onto the surface using special equipment, and all work is performed by third-party specialists. The participation of the home owner in the insulation process is minimal.

Mineral wool

It is somewhat more difficult to work with mineral wool. At the same time, this is one of the most effective ways to insulate a corrugated roof. Installation takes a little longer than previous types. Additionally, you will have to purchase a hydro- and vapor barrier membrane. These elements are an integral part of working with mineral wool.

Since the material is porous, it easily absorbs moisture and condensation. With prolonged exposure, the processes of rotting and mold formation begin. To prevent these processes, layers of hydro- and vapor barrier are used. The bottom layer of the membrane does not allow condensation to pass through from the interior, while the top layer prevents getting wet when condensation forms on the inside of the corrugated sheet.

If you take a step-by-step look at the stages and technology of work, it is not difficult to perform insulation with this material. The order of the layers must be carefully observed. If we consider the roofing insulation “pie”, starting from corrugated sheeting, it looks like this:

- waterproofing (usually a waterproofing membrane);

- a layer of insulation, in this case, mineral wool;

- vapor barrier membrane layer;

- interior finishing (this layer is optional and is performed as necessary).

The next step is to select the form of insulation. Mineral wool is presented on the construction market in two forms: rolls and sheets.

All parts are adjusted to the distance between the rafters. It is most convenient to use a painting knife. Fastening is carried out with nylon thread, as well as 50mm*50mm slats for additional cross-insulation. Be sure to spread between the rafters, while filling all the voids and cracks. It is not recommended to compress mineral wool, therefore the marking and preparation of sheets must be done to the maximum size. A layer of vapor barrier membrane is fixed on top and covered, if necessary, with a finishing, decorative coating.

Polyurethane foam

This is one of the most cost-effective insulation options. And at the same time, it can become the only solution for roofs with complex terrain and geometry. Its second advantage is the low weight of the finished layer.

Work with it is carried out with special equipment with a sprayer. Polyurethane foam is applied in a thin layer to the entire internal surface of the roof, without forming voids or gaps. As a result of the work, a thin, light insulation is obtained that perfectly retains heat inside and does not let in cold air from the outside. The material has a slight soundproofing effect.

Another plus is minimal preparatory work. All that is required is to free the roof surface from large debris and contaminants. Polyurethane foam adheres perfectly to any, even the most difficult, surfaces on its own. No additional installation work is required.

The downside is the additional work required to install ventilation holes. Polyurethane foam is completely vapor-proof, which means that it is necessary to ensure constant air circulation in the room.

Extruded polystyrene foam

Another type of modern insulation. It features high thermal insulation and increased strength. Working with it follows the same steps as with foam plastic or other sheet insulating materials.

The expanded polystyrene sheet is adjusted to fit between the rafters. Excess material is removed using a painting knife. Installation is carried out using polyurethane foam and self-tapping screws (while the foam dries, then removed). There must be an air cushion between the insulation sheets and the top layer of waterproofing. Its size is 2-5 cm. All joints, cracks in the side joints of sheets and rafters are foamed with polyurethane foam. The result is a flat, smooth surface. A vapor barrier film is installed as the bottom layer. It will protect the rafter part from condensation.

