Positive Features

Malfunctions of the Baksi boiler, of course, sometimes occur, but it still has more positive features - automated operation, environmental friendliness, reasonable cost, ease of operation, and maximum adaptability to difficult conditions. The last feature is relevant for Russia.

Because the equipment is automated, it can operate for a long time according to a specific program. This is convenient for country cottages in which the owners do not live permanently, but from time to time. When such boilers operate, carbon dioxide is released into the air, which is absorbed by plants. This indicates the environmental friendliness of such devices. The manufacturer has made sure that the buyer repairs Baxi boilers as rarely as possible. The main faults and solutions are described below.

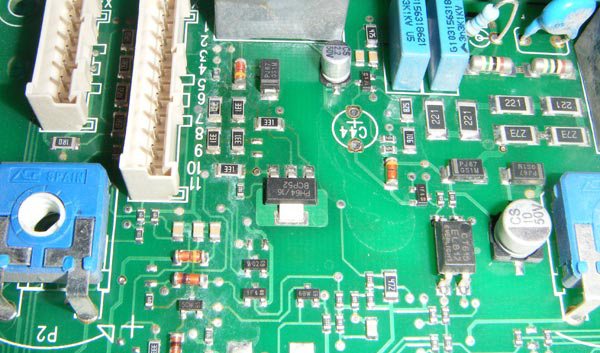

During the manufacturing process, equipment is equipped with protective chips that are capable of leveling out voltage fluctuations in the network.

Common boiler problems

You must be prepared for the fact that during operation of the equipment, malfunctions of the Baksi boiler may occur. This may be due to non-compliance with installation technology or operating instructions for the device. In some cases, malfunctions result from the use of low-quality coolant. In order for the owner of a house or apartment to be able to eliminate the cause when a malfunction occurs, it is issued in the form of a code on the display.

Below are a number of malfunctions that occur most often. Thus, error 01E indicates that the equipment has overheated. 02E indicates low water level in the heating system. This error can also occur if the flow sensor circuit is broken. If there is no flame signal, you will be able to see 03E on the display. A false flame message is indicated by the number combination 04. 05 indicates an open circuit in the temperature sensor. If malfunctions of the Baksi boiler occur, then in most cases you can fix them yourself. However, you should not start work if you cannot correctly determine the cause of the problem.

Installation features

Baksi devices use gas as a coolant, and despite all its undeniable advantages, it is dangerous. Gas boilers require a professional approach. The slightest error in installation can lead to very negative consequences. Installation of the device should only be carried out by highly qualified specialists. List of problems that DIY work can lead to:

- Freezing of the device in the winter season.

- The occurrence of an explosion.

- Fire.

- Penetration of carbon monoxide into residential areas.

Of course, modern gas devices have a high-quality protection system, but even “smart” automation is not always able to cope with problems that arose due to unprofessional intervention.

If we talk about a less serious outcome of the matter, the most common problem with self-installation is the incorrect operation of the equipment. For example, the device may not turn on and display error codes, despite the fact that the device is fully operational. Baksi boilers are energy-dependent units. They are not able to function without being connected to the mains. The connection rules are quite simple and are no different from the requirements for installing a standard electrical device. The device is connected to a 220 V network; grounding is required.

Of course, if there is no grounding, the boiler will not turn on with a “bang” sound, but this may negatively affect the operation of the equipment. Quite often, the boiler displays error codes due to simple connection errors. If at the moment it is not possible to ground, you should purchase a stabilizer with galvanic isolation.

In addition to the need for grounding, there are other features when installing equipment. It is very important to follow these recommendations:

- In order for the boiler to function properly, the pressure must be 170-250 V. At a lower voltage, the equipment will turn off, and at a higher voltage, the varistor will burn out.

- The sinusoid should flow without disturbances. Such devices react very negatively to voltage surges. Professionals advise installing additional voltage stabilizers. When installing gas boilers, there is no need to use UPS devices.

- The connection must be made through a separate machine.

- If the model is phase-dependent, it is necessary to maintain the correspondence of phase and zero.

We recommend: Pressure testing of the heating system - the most complete information

Error 01

Malfunctions of the Baksi boiler can be indicated by the above combination, which occurs most often. Acts as a common cause of decreased flow or blockage in the heating system. You can also see this error if the circulation pump fails. In order to fix the problem, it is necessary to analyze how correctly the heating system works. The filter should also be checked; air may become trapped in it; if necessary, it will need to be removed.

