materials and methods for carrying out insulation work

Any builder knows that groundwater has a destructive effect on the foundation of a building. Moisture, penetrating into the structure of the material and freezing at low temperatures, expands, tearing off its fragments. Within a few years, the foundation may become unusable, after which the entire building may collapse. To avoid this, waterproofing the foundation is necessary: there are a variety of materials for this. You just need to choose the most suitable ones and apply them correctly.

There are different ways to protect a building structure from moisture. One of the most effective is built-up foundation waterproofing. This became possible thanks to the appearance on the construction market of new roll materials reinforced with polyester and having high tensile strength. They, unlike previously used glassine, roofing felt and roofing felt, are not subject to rotting, have better water-repellent properties and a longer service life. Among the most popular are isoplast, isoelast, mostoplast, bikroplast, ecoflex, technoelast (Russian production), aquaizol, krembit, spoliizol (manufactured in Ukraine), testudo, helastopley (Italy). The basis of these coatings are synthetic products such as fiberglass, fiberglass and polyester.

The foundation is protected with two layers of rolled material: it should be glued carefully, protecting it from possible mechanical damage (for example, during backfilling) using a geomembrane. Corrosion-resistant materials are suitable for waterproofing work. It is worth paying attention to compliance with all the rules by which foundation waterproofing is carried out: ENiR prescribes the installation of both primary (using rubber-bitumen mastic) and secondary protection. In this case, secondary protection consists of covering the base with rolled material. It is best to do this during the period of concrete hardening, when the construction of walls cannot yet begin.

Welded waterproofing is used to protect the base of the foundation, waterproof its side, and also to create a barrier layer between the foundation and the load-bearing walls of the house

The Technonikol brand is represented on the market of rolled waterproofing materials with high-tech products such as Vent, Solo, Technoelast and cheaper ones (for example, Bikrost). Using any of these materials, foundation waterproofing can be done efficiently: TechnoNIKOL has reliably proven itself on construction sites.

There is a division into classes: “Premium”, “Business”, “Standard” and “Economy”. The first includes Westoplast and Technoelast: bitumen-polymer materials produced from the best quality raw materials and using the most advanced equipment. With the help of such a waterproofing material, you can reliably protect the most important objects from groundwater. They withstand the most difficult conditions and have a long service life.

TechnoNIKOL roll materials are used for waterproofing the foundations of buildings of any type

This method of protecting the base can be used for:

- reinforced concrete blocks, provided that the seams between them are sealed using cement-sand mortar;

- for lightweight concrete filled with vermiculite, perlite, etc.;

- for slab foundations;

- for heavy concrete with granite crushed stone and gravel filler;

- brickwork after leveling it with cement-sand plaster mortars.

Work order:

- Before gluing roofing felt to waterproof the foundation, the surface is thoroughly cleaned of small particles, cement laitance and other contaminants. Cut off sharp edges and corners so that they do not damage the rolled material.

- A primer (primer) is applied to the base, which improves the adhesion of the built-up waterproofing to it. It binds the remaining fine dust and fills microcracks and pores, thereby strengthening the surface. In addition, it is moistened, which has a beneficial effect on the speed of work.

- After applying the primer, a certain time must pass (up to 24 hours) for it to dry: a dry surface cannot be sticky. Drying time depends on environmental conditions and type of primer.

- The rolled material is fused by heating its back surface using a gas torch or blowtorch. During operation, the waterproofing material is pressed tightly against the base, gradually unwinding the roll.

The rolled material is fused using a gas torch.

Vertical waterproofing of the foundation is carried out by gluing materials after melting their underside. In some cases, a “free” method is used, in which only longitudinal and transverse joints are fused, and the bottom layer is mechanically attached to the structure. If such devices are not available, the roll is cut into panels of the required length, which are laid horizontally for a day so that the strips are well aligned. The air temperature should not be lower than +15 °C.

TechnoNIKOL for garage roof: varieties and characteristics

How to cover a garage - TechnoNIKOL ! Such a soft roof refers to flexible finishing coatings made on the basis of bitumen. The material is based on fiberglass or polyester , impregnated and coated on the top and bottom sides with a special type of bitumen.

