Autonomous gas heating systems

The use of natural gas is relatively inexpensive and safe compared to other sources of thermal energy. Modern gas equipment is capable of automatically ensuring optimal consumption of blue fuel and maintaining comfortable conditions in the building.

The reasons for using autonomous gas supply systems may be the following circumstances:

- absence of a main gas pipeline in the accessible vicinity;

- the high cost of designing and supplying gas from it to the house;

- errors during the construction of a private house, in which connecting the main gas is impossible for safety reasons. The requirements for the design and operation of autonomous systems are much softer.

For autonomous gas supply, the project is developed individually for a specific building. In this case, the developer may be offered a choice of fuel supply source: a gas tank or household gas cylinders.

Liquefied gas can be supplied to the heating system of a private home from a gas holder or from gas cylinders

Autonomous gas-cylinder equipment is often installed even in houses where there is central heating. This device allows you to control the heating mode and save money on heating. An autonomous heating system from gas cylinders is cheaper both in terms of the cost of equipment and the price of gas.

Video: heating with propane-butane

Connecting autonomous gas to the dacha

An important advantage of an autonomous gas supply to a home is that the prices for gas used in this system are quite stable and do not tend to grow rapidly. Thus, not only the independence of choosing a place to build housing speaks in favor of an autonomous gas supply to the house, but also tangible savings in money.

Call from the manager

Engineer visit and estimate preparation

Site preparation (delivery of equipment) and installation of a gas tank

Installation and installation of underground gas pipeline

Installation of autonomous gasification safety systems

Putting the system into operation

Properties of liquefied gas

Gas for cylinders is somewhat different from natural main fuel. It is characterized by:

- higher efficiency;

- low fuel cost;

- ease of use;

- ability to use a variety of equipment.

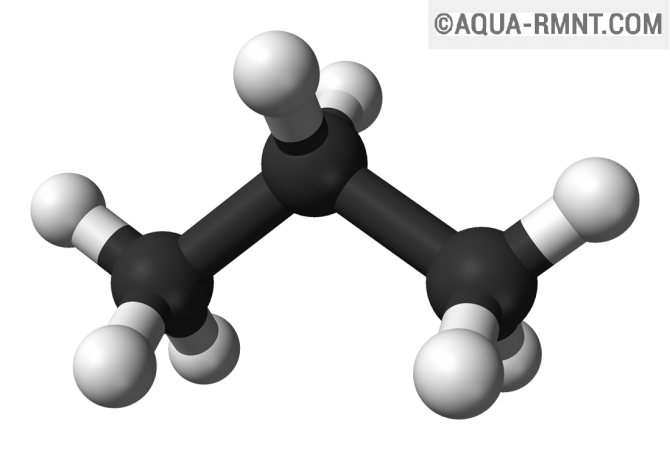

This fuel is produced on the basis of propane. It is safe for human health and has no harmful effects on the environment.

The chemical formula - C3H8 - indicates that it belongs to the alkanes class of hydrocarbons. The natural source is natural gas, which is released by the cracking of petroleum products during the separation of associated petroleum gases as a by-product.

Propane is a gas belonging to the class of alkanes and is colorless and odorless.

In its pure form, propane does not have any odor, and specially added additives give it a well-known aroma. They are used for identification purposes when leaks occur. Propane is low-toxic, but has a mild narcotic effect on the central nervous system.

Application area of propane

The most extensive use of propane is as a fuel. It is used:

- in industry - for performing gas-flame work and welding metals in structures for non-critical purposes;

- in construction - for heating industrial and facility premises;

- in road work when bitumen and the road surface are heated;

- in the food industry - in gas stoves and water heaters.

One of the new areas of application of propane is its use as automobile fuel. It is cheaper than gasoline or diesel fuel and has a positive effect on increasing the service life of internal combustion engines.

Calculation of the need for liquefied gas

Preparatory measures for installing this type of gas equipment are very important. Miscalculations by an insufficiently qualified designer or low professional training of builders subsequently become very expensive. Heating systems do not reach their rated specifications, and to ensure normal living conditions it is necessary to increase fuel consumption.

