Best qualities

Distinctive features of TechnoNIKOL extruded polystyrene foam are:

- low thermal conductivity;

- almost zero moisture absorption;

- environmental cleanliness;

- resistance to compression and deformation;

- life time.

Each parameter is important for understanding the effectiveness and breadth of use of polystyrene foam.

Low thermal conductivity is ensured by the presence of sealed volumes in the material with a gaseous environment inside.

Extremely low moisture absorption is achieved due to the tightness of the internal volumes of the insulator slab. Water can only fill the outermost granules damaged when cutting the material. Thermal insulation without cutting has an indicator equal to zero.

The material is absolutely safe during installation and operation. Expanded polystyrene has a certificate of compliance with environmental safety requirements. The styling technician can work without protective equipment. The installed polystyrene foam heat insulator does not emit harmful substances into the atmosphere.

Created under pressure, the material has increased mechanical strength. This quality allows it to be used for insulating horizontal surfaces with laying screed.

The chemical basis of the heat insulator is extremely stable and stable over time, which allows the finished product to maintain its operational properties in terms of insulation quality for a long time. The material is not destroyed under the influence of electric magnetic fields.

Polystyrene insulation: what is it and how does it differ from polystyrene foam

A fairly large number of people do not fully understand what polystyrene is and how it differs from traditional insulation for house walls - polystyrene foam. Let's just say - polystyrene foam is a large group of materials made from plastic masses (plastics, if we speak in Russian) by foaming - as you understand, plastic comes in different forms and, therefore, depending on what is foamed, different materials are obtained. This means that polystyrene is one of the types of polystyrene foam, which is characterized by high strength, density and at the same time is very fragile. So, in general, it is incorrect to ask the question of how foamed polystyrene insulation differs from polystyrene foam - these are the same material, only with different properties.

You understand that the properties of insulation play a significant role in its selection, and if this property plays into a person’s hands, then it is elevated to the rank of advantages. If it’s not to your advantage, then, accordingly, on the contrary, it is considered a disadvantage. If the former outweigh, then the material remains in demand; if there is more of the latter, then it remains on the margins of history, which does not happen with polystyrene. And it’s quite easy to verify this by comparing it with the material that we usually call foam plastic.

- Light weight. It’s hard to say that standard polystyrene foam weighs a lot, but, nevertheless, expanded polystyrene foam weighs even less. What does this give? Yes, in general, nothing except the ability to use less durable glue to install it - its other characteristics are more important here.

- With a relatively low weight, it has higher thermal insulation performance, which is achieved thanks to the material from which it is made and technology. Without going into details, we can say this - this is a mass of small air bubbles that become a serious barrier to cold or warm air. In contrast, classic polystyrene foam works a little differently - and it is for this reason that where polystyrene with a thickness of 50mm is used for effective insulation, polystyrene with a thickness of only 30mm can be used.

- Density. I won’t describe much here, since many people know that deformed polystyrene foam does not return to its place. Expanded polystyrene is practically not deformed at all, and if the load on it is correctly distributed, it can even serve as a base for a floor. It is this factor that allows us to talk about polystyrene as floor insulation - in this respect it is better than polystyrene foam. It does not create a spring effect, in which when moving along the screed, a person does not feel some vibrations, as is the case with standard foam plastic.

- Unlike the same classic foam, polystyrene is able to withstand even the effects of alkalis and various acids.

And that is not all. According to official data from manufacturers, polystyrene filler is a fire-resistant material. In addition, it does not release any toxins or other harmful substances into the environment. This material has only one drawback (naturally, if we compare it with the same classic polystyrene foam) - fragility, which will require additional protection for this material.

Insulation in numbers

General technical characteristics of expanded polystyrene are expressed in the following figures:

- specific thermal conductivity is in the range from 0.032 to 0.036 W/mK;

- vapor permeability in the region of 0.01 mg/m h Pa;

- density varies from 26 to 35 kg/m3;

- water absorption is 0.2% of the immersed volume;

- elasticity is 17 MPa;

- bending strength – 0.35 MPa;

- deformation of 10% during compression occurs under a load of 200 - 400 kPa;

- flammability class G4 (highly flammable);

- operating temperature from – 70 to + 75 °C;

- service life – 50 years.