A malfunction of the Baxi gas boiler may occur when the impeller of the circulation pump is damaged.

Error classification

Baksi gas boilers have energy-dependent automation. For convenience, special error codes are displayed on the control display.

Conventionally, all problems can be divided into two types:

- complete blocking of the heating system;

- transition of the equipment to standby mode.

Very often, if the gas system is completely blocked, a manual restart of the unit is necessary, since the boiler stops functioning only during serious breakdowns that can lead to a threat to life and health.

The display shows the temperature as well as an error code in case of breakdown

Such problems include:

- stopping the fuel supply;

- system overheating;

- lack of traction.

Sometimes breakdowns occur that the system can handle on its own. In this case, the device restarts and continues to function. However, this happens very rarely.

Troubleshooting:

- Code E01 appears on the display only when the flame sensor is triggered. In some cases this may happen accidentally. You need to make sure that the gas supply is normal and the sensor is connected correctly. After this, press the R key and hold it for 2-3 seconds.

- Problem E02 is related to the thermostat. The system can issue such a code if the water is overheated or the sensor transmits an incorrect signal. Signal disruption is possible if contact is broken or the sensor is broken. Overheating also occurs due to improper circulation of the heat exchanger. This happens if there is a lot of scale in the equipment, the heating circuit filter is clogged, the pump is broken, or the unit is air-filled. The thermostat may break down or the contact between it and the control board may be broken.

- If error E3 occurs in an open gas boiler, there is most likely a draft problem. This can happen if installed incorrectly. In addition, the thermostat sensor could be broken or the contact could be lost. In a closed system, the same problems are possible, as well as a faulty control relay or a broken fan. You can clean the fan yourself and lubricate the radiator bushing and axis.

- Code E4 appears when there is no flame control. This usually happens due to a clogged chimney or other chimney problem or bad wiring. The error may warn of instability of the network voltage or failure of the electronic board.

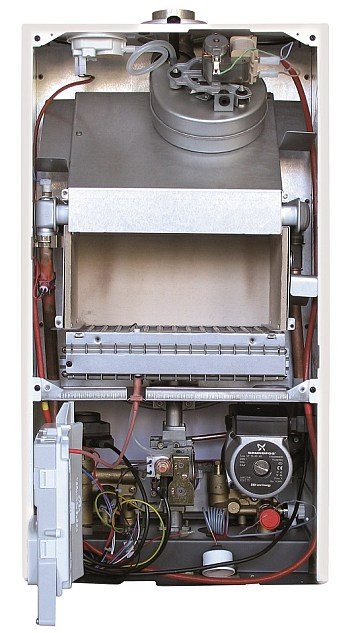

Opening the boiler in case of breakdown:

One of the most common problems is error E10 on a Baxi gas boiler. This problem is associated with the sensor responsible for water circulation and pump operation. The Baxi E10 code appears if:

- gas pressure is reduced;

- there is a fault in the board contact;

- problem with the pressure switch;

- pump sensor failure;

- The filter in the heating zone is clogged.

When an E 10 error appears on a Baxi boiler, it is not always possible to fix the problem yourself. If the pump breaks, it should be replaced. You can also clean the filters yourself. Sometimes this is enough to fix the problem. More serious repairs should be carried out by a professional.

The name of the buttons and their functions on the Baxi boiler

Error a00

If this error code is displayed on the screen, this does not mean that the boiler is faulty. This code may appear on the display when the “Info” mode is activated. “Error” a00 rhythmically changes to numbers that display the current temperature at the inlet pipe of the heating circuit.

Error e00

This malfunction is very serious, since it indicates that the electronic control board of the boiler has failed. Error e00 can only be resolved with the help of a service center representative, and under no circumstances should you attempt to resolve this error on your own.

Error e03

This error can occur in a situation where, for some reason, the pneumatic relay does not work correctly. Also, an error code e03 may appear if the traction sensor is faulty. Also, this malfunction can occur in a situation where, for some reason, there is difficulty in removing combustion products. This may be due to:

- improper installation of the chimney;

- chimney blockage;

- failure of the exhaust turbine;

- complete failure of the pneumatic relay.

