Do-it-yourself insulation of the foundation of a wooden house

The foundation in a wooden house is the main source of heat loss.

Firstly, it is in direct contact with the ground, and secondly, it is made of a concrete monolith or slabs that have a high degree of thermal conductivity, which means that heat will escape from the home through it. Insulating the foundation of a wooden house is a necessary and effective means of combating heat loss. When and how to do it yourself and what materials may be needed? Let's take a closer look. The most optimal moment for insulating the foundation is at the construction stage, when the walls have not yet been erected and there are no rough floors. However, the problem is most often noticed during the operation of the house.

First of all, you need to decide on the method of insulating the foundation - will you do it from the outside or from the inside.

Methods for insulating the foundation part of a wooden house

Insulating the foundation from the outside is most often done using expanded clay, polystyrene or polyurethane foam. The affordable price level of these materials and high thermal insulation capabilities have a direct impact on this choice. Moreover, the likelihood of resolving this issue with your own hands is attractive.

Insulation with expanded clay

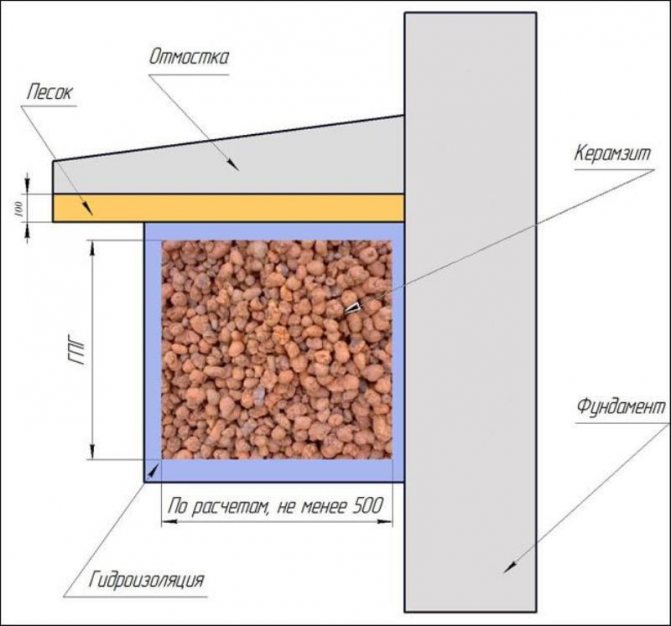

The material absorbs moisture and removes it from the base of the house. In the case of a correctly implemented insulation scheme, an air gap is formed, which is also a good heat insulator. Thanks to this, the likelihood of foundation freezing is minimized. Do-it-yourself insulation of the base of a building with expanded clay involves several stages.

Stage No. 1

When insulating a built house, it is very important to thoroughly clean the surface of the soil. If necessary, cracks should be repaired. Waterproofing can also be carried out.

Stage No. 2

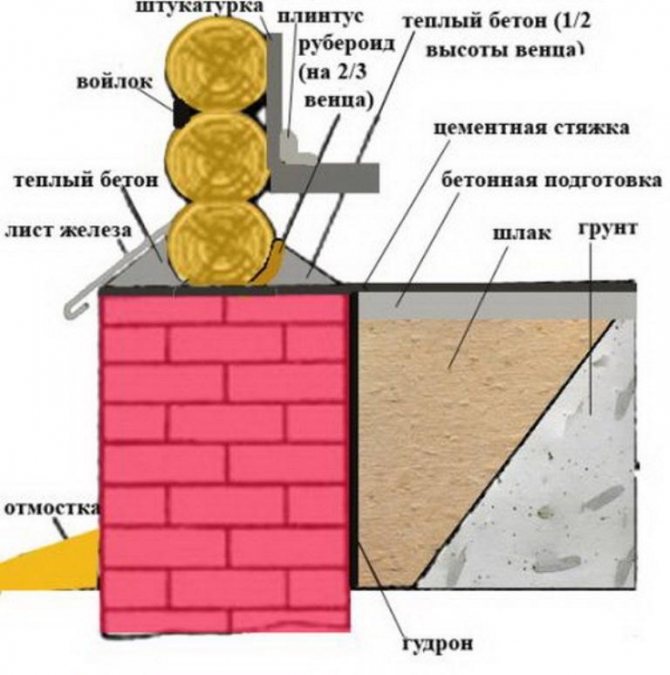

At the next stage, the trench is filled with soil. A small concrete blind area is made on top of the formed embankment. It will protect the thermal insulation material from moisture. The basement part of the base of a wooden house can be insulated by plastering.

Stage No. 3

If necessary, you can also insulate the basement with your own hands using expanded clay. The insulation is poured during the flooring stage. A sand cushion is first prepared, on top of which a layer of waterproofing is placed.