The level of gas consumption in a private home must be calculated taking into account the size of the premises, the number of people living and the type of heating equipment

When starting to purchase equipment, you need to make sure that it meets the needs of your home. To do this, you can use the practically established ratio. To provide high-quality heat, you need to spend one kilowatt-hour of thermal energy for every 10 square meters of heated premises. In this way, you can obtain primary data on the required boiler power.

When considering the line of products offered on the market, you need to select a product that is suitable for the given parameter.

It should be borne in mind that the value obtained in this way concerns only heating; the consumption for other gas appliances must be calculated separately, taking into account the intensity of their use.

Advantages and disadvantages of autonomous gas supply

Like any engineering system, autonomous gas heating at home has its own nuances.

Pros:

- High reliability and performance of equipment. The service life of a gas tank is 30-40 years;

- Availability. This system can be installed in any area, no matter how far the house is from the city or gas suppliers;

- Versatility . Liquefied gas coming from the tank can be used both for cooking and for heating rooms;

- An autonomous system allows homeowners to save on gas consumption . The fact is that propane is usually pumped into gas containers - and this type of gas is considered the cheapest;

- If necessary, an independent gas supply system can be connected to other communications . Moreover, homeowners will not have to invest significant sums for their reconstruction;

- Unlike coal and wood boilers, an autonomous gas heating system does not require daily refueling . After launching the equipment, the cottage owner does not have to worry about refilling the tank for 6-12 months;

- This will cost much less than connecting to the main gas (in the Moscow region, installing a gas tank usually costs from 100-150 thousand rubles).

Other advantages of autonomous gas heating include the environmental component. Unlike coal and firewood, there is virtually no release of harmful substances during gas combustion. There is no odor inside the house, and no soot or soot remains on boilers, equipment and premises.

10 most common mistakes in interior design

What materials are the roofs of cottages usually made from?

Insulation for the dacha. How to choose? Which is better?

Is it possible to make money by purchasing (reselling) land plots in the Moscow region?

Farmland. Their composition and features of use

Individual planning and design of a country house

Shower without a tray in the bathroom of your home. Is it worth doing?

In one language: Dictionary of basic business terms in real estate

Life and work in the Moscow region. What is the salary level in the Moscow region?

Automatic watering system for the site. What is important to consider when designing and installing?

Minuses:

- The costs of autonomous gasification can be quite large . As we have already written, autonomous gas equipment itself is not that expensive (when compared with other types of heating). However, the costs of installing it and laying pipes can be very high due to the characteristics of the site, soil and the location of communications in the house. And instead of 150 thousand, the owner of the cottage will have to pay all 350 thousand rubles;

- Unlike a main gas pipeline (which runs through pipes on its own), an autonomous gas system requires the participation of the owner . Firstly, you need to call a car in a timely manner to pump gas. Secondly, the owner must constantly monitor the serviceability of the equipment, order annual diagnostics and, if necessary, pay for repairs;

- It is believed that any gas cylinders and containers are not safe , and if they break down, an explosion may occur. In practice, such cases are quite rare and always occur due to violations of operating rules. According to safety standards, the gas tank must be buried in the ground no closer than 10 meters from the building, and independent installation is prohibited.

- The system requires constant checking for methane leaks . Water ingress can lead to gearbox failure;

- Risk of encountering unscrupulous suppliers. In some regions, liquefied gas suppliers deliberately inflate the price, since there is no competition in the market. Before installing autonomous heating, it is necessary to evaluate whether this system will actually be more profitable than others.

Autonomous gas supply device

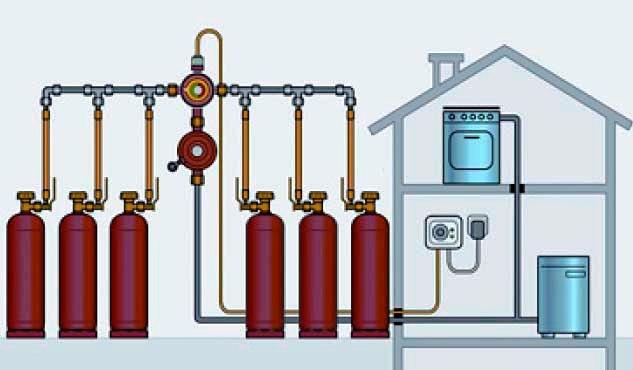

As mentioned above, there are two types of liquid fuel gas supply systems: gas tank and gas cylinder.

