How and with what to insulate a veranda with half-brick walls from the inside inexpensively?

Italian brick.

The veranda is heated. What is the cost of the material?

Experts advise insulating a cold veranda from the outside, but rarely inside when there is no choice.

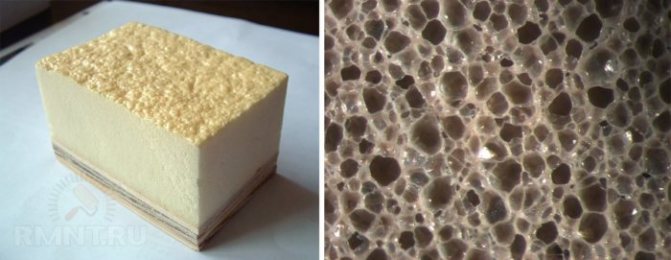

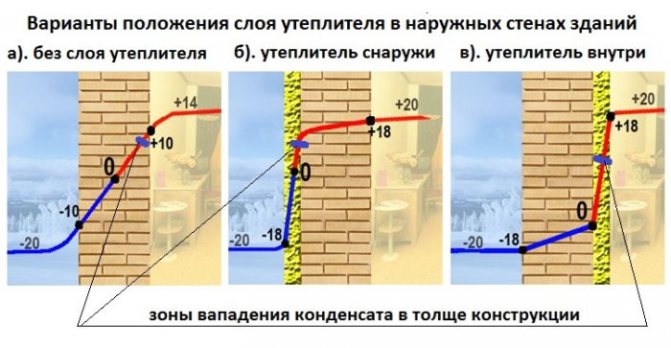

In an uninsulated half-brick wall, the contact of room air and cold outside air occurs in the brick, this is normal, there is a dew point there. Insulation from the street side moves it outwards, internal insulation moves it towards the veranda. Condensation accumulates between the wall and the insulation or directly in the insulation. The resulting moisture inevitably causes the appearance of fungus, which will then appear on the finishing material (plasterboard, planed board, etc.).

According to the rules, the vapor permeability of a multilayer wall should increase from the inner surface to the outer one.

If there is mineral wool or glass wool inside, which allows steam to pass through well, then next comes brick, which allows steam to pass through much less well. It's cold outside. The steam passing through the mineral wool hardly penetrates further, but it cools and condensation appears. The wall is getting wet.

Once internal insulation of the veranda is chosen, the vapor permeability of the inner layer should be almost zero.

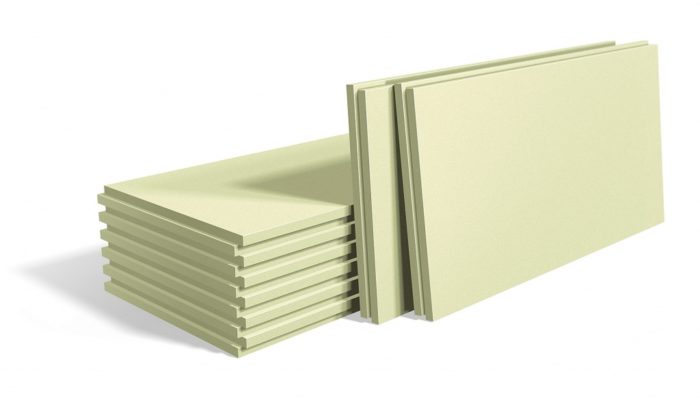

Extruded polystyrene foam is better (it has the lowest vapor permeability), polystyrene foam and polyurethane foam are worse.

Insulation materials with high vapor permeability (mineral wool, etc.) must be carefully waterproofed.

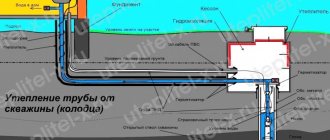

Penoplex is a type of extruded polystyrene foam; it is mounted directly on the wall, leveling it. In case of unevenness, knock the plaster down to the brick, level it with a new layer of plaster, and after drying, apply liquid glass (waterproofing + antiseptic).

Penoplex plates are placed on glue or “fungi”, not allowing a continuous vertical seam (staggered), the joints are protected with sealant.

After a gap of several cm, a frame is mounted, which is attached to the floor, ceiling, adjacent walls, but does not come into contact with the insulated wall. A screen made of vapor barrier material is stretched over it, a slatted sheathing is made on it, and covered with plasterboard or clapboard.

Other options for insulating the veranda from the inside.

Lay another half-brick wall inside, filling the gap with insulation (mineral wool), the dew point will be in the mineral wool, but condensation will not escape inside.

You can strengthen the “warm floor” system on the wall of the veranda and cover it with a false wall made of GKP PS. This is a “sandwich” - a gypsum composite panel with polystyrene glued on the inside.

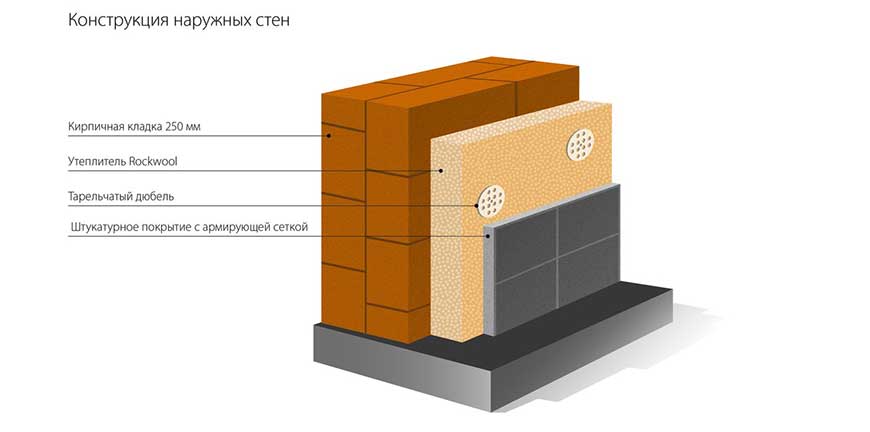

Wall insulation process

Just so you know, heat is partially lost through the external surfaces of a building; more attention should be paid to the internal space, namely the floor, roof and vertical enclosing structures. Let's try to figure out how to properly insulate a brick wall from the inside.

It makes sense to resort to this measure if the side parts of the house are insufficiently thick. Most often, mineral or stone wool and polystyrene foam are used for these purposes. Extruded material, cork, and “warm” plaster are also no exception. The order and complexity of the work performed depends on this. But first of all, you need to properly prepare the foundation.