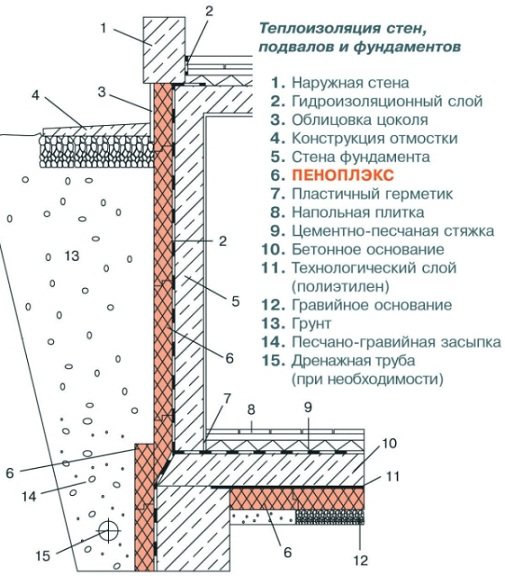

Polystyrene insulation

Polystyrene is presented in the form of a modification of polystyrene foam, characterized by mechanical strength. To achieve the maximum effect of insulation outside the house, it is recommended to give preference to material with fire retardant additives.

- Preparing the foundation. At this stage, the base of the house is freed from soil, dust, traces of oil and bitumen. If necessary, cracks are sealed.

- Installation of polystyrene plates. The insulation is attached to the base of the building using an adhesive mixture. It may take about 48 hours for the material to dry completely.

- Basement insulation. Polystyrene from a wall made of wooden material should be separated by using non-combustible insulation. Basalt wool can be used as such a material.

The main feature of using such insulation is that it is tied to the depth of the material. The larger it is, the higher the quality of thermal insulation will be. To install polyurethane foam you will need to perform a number of steps:

- Prepare the soil.

- Prepare the foundation.

- Waterproof the foundation of the house.

- Installation of insulation.

- Arrange external protection.

At the stage of excavation work, the base of a wooden house is completely freed from soil and excess dirt. For maximum effect, it is recommended to place a sand cushion at the bottom of the trench.

The cleaned foundation must be well primed. This will allow the thermal insulation material to perform its direct functions for the maximum period of time.

The implementation of a waterproofing layer allows you to minimize the likelihood of moisture penetration into the room. Thanks to this, the total service life of the building will tend to increase.

Polyurethane foam is positioned as a sprayed insulation. This structural feature of the material guarantees seamlessness and perfect evenness of the coating. High adhesion to any coating facilitates the issue of arranging external protection for the base.

Important! Polyurethane foam does not tolerate direct exposure to sunlight very well, therefore, if it is used to insulate the base, it is recommended to additionally cover the coating with other materials.

Insulation methods

Before you begin the process of insulating the foundation, you should examine it and decide on the need for this work. In addition, you should check the attic floor and ceiling. Perhaps they are the ones who need insulation. Insulating the foundation of a wooden house from the outside is the easiest way.

In this case, the dimensions of the internal space are not lost, there is no need to move pieces of furniture, and dust and dirt do not form in the premises. In addition, insulation helps protect the basement and subfloor from freezing and ensures their waterproofing. After this, the concrete structure will not be subject to freezing and thawing and will therefore last for many years. External insulation is carried out by pasting the walls with various materials. The most popular of them is polystyrene foam, as it practically does not allow moisture to pass through and retains heat well.

The cheapest type of this material is polystyrene foam. Insulation using extruded polystyrene foam, also called foam complex, is more expensive.

Causes and Effects

Before insulating the foundation of a house, you need to answer a very important question. Why actually do this?

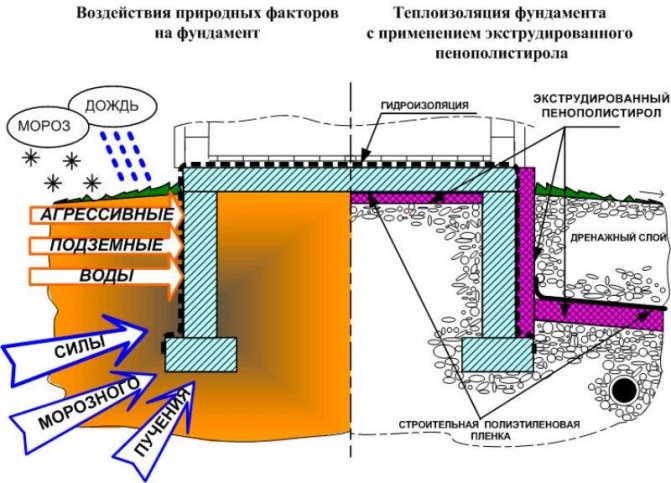

Insulating the foundation from the outside and from the inside gives us a lot of advantages and prevents various unpleasant situations.

To begin with, let us remember that all structures in the house are in contact with each other. The walls are supported by the foundation, the roof is on the walls, there are floors between them, etc.