The Venturi tube, which is used to measure the draft force in the smoke exhaust duct, may also be faulty. When the turbine starts, the pressure in the chimney changes, and this change is captured by the Venturi tube. The tube is connected to a pressure switch in which the membrane is located. The membrane reacts to pressure changes, and its movement closes or opens the contacts of the microswitch of the pressure sensor. Incorrect operation of these elements can cause error e03 to appear.

You also need to check the turbine itself. First of all, the presence of free rotation of the shaft is determined, and then the fan itself is checked. The presence of voltage at the terminals of the wire that comes from the electronic board is also checked. The windings of the turbine electric motor are also checked. Their resistance should be in the range from 38 to 48 ohms. If the resistance does not meet these parameters, the fan should be replaced.

We recommend: How to make a bio-fireplace with your own hands: assembly instructions

Along with the turbine, you need to check the condition of the chimney and the correctness of its installation. The air relay must also be carefully checked for operation. You can use a pressure gauge to check.

Also, the cause of error E03 in Baksi gas boilers may be poor contact on the connectors that connect the electronic board to the turbine and relay. Poor contact can be caused by oxidation, which can occur when moisture gets into the connector.

Code E02 – thermostat-fuse against overheating

The manifestation of this error, displayed on the display as “E02” or “02E”, can also be accompanied by various variations of defects.

An example of the appearance of code 02E (E02) on the display of the Caldera Baxi Roca Victoria boiler model. Meanwhile, this kind of failure is also typical for other models.

In particular, the following defects may appear:

- the temperature of the main circuit water is exceeded;

- the circuit temperature sensor is faulty;

- no contact on the heating circuit temperature sensor;

- the coolant circulation in the primary heat exchanger circuit is insufficient;

- clogging of the filter, heat exchanger, presence of air in the system;

- circulation pump defect;

- fault on the electronics board.

The same errors are typical for boiler models that do not have a display. They are determined by the presence of a glowing indicator with a temperature marker.

Code E01 and E04 – flame control sensor

A situation typical for most models is related to the functionality of blocking the boiler ignition system. The classic error code for such cases is “E01” or “01E” (and also “E04” or “04E”), displayed on the information display.

If the design does not provide for a display, the same error is identified by the corresponding LED indicator.

Instability of the gas supply, malfunction of the flame control sensor and other technical malfunctions of Baxi equipment are the result of the appearance of code E01 (01E)

Relationship between error and possible situations:

- no gas supply;

- the contact on the flame sensor is broken;

- the flame control sensor is dirty;

- malfunction of the ignition system;

- on the power line, phase and zero do not correspond;

- malfunction of the gas tap, electronics, coaxial chimney.

Accordingly, based on possible malfunctions, you should check all of the specified components (elements) to ensure correct operation, and if not, carry out repair measures.

Error e05

A malfunction with this code indicates that the temperature sensor of the heating circuit is not measuring the temperature correctly. This can be caused either by a failure of the sensor itself or by a failure of the electronic board. In rare cases, it happens that contact between the electronic control unit and the temperature sensor simply disappears. In this situation, you need to carefully check the connectors that connect the temperature sensors to the electronic board.

Error e06

An error with this code also indicates a malfunction of the temperature sensor, but not of the heating circuit, but of the DHW circuit. This error can be triggered by the same reasons that are described in the previous section.

Codes E12 and E13 – DGP malfunction

The appearance of code “E12” (“12E”) or “E13” (“13E”) on the boiler display clearly indicates malfunctions associated with the operation of the differential hydraulic pressure switch.

Usually, during testing, a signal from the device is not detected, or there is a signal, but does not correspond to the specified characteristic (false signal)

The reasons for the appearance of the marked code may be:

- stopping the pump;

- presence of air in the hot water system;

- low circulation rate;

- there is no contact on the TIR or a “stuck” contact;

- membrane damage or filter clogging;

- Impulse tubes are clogged.

Accordingly, a technical check should be carried out to determine the malfunction of a specific element.

And in order to eliminate the problem, it is necessary to replace the faulty element or carry out preventive restoration work.

Error e10

Malfunction e010 occurs when the signal from the hydraulic pressure switch disappears. An error with this code may be caused by the operation of a sensor that monitors water pressure. There have been cases where an error with such a code occurred when the contact between the relay and the electronic control board was lost.

There are four main causes of error e10:

- Leaks in the heating system.

