When do you need to insulate?

Wood has low thermal conductivity, but the disadvantage of the material is its response to changes in humidity and temperature. The door block dries out, swells, warps and even cracks. There are three main reasons signaling the urgent need to insulate a wooden door in a country house:

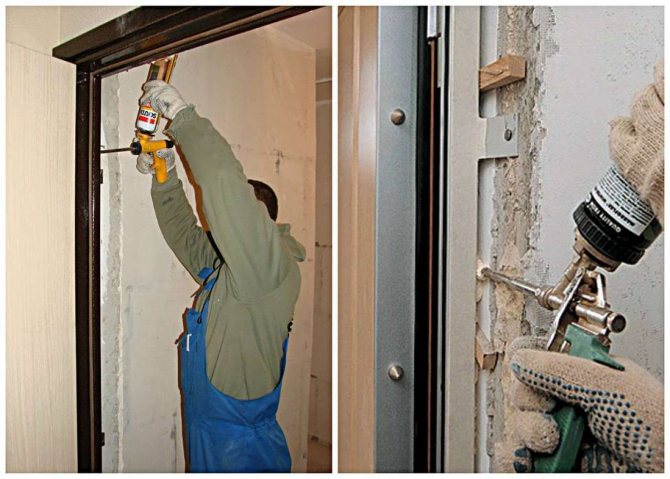

- Formation of gaps between the frame and the ends of the opening walls . Initially, during installation work, all gaps are foamed. Foam is a good insulator, but over time it loses its properties. Destruction occurs faster on the street side if platbands are not installed. Foam deteriorates from exposure to the sun. Another cause of cracks is the misalignment of the bowl.

- Formation of gaps between the frame and the sash . The most common defect in a wooden entrance door occurs due to poor wood, poor-quality installation and long-term use. Often the owner himself becomes the culprit when he trims the swollen sash so that it closes better. After drying, the product decreases in size and a gap forms.

- Wear of insulation. Each thermal insulation material is selected taking into account operational requirements. If they were not initially followed, the incorrectly selected insulation loses its effectiveness. For example, mineral wool quickly cakes, and due to dampness it decreases in volume. Any old wooden door, as well as a thin leaf, needs to be insulated.

Insulation of plastic windows

The main stages of insulation of PVC windows:

- Eliminate gaps by adjusting hinges

- Sealing with rubber seal

- Sealing with silicone sealant

- Sealing window slopes

- Sealing the lower part of the window sill

Adjustment

To eliminate cracks and gaps by adjusting the hinges , the technician will need about 10-15 minutes per sash.

This problem arises due to the fact that, during installation, installers must adjust the hinges, then the windows close evenly and the sashes fit snugly to the frame. In new buildings this is practically not monitored. Therefore, it blows from the windows as if they were not closed at all.

Sealing plastic windows with sealant

If adjusting the hinges does not completely solve the problem, an additional rubber seal is attached around the perimeter of the sash. 10 minutes to degrease the surface and install the seal on one sash .

Repairing cracks with sealant

If the defects are too large, the rubber seal may not be enough, for example, if the sashes simply differ in size by 5mm. This is often found in new buildings: low cost of windows, lack of control, the result is that the windows are not suitable for use. It will take approximately 10 minutes to treat one sash with sealant .

Sealing window slopes

It takes about 30 minutes to insulate one window .

- We dismantle plastic slopes

- Removing low-quality insulation

- Filling the voids with insulation

- Installing plastic slopes back

Often, when putting a house into operation, plastic slopes are installed; the distance between the window and the wall is simply filled with scraps of insulation; naturally, it does not keep the cold from penetrating inside. We recommend dismantling the plastic altogether and making connections from gypsum plaster, then filling the slopes and painting them with water-based paint.

Window sill sealing

This work will take about 10 minutes .

When installing window sills, the junction of the window sill to the wall is often not insulated, leaving free space there. To insulate it, depending on the size of the voids, you can use sealant, dry insulation, or simply polyurethane foam.

After the foam has dried, it is necessary to cut it off and fill the joints, then paint or wallpaper the wall, depending on the existing finish in the room.

© Article prepared by Retzer LLC, March 21, 2014

Which insulation is better to choose?