To do this, the walls are cleaned of dirt,

impregnated with primer. Then you have to choose the method of internal insulation. Always remember that recklessness in this matter can contribute to aggravating the situation rather than improving living conditions.

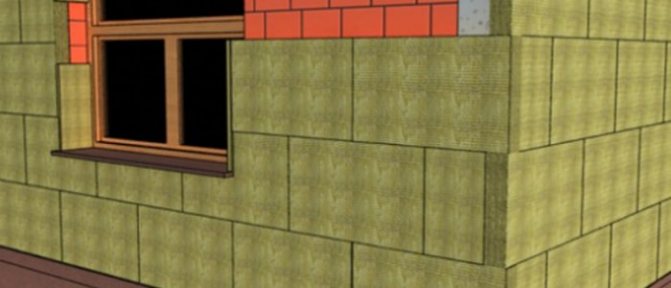

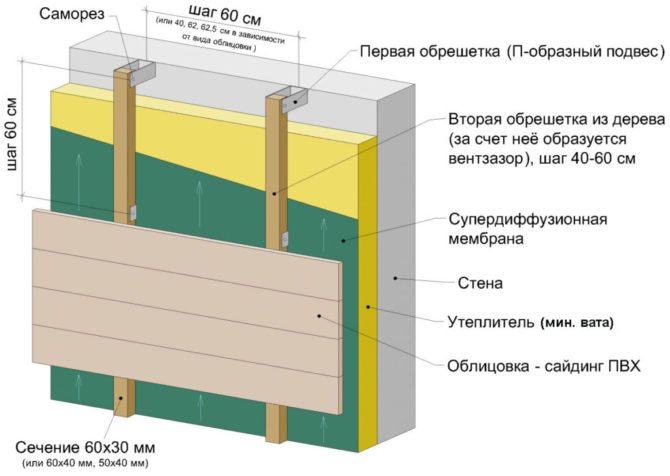

- The frame method cannot be called simple, so anyone can handle it. This requires knowledge and skills in creating a metal frame, onto which finishing material in the form of plasterboard will subsequently be attached. This technology consists in the fact that first metal profiles or wooden beams are fixed on the wall at intervals of 60 cm, and then heat-insulating material is laid between them in two layers. You still need to lay a vapor barrier material with a foil side on top to form an airtight layer. The film is fixed to the frame. The presence of a membrane is especially important because it protects the coating from the negative effects of moisture. Finally, the base is covered with a finishing material, which is most often used plasterboard.

- Frameless method - implementing this option will not only be easier and faster, but also more profitable from an economic point of view. You will need to clean the walls from the finishing base, then plaster the surface and putty it. The next step is laying the waterproofing material (film). The glue is applied to the surface in large quantities, the foam is pressed onto it as tightly as possible; to ensure complete pressing, it does not hurt to roll it with a roller. Maintaining intervals in this case is not mandatory. After gluing the heat insulator, a vapor barrier is installed and you can begin finishing.

How to insulate a half-brick wall?

Facade insulation will help maintain comfort and warmth in a half-brick house. External insulation is aimed at good heating of the walls and shifting the dew point to the outer surface. Thanks to this, condensation does not accumulate, which allows the previously wet wall to dry due to the divergence of steam.

For thermal insulation of external surfaces, foamed polystyrene and polyurethane, gas-filled polymers are used. These materials have proven themselves to be excellent due to their moisture resistance, lightness, stable shape and strength.

How to insulate a wall from the inside

Hello! Please help me with advice. We installed heating on the terrace and decided to insulate the wall under the window. The width of the window is 3 meters across the entire wall; we need to insulate an area of 3 x 1.5 meters. The wall is made of wood, the inside is lined with gypsum board (painted), we will not remove it, the outside is lined with half a brick. We want to use URSU PureOne as insulation and cover the inside with plasterboard. We also purchased 50 mm penofol, vapor-permeable and vapor-tight membranes. Please tell me how to insulate it to avoid unpleasant consequences in the future (moisture and mold)? In what order should I put the materials? Is it possible to use URSU and penofol at the same time? And is it necessary to leave an air gap for ventilation? Thanks in advance for your answers.

Taisiya, if you don’t want to touch the drywall, then I advise you to make it simpler and more reliable, take penoplex (100 mm), glue it onto the mounting foam to your wall, foam all the joints around the perimeter and between the sheets, putty with façade putty with a mesh and then you can either glue it wallpaper or paint.

Moisture will accumulate on the internal gypsum board wall, how will you remove it from the inside?

First of all, not you, but you. And secondly, the dew point with 100mm penoplex is located inside the insulation but not like on the surface of drywall, for your information. And in your case, the Condensate will be 46.32 g/m2/hour, and it is not known who else will leak

It will not leak, but will ventilate

The gap will be needed to prevent condensation.

Taisiya, the fact is that in your case, what you call a “vapor-tight membrane” will not work correctly if you do not make holes from the outside of the wall. Since it is installed as an external “VENTILATED” protection of the insulation from accumulating moisture. That is, you will have to make holes in the wall below and directly below the window. In your case, I would still dismantle the plasterboard and install ventilation windows at the bottom of the wall and at the top (accessible) point. I would install a groove, or, as a last resort, I would waterproof the lower part where there would be a gap of 20-30mm between the wood and the vapor diffusion membrane, and waterproof the wood itself. Then you arrange a vertical sheathing with a 20X40 - 40 block to the wooden wall. Sheathe it in a stretch with a vapor diversion membrane, overlapping it to the street by 10 cm (drops of moisture will flow down it) and arrange a frame 50X100 across - 50 to the membrane. Insulate the insulation with Rockwool Cavity Batts basalt wool, 100 mm thick. Cover with waterproofing. And only then re-sheathing and gypsum boards. All wooden parts are treated with weather-resistant and water-repellent impregnation, for example Drevotex. It will be right.

Why complicate the design so much after dismantling, when you can simply glue polystyrene foam (100mm) onto the brickwork and that’s it, and then putty, glue wallpaper, do any finishing.

Taisiya, you have two options for insulation with penoplex (100mm) without dismantling and chiseling, or as Dmitry Barinov described with dismantling and chiseling. Other options are not possible because Mineral insulation requires ventilation.