- Failure of the expansion tank, or lack of air in it.

- Failure of the water pressure sensor in the heating circuit.

- Clogged “oblique” filter on the return line.

Codes E21-22 and E97-99 – electrical and electronics

Both codes - "E21" and "E22" - indicate faults associated with the electronic board. Code “E22” may appear if the supply voltage drops below the control value (162V).

The same code is displayed on the display if the quality of energy supplied to the boiler does not meet the stated standards.

For code “E21”, a characteristic point is the scattering of controller parameters and disruption of normal gas combustion. If you lack experience and relevant knowledge, it is better to entrust board repair to a specialist.

Errors “E97”, “E98”, “E99” - all three codes are usually associated with defects in the electronics - electronic board.

Code “E97” indicates the frequency of the supply voltage does not comply with the standard. The code “E98” indicates defects that are present specifically on the electronic board.

The same thing is indicated by the code “E99”. True, the “99E” error can also be caused by too low gas pressure, as well as a malfunction of the flame sensor

The simplest defect is loss of electrical contact on the gas valve relay. In other cases, the board usually needs to be replaced.

Codes E25-27 and E32 – temperature defects

The appearance of any of these codes - “E25”, “E26”, “E27”, “E32” - is usually preceded by temperature changes in the heating circuit, occurring at a faster rate than set by the control system.

For example, if the temperature of the heating circuit (HC) increases by more than 1 degree per second, the code “E25” (“25E”) is displayed on the boiler display. For code “E26” (“26E”) to appear, the temperature exceeding the set temperature by 20 °C is usually sufficient.

We recommend: Review of the Breneran long-burning stove with a water circuit: instructions for use

Malfunctions or failures marked on the display with code E26 (26E) are a reaction to temperature deviations. Due to temperature failures, other codes of the same group may appear

Reasons that traditionally cause such codes:

- blocking the circulation pump;

- filter clogging;

- air inside the system;

- defective temperature sensor KO;

- electronics malfunctions;

- Incorrect installation of the DHW sensor.

To eliminate it, it is necessary to carry out preventive measures aimed at checking and testing DHW and CO units. Air in the system is removed using standard plumbing practices.

The performance of the circulation pump is checked by electrical and mechanical parts.

Codes E50 and E62 – NTC sensor and flame control

The automation of Baksi boilers is adjusted to certain parameters of combustion stability, as well as to a certain temperature range of flue gases.

Error E62 – burner flame control sensor

If any of the two parameters (or both at once) goes beyond the settings, the automation is activated, and the code “E62” (“62E”) appears on the control display screen.

Traditional reasons:

- faulty or dirty flame control sensor;

- faulty NTC sensor;

- electronic board defects.

Sensors are tested by replacing them with known good ones, and electronics are tested with instruments designed for such purposes.

Error E50 – NTC temperature sensor

The occurrence of the “E50” error is typical for boilers of the ECO-5 and Main 5 models. The “E50” code is usually displayed on the control display due to the detection by the flue gas heating temperature sensor above 180 °C.

Another sensor present in the design of the Baxi boiler, a defect of which leads to the appearance of code E50 (50E) on the control display

In turn, a rise in temperature above the set limit may be due to:

- low coolant circulation rate;

- clogged filters;

- the appearance of hydraulic resistance in the system;

- low concentration of antifreeze;

- circulation pump defects;

- system contamination or air ingress.

Also, the fault code “E50” (“50E”) is displayed on the display when the NTC sensor breaks down, due to electronic malfunctions, due to incorrect settings of the gas supply valve.

Accordingly, elimination is ensured by consistent testing of the designated units and carrying out the necessary work.

Error e25

This error in Baksi boilers can also be caused by a large amount of air that has accumulated in the heating circuit. The airiness of the heating system contributes to the rapid heating of the coolant, and it is to this rapid heating that the electronics of the gas boiler reacts - it turns off the heating device, displaying error E25 on the screen. Also, the occurrence of this malfunction can be caused by a breakdown of the circulation pump, or failure of the temperature sensor. Most rarely, this error appears due to incorrect operation of the electronic control board, or lack of reliable contact between the circulation pump and the electronic control unit.

E26

The set temperature is exceeded by more than 20 degrees. Error e26 occurs for the same reasons as e25, and similar methods of elimination.