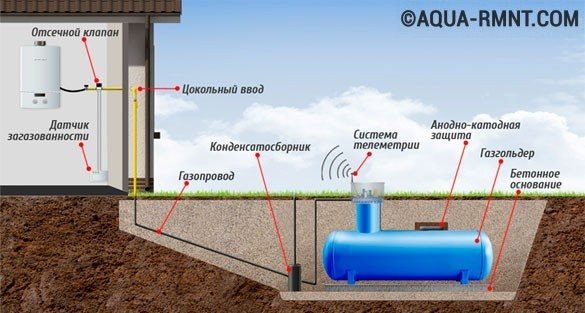

Gas supply with gas holder

A gas holder is a sealed container filled with a liquefied gas mixture of propane-butane. During operation, propane is released in the vapor phase and fills the free space in the tank. From here, through a reducer, it enters the external gas pipeline. The reducer is designed to reduce the pressure in the gas pipeline system to the technological standard.

To install the device on the site, you need:

- Dig a hole corresponding to the size of the gas holder. Its depth should be 30–40 cm greater than the corresponding soil freezing parameter for the installation site.

- Place a drainage layer of gravel and sand at the bottom of the pit.

- Lay or pour a concrete slab on top of the drainage layer.

A gasholder is a large metal container that is buried in the ground and secured to a concrete slab.

- Install stainless steel anchors on the slab. Their purpose is to secure the container to the base, preventing it from floating up in conditions of spring flooding.

After filling the pit with the container, only the neck protrudes to the surface, on which control and control equipment is installed.

After installing and fastening the gas tank to the concrete slab, it is covered with earth so that only the filler neck with control and recording equipment remains at the top.

Anodic-cathodic protection is intended to protect the tank body from corrosion of electrochemical origin. To do this, a tread device with an activator is installed in the pit. The protector is an anode made of a magnesium-based alloy, placed in a cotton bag into which the activator is poured. Its composition: somite and building gypsum - 25% of the composition each, the rest is bentonite clay. The anode is connected to the tank body with a wire.

A protective device made of magnesium alloy is installed in the pit and protects the metal surface of the gas tank from corrosion

The operation of the device is based on the formation of a potential difference between the anode and the housing, as a result of which reduction reactions occur on the housing. The life cycle of the gas tank body increases several times.

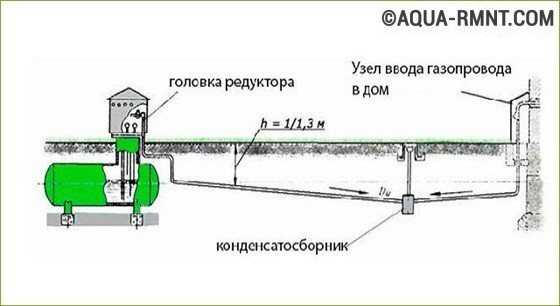

An indispensable condition for the operability of the system is a condensate collector. It is formed from butane vapor in vertical areas during operation in winter conditions. The condensate collector is installed at the lowest point of the system, and a tube is led out from it. If the condensate is not drained, the operation of the system may be stopped by the formation of butane plugs.

The condensate collector is installed at the lowest point of the gas line, so the resulting moisture enters it by gravity

The tank is installed at a distance of 5–10 meters from the house and connected to it by a pipeline in the ground.

Video: installing a gas tank

External gas pipeline

To install an external gas pipeline, a low-pressure polyethylene pipe without joints is used. Such pipes are most often supplied in coils, so finding a product of the required length is not difficult.

A distinctive feature of a pipe intended for supplying gas is a yellow stripe on the outer braid

The main advantages of polyethylene pipes compared to metal ones are as follows:

- seamless design - joints have always been the weak point of any pipeline, especially those operating under pressure;

- flexibility - the pipe easily copes with soil movements during seasonal movements;

- the life cycle of such a product significantly exceeds that of metal analogues.

Connection to the in-house gas supply system is made through the foundation base with the obligatory installation of a shut-off valve.

The gas pipe must pass through the main wall and be equipped with a shut-off valve at the inlet

The base connection is a connection between a polypropylene pipe and a steel pipe. It is produced using a special case. A mandatory input element is a welded valve and a siphon device to compensate for possible foundation movements and soil heaving during freezing.