Before buying a material, you need to figure out what function it will perform in the building envelope system and understand how this system will work. Let's figure it out. You need to provide 2 main parameters: additional thermal insulation to save energy resources and eliminate the formation of condensation inside the wall (precisely eliminate it, and not install gutters for water drainage, as recommended above. The formation of condensation is no longer a properly designed enclosing structure.) A little theory. Vapors from a warm room migrate to the street, passing through the enclosing structure, in this case a multilayer one. Each layer has such a characteristic as vapor permeability. If we divide this characteristic by the thickness of the layer, we obtain a value called resistance to vapor permeation. The higher this characteristic, the less a certain layer allows vapor into the wall structure. If you look at the pie of the enclosing structure from the inside out, then the layers should be positioned so that their resistance to vapor permeation decreases as they move outward. Then the steam will not condense in the thickness of the wall, but will safely come out. But this is only ideal. In fact, the condensation process is also influenced by the distribution of isotherms throughout the thickness of the wall. In your version, the most problematic isotherm will be the plane: painted drywall insulation. If, for example, it is +20 indoors, -20 outside, and -10 on our border. Then the steam will begin to condense if it is more than 2.14 g. per m3. If it is less, then it will pass further as steam. If, for example, there is +10 degrees at this boundary, then the steam will begin to condense when it exceeds 9.4 degrees. per m3. Those. we need to provide conditions such that the temperature at the boundary is as high as possible and the amount of vapor is as small as possible. Since we have insulation from the inside, we practically cannot influence the temperature. More precisely, the better the insulation, the lower the temperature at the border (this is the whole absurdity of insulation from the inside). But we can influence the amount of vapor, in 2 ways. 1. Limit the influx of vapors by using materials from the inside of the room with high resistance to vapor permeation (vapor barriers).2. Ensure a good flow of vapors after the border to the street. In your case, wood and brick are quite vapor-permeable materials, and drywall even more so. But if it is painted with oil paint, which is a good vapor barrier, then this drywall needs to be removed. Let's return to point 1. How to ensure good vapor barrier? Dmitry Zhukov suggested that you make insulation with extruded polystyrene. From the point of view of insulation and vapor transfer, it is an ideal solution, because it does not absorb moisture and therefore its thermal insulation properties do not deteriorate during operation. In addition, it has a very high resistance to vapor permeation and will be an additional barrier to vapor. But the question of the environmental friendliness of this design remains open. If mineral wool is used, then it is necessary to use a very powerful film vapor barrier with a coefficient. vapor permeability tending to zero and cover it with plasterboard. In this case, special attention should be paid to the quality of its installation. For Orenburg, the thickness of the insulation should be about 150 mm. You don't need a vapor-permeable membrane. It is relevant when insulating from the outside and when using a ventilated gap. Penofol can be used. It is also a good vapor barrier. The insulation scheme proposed to you by Dmitry Barinov with the installation of ventilation windows through brick and wood is absolutely stupid. Because in this case, we exclude two layers from the insulating pie: brick and wood. And they must compensate for them by increasing the thickness of the insulation.

“From the point of view of insulation and vapor transfer, it is an ideal solution, because it does not absorb moisture and therefore its thermal insulation properties do not deteriorate during operation. In addition, it has a very high resistance to vapor permeation and will be an additional barrier to vapor. And he’s not breathing at all.” Wonderful. The heap can also be sheathed with plastic film, it has a vapor permeability coefficient of 0.00002. I'm talking about a wall that will breathe without releasing heat. It is possible that two layers of the wall will have to be eliminated.

“Breathing walls” and insulation from the inside are nonsense... And having ventilated, you get a kind of external insulation with a system of ventilated facades. Only this facade in this case is half-brick masonry and a wooden structure. Not a lot. In addition, the enclosing structure will lose an important characteristic such as heat resistance (heat capacity).. And when we insulate from the inside, it is not high anyway..

Hello! Many thanks to everyone for the proposed solutions to our issue. Special thanks to Vladislav Peregudov for his detailed answer, citing the theory from the fundamentals of thermal engineering. Very consistent and accessible. We spent two days thinking about the proposed options. We are inclined to the following: remove the painted drywall, insulate it with mineral wool + penofol, vapor barrier with isospan B and sheathe it with gypsum plasterboard. Questions arose again: 1) According to the instructions, Izospan is mounted on the insulation. If we use mineral wool + penofol, does it mean we need to lay it on penofol? Then the reflective surface of the penofol will be covered. Which is correct? 2) Is it necessary to leave an air gap for ventilation and where (between which layers of the wall)? 3) What if you don’t remove the painted drywall, but simply make ventilation windows in it, thereby excluding this layer from the insulation cake? Is it possible to limit this? 4) And if we remove a layer of painted drywall, won’t this lead to the transfer of condensation to the next layer - wood and its destruction, and this is the main load-bearing structure of the wall? Answer, please. Thank you.

Materials for insulation from the outside

Protecting the walls with thermal insulation material from the outside from cold and humid air helps them dry out if there is excessive accumulation of moisture. Insulation materials include:

- Mineral wool is a solid and semi-solid slab made from silica and basalt. It is treated with special means to impart waterproof and vapor-proof properties. It has a density from 80 to 150 kg/m3 and thermal conductivity - 0.030 W/m. The material is divided into the following types: simple;

- lamella - due to the perpendicular arrangement of the fibers, they are excellent for insulating uneven surfaces and brick walls.

- easily ignites;

- high price;

Return to contents

How are they insulated?

Moisture absorption and moisture permeability of structures in buildings made of sand-lime brick is eliminated by insulating them. In addition, thermal insulation keeps your home warm in winter and cool in summer. The insulation of walls depends on their thickness. There are two types of insulation:

- from the inside;

- outside.

Internal insulation of structures in houses made of sand-lime brick is rarely done, since the dew point moves inward, which contributes to the formation of condensation on the walls and requires the installation of an effective ventilation system. In addition, the slopes, floor and ceiling will need to be insulated. The insulation can be basalt fiber slabs and foam glass.

To insulate walls from the inside, only environmentally friendly materials with low flammability are used to avoid the release of harmful substances into the room.

The outside of sand-lime brick is insulated using the following materials:

- mineral wool;

- Styrofoam;

- polyurethane;

- expanded polystyrene.

How to insulate a half-brick house?

When choosing cladding, the material of the building, the nature of the residence are taken into account and it is determined whether the work will be carried out from the inside or outside. It is better to insulate a house from the outside for the following reasons:

- The usable area does not change.

- The original tightness of the material remains intact.

- Protection against temperature changes.

- Additional protection of the original masonry from pests.

- The service life of the house is extended.