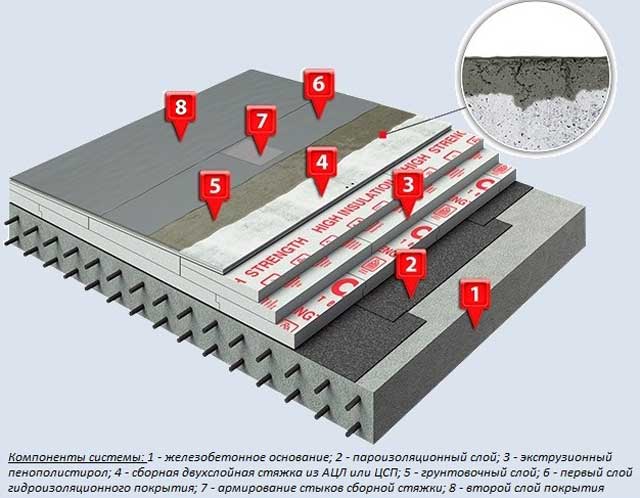

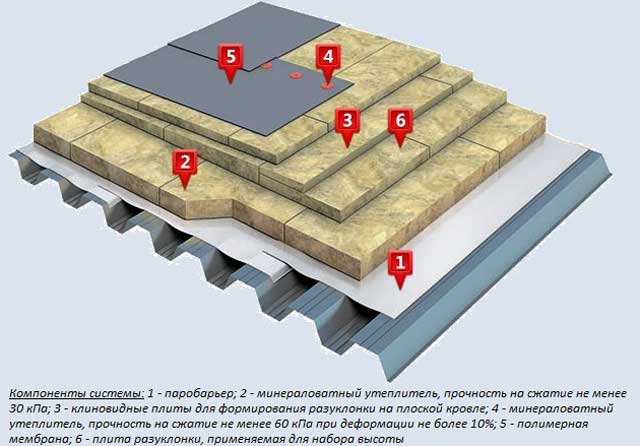

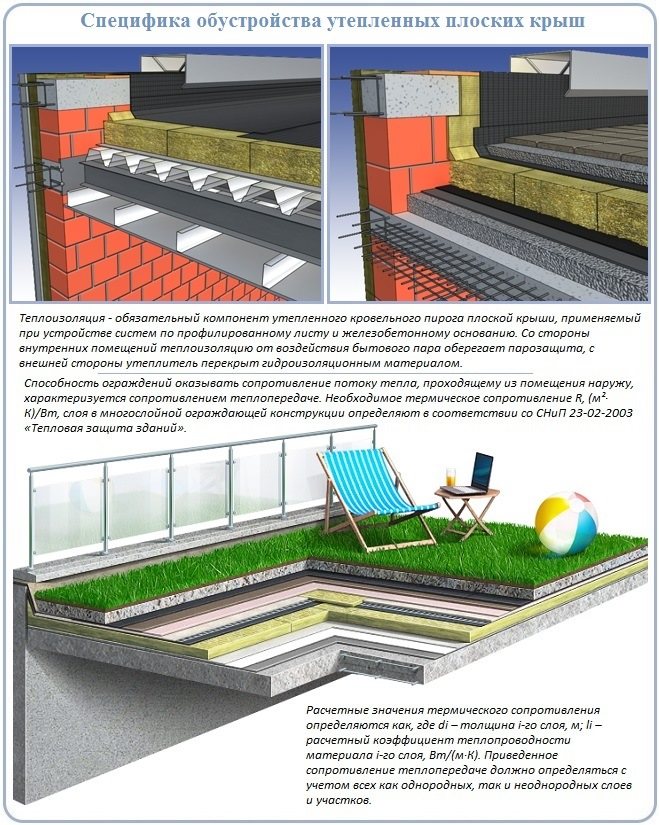

Insulation for flat roofs: technical nuances ↑

To insulate a flat roof, use almost any material that is suitable for thermal insulation of the ceiling and walls. The following are especially in demand:

- Expanded polystyrene. Lightweight, fairly strong and rigid slabs act as a layer. A screed is poured over them. Modification of expanded polystyrene – extrusion material. It has a dual use: as a basis for installing a finishing roof or a thermal insulation layer under a concrete screed.

- Basalt mineral wool. This is a fibrous semi-rigid or rigid material that can be used, respectively, as a base for waterproofing or as a component in a multi-layer insulation system.

Mineral wool is laid in dry weather, and the work must be completed on the same day. If the material gets wet, it will have to be replaced with a new one, since the old one will already lose its insulating qualities.

- Polyurethane foam. Another option for effective roof insulation. It applies perfectly, without forming seams, and is non-flammable.

- Foam concrete. A relatively new material, reminiscent of concrete in durability and solidity, and foam in its weight and structure. An ideal flat roof insulation that does not create a serious load.

When choosing the type of insulation, in particular, it is necessary to proceed from the protocol regulating measures to guarantee the fire resistance of an object, and the thickness of thermal insulation, calculated in accordance with the recommendations of SNiP on the thermal protection of structures.

SP 23-101-2004 design of thermal protection of buildings (3.9 MiB, 1,396 hits)

In addition to standard slab insulation for roofing, wedge-shaped slabs are made from these materials, with the help of which they organize the natural flow of atmospheric water to the gutters from a flat roof.

On a note

Wedge-shaped insulation cannot be considered as a worthy replacement for a layer of thermal insulation. Wedge-shaped slabs solve exclusively drainage issues.

Summing up

All work on insulating a finished roof made of corrugated sheets is carried out from the attic side. Removal of roofing material is not required. There are several technologies to choose from. Their effectiveness depends on several factors, including:

- correct selection of insulation material;

- accuracy of calculations of the required thickness;

- competent implementation of vapor and waterproofing work;

- careful study of joints, cracks and other gaps.