To make an insulated wooden door with your own hands, you will need thermal insulation material, as well as material for the top decorative finish. The gaps are sealed with a sealant. When the question arises of how to insulate a wooden door in a private house, pay attention to the following materials:

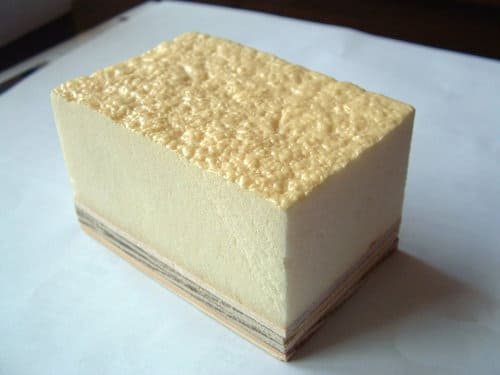

- polystyrene foam as internal insulation for wooden entrance doors. The slabs can be sheathed on the side of the room.

- Foam rubber is considered the most common insulation material, which is covered with artificial leather on top. Porous material allows you to create a volume effect. Foam rubber loses over time and crumbles into crumbs.

- Mineral wool does not burn, has good thermal insulation properties, but quickly cakes. When exposed to dampness, it accumulates moisture. Under the weight it slides off a vertical surface.

- Foamed polyethylene - isolon has a structure similar to foam rubber. The material has better thermal insulation properties and a longer service life. Isolon does not tolerate long-term exposure to direct sunlight.

- Polyurethane foam is applied by spraying, firmly adheres to the wood, and penetrates into all cracks. The disadvantage is the impossibility of performing work without special equipment.

- Expanded polystyrene resembles polystyrene foam, but has improved characteristics. The material has self-extinguishing properties when exposed to open fire.

When choosing insulation for the doors of a wooden house, it is important to consider the thickness of the material. Thick layers will weigh down the sash and create an obstacle to normal closing. Thin is useless. You need to find a middle ground between these two parameters.

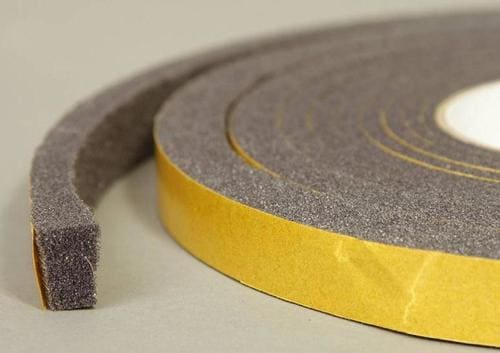

Types of seals for door frames

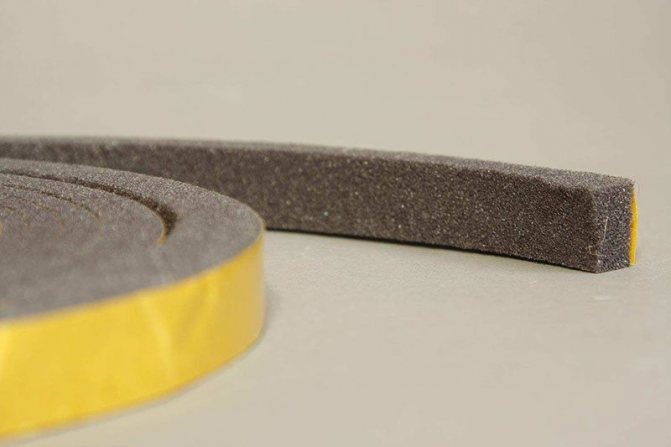

In addition to thermal insulation, you will need a sealant to seal the cracks around the perimeter of the canvas. It is a tape that differs in thickness and material:

- The foam strip is fixed using an adhesive base. The seal wears out quickly during the season.

- The silicone strip is resistant to dampness and elastic. Over time, it begins to stick and tear into pieces.

- The rubber seal for wooden doors will last for many years. The tape is resistant to wear, dampness, and mechanical stress.

- Thermoplastic is the best in terms of wear resistance, but is difficult to install.

- The polyurethane strip is glued due to the adhesive base. The characteristics are not inferior to a rubber seal.

Thermal insulation cannot be done without decorative finishing. Usually the insulation is covered with artificial leather. Fixed with furniture nails with a wide decorative head. On the inside, the canvas is sheathed with laminated MDF panels. Genuine leather trim looks beautiful, but the material is very expensive.