The thermal conductivity of brick and concrete is not much different. There are some differences in the thermal conductivity of a wooden and brick private house, but they are not significant.

Concrete freezes just as quickly as brick. So why do many people prefer to insulate the floors and walls of a private home, but ignore the insulation of the foundation? Because they do not take into account the process of heat transfer from one structure to another.

All structures in the house interact. They interact with each other to a much greater extent than we might think.

Let's take, for example, a house with a strip foundation and no basement. A strip foundation, even when we are talking about the type of shallow foundations, also needs insulation. Without insulation, it will freeze and then transfer its temperature to the walls. The temperature of the walls will drop, which will immediately affect the temperature inside the room.

Freezing of the foundation strip will also affect the temperature of the floor of a wooden or brick private house. The temperature of the floor depends on the temperature of the soil underneath or the temperature inside the basement.

If the soil has cooled down greatly and also begins to freeze, and without high-quality thermal insulation of the base it will certainly begin to freeze, then this will immediately lower the temperature of the floor, which, of course, we would like to avoid.

Owners of private houses made of wooden beams simply need insulation. Since it is very important for wooden beams to maintain normal temperature conditions and protect the structure from contact with water.

No less important is the insulation of the strip foundation if the design of a private house inside involves the construction of a basement. The condition of the air in the basement directly depends on the thermal insulation of its walls. And the walls of the basement in most cases are the walls of the foundation.

Polystyrene insulation

Polystyrene is a modification of polystyrene foam. Its main advantages are resistance to getting wet and special strength. Today, this material is presented on the market with different density and thickness parameters. Therefore, choosing the right one will not be difficult.

Its main drawback is its flammability, which is dangerous for wooden buildings. Therefore, it is used only for the underground part of the foundation. Therefore, it is recommended to use polystyrene with fire retardant additives for the base. The foundation is insulated in the following order:

- The foundation is cleaned of soil and dust residues, as well as traces of bitumen and oil. Otherwise, the material may lose its thermal insulation characteristics. If necessary, repair work on the surface should be carried out using coating waterproofing.

- The boards are glued using special glue. Apply it along the edges at several points. The polystyrene is then kept in air for a minute, then pressed tightly to the surface of the foundation. The splits are glued by aligning the mounting grooves on them. The glue dries within two days. After this, you can fill the underground part of the foundation.

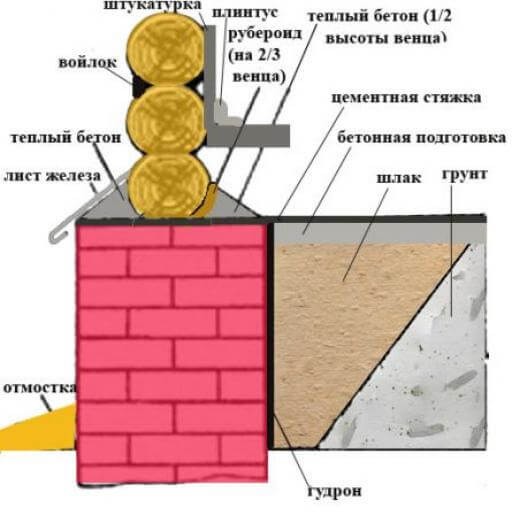

- Insulation of the base of a wooden house is carried out according to the same scheme, only using a layer of basalt wool. It is laid on top of the base using a strip 15-20 centimeters wide. After the plates are glued and the glue has dried, it will be necessary to secure them additionally using special dowel nails. To do this, drill holes into the concrete and hammer in the dowels until their heads are completely seated.

Polyurethane foam insulation is a new popular technology. The high cost of insulating the foundation in this way is due to the use of a special spraying installation and the payment of specialist labor. However, the costs will be more than recouped due to excellent thermal insulation. The foundation will need to be cleaned of dust and damaged areas repaired. This insulation method is used both outside and inside the building.

Insulation with expanded clay

One of the long-standing popular methods of insulating the foundation of a wooden house is using expanded clay. This material is perfect for underground and underfloor areas. The essence of the process is to create a cushion that will absorb and remove moisture thanks to the air space at the surface of the foundation.

Air is an excellent heat insulator. Therefore, the use of expanded clay reduces the risk of foundation freezing. In addition, this material acts as waterproofing. How to insulate the foundation of a wooden house using expanded clay? The step-by-step process is as follows:

- The foundation is dug out to its full depth and cleared of dust and soil. If necessary, cracks are sealed with cement mortar, and the surface in places of destruction is leveled. For additional waterproofing, coating or pasting is used.

- The resulting trench is filled with expanded clay to the ground level. Afterwards, a concrete blind area is made to protect the expanded clay from moisture and siltation. The basement part is insulated with slabs or by plastering.