Internal gas pipeline and security systems

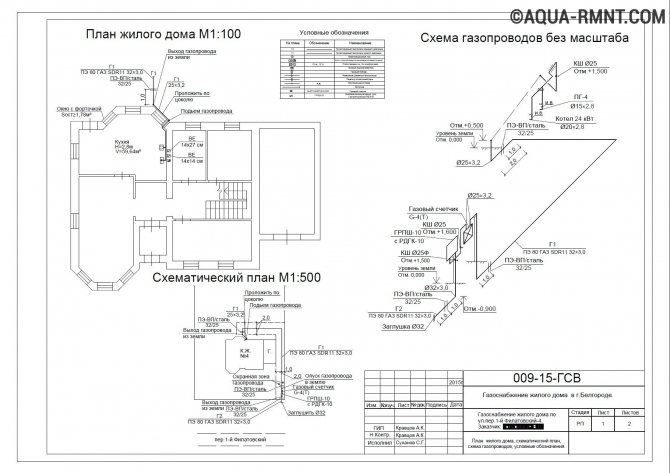

A distribution wiring is created inside the house to supply fuel to consumption points. It is made of steel water and gas pipes in accordance with GOST 3262–80 with a minimum number of connections. Pipe installation is carried out in accordance with the developed and approved project. The right to execute technical documentation is confirmed by an appropriate certificate.

The autonomous gas supply project specifies a complete diagram of the gas pipeline from the installation site of the storage tank to each consumer

The following devices are required elements of the distribution in-house wiring:

- sensor for monitoring the level of gas pollution in the room - continuously checks the presence of gas in the room. Trigger level - reaching 20% explosive concentration. Sound and light signals are given, and the automatic shut-off valve for gas supply to the distribution system is activated;

- Thermal shut-off valve - designed to shut off the gas supply in the event of a fire in the room. Triggers when the temperature rises to 90–100 oC;

- A device for remote monitoring of the gas level in a gas tank. Usually included as an option.

Photo gallery: gas main monitoring devices

The gas analyzer monitors the excess of the safe level of gas concentration in the room

The shut-off valve turns off the gas supply when the temperature rises at its installation site

Thermal shut-off valve closes the gas supply line in the event of a fire

Video: autonomous gas supply

Using more than one gas supply container

Sometimes it is practiced to install several gas tanks. They can be used individually or connected to each other in the liquid and vapor phases. This allows you to increase the volume of stored gas and increase the area of its evaporation. Connected containers can be refilled either individually or several at the same time.

In a system of two gas tanks, one of the devices can be used as a backup or as a separate source of gasification for part of the buildings on the site

Twin tanks allow you to more effectively regulate the gas supply control mode and increase the period between refills.

It should be remembered that the gas tank must be installed no more than forty meters from the location of the filling tank.

Gas consumption for autonomous heating

To make a decision about installing an individual gas supply, you need to evaluate a number of factors that can have a significant impact on the efficiency of the system:

- regional climate features, duration of the heating season;

- size of heated area;

- materials of floors and walls and their ability to withstand unproductive heat loss;

- area of windows and other translucent structures;

- own preferences for temperature conditions;

- nature of residence - permanent or temporary;

- operation of backup and auxiliary gas equipment - gas stoves and water heaters, gas generator.

As a rough preliminary estimate of gas demand, you can use the figure of 26–30 liters per square meter of area for the St. Petersburg region or Moscow region when making calculations.

Video: heating with liquefied gas (propane) - consumption, use experience

Autonomous heating of the house with gas – FORUMHOUSE specialists talk about the nuances and features

Summer has come, but the question of how and with what to heat a country house does not lose its relevance.

Regular readers of our site have already read the article: “Features of choosing a water supply and heating system.”

Despite the fact that there are many heating systems on the market, many country residents would like to heat their home with main gas.

However, it is not always possible to connect to a pipeline with “blue fuel”. If there is no gas and gasification of your individual housing is not possible in the near future, liquefied gas from cylinders will be an alternative.

Is gas heating profitable?