If all recommendations are followed, the roof will be warm and reliable. Even a novice master can perform this operation. The main thing is to stock up on time, patience and approach your work responsibly.

Insulation of the roof from the inside is carried out not only in order to create an additional room in the attic, but also to maximize heat retention throughout the entire house.

Installation of corrugated roofing

Characteristics of roof insulation.

At the first stage of construction, the sheathing frame is constructed. Logs are attached to the rafter system at intervals of 1 to 1.5 m. For the logs, a board (jointed or non-jointed) 140-150x40 mm is taken. The width of the board is 140-150 mm, which means that the thickness of the roofing pie will be 140-150 mm, since the logs are attached “on edge”.

A 20x120-140 mm board is placed across the logs. This can be any timber, including unedged boards. It is stuffed at small intervals, about 5 cm.

The roofing material is directly attached to the resulting sheathing frame. A detailed description of this process will be discussed in another article.

The need for roof insulation

It is unlikely that anyone will insulate the attic roof. The cold attic in private houses of old traditional construction serves as a storage place for things that have served their time.

A complex insulated roofing assembly can be constructed by a person who, with the help of an attic, intends to significantly increase the volume of a residential location. That is, he creates additional living space under the roof of his house.

Its construction will require different technological content. The traditional roofing assembly has been thoroughly modernized, introducing into its structure new elements necessary for the construction and long-term functioning of the insulating layer.

The modern attic usually serves as the main sleeping area for family members. The premises are equipped with all types of plumbing and sewer systems:

- showers;

- toilets;

- natural and forced air ventilation;

- electricity.

All this requires a certain positive temperature for its normal functioning.

An insulated roof covered with corrugated sheets, metal tiles, painted reeds and other roofing materials can create a favorable operating conditions.

What thermal insulation materials are needed to insulate a corrugated roof?

Private housing construction has received an exclusive direction for the manufacture of insulated attic roofs. From the various methods of installing a warm roof covering, the best option has been identified, which has become the dominant element today.

Integrated into the warm layer:

- lining or dry plaster;

- a thin layer of vapor barrier is placed on the internal finishing material;

- the space between the rafters is filled with insulation;

- then they are completely covered with a hydrobarrier (roofing felt, a special synthetic film);

- they are sewn over the top with lathing in increments of 1-4 cm. To organize the ventilation space, counter-lattice is installed in increments of 40-50 centimeters.

Corrugated sheeting is attached to the sheathing. With a pitch of 35 centimeters, there is a guarantee that the wind will not “lift” the profiled sheets.

- Use environmentally friendly thermal insulation materials.

- With low thermal conductivity.

- Does not form unpleasant odors

What to prepare before starting work

Insulation installation work

A classic of the genre - marking corrugated sheets using twine and chalk

Electric scissors – will provide high productivity

Basic requirements for materials when installing a warm roof made of corrugated sheets

When insulating a roof, you should use materials with the following characteristics that have acceptable performance:

- by thermal conductivity;

- by hygroscopicity;

- by vapor permeability;

- by elasticity;

- by compressive strength;

- by elasticity.

The installation of a warm roof requires high-quality materials. It refers to

- vapor barriers

- hydrobarrier

- insulation

- corrugated sheets.

A warm roof includes auxiliary materials: for steam removal, waterproofing devices.

Today, construction trade enterprises will offer the developer a wide range of goods, both domestic and imported. Usually these are polyethylene films with the necessary performance characteristics. Inexpensive but functional.

Many people still use roofing felt as a water barrier. Cardboard impregnated with bitumen cannot be a suitable location for harmful bacteria and fungal colonies that can turn wooden components and elements of the roofing system into dust.

As for insulation, all kinds of materials of organic and chemical origin are used:

- mineral wool

- stone wool

- bulk materials subject to packaging

- penoplex

- Styrofoam

- other

Types of insulation

For garages, classic and modern insulation is used.

The classic ones include :

- Mineral wool is a heat-insulating fibrous material used in construction and manufacturing. The main characteristics of mineral wool insulation: low heat conductivity, vapor permeability, durability, sound insulation, fire safety.

- Polymer insulation is a material that is characterized by high thermal insulation and water resistance.

- Fiberglass materials are moisture resistant. Obtained by processing broken glass.

Modern insulation materials are:

- Penoizol is a liquid foam characterized by water resistance, fire resistance and durability.