Seal installation

Installing frost-resistant insulation on the door leaf is only half the battle in eliminating the penetration of cold air into the living space. Even with the door closed, there remains a small gap between it and the frame, through which the cold will penetrate. Eliminating drafts is the next task for the home handyman.

To do this job, you should choose the optimal type of seal. Today, manufacturers can offer the following types of this material:

- Foam seals;

- Silicone seals;

- Rubber seals.

The first type of seal allows you to quickly and inexpensively solve the problem of drafts. It is ideal for the doorway of a structure such as a dacha, where there is no high intensity of opening and closing doors.

Foam rubber seal - inexpensive, but also short-lived

Using a silicone door seal will help eliminate drafts for a longer period of time than a foam rubber counterpart can do. The shape of the product ensures that the canvas is pressed tightly against the box, which will not allow air masses to move inside the room.

The best option is a rubber seal. Thanks to its characteristics, it allows you to get a warm opening for a long time, even with the most intensive use. In addition, the variety of shapes of this product makes it possible to install it on all types of door blocks.

For intensive use of doors, a rubber seal is used.

Having chosen the desired seal option, all that remains is to install it in place. There are two main installation options:

- Using an adhesive strip.

- Using a harpoon in the groove.

The fastest way to install a new door seal is to use self-adhesive products. But this type cannot please you with its durability, so many experts recommend harpoon mounting in a groove.

It will be quite difficult to select a small groove in the quarter without disassembling the boxes. Therefore, it is permissible to carefully nail the seal with small nails. Fastening must be done in the very corner of the quarter. This will allow the canvas to take its position in the door block without difficulty and provide reliable protection from drafts.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Caring owners are interested in the question of how to insulate a wooden entrance door in a private house with their own hands. This is important, since statistics show that a third of the heat in the room escapes through them due to the formation of a gap during their use. You can do everything right by following the recommendations of experts.

How to insulate a wooden door?

The insulation of a wooden door begins with preparatory work :

- weakened hinges are secured with new elongated screws;

- if thick, heavy insulation is used, install an additional loop;

- eliminate box distortions and fabric defects;

- check the condition of the seal around the perimeter of the door frame at the junction with the walls;

- replace broken fittings: lock, handles, peephole, latch.

After all defects have been eliminated, installation of insulation on wooden entrance doors begins.

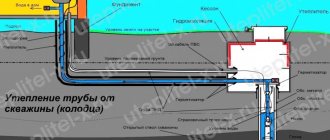

a vapor barrier necessary when insulating wooden doors? When arranging the installation seams of the door block - it is necessary. The gap between the box and the wall is sealed with foam. To prevent the thermal insulation from deteriorating, the seam is covered from the street with PSUL tape. From the room side, the foam is destroyed by vapors. For protection, the seam is sealed with vapor barrier tape. A vapor barrier may be required for the product if it is installed in a damp room and mineral wool serves as thermal insulation.

Installing a seal on a door frame

The first salvation from heat loss is to install a seal on a wooden door to eliminate gaps between the sash and the frame. The tape is selected according to the thickness corresponding to the size of the gap. A thin strip is useless, and a thick strip will interfere with the normal closing of the canvas. Installation of the seal consists of the following steps:

- Measure the gaps between the sash and the frame and select the thickness of the tape.

- A self-adhesive seal is glued into the groove around the perimeter of the bowl.

- The silicone tape is fixed with the staples of a construction stapler.

If the gap size is different around the perimeter of the door block, which often happens during deformation, the groove in the frame is widened and deepened. The edge of the blade is passed with a grinder. A two-layer or three-layer tape is glued to the new groove.

A properly glued seal should fit snugly around the entire perimeter of the sash and not interfere with its free closing.

Sealing with rollers

You can insulate the joint around the perimeter of the door frame using leatherette rollers with foam rubber inserted inside.

- Measure the length of all sides of the sash. According to the results, four strips of 100 mm wide are cut out of leatherette.

- The strips are placed against the edge of the sash with the wrong side up. Near the edge of the door leaf, the leatherette is fixed with a stapler.

- Thick foam rubber is placed inside each strip and a roll is formed.

- Secure the second edge of the leatherette with a stapler.

Installation of double doors

A good way to insulate your home is to install a double entry door. Due to the formation of an air space separating the room from the street, heat is retained. The disadvantage of this design is the reduction in space.