Return to contents

Insulation with mineral wool

The material has a rigid structure, so mineral wool slabs are cut with a knife or saw. Scissors are not suitable for use, since when cut they compress the material, destroying the structure of the thermal insulation. For dense filling when cutting, a margin of 0.5 to 2 cm is needed. The cut of the rolled wool is made rolled up, and the slabs are cut separately. The thickness of insulation on building facades must be at least 10 cm. Insulation methods:

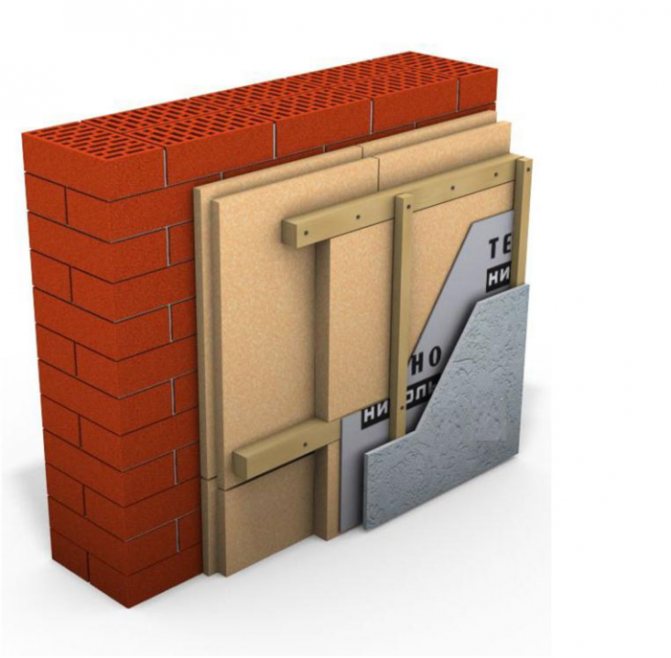

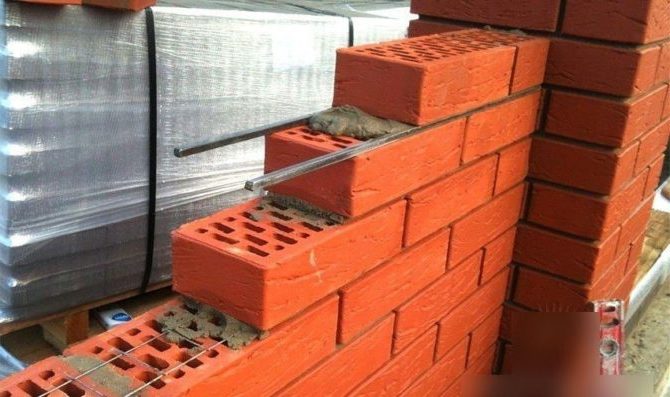

- Mineral wool is taken in slabs, the dimensions of which are used to build a wooden frame. The wall is smeared with adhesive and the “windows” are filled with cotton slabs. Waterproofing and thermal insulation is done between the main and external walls. The house is faced with brick.

- Along the entire perimeter of the main masonry of the house, anchors are inserted, which serve as the base holder for the mineral wool slabs. All walls are lined with insulation and secured with clamps. The house is faced with brick with a small gap. The seams are rubbed and leveled. The house is covered with siding or additional plaster, which is applied to the reinforcing mesh, and then painted.

How to insulate a half-brick wall

External insulation of a house is a direct way to create a warm and cozy living space in a half-brick building. Insulation from the outside allows you to achieve significant heating of the walls of the house by shifting the “dew point” from inside the building to its external contours. This technique prevents the formation of condensation. This means that the wall, which was previously wet, will now be able to dry out, since it will not collect water vapor.

The materials that are most often used to insulate a half-brick wall are:

- expanded polystyrene;

- foamed polyurethane;

- gas-filled polymers.

We insulate a brick wall from the inside

Content

Features of brick construction

- What materials are used?

- Description of the stages of implementation of various methods

- What else needs to be insulated?

Brick houses were famous for their performance characteristics. They are durable, reliable and strong, but require additional insulation. The issue has become especially acute due to the increase in heating costs for residential premises. People have to save every kilowatt, and as a result they have to freeze.

An excellent way out of a difficult situation is to prevent heat loss. It is necessary to familiarize yourself with the topic of how to insulate the walls of a brick house from the inside. It’s not difficult; if you take a responsible approach to organizing the process, you can do everything yourself.

Materials for thermal insulation on the outside of the building

Protecting the surface of the walls from the outside with a thermal insulator effectively helps dry them if excess moisture has accumulated. Such materials include:

Mineral wool is slabs of solid and semi-solid structure, which are produced on the basis of basalt and silica. During manufacturing, they are treated with specialized means that give the insulator the ability to repel water and be impermeable to steam. The density of the material is 80-150 kg*m3, thermal conductivity is 0.03 W/m. There are the following types of material:

- ordinary;

- lamella - characterized by the perpendicular orientation of the fibers of the structure, which makes it possible to effectively insulate surfaces with distorted geometry and brick walls.

Foamed polystyrene is a material that has increased strength and is easy to install. Has a low moisture absorption index. Its density can vary in the range of 15-50 kg*m3. Relatively inexpensive. The service life of the insulator is 25-35 years. After this period of time, the material loses strength and crumbles, which helps to increase the thermal conductivity of the wall. The slabs are produced in thicknesses from 1 to 50 centimeters. Not suitable for arranging an internal insulating layer. It has a number of disadvantages:

- not resistant to fire;

- vapor-tight;

- Suitable for external thermal insulation only;

- attractive to rodents.

Foamed polyurethane is a symbiosis of polyol and polyisocyanate, which turns into foam when exposed to temperature. The thermal conductivity of the insulator varies in the range of 0.019-0.035 W*m3. It is permeable to air and has a partially elastic structure, which is distinguished by sound insulation properties. Not afraid of acids and chemicals. It is moisture resistant, almost does not burn and has a significant service life. It also has a number of disadvantages:

- sufficiently expensive;

- does not react with organic solvents and mineral acids;

- can leak steam;

- installation requires the involvement of professionals;

- after the expiration of the operational period, it is not able to perform its functions.

Insulation of a brick wall with plaster mixture

How to insulate a brick wall from the inside with your own hands using a plaster mixture? First of all, a grille is fixed on a vertical surface (it can be made of metal or fabric). It is necessary so that the solution can cling to something. The mixture is applied in several layers, the first is done by spraying and rubbing. Thus, the plaster fills all the holes present, it should be a little liquid. The work is done with a tenacious brush, a brush for painting work.