The top side has an additional basalt topping , which makes the material resistant to mechanical, atmospheric and temperature influences. The underside of the material is equipped with a self-adhesive bitumen layer with a protective film.

Technonikol roofing materials is their varied colors. The surface covered with this type of soft roof is not only durable, but also aesthetically attractive.

TechnoNIKOL garage roofs come in the following types:

- soft tiles;

- welded roll coating.

Advantages and disadvantages

TechnoNIKOL soft roofing has many advantages and disadvantages compared to other garage roofing materials:

- Resistant to both high and low temperatures. It will perfectly withstand heat of plus 50 , and frost of minus 50-60 degrees .

- One hundred percent waterproofing even in conditions of heavy rains and active snow melting.

- Anti-corrosion . The material does not rot, does not rust or oxidize at any level of air humidity.

- Resistant to wind and mechanical stress. Even the strongest hurricanes are not afraid of this roof. It cannot be torn off by a strong gust of wind, nor can it be damaged by hail or branches falling to the surface.

- Ease of installation . You can cover a garage with such materials yourself, without the use of special equipment.

- Attractive price. A variety of materials in different price categories will allow each consumer to find an option that suits them.

TechnoNIKOL soft roofing is the need for a continuous base for its installation. This requires additional costs for installing a pitched roof and laying a layer of plywood on it.

Installation terms and conditions

Features of installing a soft roof depend on the selected type of material. There are two main installation methods: fastening and fusing . The first is used on sloping roofs and requires the use of fasteners with nails, screws, and staples. Built-up roofing is designed for flat roofs . Rolled materials are rolled out over the surface and secured by heating with a gas burner.

, the roof base must be carefully prepared before installation . The surface is leveled, cleaned and thoroughly dried.

IMPORTANT! Only dry weather, without rain or fog, is suitable for installation, otherwise bubbles will appear on the surface of the material.

The air temperature for work should be no lower than plus 6-7 degrees and no higher than 25-26 degrees. The best time to work is from spring to early summer and early autumn.

Preparing the base

The longevity of a roof using TechnoNIKOL depends on the correct installation of the roofing pie and the organization of ventilation of the space under the roof. A roofing pie is a multi-layer structure that protects the interior space from precipitation and retains internal heat.

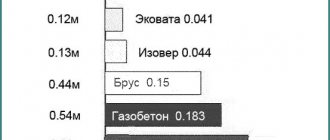

The design of the pie depends on material :

- Wooden cold roof . The roofing pie consists of layers:

- roofing;

- lining;

- base (plywood flooring). Experts recommend using moisture-resistant chipboard or OSB. The thickness of the plywood is ten to eleven millimeters. A gap of 3-5 mm is left between the plates in case of possible expansion due to changes in temperature and humidity;

- sheathing. The sheathing material must be impregnated with an antiseptic;

- rafter layer.

- Warm wooden roof . Its design requires the installation of additional insulating layers:

- roofing material;

- lining;

- diffuse membrane;

- insulation;

- vapor barrier;

- plywood base;

- sheathing;

- rafter leg;

- sheathing for insulation;

- lining of the internal roof space.

- roofing material;

- slope - expanded clay fill or concrete screed;

- thermal insulation;

- vapor barrier membrane.

Read more here about how to make a screed on the garage roof with your own hands.

Types of waterproofing materials for floors

Rolled waterproofing produced by modern manufacturers differs in the method of its attachment to the base and the type of base material. Based on the method of fastening, it is customary to distinguish between adhesive, weld-on and mechanically fixed waterproofing materials.

Fused insulation usually has a backing made of fiberglass, fiberglass or polyester, which have become substitutes for the traditionally used cardboard.

The binding component of roll waterproofing is bitumen mastics and their bitumen-polymer grades (often with the addition of atactic polypropylene (APP), which is also called artificial plastic or styrene-butadiene-styrene (SBS), also called artificial rubber).

Roll fused waterproofing is one of the most popular materials due to its performance, easy installation and affordability. When installed correctly (following the required technology), such waterproofing forms a single whole without cracks or joints, which significantly increases its waterproofing qualities.