Technical characteristics of expanded polystyrene brand "TechnoNIKOL Carbon Eco"

The density of TechnoNIKOL extruded polystyrene foam was mentioned above, but the material described has many other characteristics that you should learn about before purchasing the product. For example, it may belong to the Carbon Eco line, which is excellent for thermal insulation of cottages and summer houses. If we compare with Technoplex, then in the production of TechnoNIKOL Carbon Eco we use nanocarbon additives, which increases the strength characteristics of expanded polystyrene.

The thermal conductivity coefficient of this type of insulation is 0.029 W/μ, while absorption during full immersion for a day is equal to 0.2% of the volume of insulation. The vapor conductivity coefficient is equivalent to 0.011 mg/mchPa, but the elastic modulus is 17 MPa. During the production of Carbon Eco, fire retardants are added to the ingredients, which will contribute to the attenuation of the material in the absence of direct exposure to flame.

Universal heat insulator

Technonikol xps extruded polystyrene foam fully realizes its improved thermal insulation characteristics when insulating balconies, loggias and floors, dachas and private households. Due to the large range of insulation materials produced for these purposes, it was given its own trade name - TechnoNIKOL Technoplex.

Expanded polystyrene TechnoNIKOL xps 30 is available in various modifications in terms of density, strength and thickness.

TechnoNIKOL xps 30 200 standard type is used mainly for insulating unloaded vertical surfaces of interior spaces. With a density of Technonikol xps 30 200 type standard of 30 kg/m3, it can withstand a load of 200 kPa. The dimensions of the Technonikol xps 30 200 standard plate are 1200x600 mm.

To insulate loaded surfaces, professional builders use TechnoNIKOL xps 30 250 standard type. This material can withstand 25% more compression load. TechnoNIKOL xps 30 250 standard type is available in thicknesses of 20, 30, 40, 50 mm. The 20mm sheet does not have an L-shaped edge. It is recommended to use Technonikol xps 30 250 standard for thermal insulation of external load-bearing structures.

Another representative of this brand is TechnoNIKOL xps 35, characterized primarily by the maximum possible density of 35 kg/m3. This gives it a maximum mechanical strength of 300 kPa and the ability to be used for insulating floors under concrete screed.

To secure sheets to a vertical surface, it is best to use polystyrene foam glue.

We insulate professionally

To insulate the zero level of a building, foundation and roof in use, a professional material with increased resistance to compression is required. A product line with the Prof extension has been developed and is being produced: TechnoNIKOL carbon prof polystyrene foam. It is used by professional builders.

TechnoNIKOL carbon prof 300 has the lowest thermal conductivity threshold and can withstand a load of 3 kg/cm2 at a density of 30 kg/m3. The most convenient to use are carbon prof 300 slabs 1180x580x50 mm.

Expanded polystyrene TechnoNIKOL carbon prof 400 belongs to the same category. With similar characteristics, it compresses by 10% under a load of 4 kg/cm2. To obtain such a load, it is necessary to fill the slab with concrete 1.25 m thick. TechnoNIKOL carbon prof 400 has an internal density of up to 36 kg/m3.

XPS carbon prof does not absorb water and provides a certain degree of waterproofing of building structures.

Characteristics of expanded polystyrene brand "TechnoNIKOL XPS 35-300"

TechnoNIKOL extruded polystyrene foam, the characteristics of which will be presented below for the XPS 35-300 variety, can be highly resistant to compression. For the mentioned option, this indicator is 300 kPa, which allows it to be used for thermal insulation of structures loaded during operation, namely roofs, etc. The density of the material is 35 kilograms per cubic meter, and the resistance to bending is 0.4 MPa, which is a very impressive indicator, especially when compared with similar materials.