It is recommended not to exceed the maximum thickness of the first layer, which is 5 mm. The next step is to apply a primer, which is the most significant thermal insulation layer. This is done using a spatula, slowly, so that the primer does not crumble, because it may not support its weight. The layer thickness is 50 mm.

Insulating brick walls from the inside is actually an elementary process. Following the instructions, you will be able to complete all the steps correctly without making serious mistakes.

Features of independent thermal insulation of a half-brick building

When choosing future cladding, do not forget to take into account the type of material from which the building is built, the seasonality of people living in it and the type of insulation - internal or external.

There are a number of reasons why it is better to insulate a house from the outside:

- there is no change in the usable living area of the rooms;

- the initial level of tightness of the building material does not change;

- reliable protection against temperature surges;

- the original masonry will be reliably preserved from rodents and insects;

- the operational life of the building is extended.

Thermal insulation using mineral wool

The structure of the material is quite rigid, which allows you to cut mineral slabs with a saw, hacksaw or just a sharp knife. It is not recommended to use scissors, as they compress the material being cut and the integrity of the insulator structure is compromised. To make the insulation fit more tightly, when cutting, you should leave a reserve of material in the range of 0.5-2 centimeters.

Mineral wool in rolls is cut without unrolling it. Slab options are cut separately from each other. The recommended thickness of the insulating layer should be over 10 centimeters.

- Mineral wool slabs are prepared, according to the dimensions of which a wooden frame is mounted. The wall is treated with an adhesive solution, the cells are filled with insulation boards. Insulation from moisture and cold must be installed between the outer and inner walls of the building. Then you can start creating the brick cladding.

- The basis for fastening mineral wool will be special anchors mounted along the contour of the main masonry of the building. The insulation is laid on the walls, after which it is fixed using clamps. Brick cladding is done while maintaining a small gap, after which the existing seams can be leveled and grouted. The building can be faced using siding or an additional layer of plaster. It is laid on top of the reinforcing mesh and painted.

Thermal insulation with foamed polystyrene

The cladding of the external walls of the building begins with the assembly of a wooden frame. The thickness of the insulating material should match as closely as possible the thickness of the slatted base. The surface of the wall should have a rough texture, then it will be easy to apply a special adhesive solution to it for installing fragments of insulation. Metal corners are mounted on the anchors, the joints are joined using mounting tape, and then rubbed down. Then a special film is attached to serve as protection from wind and moisture. Leave a gap for ventilation of 3 to 5 centimeters.

How to insulate a brick wall from the inside - popular heat insulators

The better way to insulate a brick wall from the inside is to minimize heat loss. Particular attention should be paid to the characteristics of materials offered by modern manufacturers. If everything is clear about the place of use, then the density and conductivity coefficient still have to be chosen. It is also resistant to negative factors and natural origin.

Nowadays in construction

Both artificial and natural options are used, which are again gaining popularity. The most popular is mineral wool; with a density of 20-200 kg/m3, it has a thermal conductivity coefficient in the range of 0.041-0.044 W/(m*K). This is an excellent option for indoor use; due to high moisture absorption rates, it is not suitable for outdoor use.

The next most popular is polystyrene foam. This material differs in slightly lower thermal conductivity and density range from the previous version, but benefits from its inability to absorb moisture. The disadvantages of the material include zero vapor permeability, fragility, flammability, and the ability to release toxic substances.

For external and internal work

extruded polystyrene foam can be used; its difference from the conventional version is its higher strength index. Material like expanded clay is used only for in-wall insulation. “Warm” plaster is more universal in this regard.

The level of its thermal conductivity reaches 0.065, and its density is 340. It is important to know that the layer of plaster should not be more than 50 mm; in some situations, additional reinforcement of the foundation of the house is required.

An excellent way to minimize heat loss is to use cork insulation. It is of natural origin and is also characterized by excellent performance qualities. However, we must not forget about such an important drawback as a high degree of flammability.

When in doubt, focus on the following indicators:

- coefficient of thermal conductivity, water absorption;

- density;

- flammability class;

- vapor permeability;

- durability;

- ability to isolate sound;

- environmental friendliness.

If you are new to the construction business, then an important selection criterion is the complexity of installation. The speed and ease of the process depends on this.

How to insulate a wall in a brick floor?

The bottom line is this: there is a room with a brick floor, you need to line the walls with plasterboard. Who knows what kind of thermal insulation is best to lay between plaster and brick, what kind of vapor barrier is needed? Is foam plastic good for these purposes?

Why do you need insulation in the Krasnodar Territory, it’s already warm here!!

) You don’t even have winter there, just a rainy summer)

But in general, according to science, the following is done. The minimum temperature is outside. The desired temperature inside is invented. This results in a temperature difference. The heat transfer resistance of the wall is calculated = thickness (m) * coefficient. thermal conductivity The thermal conductivity coefficient depends on the wall material and is taken from reference books. heat loss is considered = (wall area (m2) * temperature difference) / heat transfer resistance. Well, you decide for yourself what material to use for insulation. Worse material means more heat loss, and you have to pay more for heating. Well, in fact, only you can solve the equation where, on the one hand, there is payment for electricity, and on the other hand, the cost of material for thermal insulation.

The formula is simplified. The normal location of the wall is read (north, south, etc., vertical, horizontal), and coefficients are set for this. But it still turns out quite accurately without them. There will be heat loss through the roof and even more through the roof. (warm air in the room accumulates under the ceiling, which means the temperature difference will be greater) both through the floor and through cracks. Will there be ventilation? there is the heat capacity of the air, its temperature outside. You can calculate the heat loss from this matter.

Now, if you don’t want to look in reference books: coefficient. Thermal conductivity (W/(m*degree)) brick 0.56-0.87 concrete 1.86 reinforced concrete 2.04 foam concrete 0.14-0.29 steel 58 polyurethane foam 0.052 mineral wool 0.06 plasterboard 0.21 fiberboard 0.16 chipboard 0.29 plywood 0.18 pine 0.18 roofing felt 0.17 glass 0.76

polystyrene foam is a wonderful material for insulation, only flammable, with all that it implies. It's a complete ass if you need to run electrical wiring through it, for example. Well, to be honest, fuck him. Because there is an opinion that everything that is flammable will sooner or later catch fire. Why plant a mine on yourself? Especially in the Krasnolarsk region. I understand that in Antarctica there is a problem with heat loss, but what do you have there?

Don't forget about the vapor barrier. Water from the room should NOT penetrate cold walls at all.

