During the cold period, panel buildings are subject to freezing and condensation accumulation.

The problem is worse in regions with harsh winters and adverse weather conditions. The only solution is to insulate the external walls of a panel house.

Insulation of a panel house is required quite often.

Features of insulation of external walls of a panel house

Insulating the facade is considered a more justifiable action than installing insulating materials inside the house.

Experts explain this with several nuances:

- The dew point moves towards the insulating layer. As a result, moisture does not accumulate in the panel, and the likelihood of mold formation is eliminated. In winter, condensation freezes, so the service life of concrete walls increases.

- Fastening the insulation to the outside of the building allows you to save usable space in the room.

Internal thermal insulation work prevents effective heating of the room. This contributes to the appearance of microcracks and mold. The problem is aggravated in corner apartments, which are subject to strong gusts of wind and temperature fluctuations.

When insulating walls from the inside, moisture can accumulate on the surface, which contributes to the gradual destruction of concrete slabs and damage to the material by fungus.

What is the difference between internal wall insulation in an apartment building and external insulation?

The walls of any high-rise building can be made warm not only from the inside, but also from the outside. It is much more common to find insulation of façade walls internally than externally - it is believed that the former is more justified. For now, let’s leave this point of view unanswered and just say that there are cases when it is possible to create only internal facade insulation, which, like external insulation, has its own individual advantages.

Insulating walls in an internal high-rise building allows you to solve the problem of heat conservation with great efficiency. The creation and organization of internal heating in any apartment building should be incredibly precise - even the slightest miscalculation can lead to the facade wall and insulation starting to get wet. If this happens, the formation of dampness and, subsequently, mold will begin, and as a result, the durability of the walls and the energy-saving properties of the insulation will decrease.

This is what classic spot insulation of an apartment building looks like

Insulating the walls of an apartment building from the outside of the façade type has other disadvantages:

- Instant cooling of the facade and walls

- Reducing room space

- Mandatory freezing of walls

- It is necessary to create hood systems

- During facade insulation you will have to leave the apartment for a while

Lots of shortcomings, isn't it? What are the strengths of internal facade insulation, and there are quite a lot of them.

Advantages of internal type of insulation:

- High-speed wall heating

- Possibility of self-insulation, but with full and, accordingly, sufficient qualifications of a home craftsman

- Internal façade wall insulation can be done directly during renovation

- An excellent solution if it is prohibited to change the existing historical appearance of the building

External facade wall insulation has a number of strengths:

- The heat will remain much longer

- The room will maintain a constant temperature - in winter and summer

- The insulation becomes a protective layer and protects the walls from harmful external environmental influences

- The space and area of the apartment is not reduced

- During facade insulation procedures, you can continue to live in the apartment (insulation of the walls of an apartment building from the outside is not carried out in one day)

Disadvantages of external facade wall insulation:

- It will not be possible to carry out the work and do the external façade insulation on your own as you will need climbing equipment

- External façade wall insulation is often unacceptable (more on this later)

- Insulation of external facade walls always changes the appearance of the house.

Of course, if measures to insulate the facade are carried out on an old Khrushchev building, then the facade will ultimately benefit - it will become stylish and bright. Another thing is that not in every case it will be possible to find a consensus with neighbors. If the residents of a multi-storey building have not reached a general agreement, the external insulation will have to be carried out in fragments - the result may be something like a mosaic.

See also: How to properly paint or paint walls

Sometimes insulating the roof of a private house is much more difficult than insulating an apartment building

Choosing insulation

When choosing a suitable thermal insulation material, a number of criteria must be taken into account:

- Placement of panel construction and climatic conditions in your area.

- Average precipitation, wind strength and speed.

- Financial possibilities for purchasing an insulator.

The list of necessary materials and a project for the upcoming work should be compiled by the company managing the premises or the community of home owners. Thermal insulation is carried out by specialists with professional mountaineering skills.

Styrofoam

The material is light in weight and easy to work with (attach to the wall surface). In addition, it provides good noise and heat insulation and is not afraid of moisture. The service life reaches 30-50 years.

Foam plastic is a cellular insulation obtained by foaming polymer raw materials.

Only those foam models that are not subject to spontaneous combustion are suitable for work. They are marked G1, indicating low-flammable products.

When choosing, it is important to clarify the product’s compliance with GOST requirements and availability of certification.

The foam is attached to the walls using dowels or an adhesive mixture. Often, specialists combine 2 methods in order to obtain a strong fixation.

The disadvantage of polystyrene foam is the release of harmful substances during combustion. In addition, the plates are afraid of mechanical damage and ultraviolet radiation.