A threshold is set for the indoor unit. Insulation is additionally laid on the slopes between the doors. There are designs where two doors are hinged on one deep frame.

When insulating entrance doors, you must remember that moisture affects the canvas from the street side. Treatment with impregnation, painting with paint or varnish will help protect against dampness as much as possible. Drying oil creates good waterproofing.

Today, wooden entrance doors are practically not used. Metal doors are installed in modern private houses and cottages, providing more reliable protection for the premises. However, many houses still have wooden doors. For example, in a country house or in a rural house, or in an apartment in a multi-story building.

Old street doors need insulation, because... Wood tends to dry out, cracks appear in the door leaf, and the door itself can become tightly deformed over time and move away from the frame. All this harms not only the aesthetic component of the door, but also its operational properties. Despite the fact that wood is a good heat insulator, the door block needs additional insulation.

Let's consider in detail how to insulate a wooden door for the winter from the outside and inside so that it does not blow and the cold does not pass into the house. There are several methods of thermal insulation, depending on the type of thermal insulation material used.

Thank you for reading our article!

Rate the quality of the article on a scale from 1 to 5.

Add a comment Cancel reply

Mikhail / 10.21.2019 13:48

I have wood-based entrance doors in my house. You constantly have to deal with the fact that cold air penetrates into the cottage. I followed the advice of the builders and insulated them, which made the house cozy. The work is carried out with your own hands with high quality, following the technology recommended by the craftsmen. During these works I used isolon, which allowed me to achieve my goals.

Vladimir / 10.21.2019 13:48

Insulating the doors allowed me to reduce heating costs. I used polystyrene foam.

The first autumn cold has arrived unnoticed, and if your apartment or country house has become uncomfortable like autumn, you should take a close look at the front door and windows - most likely, you will have to start insulating them. We won’t touch the windows now, let’s talk about the door, since this is where the most problems occur. Especially if the door is wooden and has served for many years.

Insulating a wooden front door is not as difficult as it might seem at first glance: having a simple tool and more or less stable handling skills, your personal desire and our advice will help correct the situation and meet the cold winter with dignity.

So, there are, by and large, only two ways to insulate the front door:

- Sealing the door frame in the areas where the door leaf adjoins;

- Insulation of the door leaf using thermal insulating materials.

Door seal

To seal the doorway, you will need to purchase a special rubber seal. This sealant, in the form of a tape rolled into a roll, is widely available and inexpensive, and has an adhesive base on one side, which greatly simplifies its installation.

How to insulate a wooden door in a private house or apartment

The standard set of materials for door insulation includes three components:

- insulation;

- seal;

- decorative materials for finishing: dermantin, artificial leather, thick fabric.

You can buy a ready-made kit for insulating the front door (cost from 490 rubles). This set consists of dermantine, foam rubber, rollers for decorating the door, tapes for securing the dermantine around the perimeter and center of the canvas, nails with decorative caps and a sealant.

But, as the masters advise, you can select the necessary materials for the work yourself, i.e. buy separately. It will be, if not cheaper, then better in quality.

- foam rubber

(45-900 rubles/sq.m.) Due to the fact that the door leaf of a wooden door is solid, insulation is done on top of it. For this purpose, soft insulation materials that can hold their shape well are best suited. Door insulation with foam rubber is justified by the low price of the material, availability, and ease of installation. It also makes it possible to choose the desired thickness, because... Available in a thickness range from 3 to 100 mm. To insulate a wooden door, foam rubber up to 30 mm thick is used.

- isolon

(thickness from 2 to 20 mm). Available in two types: foil (price - 150-270 rubles/sq.m.) and regular (70-80 rubles/sq.m.). The advantage of isolon is the thin thickness of the material, which ensures excellent thermal insulation of wooden doors without significantly increasing their dimensions.

- batting, synthetic padding, felt

. These materials can also be used as insulation materials, but they are rarely used;

- mineral wool

(price 70-250 rubles/sq.m.) Serves as an excellent insulation material, but the thickness of the mineral wool increases the dimensions of the door, which does not make it a good alternative to foam rubber;

- polystyrene foam

(from 2500 rub./m3). Rigid insulation, used for external insulation of the door. Installing foam plastic requires the manufacture of a frame and the use of rigid decorative material (for the covering panel), which entails an increase in the thickness and weight of the door and the replacement of hinges. And in terms of thermal insulation properties, the foam on the door is similar to foam rubber with dermantine upholstery.