E27

Incorrect location of the temperature sensor in double-circuit boilers. Error E27 is caused by a sensor failure or incorrect installation. How to fix this failure is to check the operation of the sensor and its position.

E32

Error E32 signals the formation of a large amount of scale in the heat exchanger. To eliminate this, you need to clean the heat exchanger from scale. To clean it with a reagent, you need to remove the heat exchanger, first draining the water from it and turning off the water and gas supply valve.

E35

A parasitic flame appears before the flame sensor sends the gas valve open. Error E35 appears when water appears on the electronic board, the gas valve is depressurized, the parameters in the electrical network do not meet the requirements of the instructions for the unit, or the board has failed. Most often, installing a stabilizer and grounding helps in this situation.

Heating boiler board

E40

Blocked chimney or too low gas supply pressure. There can be many reasons for the E40 error, the main ones are a lack of gas supply, a violation of draft in the chimney, insufficient air, incorrect operation of ionization sensors, exhaust gases, failure of the gas valve, and the board does not work. You can check the chimney yourself; it is better to entrust the rest of the diagnostics to a specialist.

E41

Error e41 has the same causes and solutions as e40.

E42

Indicates loss of flame. Error E42 occurs when the chimney is clogged, there is no contact between the board and the fan, the fan is faulty, or the rules for installing the chimney are violated. You can check the draft in the chimney with your own hands; for everything else, it’s better to call a specialist.

E96

Error E96 lights up on the Baxi Main Four display when the mains voltage drops. In this case, restarting the unit may help. If the situation repeats, invite a specialist from the service company. On a Baxi SLIM device, this code occurs if there is a malfunction in the control panel. Only calling a specialist can help here.

Boiler Baxi Main Four

E97

If the frequency setting of the signal supplied to the board does not match, error e97 lights up. To resolve this, change the frequency.

Reason for error

Such a malfunction of the Baxi gas boiler can occur if the system is aired and there is a lack of coolant in it. If the circulation equipment is in working condition, but is not able to gain normal speed, this can lead to equipment failure. Damage to the impeller will lead to the same error. Quite often the flow sensor in the system does not work and the distribution valve turns out to be closed.

Basic malfunctions of gas equipment. Why do they arise?

When operating any equipment, especially something as technically complex as Baxi boilers, various emergency situations arise, the elimination of which depends on the user’s ability to diagnose the breakdown, purchase the necessary spare parts and repair the fault.

Consider the most common malfunctions of the Baxi gas boiler and the main spare parts for eliminating them.

Pressure drop in internal systems

The main reason for sudden surges and drops in pressure and a decrease in equipment efficiency is a malfunction of the coolant, namely a coolant leak. If the device is not repaired in time, there is a risk of loss of essential spare parts and complete failure of all systems. To eliminate the pressure drop, it is necessary to measure the dropped pressure from time to time, taking into account that the norm is a pressure of 1.6 atm. and replace basic spare parts that have become unusable. Error with designation e01 or e10.

The equipment does not turn on

The main reason for the repair is the failure of the main draft sensors due to freezing of the air intake pipes. This occurs when there is a sharp drop in external temperature and a decrease in pressure in internal systems. Fixing the breakdown involves repairing the frozen tube, namely removing it by 10-15 cm and replacing it with a new one. Error with code e10.

Pressostat boiling

The cause of this malfunction is the penetration of condensate into the boiler and an increase in pressure several times. Untimely repair of Baxi gas boilers can lead to damage to the flame modulator. For maintenance, special spare parts in the original configuration are required.

Stabilizer failure

Frequent pressure drops lead to breakdown of sensors, which, in turn, stop ensuring the operation of the stabilizer. The breakdown can only be repaired by purchasing and replacing spare parts. Error coded e01.

Rice. 2 Stabilizer

Gearbox

In addition to the above reasons, the pressure may drop due to a gearbox failure, which entails an immediate need for its maintenance. Error e03.

The listed faults are the most common, but not the only ones. However, in order to avoid various troubles. As with any other equipment, it is necessary to carry out maintenance of the Baxi gas boiler at least twice a year, check the performance of the main units and, if necessary, carry out maintenance.

How to solve problems with gas equipment yourself? Above, we briefly examined the main reasons for the need to repair the Baksi gas boiler, however, it is difficult for the average user to independently diagnose, and therefore should understand in more detail the main faults and ways to solve them.