Well, my personal opinion is that you can use something like isover. It comes in foil, i.e. right along with the vapor barrier.

Material calculation

To effectively insulate a house and avoid moving the dew point inward, you need to correctly calculate the thickness of the insulation. The thickness of the material depends on its thermal resistance. The average indicator of this value for walls in private and multi-storey buildings should be at least 3.5. The lower the thermal resistance of the wall, the thicker the layer of insulation material will be. The calculation is performed using the formula: R=d/k, where d is the thickness of the material, k is the thermal conductivity coefficient. Indicators k are a constant value and are given in the table.

| Material name | Thermal conductivity, W/m*K |

| Silicate brick | 0,7 |

| Mineral wool | 0,07—0,048 |

| Polyurethane foam | 0,041—0,02 |

| Expanded polystyrene | 0,05—0,038 |

| Styrofoam | 0,7 |

| Foam glass | 0,11 |

For example, calculate the thickness of a layer of polyurethane foam to insulate a structure made of sand-lime brick with a thickness of 0.5 m. First, determine the thermal resistance of the wall: R = 0.5/0.7 = 0.71. This indicator is calculated for polyurethane foam: R (p) = 3.5—0.71 = 2.79. The insulation layer is found according to the formula: d = R (p) xk = 2.79 × 0.02 = 0.0558 m. Thus, the polyurethane foam layer must be at least 55 mm.

How to insulate a brick wall from the inside

In private housing construction, brick buildings are positioned as structures that will last for centuries, which will become a family nest for subsequent generations. There is a certain reason for this, a brick house is really strong and reliable, but its heat saving indicators lag behind modern requirements. Taking into account rising energy prices, heating a brick house, even with mains gas, is quite expensive. If it is not possible to install thermal insulation from the outside, you need to decide how to properly insulate brick walls from the inside of the building.

Internal insulation of brick walls

When insulating a brick wall from the inside, the main problem is how not to make a mistake with the selection of thermal insulation material. Firstly, it must have high thermal insulation properties. Secondly, when insulating from the inside, the useful space of the room is “eaten up” - therefore, you need to buy insulation for brick walls with a minimum thickness.

The wall itself, insulated from the inside, does not become warmer and freezes even more. The dew point moves inward. Do not use loose fiber sealants because they absorb moisture and lose their properties.

To cut off moisture, it is recommended to install high-density basalt slabs. Such products cost an order of magnitude more than “light” slabs. Specific recommendations: ROCKWOOL (ROCKWOOL) Panelrock, IZOVOL (IZOVOL) 90, TECHNONICOL Technovent standard, etc.

It is even better to use materials based on extruded polystyrene foam with zero water absorption - Styrofoam IB 250 A, URSA XPS. Thermal insulation material PENOPLEX (PENOPLEX) is also ahead of mineral wool in terms of water absorption and is very thin.

Features of brick walls

The undeniable advantages in strength and rigidity of brick houses are outweighed by their insufficient thermal efficiency. The standard thickness of masonry for heat conservation for the 2nd climate zone is 64 cm, i.e. 2.5 bricks, while sufficient strength for 1-2 storey buildings is provided by masonry of 1 brick, and up to 5 floors inclusive of 1.5 bricks.

Achieving standard energy efficiency of a house by increasing the thickness of brick walls will increase the cost of construction due to an increase in the amount of material and the amount of work. The increased weight of the structure will require a more powerful foundation. Brick buildings are thermally inert: they take a long time to warm up and take a long time to cool down.

Important! There is a direct relationship between the thickness of the brickwork and its thermal inertness. The thicker the wall, the longer it will take to warm up and the longer it will give off heat.

Temperature inertia is an undeniable plus for permanent residence buildings, but for country cottages where people come for the weekend, it is a minus: by the time the house heats up, the weekend will end. Frequent heating and cooling cycles negatively affect the integrity of the walls. The best method of increasing the energy efficiency of a brick house is its external insulation. If it is impossible to install insulation from the outside, it is allowed to insulate a brick wall from the inside, subject to the rule of increasing the vapor permeability coefficient from the inside to the outside.

Thermal insulation using a multi-layer system

Insulation of a brick house with penoplex is carried out using a system in several layers. First, in the same way as in the previous version, the surface is cleaned of any defects. If necessary, problem areas are treated with plaster or primer.

Is penoplex suitable?

Penoplex is ideal as a thermal insulation material. Insulation for brick walls is attached to the wall using special adhesive mixtures. The material must be evenly distributed around the perimeter of the wall. Subsequent insulation of a brick wall with penoplex is carried out by securing the material with umbrella dowels. The composition used for fastening can also be used to seal the seams.

Then a layer of plaster is applied to the pre-installed reinforcing mesh (plastic mesh can also be used).

The main difference from the previous method is that the finishing stage, that is, plastering, is carried out in several layers. After this, you can begin to paint the walls.

Rules for insulating brick walls

When planning the construction of a brick house, include insulation for the brick wall inside the masonry in the estimate. Polystyrene foam, extruded polystyrene foam or PIR boards can handle this role. If the house has already been built, it is optimal to insulate it from the street side, but this is not always possible. Installation of the external insulating layer can include:

- the presence of permanent exterior finishing;

- proximity to a fence or other building;

- historical or architectural value of the building.

Important! The Town Planning Code does not allow the outside of apartments in multi-storey buildings to be insulated, because... this entails a change in the appearance of the building.

Insulation of internal walls is the only option to increase heat saving if it is impossible to install insulation outside or inside the load-bearing walls of the house. If the area of a country house allows the use of slab material without compromising the size of the rooms, then the corner room of the apartment can be insulated either with penofol or warm plaster, which, due to their insignificant thickness, will not lead to a significant reduction in usable area.

One of the negative aspects of insulating internal walls is freezing of the outer wall due to lack of heating from the inside. But it is not so much freezing that harms structures, but moisture condensing on a cold surface. High humidity leads to the formation of mold and mildew, which negatively affects human health and the integrity of structures. To minimize the appearance of moisture in the insulation, you must follow the principle of increasing the vapor permeability coefficient of materials from the inside out.

Insulation using foam plastic

There are opponents of this material who unanimously claim that polystyrene foam is a good treat for rodents. However, this statement has nothing in common with the real state of affairs. Polystyrene foam, as insulation for external brick walls, has proven itself to be excellent even in the most unfavorable conditions.

What to do with rodents?