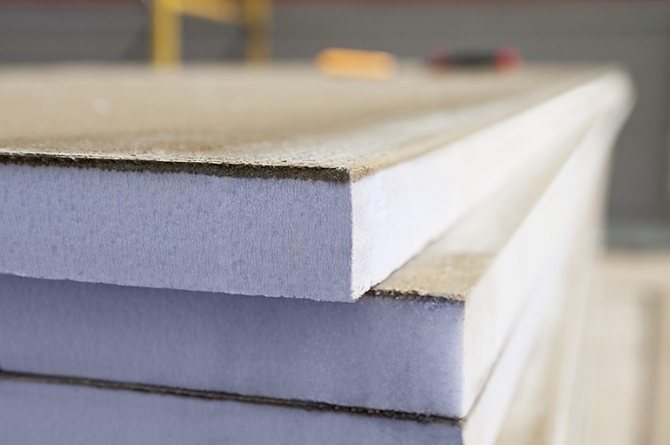

Expanded polystyrene

Extruded polystyrene foam has the same degree of sound insulation as polystyrene foam. At the same time, it is 4 times denser, which increases the efficiency of insulation.

Expanded polystyrene is successfully used to solve various construction problems.

The material has become widespread due to its versatility - it can be used for thermal insulation of any structures, insulating roofs, walls, foundations or basements. The canvas does not absorb condensation, so it does not swell or shrink. When interacting with chemicals, the slab is not destroyed. In terms of the degree of thermal insulation of a building, it is 1.5-2 times better than foam plastic or glass wool.

The insulation contains no formaldehyde, so the slabs do not emit a harmful odor during operation. Additional advantages include quick installation and a service life of up to 50 years.

In this case, the porous material can be attacked by rodents, which build passages and make holes in the pores.

When exposed to high temperatures, polystyrene foam quickly ignites.

Mineral wool

Mineral wool is one of the most common insulation materials for panel houses. There are 4 main types of this material:

- Glass wool.

- Slag-like.

- Stone wool.

- Basalt wool.

Mineral wool is a convenient material for insulation.

The fiberglass-based material is elastic and durable. When fastening the slabs, you must take care of personal safety equipment by wearing overalls and a mask.

Less commonly, panel houses are insulated with slag wool, since it is not highly heat resistant. To achieve the required results, a thick insulating layer must be laid.

If you want to maintain the breathability of the walls, you need to choose stone wool.

The basalt variety does not contain harmful impurities and does not ignite when the temperature rises to +1000°C. It can be used to insulate private houses.

The disadvantages include the need to pre-treat the material with a water-repellent composition in order to reduce moisture absorption. Mineral wool weighs more than polystyrene foam, which increases the cost of services for the transport company delivering it to the site.

Penofol

Penofol is a complex thermal insulation material, which is made on the basis of foamed food grade polyethylene and polished aluminum foil. The insulation is characterized by high moisture resistance, good absorption of vibrations and sound vibrations, as well as safety for the environment and the body.

Penofol is a two-layer heat-insulating building material.

But due to excessive elasticity, the material cannot be finished with plaster or paint. In addition, specialists may have difficulty fixing the layer, because existing adhesive mixtures do not stick to polyethylene foam. The problem is eliminated by choosing varieties of penofol with a self-adhesive surface.

Cork

Insulation is available in the form of rolls or slabs. The bark of natural cork (a special type of Mediterranean oak) is used as the raw material for production.

The material is environmentally friendly and safe for health, has good sound and heat insulation, is small in thickness and invulnerable to rodents. In addition, it can be used as a topcoat that does not need to be finished.

Cork is a unique material whose structure includes millions of tiny pores.

The negative aspects are manifested in the need to carefully prepare the surface for laying the slab, which increases the cost of the work. High-quality cork costs 2-3 times more than artificial analogues. The price for a sheet measuring 1 m² and 3 mm thick is 630 rubles.

Advantages of external wall insulation

Many people prefer to do internal insulation. However, this method is ineffective. Not only does the useful space decrease, but also the insulation used can contribute to the development of an allergic reaction in a person. It is simply impossible to stay in the apartment during renovations, so you have to look for temporary housing for yourself and your family. It is worth agreeing that not everyone has such an opportunity. Another drawback of interior work is that insulation insulation insulates the wall from the heating system and the dew point (moisture condensation) shifts into the insulation. This leads to constant accumulation of moisture, resulting in the formation of fungus and mold, which negatively affect health. It is for this reason that a panel house is best insulated from the outside.