Materials used for foundation insulation

How to insulate the foundation of a house? The following materials are currently widely used to insulate the foundation of a wooden house:

- Expanded clay. This material is very popular due to its relatively low cost. When insulating with this material, a cushion is created directly next to the foundation, which absorbs and removes moisture well from the foundation, due to which an air layer is created near the surface of the foundation. The presence of air is what ensures a good level of thermal insulation of the foundation and reduces the likelihood of freezing. In addition, expanded clay acts as a waterproofing agent.

- Foam plastic (polystyrene, penoplex). Plates made from these materials are durable and resistant to getting wet. Despite the fact that these materials are fire hazardous, when insulating the foundation, their use is recommended for thermal insulation of the underground part of the base of a wooden house. The above-ground part of the foundation (basement) should be insulated using polystyrene slabs with fire-retardant additives.

Polyurethane foam. Insulation by spraying with this substance is very popular at present, however, it is still quite expensive, since expensive equipment is used to apply this material. At the same time, it should be taken into account that the efficiency of using such technology is very high. Due to the complexity of the work, it is necessary to contact specialists to carry it out. This type of insulation is carried out both outside and inside.

Insulation of the foundation using expanded clay

How to insulate the foundation of a house from the outside with expanded clay? To carry out insulation using this material, the following measures must be taken:

- It is necessary to dig out the foundation along the perimeter to its full depth, and clean its surface from contamination (dust, soil).

- Carry out repairs. If cracks appear, they must be repaired with cement mortar.

- Carry out waterproofing measures.

- Fill the trench with expanded clay and make a concrete blind area on top.

- The base is insulated using slab materials or plastering.

How to insulate the foundation of a house inside? In addition to insulation from the outside, insulation with expanded clay is also carried out from the inside of the house. To successfully solve this problem, an expanded clay cushion is formed into the semi-basement spaces, before laying the subfloor (expanded clay is poured onto a layer of sand covered with film waterproofing).

How to insulate the foundation of a wooden house if you have to save money? Sometimes they don’t do a continuous backfill under the house, but in order to save money, they form an expanded clay cushion around the perimeter of the foundation from the inside. To carry out the work in this case, formwork is made and expanded clay is poured into the space between the surface of the foundation and the formwork. It should also be noted that before starting insulation work, it is necessary to waterproof the foundation of the house.

Insulation of the foundation with foam plastic boards and polystyrene foam

How to insulate the foundation of a house with polystyrene foam? To carry out the work, do the following:

- Before insulating the foundation of a house, it must be carefully prepared - freed from various contaminants, including traces of bitumen and oil, otherwise polystyrene will not be able to fully perform its heat-insulating function.

- The foundation is repaired and waterproofed using coating waterproofing.

- To install polystyrene boards, special glue is used. The plates are combined, fixing the tight contact of the mounting grooves.

- The glue must dry well, for which you should wait 2 days.

- The foundation is backfilled.

- To insulate the basement, you must first cover the wooden structures of the house with non-flammable insulation. As a rule, basalt wool is used for this purpose. Then you need to strengthen the polystyrene foam boards using glue and wait until it dries. Finally, the insulation boards are secured with dowel nails.

Expanded polystyrene has a very wide range of applications. It is characterized by high water absorption, vapor permeability, biological stability, durability and preservation of properties when exposed to solvents. To reduce the fire hazard of expanded polystyrene during its manufacture, substances are added that reliably protect it from ignition. External insulation is considered more rational and effective.

How to insulate the foundation of a house with polystyrene foam? To carry out such work it is necessary:

- strengthen polystyrene foam slabs on the surface of the foundation to the depth to which the soil freezes,

- it is especially necessary to insulate the corners of the foundation, so the thickness of the thermal insulation in these critical places should be 1.5 times greater,

- after waterproofing, the polystyrene foam slabs are glued from bottom to top (the glue should not contain solvents; apply the glue to a dry surface),

- After gluing the insulation boards, to ensure reliability in the ground part, it can be secured with dowel nails.

Thus, before insulating the foundation of a wooden house, you need to choose the material that will create the best conditions for creating comfortable conditions in the house. It is also necessary to carefully calculate the amount of thermal insulation material, purchase special glue if you plan to use polystyrene foam or expanded polystyrene, and also buy dowel nails to securely fasten the insulating boards to the ground part of the foundation. After completing the foundation insulation work, you can finish the house with siding - this will be another barrier against heat loss from the home.

Additional recommendations

Insulation of the semi-basement space. This measure is effective enough to insulate floors. Expanded clay is poured during the process of laying or replacing the subfloor. To do this, first make a sand cushion, and on top - film waterproofing. Expanded clay is poured over the film.

To save material, backfilling is not carried out over the entire area of the room, but only along the inner perimeter of the foundation. In this case, wooden formwork is used. It is firmly fixed with struts, and then expanded clay is poured between the foundation and the formwork.