Mice and rats can also live in glass wool. However, this happens when the building is poorly protected from the same rodents. The sealing of the basement sections of the building was not carried out at an appropriate level. Hence the problem. This means that a really effective solution is to protect the basement parts of the house with a metal mesh, where rodents can get into the insulation, in particular, into mineral wool or polystyrene foam.

Requirements for insulation for interior work

When choosing a heat-insulating material, you need to take into account not only its heat-saving ability. The following qualities are important:

- ease of installation;

- environmental cleanliness;

- non-flammability;

- no harmful emissions when the temperature rises.

With a small area of the insulated room, slab material 50 mm thick plus a ventilation gap will lead to a smaller room. In this case, it is permissible to use penofol, which combines the functions of insulation and vapor barrier.

Important! the foil surface of penofol works to reflect thermal radiation only if there is a gap between the insulation and the finish.

Material selection criteria

To understand how to properly insulate a brick wall from the inside, decide who will install the insulation. Professionals know what materials are combined with each other and how to avoid cold bridges. When doing the work yourself, use a special calculator to calculate where the dew point will be in the insulation pie. It must be moved as far as possible to the outer surface of the enclosing structure. The dew point in the insulation will cause it to become wet and reduce its thermal insulation properties.

Nuances of internal insulation

There are 2 key factors that influence the choice of finish for wall insulation:

- Vapor permeability. Dew point.

The vapor permeability indicator in a residential building should increase from the inside of the surface to the outside. This is explained by the fact that in cold weather the humidity in the room will be higher than in the yard. When leaving the building, moisture passes through all openings and brick walls along with warm air.

If the exterior finishing has a high vapor permeability value, then moisture will leave the building without any problems. Otherwise, it will be retained in the finishing material, which will cause it to deteriorate and deform over time.

It must be taken into account that the vapor permeability of brickwork is extremely low, so the insulating coating should have an even lower value.

The dew point is the area where air condenses as it cools. If the walls are built without a layer of thermal insulation, such a point will be located directly in the finish. Insulating walls from the inside will lead to the formation of a dew point on the inner surface, which causes dampness to form in the home.

External thermal insulation will allow you to warm up all the walls and reliably protect them from moisture. Because of this, experts recommend insulation on both sides of the building.

Scheme of insulation of the internal surface.

How to insulate a brick wall from the inside? Insulation inside a brick house can be carried out using different coatings, which differ in performance characteristics, installation method, external parameters and price. At the same time, some materials are used for interior cladding, while others are used for finishing the house outside.

Types of thermal insulation materials

If the homeowner has basic construction skills, the question of how to cheaper insulate the brick walls of a house from the inside is solved by saving on wages for hired workers. Study the types and properties of modern insulation and do the work yourself.

Mineral wool

An effective heat insulator, produced in the form of plates and rolls. To insulate the walls of a brick house, it is necessary to use slab varieties. Mineral wool in rolls is intended for installation on horizontal surfaces; vertical placement of rolled mineral wool will lead to its slipping and a decrease in thermal efficiency. To insulate walls, choose insulation with a density of at least 35 kg per m3. Advantages of mineral wool:

- affordable price;

- environmental cleanliness;

- non-flammability;

- light weight;

- ease of installation;

- energy efficiency.

Attention! When working with mineral wool, you must use protective clothing, goggles, gloves, and a respirator.

The disadvantages of the material include its dustiness and the need to install a vapor barrier on the side of the warm room. When installed in interior partitions, mineral wool improves sound insulation.

Expanded polystyrene

Lightweight and cheap material with high thermal insulation ability. Has high vapor permeability. The disadvantages include:

- flammability;

- release of toxic substances when temperature rises.

Extruded polystyrene foam does not support combustion, but when heated it emits toxic fumes. The low vapor permeability of EPS allows it to be installed without a vapor barrier film.

Note! Both types of PPS are not recommended for insulating baths, saunas and other high-temperature rooms .

Warm plaster

A cement-based mixture containing additives from expanded clay, perlite, expanded polystyrene and other substances that help insulate brick walls due to their insulating properties. Warm plaster is the optimal answer to the question of how to insulate a corner apartment. The insulating layer of plaster is applied similarly to a conventional mixture, no more than 4-5 cm thick. The absence of cold bridges, ease of application and subsequent finishing will allow you to insulate an apartment in a brick house from the inside.

Insulation for brick walls

Insulation for brick walls

Brick houses have served more than one generation of owners. Despite the high cost of brickwork, people consider brick to be the best building material. The high cost of a house justifies itself over time; brick has practically no drawbacks except for one thing - increased thermal conductivity. Walls 50 cm thick retain internal heat three times less than normal, but then what about thinner ones? The only way out is brick masonry walls with insulation as a prerequisite.

If you did not take care of insulation during the construction stage, the need to perform this work will appear sooner or later. The problem also applies to people who bought a brick house that was built a long time ago, or who live in a brick high-rise apartment. And here the question arises: to apply an insulating layer from the outside or from the inside.

The answer is:

1) it is advisable to insulate brick walls from the outside; 2) use internal insulation when, for some reason, external insulation cannot be done.

External insulation of brick walls

There are a large number of products on the building materials market, among which you can easily find the most suitable thermal insulator for a brick building from the outside:

- Styrofoam;

- mineral wool;

- extruded polystyrene foam;

- expanded clay;

- cork insulation, etc.

|

|

Let's take a closer look at mineral wool - this is the general name for inorganic fibrous materials. It is divided into three groups (slag, glass, basalt) and is produced in rolls and slabs. Basalt slabs are the most high-tech insulation for external brick walls ; they are recommended to be used in work. The raw material for production is natural basalt fiber, which does not contain formaldehyde inclusions. In a home insulated with these slabs, you are guaranteed a reduction in heating costs of up to 50-60%.

Basalt slabs for insulating brickwork outside

In the assortment of TECHNONICOL slabs, pay attention to two positions: Technoblock (for insulation in layered masonry) and Technofas (under a protective layer of decorative plaster). We move on to the TERMOLIFE line and choose Thermolife Cavity (suitable as a middle, i.e., thermal insulation, layer in layered masonry) and Thermolife façade (for external thermal insulation under a thin plaster layer). Similarly, review all commercially available products, read their technical characteristics and choose the right insulation for brick walls, price is a limiting factor for many, but if you have the money, buy products from well-known world brands: Knauf Insulation FRK, Rockwool Cavity Butts (Rockwool facade butts ) and etc.