Advantages of outdoor work:

- heat savings are more than 50%;

- the living area is not subject to change;

- the wall is protected from freezing and thawing;

- the panel house becomes more durable;

- no need to look for another place to live during renovation;

- insulation materials used for work also serve as sound and insulators.

Insulation methods

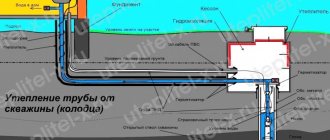

Various methods and materials are suitable for external wall insulation. Often, to thermally insulate a facade, it is only necessary to finish the external seams, and not to lay the sheets. Also, a layer of waterproofing is immersed in the voids between the concrete slabs, which prevents the passage of moisture.

The main methods of fixing insulation include gluing sheets or installing using dowels and other fasteners. Work on further finishing of the insulated surface begins a few days after the material adheres securely to the wall.

When using the mechanical method, it is better to purchase fungi based on plastic sleeves. You need to make holes for them and cover the heads with plaster.

Various methods are suitable for external wall insulation.

Technique for facade insulation of an apartment building

There are two different approaches to insulating facade walls:

- Wet insulation (also called wet facade) - this technique involves fixing the insulation directly to the facade walls of the home. After attaching the heat insulator to the walls, an armored mesh is placed on it. Then a layer of plaster is applied on top and the spilled surface is simply painted over. Insulation using the wet facade technique can be carried out exclusively in dry weather in the summer. All installation work takes approximately 3-4 days, and the lifespan of such a façade is more than 25 years, but additional measures are required to maintain the health of the façade - these must take place every 5 years.

- Ventilation insulation - this technique is more expensive in terms of financial investments. But it is more reliable and efficient. Its principle is simple - a small metal frame is fixed to the insulated wall, and a layer of insulation is placed in it. After this, the finishing is fixed on the resulting foundation. A small gap is formed between the external façade finishing and the heat insulator, which allows you to insure the wall against the appearance of fungus and mold; this happens because, thanks to the gap, moisture does not accumulate. External insulation of the walls of an apartment building from the outside according to the ventilated facade technique can be different from a visual point of view, in contrast to wet insulation, which involves the use of only classic plaster followed by painting. A ventilated insulation façade can be created using siding, panels and other finishes. Properly done insulation using ventilated facade technology can ultimately last up to 60 years.

See also: What is the name of the grid for photos on the wall?

Either of these options requires skilled climbers to work at heights. And high-quality facade lifts in Novosibirsk, for example, need to be chosen from trusted companies whose documentation and quality will meet all requirements.

The best insulation is that which is carried out not only from the outside, but also from the inside.

How to choose a material for creating insulation for facade walls

In modern construction, ordinary polystyrene foam and mineral wool are most often used for facade insulation. In addition to them, there are several more options - we will analyze each of them in detail.

Step-by-step instruction

Correct installation of external insulation is the key to its durability. There are several factors that affect the quality of work. Among them is the type of fastening material. In most cases, dowels or a special adhesive mixture are used. In addition, combined solutions are used in construction practice.

Insulation work does not take 1 day, because... you have to wait for the glue to dry before starting the next stage.

Experts recommend starting work in the summer or early autumn, before heavy rains arrive.

The first step in thermal insulation of the facade of an apartment is the search for a suitable material. If you are guided by price when choosing, then it is better to give preference to foam plastic. The slabs are inexpensive and lightweight, which makes them easy to lift to a height and hold during installation.

The insulation density for thermal insulation of a panel house should be 18 kg/m³ or more.

Laying insulation material

The insulated surface is pre-coated with an adhesive base. It can be applied using a notched trowel or other suitable device. When pressed, the layer will be evenly distributed over the surface between the insulation and the wall.

The insulation material is coated with an adhesive base.

The rows are laid out from the top to the bottom, following the brickwork pattern.

Each material is aligned horizontally and vertically using beacons or thread.

In order to increase the strength of fixation, the insulation can not only be glued, but also secured with dowels. The tops of these elements need to be slightly pressed into the surface of the material. When processing rooms with a corner configuration, it will be necessary to finish the joint between the slabs.

If voids appear between the materials, they can be filled with the remaining sections. The corners are covered with special metal corners, which are fixed with plaster or glue. Finally, you need to sand and plaster the surface.

Installing a reinforcing mesh

An adhesive mixture 0.5 cm thick must be applied to the thermal insulation layer. This is required to absorb and securely fix the reinforcing mesh, which is intended to hold the plaster layer. It is recommended to secure a large and solid fragment, providing space for windows.