Why do experts not recommend insulating the foundation from the inside? The fact is that this can only be done if there is good ventilation in the basement. In addition, internal insulation can shift the dew point, as a result, the foundation will begin to collapse from exposure to cold and moisture.

Insulation in the basement increases humidity, which can only be removed by ventilation. And these are additional costs. In addition, part of the usable area will have to be used for the “pie”.

If it is impossible to do without internal thermal insulation, then it is recommended to use polyurethane foam for these purposes. It will provide maximum protection from moisture. In any case, without insulating the foundation, you risk getting a damp and cold first floor.

In addition to insulating the foundation of a wooden house, insulation of external walls is also required, which is described in detail in this article. We talk about insulating the walls of a house from the inside here.

How to insulate the foundation of a wooden house with your own hands

Preface . All structures of residential and industrial premises should be thermally insulated. A layer of insulation will not only save heat during the cold season, but will also protect building elements from freezing, increasing the service life of structures. Let's consider how to properly insulate the foundation of a wooden house, and what materials should be used. At the end of the material, watch the video instructions for insulating the foundation.

How to insulate the foundation of a wooden house from the outside or inside depends mainly on the design of the base. External and internal insulation have their advantages and disadvantages. For example, insulating the foundation of a wooden house from the inside with your own hands will cost less, but this will not save the concrete from freezing. External insulation will extend the life of the structure and protect the concrete from temperature changes.

Alternative insulation option

Scheme of foundation insulation with expanded polystyrene from the outside of the foundation.

In order to insulate the foundation of a wooden house from the outside, expanded clay is often used, but after materials such as polystyrene and polystyrene appeared, they began to supplant the first method of insulation. It is worth noting that the method of work in which expanded clay is used is almost no different from the one in which polystyrene foam is used, however, there are still differences between these methods.

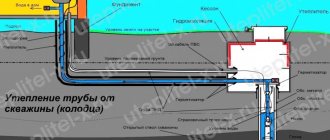

Thus, insulating part of the foundation of a wooden house involves constructing a wide pit (1 m). After the trench has been prepared, you can proceed to the installation of the waterproofing layer. The next layer will be expanded clay, which must be filled in in sufficient volume, this is due to the poor thermal conductivity of the material. Next comes the waterproofing layer, which is used as roofing material; it must be sprinkled with earth or sand.

Insulation can also be done using penoplex; this insulation has a closed porous structure that is not capable of allowing water to pass through. One of the main advantages of this material can be considered resistance to water. Other qualities include water resistance, strength, and low thermal conductivity. A week after waterproofing the foundation, you should begin to insulate it with penoplex.

Installation of the slabs can be carried out without gaps, since penoplex has special grooves for fastening. Insulation is carried out using an adhesive bitumen composition. In this case, the glue should be applied to small areas, doing this gradually. It is important to remember that each slab must be pressed tightly against the foundation and must be held for 5 minutes.

Is it necessary to insulate the foundation of a wooden house?

How to insulate the foundation of a wooden house

We’ll answer right away that, of course, it’s worth it, since no one likes it when the floor is cold and cold air blows down their legs. If the foundation of a wooden house is not properly insulated for the winter, then the cost of heating the premises will increase many times over, not to mention the cold floor on the ground floor. At the same time, even insulating the window sills for the winter will not help to maintain proper heat in the house.

It is important to know that waterproofing and insulating house structures is an important point during construction. In addition, it is important to know how to insulate the foundation of an already built private house. When solving this issue, the first thing you need to do is choose moisture-resistant thermal insulation. It is best to choose penoplex material characteristics - high density, moisture resistance and long service life.

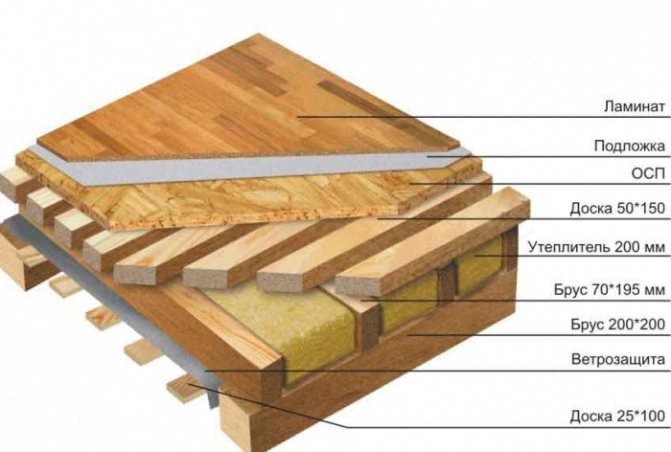

Pile foundation

How to insulate the foundation of a wooden house on stilts? For a pile foundation, as for a columnar foundation, a fence is built - an imitation of a base, closing the space between the piles. This will already reduce heat loss to some extent. For effective thermal insulation of a pile foundation you need:

- arrange a basement,

- insulate it inside and out,

- insulate the floor.