We insulate environmentally

The use of nanocarbon admixtures for the production of insulation made it possible to obtain TechnoNIKOL carbon eco sp. The certificate of environmental compliance issued by TechnoNIKOL carbon eco sp allows its use for insulation work in residential buildings, healthcare facilities, preschool and school education. The addition of fire retardants to the starting material TechnoNIKOL carbon eco sp significantly reduces the level of fire hazard xps carbon eco. When insulating the walls of buildings, xps TechnoNIKOL carbon eco 1180x580x50 mm slabs are most popular.

Foam plastic for wall insulation

Polystyrene foam is an economically advantageous material. Economic benefits manifest themselves not only at the construction stage, but also at the subsequent operation stage. This is achieved due to high heat retention rates for insulating walls and other structural elements, as well as a reliable level of fire resistance.

When it comes to wall insulation, foam plastic takes more and more leading positions every year. Insulating walls with foam plastic has proven itself to be highly effective in this area. Up to 50% savings will come from wall insulation with foam plastic . Polystyrene foam also shows its effectiveness in the summer, keeping it cool.

During installation, slab thickness standards must be observed. For external walls this figure is 50 mm, and for internal walls 30 mm. Density - 25.

Using this material, you can carry out work on external and external insulation of walls. Outside, the installation process takes place using cement mortars, various mounting devices, glue and other things. When installing foam plastic, the inner side will have a good level of noise protection. It is necessary to use plasterboard sheets. You can use an alternative option - plaster.

The plates that are involved in the fastening process for the outer part must meet a thickness of 50 mm. The inner side will require 30 mm. The wall, which is located on the outside of the room, must first be treated with cement mortar. It is applied using a special metal mesh. After completion of the work, we can assume that the foam has been successfully installed.

Density. Index

When working on wall insulation, polystyrene foam has a density index of 25. An external wall with a 50 mm sheet will have high heat retention rates, as well as additional sound insulation.

Polystyrene foam with a density of 25 looks quite advantageous compared to its counterpart, whose density is 15. The main differences are in quality. You can feel a big difference in the quality of foam with a density of 25 and 15 without even starting to use them.

The extruded polystyrene brands presented earlier in the article have the following density indicators:

- 31C (from 28.5 to 30.5 kg).

- 31 (from 28 to 34 kg).

- 45 (from 38.1 to 45 kg).

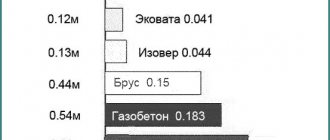

Vapor permeability properties

The vapor permeability indicator directly affects the efficiency of air exchange that occurs between the inside of the premises and the outside. This happens due to the fact that the air outside has a lower temperature than the inside.

When there is an exchange of air from the inside to the outside, the level of permeability should increase. In terms of vapor permeability, traditional foam plastic is superior to extruded foam.

Indicators:

- Traditional foam has 0.063 mg/(m*h*Pa).

- Extruded foam has 0.013 Mg/(m*h*Pa).

External insulation must be done exclusively with traditional polystyrene foam (density 25) ; extruded polystyrene foam (density 15) is suitable for internal insulation.

Why is this so? If you use extruded polystyrene foam for external insulation, this will lead to undesirable consequences. Its low vapor permeability has a high level of insulation; this will lead to the accumulation of moisture, which will not allow the materials to dry out and ventilate.

We insulate and protect

The unreasonable use of flat roofs can be corrected by using TechnoNIKOL carbon prof slope polystyrene foam. Using these slabs you can create a roof slope of 1.7, 3.4 and 8.3%. TechnoNIKOL carbon prof slope additional slabs placed in a separate position can significantly speed up the insulation of surfaces adjacent to ventilation shafts and skylights. The installation of TechnoNIKOL carbon prof slope makes it possible to change the direction of flow of rain and melt water without additional costs.

We insulate reliably

To insulate road objects, areas of territories, heavily loaded roofs and buried foundations, it is necessary to use TechnoNIKOL xps carbon solid polystyrene foam. Solid materials provide a strong and rigid foundation under (above) engineering structures, preventing soil freezing and displacement of laid coatings. The production of the following brands has been launched: TechnoNIKOL carbon solid 500, 700, 1000. With the same characteristics, they are distinguished by maintaining integrity under load in kPa, reflected in the number of the name. A good result with such indicators is guaranteed.