It seems that organizing autonomous gas heating of a private house is easy and simple. All you need is:

- Buy a gas boiler. Most boilers operating on main gas can also operate on liquefied gas. To do this, you need to change the injectors and, if necessary, reconfigure the control system;

- Purchase a reducer, gas equipment and shut-off valves;

- Connect and configure the heating system.

The main questions that arise for any homeowner who is thinking about a liquefied gas heating system:

- Will I be able to heat the house;

- How long can a boiler operate on one cylinder?

Autonomous gas heating of a private house is best organized using liquefied gas cylinders with a capacity of 50 liters.

The practical experience of forum members suggests that heating a private house with gas from cylinders is unprofitable if the cottage is poorly insulated and the building has large heat losses. It is also necessary to take into account the total area of the country house. Heating with gas from cylinders of a cottage with an area of 150-200 sq.m. can cost a pretty penny.

In this case, solid fuel boilers can be an alternative.

DGL:

– I heard that one 50 liter container is enough for 1-2 days of operation (and this does not take into account the use of hot water).

DGL:

– I heard that one cylinder with a capacity of 50 liters is enough for 1-2 days of work (and this does not take into account the use of hot water).

Schweik:

– I heated a house with an area of 70 sq.m. with gas. On average (depending on the outside temperature), one 50 liter cylinder was enough for me for a period of 1 to 7 days.

Endless:

– I have a frame house that is well insulated. I heat approximately 140 sq.m. At outside temperatures down to -20°C, three cylinders are enough for 5-6 days. At – 5°C – for 10 days.

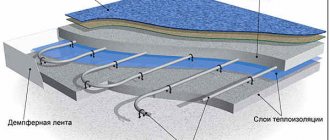

Mogol:

– I have a house with an area of 145 sq.m., the foundation is USHP, underfloor heating plus hot water supply. The boiler was turned on twice a day, for 2-3 hours. 50 l cylinders are filled with 20 kg. The temperature in the house was set to 23°C. Costs per month are as follows:

- November – 4 cylinders were used. Outside temperature +5-0°C.

- December – 10 pieces left. The outside temperature is -10 -27°C.

- January – 8 pieces left. The outside temperature is -5 – 20°C.

- February – 7 pieces left. The outside temperature is -5 -15°C.

- March – 6 pieces left. The outside temperature is -5 +5°C.

One gas cylinder holds from 35 to 42 liters of gas, in liquid form it is 22 kg. Liquefied gas consumption for any boiler is 15 liters per day per 100 sq.m. heated area.

Before you understand whether the game is worth the candle and whether autonomous gas heating of a country house will pay off, you need to familiarize yourself with the following data, which presents the economic feasibility of this or that type of heating.

2. An electric boiler operating in conjunction with a thermal accumulator (thermal accumulator) at a night tariff = 0.92-1.32 rubles/kWh.

3. Pellet boiler = 1.20 -1.32 rubles/kWh.

For comparison, the heating efficiency of liquefied gas is only 2.32 rubles/kWh.

When calculating the efficiency of a particular heating system, it is necessary to take into account that in the suburbs of Moscow and other regions there may be their own priorities in choosing fuel, which depend on its availability and climatic conditions. In some places it is cheaper to heat a house with coal, and in others with wood.

When calculating the profitability of heating with liquefied gas, many forget that the cylinders will have to be transported to a gas station on average once a week, and this is an additional expense - both monetary and time. Therefore, heating with liquefied gas can be profitable if 4 conditions are met:

- Small house area - up to 100 sq.m.;

- The house is well insulated;

- In the near future, it is planned to gasify your village; main gas will be connected. In this case, heating with liquefied gas is a temporary measure that allows you not to buy two different boilers;

- A liquefied gas boiler is a backup boiler and works in conjunction with other heating appliances.

Pros and cons of autonomous gasification

The release of gas energy occurs through its combustion. In this regard, this type of fuel is considered explosive, which prompts strict control of its use. Therefore, having decided to install an autonomous system in a country house, you should entrust its design and installation to qualified performers who have the appropriate licenses to perform the work.

Autonomous gasification is a technically complex system in which all components and systems provided for by the project are required. Their exclusion from the design or replacement with cheap analogues is fraught with serious consequences.