You can build a thin brick wall around the perimeter, or you can use slab materials that are attached to the sheathing. If you choose the option with a brick wall, you need to pour a shallow concrete strip 20 cm thick on which the wall will be built. It is not necessary to use ceramic bricks; you can take foam blocks or foam glass.

Important! The space under the floor should not be sealed. After installing the intake, vents must be made in it - ventilation holes measuring 10-15 cm. They are placed evenly on all sides of the house so that they are opposite each other.

To fasten panels or slabs, a sheathing is made from a metal profile or wooden blocks. For example, DSP can be used as outer cladding. There are already insulated facade panels that perform decorative and thermal insulation functions.

A shallow trench is dug under the casing, into which a layer of sand (2-3 cm) is poured, expanded clay is placed on it, and the trench is covered with earth on top, so that there is no gap between the soil and the casing.

The video shows the structure and insulation of the false base:

To insulate a pile foundation, use

- expanded polystyrene,

- Styrofoam,

- foam glass in blocks,

- liquid penoizol (urea foam).

The first two options are most often used. Foam glass is too expensive for a private home, and liquid foam insulation requires special equipment or the work of specialists, which is also expensive. It’s easier to insulate the foundation of a wooden house with your own hands using polystyrene foam or expanded polystyrene from the outside. The main thing is that the material does not absorb water, so mineral wool will not work here. The foam is glued to the adhesive foam; for reliability, you can use additional wooden planks, which are attached with self-tapping screws to the sheathing through the foam.

Important! It is advisable to attach polystyrene foam or polystyrene foam to the guides, and not between them. In this case, there will be no gaps or cold bridges, since the thermal conductivity of wood, and especially metal, is greater than that of foam plastic.

You can insulate a pile foundation with polystyrene foam or EPS from the outside or the inside. If this is done outside, then the insulation is attached before finishing. If the finishing is already attached to the base, for example, if these are facade panels or DSP boards, then the insulation is mounted from the inside.

Floor insulation

To insulate the floor in a wooden house on a pile foundation, I usually use mineral wool, basalt wool, expanded polystyrene, foam plastic, and liquid insulation.

Thermal insulation is done during the construction and installation of the floor as follows:

- They make a subfloor on which the insulation will lie.

- A vapor barrier and windproof layer is first placed on the sheathing.

- Then they put insulation.

- Vapor barrier and waterproofing are placed on top.

- After this, a finishing floor is constructed.

The layer of mineral wool must be at least 10 cm. If it is necessary to lay wool in two or more layers, this is done in a checkerboard pattern (so that the seams do not coincide). The video shows floor insulation in a house on a pile foundation.

For waterproofing, you can use glassine, polyethylene, isospan, and wind- and moisture-proof film. Polyethylene is the cheapest option, but it is not the best.

Important! In a wooden house on a pile foundation, it is imperative to treat all wooden floor elements with an antiseptic.

The insulation of a columnar foundation differs little from the insulation of a pile foundation; the same materials and techniques are used.

How to insulate the foundation of a wooden house

Photo. Insulation of the foundation of a wooden house

The density of modern thermal insulation ranges from 50 to 98%. To calculate the thickness of the insulation layer, the thermal conductivity of the material is taken, determined by the thermal conductivity coefficient λ - this is the amount of heat passing through 1 m3 of material in 1 hour with a temperature difference of 10 degrees on different sides. It is also important to take into account the frost resistance and vapor permeability of thermal insulation.

Water conducts heat well, so if the insulation absorbs moisture, the thermal conductivity of the material will increase. For this reason, water-absorbing materials must be protected from moisture. Glass wool and mineral wool are popular materials, but require high-quality waterproofing when insulating. Extruded polystyrene foam is stronger than polystyrene foam, durable and has low water absorption.

Insulation of the foundation of a wooden house from the outside

Insulation of the lower crowns of a log house in a house

Photo. Insulation of crowns using a fillet

If there is no basement in the house, there is nothing left to do but fill the foundation from the inside, insulate the floor on the first floor and make a pile. In the old days, log houses were insulated by filling the lower crowns of a wooden house. The huts were placed on poles at the corners of the log house, and formwork was built at a distance of half a meter from the walls of the house, which our ancestors covered with earth mixed with sawdust or straw.

If a wooden house stands on a columnar or pile foundation, then it is recommended to immediately fill the foundation with heat-insulating material (soil or expanded clay) up to the floor level. Do not forget that all wooden structures must be treated with an antiseptic or mastic. Let us next consider the insulation of the foundation of a wooden house with polystyrene foam and penoplex.