The reinforcing mesh is designed to hold the plaster layer.

An additional layer of glue is applied on top of the main layer of glue.

Final finishing

Thermal insulation of walls from the outside is completed by applying a layer of primer and plaster. The composition is distributed 2 times using a roller. After each layer has dried, it is allowed to apply plaster. After an hour it should dry, after which you can begin grouting the surface to give the required texture.

This completes the main part of the work. All that remains is to paint the surface, protected from cold and other negative factors, in the desired color. The coloring composition must be acrylic.

The finishing is completed by applying a layer of primer.

If all requirements and installation rules are met, external insulation can last at least 10 years.

Element-by-element insulation of a multi-storey building

GC "Begemot" performs insulation of a multi-storey building with sprayed polyurethane foam both during the construction process and during operation. The advantage of the technique is, among other things, the absence of time delays. During a shift, one team thermally insulates up to 500...1000 m2 of surfaces (depending on the spatial configuration). Within a few hours after spraying, subsequent operations can be performed - screeding, plastering, painting, etc.

The technique does not require the use of any additional technology, equipment or customer labor. There are no cranes, winches, or loading and unloading operations. There is no waste left after working with polyurethane foam, which eliminates operations for their removal and disposal.

Insulation of roofs of apartment buildings

Insulation of the roofs of apartment buildings by spraying closed-cell polyurethane foam can be done both from scratch on newly constructed buildings and during roof repairs. The method is applicable for both soft and exploited roofs. The best option both for building a pie from scratch and for reconstruction is spraying polyurethane foam + spraying polyurea (PM). These materials provide impeccable sealing of junctions, utility outlets, etc. This cake is more durable than any other: it lasts about 40-50 years without repair. The finished coating is much stronger than conventional rolled materials. You can walk on it and move equipment without fear, it can be cleaned manually and mechanically, polyurethane foam and polyurethane foam “do not leak” in the heat, and do not become brittle in the cold.

The use of sprayed polyurethane foam in the repair and construction of roofs can significantly save time on work, while the cost of this solution does not exceed traditionally used insulation materials.

Insulation of basements of apartment buildings (technical underground)

Insulation of basements of apartment buildings (technical underground), as a rule, involves the construction of a thermal insulation coating on the floor slab of the first floor to ensure standard temperature and humidity conditions in residential premises. For this purpose, we use brands of polyurethane foam with low vapor permeability. The advantages of sprayed polyurethane foam in general and the recommended grades of material in particular are as follows.

- To spray foam, you only need to clean the surface of the slab from dirt. No additional materials or fasteners are needed.

- The foam instantly adheres to the “ceiling” surface without draining and forms a single whole with it without voids.

- You can insulate the basement ceiling of an apartment building with sprayed polyurethane foam at any time: during construction or during operation.

- Polyurethane foam is not susceptible to high humidity, and low vapor permeability prevents the occurrence of high humidity in the premises, which is typical for apartments on the first floors.

- The finished foam can simply be painted, including with fire retardants.

- Closed-cell polyurethane foam is durable, not destroyed by fungus, mold, and is not attractive to rodents.

- The foam reliably seals the joints of the slabs. Prevents the penetration of air and unpleasant odors from the basement.

- Polyurethane foam can be treated with a number of chemicals, which may be necessary when sanitizing the basement.

Insulation of the floor of the first floor of an apartment building

Insulation of the floor of the first floor of an apartment building with polyurethane foam on the side of the residential premises is carried out at the construction stage or during major repairs for further screed installation. Benefits of spray foam insulation:

- There is no need for preliminary leveling of the floor surface, which is necessary when insulating with sheet materials; it is sprayed regardless of the quality of the laying of the slabs.

- Rigid polyurethane foam does not absorb water and has no seams, so the floor screed is strong and without cracks (the water-cement ratio is not disturbed).

- PPU can withstand a lot of weight. The geometry of the coating remains unchanged throughout the entire service life, which allows subsequent screeding without additional reinforcement.

- The coating of high-quality sprayed polyurethane foam under the screed is absolutely environmentally friendly. The finished foam does not emit harmful substances.

Insulation of the floor in an apartment building on the residential side can also be carried out during the operation of the building using joists or under a screed. For this purpose, rigid closed-cell polyurethane foam with low vapor permeability is best suited. Due to the low thermal conductivity of the material, effective thermal insulation requires a thin layer - only 4-6 cm (for comparison: a polystyrene foam layer with similar thermal characteristics will be 8-12 cm). That is, the loss in the height of the room, taking into account the subsequent construction of a thin screed, will be no more than 8-10 cm; along the joists - to the height of the joists, base and finishing coating.