Disadvantages of autonomous gasification systems

Such devices free the developer from a lot of hassle caused by the need to replenish fuel tanks or solid fuel reserves. The second is also associated with significant costs of physical labor. But this is an apparent advantage, since owners of autonomous systems need to constantly monitor the condition of the system, the absence of leaks, and regularly carry out preventive measures. In addition, you need to constantly monitor the physical remaining fuel in gas tanks or cylinders so that you don’t suddenly find yourself in unheated rooms waiting for gas refills.

Advantages of using gas systems

The relative disadvantages of autonomous gasification systems include the high cost of both equipment and the cost of installation. But at the same time, one cannot ignore the other side of the economics of this problem:

- fixed costs for heating and hot water supply when using autonomous systems are much lower than those when using other types of fuel;

- When burning gas, emissions into the atmosphere are much lower than from other types of fuel. An example is the situation in Beijing, which is constantly shrouded in smoke from coal boilers;

- absence of unpleasant odor from the combustion of solid or liquid fuels;

- long life cycle of gas equipment - approximately 30–50% longer compared to liquid systems;

- high performance gas system;

- autonomy of energy supply, especially when using electric gas generators.

Installing a gas holder allows you to significantly reduce heating costs and obtain a reliable, durable and environmentally friendly source of energy in a private home

It is no coincidence that many consumers, having waited for the construction of a public gas main, refuse to connect to it and continue to use autonomous devices. Although all gas equipment installed earlier is absolutely suitable for use for main natural gas.

How much does turnkey autonomous gas heating cost?

Natural gas remains the most economical fuel for heating a private home. Gas can be supplied from the gas main using a gas tank or gas cylinders. Connecting to gas distribution networks will significantly reduce the volume of installation work.

List of works for installing a home heating system:

- Home inspection. The specialist inspects the house, takes measurements of individual rooms, advises the homeowner on technical issues, recommends a layout of equipment, etc.

- Heating design. At the design stage, the technical characteristics of the system and the optimal set of equipment are determined: the type of boiler and auxiliary equipment, its configuration, power and location of each element. How much a heating project for a private house costs is determined individually, based on the characteristics of the house and the choice of heating system.

- Purchase of a boiler and other equipment. The necessary equipment is agreed upon with the customer and purchased.

- Heating installation. Installation and piping of a gas boiler, installation of pipelines, connection of heating elements. Turnkey design and installation work is carried out strictly in accordance with technical standards, which is a prerequisite

- Heating testing and start-up. Testing, eliminating defects, starting and adjusting the system, putting it into operation.

Feedback from users of autonomous gas systems

Reading reviews about autonomous gas supply systems, you pay attention to a clear division of opinions: those who use alternative devices and those who want to install them.

Review Reviews

Based on their experience, happy owners of autonomous gas installations pay attention to the undoubted convenience of such devices, citing the ability to start the system at a time convenient for them and the desired heating mode, as well as the fact that the presence of a gas electric generator allows them to live in autonomous mode.

Summer residents are very pleased with the possibility of using the gas supply mode in standby mode, this allows them to achieve significant savings while simultaneously maintaining the house in good condition and ready for the arrival of the owners at any time.

Many people share their sad experiences of using inexpensive, low-quality system components. In particular, this applies to Indian gearboxes, the breakdown of which is almost guaranteed in the third year of operation. Moreover, this happens at the height of the heating season at the lowest temperatures. The failure is associated with the destruction of the membrane. Similar devices produced in Bavaria have been operating reliably for decades.

For those who are thinking about autonomous heating, the main problems are related to the high cost of equipment and its installation. It is estimated that their payback period is 10–12 years, and during this time additional costs are inevitable. But at the same time, potential users are attracted by the possibility of personally managing their living conditions.

conclusions

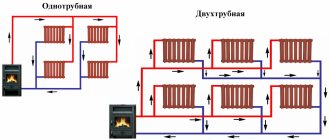

There are many schemes for installing and distributing heating in a private house - it is impossible to consider all options within the framework of one article. The choice of an economical heating system for a private house depends on many components, including the number of floors, area and architectural layout of the house in plan. When designing home heating, specialists should set the task of offering not just the cheapest and most economical heating - the chosen scheme should also heat the house as efficiently as possible, and its maintenance should be quick and inexpensive. Below you will find a detailed video on how to install gas heating in a private house with your own hands.