Calculation of the amount of material for insulating a wooden door

- insulation. The area of the insulation is equal to the area of the door leaf. As for the thickness, it should not interfere with the opening of the door. Users recommend using 30 mm thick insulation. It performs its functions well and can be securely fastened with nails;

- seal. The quantity is equal to the perimeter of the door frame;

- upholstery. The length and width of the door plus 300 mm of margin on the top and side.

Note. The amount of reserve depends on the height of the thermal insulation material.

We insulate the front door with our own hands

Insulation of metal doors

If the frame is iron, then in some cases the door leaf on one side is removable. To insulate such a door, you need to unscrew and remove one side. Afterwards, fill all the voids with foam plastic or special insulation.

In any case, there will be gaps and cracks. To get rid of them, polyurethane foam is used.

After completing the work, you need to put the removed part of the door leaf in place.

The metal door can be solid. In this case, the insulation process is more complex. The first step is to make a rectangular frame from wooden slats on the outside. After that it is attached to the door. For fastening you will need to use all your imagination. The next step is to fill the frame with insulation. Foam plastic, special insulation and polyurethane foam can also be used here. Knowing the dimensions of the door and wooden frame, a sheet of fiberboard or other finishing material is cut out. It is attached to the iron door with metal screws.

When insulating iron doors, you should look at the frame. It may not fit tightly to the doorway. If there are cracks, then polyurethane foam is used to eliminate them.

The seal on metal doors may be compromised. To eliminate this defect, I use sealant. Sometimes leatherette is used as insulation. It is used to cover the entire iron door from the outside.

If the door frame is larger than the door, a gap will form. For insulation, foam rubber wrapped in leatherette is used. The resulting seal must be nailed to the door frame around the perimeter.

Insulation of wooden doors

Wood, unlike iron, has poor thermal conductivity. This quality makes the wood itself warm. Basically, heat loss from such doors occurs due to deformation and the formation of cracks. Wood becomes deformed under the influence of the sun, moisture, and temperature changes. Therefore, it is important to paint or dry a wooden door on time.

But, if cracks do form, you will need to seal them with something.

The adjustment of such doors is carried out using a plane. The door frame and the door leaf itself must be adjacent to each other. Do not forget that you should leave a small gap between them. As humidity increases, the door may swell. After this it will be impossible to close or open it.

To insulate the door, it is simply covered with leatherette, under which there is insulation. As the latter, it is advisable to choose polystyrene foam.

To facilitate the process of upholstering the door, it is first removed from its hinges. Knowing this, this procedure should be done in the warm season. In winter, by removing the door, you can freeze the entire apartment and the residents living in it. You will notice that it is many times easier to insulate wooden doors than iron ones.

Insulation of a wooden entrance door - technology

Note that in 9 out of 10 cases, the insulation of the doors of a wooden house is done from the outside.

Method 1 - insulation with upholstery

This is the easiest and least labor-intensive method to do it yourself. Dermantin or other finishing material is stretched over a wooden door and fixed to it with nails. Due to the thermal insulation lining (foam rubber, synthetic winterizer) and the density of the dermantine itself, a warming effect is achieved.

Method 2 - complete thermal insulation with insulation

This option is more complex, it will take some time to complete, so you need to start work without waiting for the onset of cold weather, or order the services of a specialist. A professional will do the job much faster, but will cost more.

Insulation of a metal entrance door

In order for the insulation of a metal door to give the desired result, it is necessary to use special heat-insulating materials. If you insulate a metal door only with a roller or cotton wool, it will be ineffective.

The best option for insulating a metal door would be foam rubber or isolon.

It is also important to ensure tightness. This is done using a special roller and LILIT material - polyethylene, which has been foamed.

But initially it’s worth identifying the most vulnerable places in the door frame, and also establishing where the cold comes from:

- Directly next to the door leaf;

- Through the gaps between the door leaf and the frame;

- The cold passes through the metal door frame.

Only by analyzing these factors can you determine what and where to place thermal insulation materials so that insulating the door gives the desired result.

How to insulate a wooden entrance door in a private house

Ways to cover a door with different types of insulation.

Insulating a wooden door with isolon or foam rubber

Installation of both materials is carried out using the same technology. Glue (liquid nails, dragon or PVA) is applied to the surface of the door and foam rubber/isolon is laid on it. Glue is needed to ensure that the insulation does not move during operation and operation. Subsequently, the insulation is secured with nails.