Insulating the foundation of a house with penoplex

Photo. Insulation of the foundation and blind area of the house

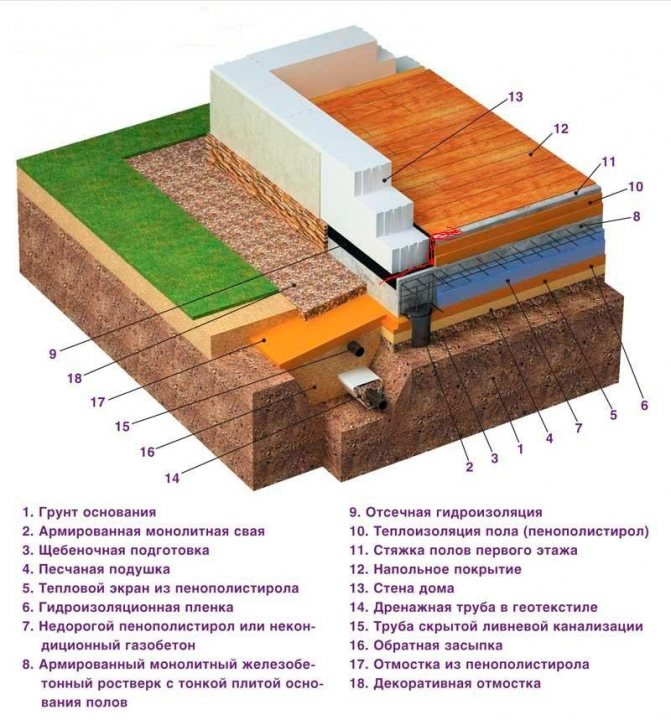

If the house has already been built, then to insulate the foundation, you need to dig a trench around the perimeter of the walls, and then you need to apply liquid waterproofing to the concrete. If a strip foundation is being insulated, then the thermal insulation layer should be at ground level; you can also make an insulated blind area around the house.

If you decide to additionally make an insulated blind area around the perimeter of the house, then the device technology is as follows. First, you need to make a trench about 0.5 m wide around the perimeter of the house. Rolled waterproofing is laid in the trench and penoplex or expanded clay is laid. A concrete blind area is poured on top or paving slabs are laid with a slope away from the house. For more details, see the article How to make an insulated blind area.

Insulation of the foundation of a wooden house from the inside

Internal thermal insulation of structures is much cheaper, however, the foundation will not be protected from freezing during the cold season. Freezing of the structure can lead to freezing of the soil and deformation of the concrete. Internal thermal insulation can be made using penoplex, expanded polystyrene, expanded clay or mineral wool. The thermal insulation layer can be sheathed with PVC panels, chipboard or OSB sheets.

Insulation of the foundation of a house with expanded clay

Filling the foundation from the inside can be done both in a house under construction and in an already built house. To insulate the foundation of a wooden house for the winter, you can do it with a shallow foundation. To do this, you should fill the soil in an even layer in the basement, and expanded clay can be sprinkled in a small layer. Or pour only a small formwork up to half a meter wide around the perimeter of the foundation.

Insulating the foundation of a house with mineral wool

If the walls in the basement are concrete, then you should first waterproof the surface and lay a vapor barrier material. Then a frame is made on the vertical structures of the foundation and basement for laying URSA mineral wool. The basalt insulation slabs are laid closely into the frame, and then the entire structure and mineral wool are covered with a vapor barrier with the smooth side facing inward.

Materials and technology for external insulation of the foundation of a wooden house

To insulate the foundation of a wooden house from the outside, the following are most often used:

- Expanded polystyrene, regular (foam plastic) or extruded (penoplex);

- Expanded clay;

- Polyurethane foam.

The choice of the type of material depends on the type and material of the foundation itself, the amount of money you can allocate for its insulation, as well as other factors, for example: soil water content or groundwater level. Thus, the methods of insulating strip and column foundations may differ, both in the choice of insulation and in the technology of work.

As for cost, the most economical option is insulation with slabs of ordinary polystyrene foam (foam), and the most expensive option is polyurethane foam. But, on the other hand, the cheapest option will not always be the most reliable.

Each of the above materials has its own pros and cons, as well as features of the technology for insulating the base of a wooden house. In order to choose the best option, we will consider them in more detail using the example of insulating a strip foundation.

Insulation with polystyrene foam

Insulating the strip foundation of a wooden house from the outside with polystyrene foam boards is currently one of the most popular solutions. This is explained both by the relatively low cost of the insulation itself and by the simplicity and ease of working with it. Expanded polystyrene or polystyrene foam is an elastic synthetic material in the form of plates of different thicknesses (1-10 cm), having a granular structure. It is air and moisture permeable, breaks and crumbles easily. Moreover, the lower its density, the more pronounced these features are.

To insulate the foundation, it is best to choose denser foam (density 25-35). The dimensions of polystyrene foam boards are usually 50x100 cm.