- Polyurethane foam is applied using special equipment. The service life is more than 70 years.

- Asstratek is a liquid insulation that is applied with a regular painting brush.

- Extruded polystyrene foam is water resistant, durable, and has low thermal conductivity.

Modern insulation materials are distinguished by specific production technology, and therefore may have a higher price.

The material must have:

- minimum degree of ignition (preferably fire protection);

- vapor permeability;

- high thermal insulation;

- ease of installation.

It is important to remember that there are different types of garages. When choosing insulation, take into account all the properties and characteristics of the material, pay attention to the manufacturer and quality. The effectiveness of your work will depend on these factors. Having followed all the recommendations and insulation techniques, you will be proud of your garage.

Corrugated sheeting with insulation on pitched roofs

Private housing construction rarely has flat roofs. Most of the objects are of pitched type. And here it is necessary to strictly observe the measure.

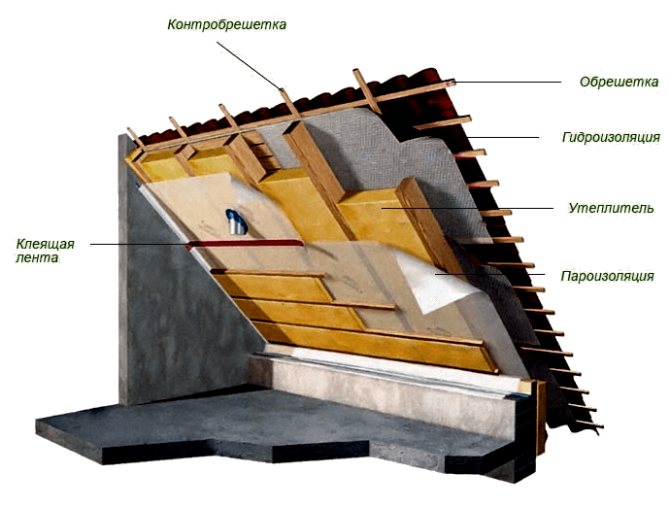

From the bottom, fixed to the counter-lattice of the corrugated sheet, there is waterproofing, in the descending direction - insulation, then vapor barrier and internal finishing lining.

The entire layer is necessary not only to retain heat in the attic. It dampens street noise.

If it were not for this layer, it would be impossible to sit in the attic during a summer rainstorm.

Roof installation. Roofing pie

It turns out that people use valuable fuel, especially natural gas, to heat the air. Help industry create the greenhouse effect. Heat escapes through objects that have attics. They are not insulated and are used ineffectively.

People have become thoughtful and today it is clear that there is an active offensive against the irrational consumption of home heat. Successfully. A significant amount of thermal energy can be conserved in attic buildings. Occurs thanks to a roofing cake consisting of various materials. To confirm these words, consider what it consists of:

- The roofing pie is formed from several dissimilar materials with different technological characteristics.

- The most important layer is corrugated sheeting, which creates conditions for the formation of the best performance characteristics of the roofing pie. It prevents it from getting wet during rain, snow, melt water, and so on.

- To help him, there is a hydrobarrier - a kind of gasket between a warm cake and metal profile sheets.

- Next, the insulation is located in the roofing system. Its task is to prevent thermal energy from entering the atmosphere and to prevent cold air from entering the attic space.

- The last layer, the vapor barrier, regulates the removal of vapors from the attic space. Even lower comes the finishing material, which creates a creative interior in the attic.

We make sure that each element of the roofing pie performs its specialized function. And the more rationally the layers are selected, the better the roofing cake will work.

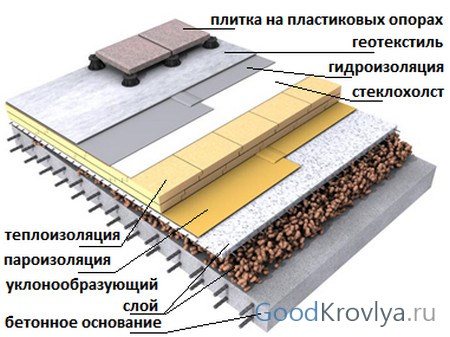

Installation of warm roofing from corrugated sheets on flat roofs

The technology for installing warm roofs on flat roofs has not gone far. It existed before, but with the advent of innovative materials, it did not become worse, but better.

Corrugated sheeting is used in large quantities in the construction of flat roofs for offices, private houses, buildings of small and medium-sized enterprises, and warehouses.