Boiler maintenance can be done in two ways:

- call a specialist;

- on one's own.

The first method of service is safer, but also quite expensive. Calling a specialist, diagnostics and the repair itself can cost more than buying a new gas boiler. Do-it-yourself maintenance is less financially expensive, but requires special knowledge and skills. Whichever method you choose, general information should be known to any user.

Rice. 3 Equipment diagnostics

What actions should be taken if the heating device for some reason fails:

- First, you need to find out the reasons for the system failure;

As a rule, the automation itself produces error codes: e01, e03, e10, etc. These values can be deciphered using the instructions that the developer compiled in such a way that the user can easily navigate if necessary. An error appears on the device display. For example, in case of pressure surges, it is best to purchase the necessary spare parts for repairs or contact a specialist.

- The second step is to search for spare parts for Baxi gas boilers. This stage is the most important, since the further functioning of the installation depends on the acquisition of high-quality spare parts. For example, if the system pressure fails, it is better to use original spare parts from well-known heating system manufacturers.

- Secondly, you can repair it yourself only if the lung damage is repairable and you do not need special equipment for this. The error, or rather its code designation, will help determine the degree of damage and the list of necessary spare parts. Thus, error e01 does not cause any particular difficulties, unlike code e03 or e10, which are associated with regulating pressure values.

Debugg

If you want to repair Baxi boilers yourself when the above error occurs, you may need to adjust the pressure. Experts advise getting rid of air that interferes with the operation of the system. You should check the pumping equipment's coil resistance and also consider the impeller, the latter of which may have some damage. Experienced users advise opening the distribution valve of the equipment, as well as disassembling the sensor housing, which will allow the flag to be cleaned.

The above-mentioned Baxi Eco Four fault codes occur in most cases due to the fact that an air lock has been created that is located in the hot water supply system. The water in the circuit is heated as required by the system, however, after the plug enters the heat exchanger, the temperature rises to the maximum, which leads to the above-mentioned error.

Causes of boiler failure

Breakdowns of Baksi boilers are rare, but still occur, because, as you know, things don’t last forever. Let's look at the most common causes of problems in the operation of Baksi boilers:

the gas went out after it turned on or while heating the water, respectively, on the screen you will see error E35, E01, E04;- it is impossible to light the boiler;

- the boiler overheats and stops functioning - error E02;

- strange noises when the boiler is operating;

- cotton near the burner;

- the radiators are not heated, although the boiler operates without interruption;

- damage to any sensor.

Having analyzed the operation of Baksi boilers, experts found the most common reasons for the failure of the Baksi gas boiler:

- incorrectly connected boiler to the 220V network;

- water has got on the microcircuit, or the burner is flooded;

- the heating system is installed incorrectly;

- water or coolant of poor quality. This significantly reduces the possibility of heating the coolant by the boiler;

- changes in the network or pressure drop.

In most cases, you will need professional help to repair your boiler.

Error 10

You can easily repair gas boilers yourself. Tips and operating rules are collected in the article. If error 10 appears on the display, then the fan may have malfunctioned, a bend may have occurred, or the tubes may have been connected incorrectly. Experienced users emphasize that this error is caused by a clogged chimney. If there are strong gusts of wind outside, the problems mentioned above may occur. In this case, sometimes there is a need to replace or repair the fan. You can check and clean the chimney yourself. More experienced technicians will analyze how correctly the tubes that go from the air sensor to the fan are connected. If there are kinks there, then you should get rid of them.

Weak burner operation

This is caused by the following factors: the pressure in the heating system is set incorrectly, the diode bridge or valve has failed. If the reason for poor burner operation is pressure, you can resort to manually adjusting the boiler by lowering the minimum pressure threshold. If the valve breaks, you need the help of a specialist. The valve is responsible for the gas supply, so replacing it yourself is highly not recommended.

You can only fix the above problems without the help of a specialist. In other cases, it is better to contact a specialist; this will help to avoid the danger that arises when replacing parts in a gas boiler.

We recommend reading on the topic:

- How to wash the heat exchanger of a gas boiler with your own hands

- How to make a solid fuel boiler with your own hands

- Step-by-step installation of a floor-standing gas boiler in a private house

- Step-by-step installation of a wall-mounted gas boiler in a private house