Polystyrene foam is flammable (except for some of its varieties, which contain fire retardant additives) and although this is not a particular drawback for foundation insulation, this feature must be taken into account when insulating the foundation base. It is best if such insulation is isolated from the lower crown with a layer of 10-15 cm of non-flammable heat-insulating material (for example, mineral wool).

External foundation insulation with foam plastic during house construction

Rice. 1 External insulation of the foundation during its construction

The technology for insulating the foundation of a wooden house from the outside with polystyrene foam is quite simple. If the house is just being built, then this work can be done simultaneously with pouring the foundation. To do this, the width of the formwork is made larger taking into account the thickness of the insulation, which is calculated and selected depending on the construction zone and is most often 3-5 cm. Before pouring concrete, foam plastic slabs are installed inside the formwork, on a sand and gravel cushion, along the outer perimeter of the foundation.

Types of foundations and methods of their insulation

A wooden house can have different types of foundation, each of which requires compliance with rules for insulation. Thus, when building a wooden house, as a rule, a shallow foundation is built, this is due to the insignificant weight of the buildings, while the foundation itself rests on the surface of the upper soil layer. Such a foundation is made using concrete or brick. A shallow foundation, in turn, can be of a slab or strip type; for this reason, the shrinkage of the structure occurs quite evenly.

When insulating such a foundation, it should be borne in mind that if the insulation has a width exceeding the depth of soil freezing, in this case a layer of soil will form under the insulation that does not freeze, and the insulation should be located at a distance of 1.5 m.

A columnar foundation is mounted from pillars that are dug to a depth of 2 m, below the freezing level. It is much more difficult to insulate such a foundation; to do this, it is necessary to install a massive base and carefully insulate the floor directly in the house.

In order to insulate the foundation of a wooden house, it is preferable to use polystyrene. If we compare this material with other insulation materials offered on the modern market, it will turn out to be somewhat more expensive, but more reliable, since it is fully capable of covering the surface without forming unwanted seams and unnecessary gaps. Insulation is often done using foil foam, since it is easy to achieve the desired effect with its help.

The pile foundation of a wooden house must also be thoroughly insulated. Extruded polystyrene foam, made in the form of slabs, can be used as a thermal insulation material; a foamed form of this material can also be used. Thermal insulation boards and waterproofing material should be laid under the base of the grillage. When used, slab material requires a three-layer layer between a bed of sand and crushed stone and the base of the slab. The strip foundation of a wooden house is insulated to its full depth using polystyrene foam boards. In order to install them, you should use plastic dowels, as well as special adhesive mastic. These two methods of fastening insulation should be used together, as their use will increase reliability during installation.

Insulation of a columnar foundation of a wooden house

Sometimes light wooden houses are built on a columnar foundation. How to insulate such a foundation from the outside? Firstly, you can arrange fences between the pillars - partitions that cover the space between them. They can be made of various materials: wood, brick, insulation boards. To install a fence between the pillars, a trench 30-40 cm deep must be dug at the bottom of which a gravel-sand cushion is placed.

When installing a wooden fence, vertical bars are attached to the posts, and edged boards 40-60 mm thick are attached to them. The lower part of the intake to ground level is covered with expanded clay. All wooden elements must be treated with an antiseptic.

When using a brick pick-up device, it is laid on a leveled and compacted pad in the form of a half-brick wall with cement mortar. Expanded polystyrene slabs (foam plastic or penoplex) can also be used for the collection device. They are attached to a metal frame made of profiles mounted between the posts.

If there is a need, after installing the fence, its external insulation can be performed along with the pillars along the outer perimeter of the foundation. This can be done with slab insulation or by spraying polyurethane foam, similar to insulating a strip foundation.

Technology of external insulation of the foundation of a wooden house

Insulating the foundation of a wooden house and insulating the basement from the outside will not only protect the foundation of the house from the negative effects of seasonal temperature changes, freezing, and groundwater, but will also help you reduce heating costs, because on average, about 25% of the total heat loss occurs at the foundation of the building.

Insulated columnar foundation of a wooden house

From this article you will learn how to insulate the foundation of a wooden house, what material is best suited for this, as well as the features of doing all the work yourself, both for strip and column foundations.

Video - Insulating the foundation of a house

Recommended viewing:

- Autonomous sewage system at home - comfortable conditions in the house and protection of the natural environment - 12/09/2014 09:53

- Construction of a porch of a wooden house - design of the front entrance - 02/09/2014 07:07

- Geodetic work on the site - determining the parameters of the site for construction work - 08/31/2014 12:06

Related topics:

- Carrying out land surveying - determining the exact boundaries - 08/27/2014 11:47

- Interior decoration of a wooden house - materials for implementing design ideas - 08/26/2014 07:18

- Drainage system of a private house - removing excess moisture from the house and from the site - 07/08/2014 04:48