Working moments

The insulation system for a brick wall based on the principle of layered (well) masonry is used in the construction of a new house. The outer wall has a protective and decorative purpose and is made of facing bricks. The second wall is the main (load-bearing) wall. Between them, in the so-called “wells”, a middle insulating layer is laid.

If the task is to insulate an ordinary brick wall from the outside, then the sequence of actions is as follows:

1) arrangement of lathing from metal profiles or wooden slats, taking into account the length/width of basalt sheets; 2) laying the insulation without gaps and cracks, fixing it; 3) facing work: insulation for brick walls is covered on top with decorative brick (similar to layered masonry), plaster, siding.

In layered masonry, the desired insulation density is from 45 kg/m3 to 90 kg/m3, for plaster – 140 kg/m3, with siding – up to 45 kg/m3 (plus good wind protection).

Internal insulation of brick walls

When insulating a brick wall from the inside, the main problem is how not to make a mistake with the selection of thermal insulation material. Firstly, it must have high thermal insulation properties. Secondly, when insulating from the inside, the useful space of the room is “eaten up” - therefore, you need to buy insulation for brick walls with a minimum thickness. The wall itself, insulated from the inside, does not become warmer and freezes even more. The dew point moves inward. Do not use loose fiber sealants because they absorb moisture and lose their properties.

To cut off moisture, it is recommended to install high-density basalt slabs. Such products cost an order of magnitude more than “light” slabs. Specific recommendations: ROCKWOOL (ROCKWOOL) Panelrock, IZOVOL (IZOVOL) 90, TECHNONICOL Technovent standard, etc. It is even better to use materials based on extruded polystyrene foam with zero water absorption - Styrofoam IB 250 A, URSA XPS. Thermal insulation material PENOPLEX (PENOPLEX) is also ahead of mineral wool in terms of water absorption and is very thin.

Installation features

If the insulation for the walls of a brick house from the inside is a basalt slab, then it is laid behind the plasterboard sheathing. Leave an air gap between the brick wall and the insulation, and then moisture condensation will shift to the cold wall.

Sequence of layers:

- vapor barrier fabric placed on slats attached to the wall;

- frame for placing finishing and insulation in its sections;

- another layer of vapor barrier;

- drywall.

The technology of insulation with penoplex and analogues is quite simple. The material is attached to the walls with dowels, the joints are sealed with adhesive tape. A vapor barrier layer should be created on top - for example, from foamed foil polyethylene. It can be glued with polyurethane foam glue directly to the insulation.

Main stages of installation

Do-it-yourself insulation of a private brick house from the inside begins with installing sheathing to match the size of the slab material. When insulating EPS or EPS, you can use wooden blocks or guides for drywall, installing them at a distance corresponding to the width of the insulation boards. For mineral wool, the distance between the sheathing elements is calculated by subtracting 1-2 cm from the width of the material for a more dense installation of the insulation. If PPS or EPS is chosen as thermal insulation, after installing them it is necessary to foam the cracks, if any. After installing the expanded polystyrene, you need to secure a layer of vapor barrier along the sheathing, gluing the seams with special tape.

Important! Ordinary tape, even double-sided tape, is not a substitute for vapor barrier tape .

When working with extruded polystyrene foam, a vapor barrier is not required. Mineral wool insulation also requires a layer of vapor barrier. The final finishing can be lining or imitation timber. Before installing the wooden planks, it is necessary to secure the counter-lattice for the ventilation gap. When finishing with plasterboard, a ventilation gap is not required.

Note! Penofol can be used as a vapor barrier.

Articles on the topic

How to rebuild a brick house - options, techniques, instructions, advice from masons

Wooden floors in a brick house - types, how to install, instructions, advice from masons

How to lay a foundation with bricks - stages of work, instructions, advice from masons

Cladding the base with bricks - materials, work, instructions, advice from masons

Cladding a house made of aerated concrete with bricks - masonry, disadvantages, instructions, advice from masons

Installing a bathtub on bricks - what materials are used, instructions, advice from masons

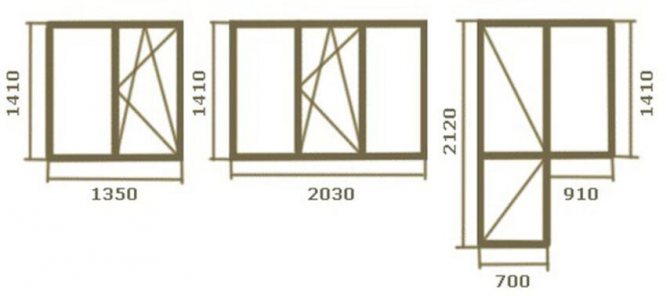

The size of a standard window in a brick house - Brezhnev, Khrushchev, Stalin, instructions, advice from masons

Cladding windows with bricks - options, stages of implementation, instructions, advice from masons

Reviews ()

Advice from professionals

Professionals know the secrets of their craft and are ready to share them with those who insulate the house themselves:

- When choosing insulation, its thickness and installation method, calculate the energy efficiency of the wall pie in accordance with the climate zone.

- When installing the sheathing, control the work with a building level. A leveled sheathing will make it easier to install the finishing touches.

- Use dry lumber.

- Having purchased compressed mineral wool, unpack it a day before installation.

- Follow the manufacturer's recommended vapor barrier overlap.

- Tape the foam joints with aluminum tape.

- Follow the material manufacturer's recommendations.

Internal insulation of the walls of a brick house using vapor barrier materials prevents the removal of moisture from the room. Take a carbon dioxide level measurement. Exceeding the standard indicates low efficiency of the ventilation system.

Sources:

https://www.remotvet.ru/questions/25588-kak-i-chem-uteplit-verandu-so-stenami-v-polkirpicha-iznutri-nedorogo.html https://etokirpichi.ru/zdania/metodika/kak -uteplit-dom-v-polkirpicha.html https://prouteplenie.com/steny/uteplit-stenu-v-polkirpicha https://mastergrad.com/forums/t13017-kak-uteplit-stenu-v-pol-kirpicha / https://strir.ru/uteplenie/kirpichnogo-doma-iznutri

Why do you have to insulate yourself?

The reality of the energy market is that private property owners have to repeatedly decide how to choose the best insulation for a brick house. Saving energy is a very sensitive issue. External insulation of a brick house should be done with carefully selected material, as it can really minimize heat loss.

Among all the methods of creating external thermal insulation, insulation for the walls of a brick house is divided into two types, in which it is possible: creating a ventilated facade and arranging a multi-layer system. They differ primarily in the method and technology of installation, but they all must perform the same task - to protect the house from the cold.