There are recommendations to fasten foam rubber with a construction stapler. But this is only acceptable if hard material is used as decoration. Otherwise, dents will be visible in those places where the material is pressed by the bracket. Or you need to fasten it in accordance with the intended pattern (scheme) of stud placement.

Advice. It is not advisable to install foam rubber in the place where the door handle is installed; it will interfere with its reinstallation and operation.

Insulating a wooden door with foam plastic

Installation of polystyrene foam, although rare, is also not difficult.

Option 1

. Thin foam plastic or polystyrene foam (no thicker than 30 mm) is laid on the surface of the canvas, fixed to the surface using liquid nails and covered with finishing material.

Note. When installing foam plastic on the outside of a wooden door, its width exactly matches the width of the door leaf. When installed from inside the door, it corresponds to the frame clearance. Otherwise, the door simply will not close.

Option 2

. A frame of dry wooden beams with a cross-section of 20x30 is placed on the door leaf. Additional stiffening ribs are installed inside the frame, made from the same timber. The frame is treated with a primer. Polystyrene foam is placed inside the cells. Then it is covered with finishing material.

Note. The disadvantage of such insulation is that the thickness and weight of the door will increase. This in turn will create additional load on the hinges.

Insulating a wooden door with mineral wool

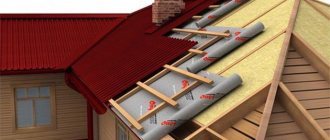

It can be done using either a frame method (like polystyrene foam) or frameless (stapled to the surface of the door leaf). In any case, a prerequisite for cotton wool is the use of a hydrobarrier film, which will protect the insulation from moisture.

Do-it-yourself door upholstery with dermantine

Let's briefly look at the technology of how to sheathe a door with dermantine. After the insulation is laid, it is covered with dermantine, which must be wrapped and secured around the perimeter of the door leaf with nails. The dermantine upholstery starts from the top of the door. During the installation process, you need to ensure that the insulation does not move to the side, and that the dermantine is stretched without distortions.

Note. This installation method, despite its obvious simplicity, has a drawback - the place where the dermantine is attached can tear, so rollers are often installed at the place where the dermantine is installed.

Door upholstery with dermantine with rollers

The cladding method involves the use of rollers to cover the place where the dermantine is attached and the gap between the door and the frame, so as not to blow.

It's easy to make rollers - you need to cut strips from the finishing material - 4 pcs. Strip sizes: width 50-200 mm, length equal to door height (2 pcs.) and width (2 pcs.)

Note. If the hinges are installed outside, the bolsters are installed only on the handle side.

The cut pieces of dermantine are attached around the perimeter of the door, a round-shaped seal is placed in them (in this case, the width of the workpiece is 50-70 mm), or twisted insulation, or dermantine folded into a roller (then the workpiece reaches a size of 200 mm). Dermantin covers the insulation, is wrapped and fixed around the perimeter.

The use of rollers allows you to beautifully decorate the place where the dermantine is attached to the door leaf and additionally protects against the penetration of cold through the door gap.

How to cover a door with dermantine

Fastening dermantine for door upholstery is carried out using decorative nails.

You should pay attention to the places where the studs are installed, because... their use allows you to further decorate the door. Some methods of installing studs are shown in the photo below. Nails must be driven in strict accordance with the intended pattern. To do this, it is recommended to apply the ornament to the surface of the dermantine using a pencil or washable marker, and then erase it.

Dermantine door upholstery pattern - examples

A beautiful pattern is created by a dermantine ribbon stretched between the nails.

Hiring a specialist to insulate the door will cost a certain amount; approximate prices for the work are shown in the table:

In order for an insulated wooden door in a private house to fully fulfill its functions, you need to perform a few more steps, namely:

- insulate the door frame

. To do this, dismantle the slope and inspect the installation site of the door frame. Assess the condition of the mounting foam that was used to insulate the junction of the box and the wall. If it is unsatisfactory, the foam is cut off and reapplied. A new slope is being formed, which it is advisable to insulate. It is convenient to use cotton wool or polystyrene foam as insulation.

- insulate the door contour

. To do this, a polymer or foam seal is glued around the perimeter of the door frame.

Such comprehensive insulation will allow you to get a good result.