Insulation of the attic (technical floor) of an apartment building

Insulation of the attic (technical floor) of an apartment building with sprayed polyurethane foam is carried out directly on the floor slab. The finished coating is quite durable, can withstand occasional pedestrian traffic, and in unused attics does not require the installation of a protective screed. Installation of the screed, if necessary, can only be carried out in areas of possible operational loads or in accordance with fire regulations in the presence of equipment and communications located on the technical floor. The foam insulation method for attics is beneficial for the following reasons:

- High speed of work - up to 1000 m2 per shift by one team.

- Insulating a technical floor or a cold attic in an apartment building will require a layer of polyurethane foam of only 5-6 cm instead of 30 cm of expanded clay.

- Screeding can be done just a few hours after completion of thermal insulation. Polyurethane foam does not draw water out of concrete, i.e. does not allow the screed to lose strength, and reinforcement is not required.

- There are no costs for transportation, storage, or lifting that are inevitable when using traditional insulation materials.

If the thermal parameters of the premises on the upper floors do not meet modern standards, it is possible to insulate the ceilings from the attic or technical floor during the operation of the house. More often in old buildings, expanded clay was used as insulation. If the attic is accessible to birds, this layer becomes simply dangerous from a sanitation point of view: pigeons are carriers of bed bugs, various infections, and their droppings are toxic. This layer must be removed.

Features of insulation of interpanel seams

Most of the thermal energy is consumed through the seams between the panels. The problem is solved by filling such voids with a monolithic mortar that eliminates all holes, cracks and cavities in the seams. The presence of such treatment increases the efficiency of thermal insulation of the house.

Compositions for treating seams are sold ready-made or as ingredients for preparing solutions. They contain polystyrene foam granules that retain heat, or air particles that protect the room from the penetration of cold air from outside.

If the distance between the plates is large enough, it is allowed to seal the seams with insulating fiber with a soft texture, such as mineral wool. The material is characterized by its ability to be compressed, ease of installation and durability.

Tips and tricks

Each method of insulating the facade of a panel house has its own characteristics. To avoid troubles at different stages of work, you should take into account a number of recommendations from experts:

- Freezing of the facade of panel slabs in an apartment building can lead to dangerous consequences. Sometimes homeowners also insulate the interior using drywall. In this case, you will need to provide a frame and secure the slabs between it. Drywall is fixed on top of the base, which is finished with a decorative layer.

- Polystyrene foam should be purchased from trusted suppliers who can provide quality certificates. The brand must have a production license, since due to the ease of production, many low-quality products are offered for sale.

- When insulating a panel house with penoplex, the facing work must be completed in one go. If you deviate from this requirement, you may encounter the appearance of large joints.

- If the apartment is insulated with foam plastic, it is necessary to prevent the appearance of condensation between the layer of thermal insulation. This occurs when the adhesive base is applied in clumps without careful distribution. As a result, air pockets are formed where moisture coming from inside accumulates.

In order for the insulation of the facade in a panel house to be carried out without errors, it is necessary to strictly follow the recommendations of experts and adhere to the step-by-step guide.

Main stages

1. Before you start insulating a panel house, all seams and depressions are examined. They must be treated with an adhesive mixture. This is necessary so that there are no voids left between the wall and the material. If they are, then the heat will escape from the room. Also treat the convex places on the wall a little with the mixture - in a thinner layer. After this, a sheet of foam plastic is applied to the surface and pressed tightly.

2. We wait 3-4 days until the foam is securely attached to the wall. Only in this case the result of insulation will be good.

3. Now you can start nailing the foam. Craftsmen do this using special construction fungi. This fungus consists of a nail, a plastic sleeve and a circle. The nail can be used from either plastic or metal. But plastic ones are best because they do not contribute to the formation of cold bridges.

4. Using a hammer drill, you need to drill several holes in the selected insulation (foam plastic). They can be located in the center of the sheet and in the middle. This will allow the building to be even better thermally insulated from the outside. Select a drill with a maximum diameter of 10 mm. Remember a very important rule - the depth of the hole should differ from the length of the fungus with a nail. It should exceed it by 2-3 cm. If this is not done, the fastener will not be able to fit firmly into the hole, but will stick out inaccurately on top of the wall.

5. Now you can begin to putty the outside of the wall. Seal everything so that no fungi remain visible. Don't worry if it turns out sloppy. When everything is dry, you can remove all the unevenness with sandpaper.