Flat roofs are:

Their structure includes bases that experience force loads. It can be

- reinforced concrete floor slabs

- corrugated sheet

- or another basis.

If the floor is reinforced concrete, then first a thin cement screed is made, insulation is placed on top, and then a waterproofing layer is applied. The final coating is roofing felt, poured with heated bitumen mastic.

This is a traditional method with a limited number of layers. If there is no lump insulation, then a layer of expanded clay is used.

In recent years, they have begun to use it as a material, a vapor layer.

They began to integrate into a warm pie

- fiberglass

- geotextiles

- other materials.

Moreover, bulk insulation began to be used as a material that forms roof slopes.

In the middle they make the layer thicker, reducing it towards the eaves.

Inversion structures are installed on already completed roofs. Gardens are laid out on them and terraces are arranged.

Warm flat roof pie

Laying the roofing pie

It is known that heat loss in a house through the roof is about 25% - which is why special attention should be paid to the issue of roof insulation. Creating a so-called roofing pie, consisting of heat and waterproofing layers, air cushions, and wood, helps prevent roof leakage, condensation formation, rotting processes, and heat loss. In addition, a properly installed roofing pie will protect the living spaces in the house from the summer heat, noise effects during rain, wind, and thunderstorms.

Roof pie made of corrugated sheets.

The degree of insulation of a corrugated roofing largely depends on whether the attic space will be residential or not. If the construction of an attic is initially planned, the thickness of the thermal insulation material should be increased, insulating it as much as possible from moisture penetration, since even with slight wetting (only a few percent) the thermal protection decreases by 2-2.5 times. The result is freezing of the roofing pie. Outwardly, this becomes noticeable by the formation of ice on the roofing material, the finishing materials in residential premises suffer, and mold and mildew form inside the pie, which contributes to the rotting of the wood structures of the entire building. Insulation of a corrugated roof requires a very careful approach.

Moisture entering the thermal insulation material can occur:

- in case of poor quality installation work;

- with intense evaporation of moisture in residential premises;

- when condensation forms inside the roofing pie.

Options for insulating a flat roof from the outside and inside

The variety of insulation options for such roofs is obvious. But they have one drawback. There is no rafter system. That is, the sinuses between the rafters. There are many options for insulating both outside and below. Choose the best insulation and hang it, for example, from a concrete floor using plastic dowels. Afterwards, the insulation is covered with a special cement mortar, painted or whitewashed.

Insulation of a flat roof

Nuances of insulating a flat roof ↑

The principles of thermal insulation for a flat roof are fundamentally different from the approach to insulating pitched roofs. The flat structure does not have rafters between which a thermal insulation layer could be placed. There is nothing to fill the sheathing on, so the formation of ventilation gaps for ventilation of the components of the roofing pie, as in pitched roofs, is impossible. The analogy can be traced, perhaps, only in the order of layers of the roof pie. It consists of the following components:

- Vapor barrier. The layer is laid on the side of the premises and blocks the path of household fumes.

- Thermal insulation. This is a barrier to the passage of heat from inside the house to the outside and vice versa. At the same time, it plays the role of sound insulation.

- Waterproofing. It protects the thermal insulation layer from the outside from precipitation.

- Finish coating. For ballast roofs, the waterproofing layer is covered with gravel, or paving slabs or a layer of soil under vegetation are laid on top of it, etc.

Important

If the sequence of laying layers, as well as the rules of construction, are violated, deplorable complications arise that force owners to spend impressive sums for repair work, and sometimes for a major reconstruction of the roof.

However, it should be noted that the need for such a design arises only if it is necessary to ensure heating efficiency, that is, to retain heat in them. So, if we are talking about the roof of a summer kitchen or outbuildings, there is no point in insulating a flat roof.

In such cases, proceed, for example, as follows:

- in the concrete roofing pie there is only waterproofing:

- on corrugated sheets - prefabricated screed and waterproofing,

How to make insulation with polyurethane foam

This is high-tech in the technology of insulating any structures of private houses. To create consistency, equipment has been created and sold that can be used to insulate both vertical and horizontal structures.

The blowing or pouring method is used. It is more productive to use a spraying method in which the following occurs:

- filling all gaps of any size;

- expanding in volume, creates a solid, durable coating.

Polyurethane foam is obtained by mixing polyol and polysacyanate, which are in a liquid state. Mixing occurs without access to oxygen during spraying. Apply the consistency to the structural elements with a pistol. As the material cools down, it increases in volume several times.