The assortment of the building materials market is surprising in its diversity in all directions. This also applies to the choice of entrance doors - from classic wooden ones to models made from the most modern materials. Wooden entrance doors are easy to make with your own hands, which is why they occupy a leading position.

Wooden doors can be massive, panel or paneled. Massive, as the name suggests, are made of solid or laminated solid wood. Paneled ones are made of thin planks inserted into a wooden door frame. There are a lot of options for paneled doors. Panel doors are assembled on the basis of a frame with various fillings and sheathed with solid sheets of thin plywood or other material.

With all the advantages of such doors, which have been tested for centuries, they have one serious drawback - over time, any wooden door loses its thermal insulation properties. However, this drawback can be easily eliminated on your own.

Sheathing

Instead of insulating building material, you can sheathe the structure with dermantine. This is relevant when insulating a room from the outside. The work is carried out following a certain sequence. Upon completion, you can make the following design:

- as functional as possible;

- stylish;

- attractive.

The sheathing is laid on top of the insulation. In this regard, you can use genuine leather or dermantine. The material needs to be laid on the door leaf and the edges folded. It is attached to it with a stapler.

Builders recommend watching closely to ensure that the building material does not sag. This will prevent it from moving. To avoid such troubles, you need to start fastening the upholstery from the center and gradually move towards its edges. At the end of the work, you need to secure the curved edges of the upholstery. Holes of appropriate sizes should be cut in the areas where the lock is located.

After completion of the repair work, all fittings are installed in their places. Installation of an insulated door is carried out at the place of its use. The completed work will be the key to a beautiful and warm door.

Reasons for reduced door insulation

A wooden door ceases to reliably protect us from external penetrations of cold air if:

- Gaps have appeared between the wall and the door block, the seal has been broken;

- Due to the skew of the door frame, there is no tight fit of the door leaf to the door frame;

- The door leaf has dried out, cracks have appeared through which frosty air can freely pass;

- The thickness of the door leaf is too small and cannot reliably protect against the cold.

The photo shows a set for insulation

In each of these cases, it is possible to insulate the wooden entrance door yourself, without the help of specialists. In addition to completing the main task, you will get a lot of pleasure from the creative process. It is very good to involve your teenage children as assistants - you will be able to enjoy communication with them, and instill in them basic work skills, and simply become closer while performing a common task.

This is interesting: Insulating a wooden door with your own hands: types of insulation and procedure

Preparatory stage

At the preparatory stage, it is necessary to identify the cause of the leak, decide on a repair option and prepare materials and tools. Regardless of the nature of the repair, we will need basic carpentry tools - a hammer, pliers, nails, a screwdriver, self-tapping screws, screwdrivers, and possibly a plane. Therefore, check whether you have all this so as not to search during the renovation process, and determine what materials you will need to purchase. Here it depends on the nature of the damage.

If you observe a loose fit of the door leaf to the walls of the frame, prepare a special seal. It is best to purchase silicone, but if this is not possible, rubber will also do.

It is not recommended to use foam rubber sealant; it wears out too quickly and becomes unusable.

If you decide to sheathe the door leaf with insulation, immediately calculate the required quantity and type of materials. Most often, leatherette, leatherette, and natural leather are used as the top layer; sometimes simple oilcloth is also suitable. You can take the simplest route and purchase a ready-made kit for insulating doors, in which everything is already provided and calculated. The main thing is that it fits in size.

Eliminating skew

In order to eliminate distortions and sagging doors that appear during operation, it is necessary to remove all hinges and check their condition. If necessary, it is better to purchase new fasteners. If the old ones are not damaged, then we simply reattach them in place, adjusting them well to ensure the door fits correctly.

Often a distortion occurs because the wood has dried out and the canvas has changed its original dimensions. In such cases, sometimes it is enough to simply cut off the excess sections and trim them for a tight fit.

If there are cracks in the door leaf

When the door dries out, it is likely that cracks will appear, through which the cold will definitely get into your apartment. What to do? Of course, the canvas itself must be knocked down or the cracks sealed using slats and putty. However, insulating a wooden door with your own hands does not only consist of basic sealing of cracks. It is very important to make the front door beautiful, because its appearance affects the overall impression of your home. And who wants it to be, to put it mildly, condescending?

Therefore, first we repair the canvas itself, and then move on to the next point - the sheathing.

Wooden door trim