Mechanically fastened roll waterproofing differs from the fused version in that the bottom layer in it is not a polyethylene film, but fine-grained sand. The prototype of this kind of roll waterproofing with a mechanical method of attaching it to the surface is the well-known roofing felt.

Modern roll waterproofing is attached to the surface using self-tapping screws or overhead strips. The disadvantage of using this material is the complexity of its installation and its insignificant effectiveness in protecting the surface from moisture.

Adhesive waterproofing or, in other words, adhesive waterproofing, similar to built-up waterproofing, has a base consisting of polyvinyl chloride or fiberglass with a bitumen-polymer component and mineral chips applied to it. Laying of adhesive waterproofing is done using mastic or glue based on epoxy resin. Reliable moisture protection is achieved by creating 2-5 layers of waterproofing material.

Adhesive waterproofing can be installed on any base - no special professional knowledge or additional tools are required for their installation. The main condition for the correct implementation of waterproofing with adhesive materials is the preparation of a flat (without protrusions) surface of the base for them.

Coating mixtures for gluing materials ↑

Adhesive mastics represent a category of products used when carrying out work using insulation, roofing and waterproofing bitumen and bitumen-polymer materials glued to the base. Waterproofing work using them is most often carried out using the coating method. Can be applied to any substrate including concrete, wood and metal.

TechnoNIKOL coating adhesive mixtures have good adhesion both to the base and to the covering bitumen and bitumen-polymer roll materials, tiles and thermal insulation boards. Many professionals prefer the TechnoNIKOL product line. The adhesive mastic of this brand has proven itself in use and is popular.

Insulating composition of rolled waterproofing materials

The main ingredients for such materials can be bitumen compositions, bitumen-polymer compositions and membrane waterproofing.

Bitumen waterproofing composition is bitumen resin mixed with crushed basalt-shale chips. This combination is used in the production of roofing felt, construction roofing felt and glass roofing felt.

The bitumen-polymer composition is obtained by adding special additives to bitumen designed to increase its elasticity and heat resistance. Plastic modifiers in such compositions are artificial rubber (or plastic). Such modifying additives are needed to increase the resistance of the bitumen component to temperature changes and ultraviolet radiation, which makes it possible to use this type of coating in areas with hot climates.

Membrane insulation belongs to a new generation of high-tech materials. It is made of high or low density polyethylene, polyvinyl chloride or polyophepine and is a thin film with a thickness of 0.2 - 2 mm. For some types of membrane waterproofing coating, a layer of corrugation is applied for more effective adhesion to the solution.

The advantages of waterproofing membranes are their mechanical strength, resistance to damage, long service life (up to 50 years), environmental friendliness, resistance to rotting and decomposition, as well as a wide temperature range from -40 to +50 degrees Celsius.

The brand's roll waterproofing is one of the main leaders among waterproofing building materials in this segment of the international market. The reason for such a high popularity of this type of TechnoNIKOL product is:

- their high level of reliability and effectiveness of protection against moisture penetration and the formation of condensate accumulations;

- biological and chemical stability;

- the ability to maintain flexibility and elasticity at low temperatures;

- the ability to withstand significant tensile loads;

- long-term (about 35 years) service life;

- efficiency;

- ease of installation.

All these qualities of TechnoNIKOL waterproofing products are due to the use of a multilayer composition having a polyester base, two layers of bitumen-polymer filler and a protective film. The production of all types of brand coatings is carried out in accordance with state standards and current technological construction regulations.

Installation technology

How to cover a garage with Technonikol ? Installation of a soft roof is simple, but requires compliance with certain rules and a strict sequence of actions, depending on the type used.

For the vapor barrier layer, it is advisable to use a special TechnoNIKOL . They consist of three layers that will help maintain a balance of temperature and humidity inside the garage.

In addition, the strength of the material allows it to be laid on any, even untreated surface. For pitched roofs , a membrane should be used; for flat roofs , perforated and non-perforated film should be used.

You can read about the construction of a pitched garage roof on our website - here.

Soft tiles

Shingles from different packages must be pre-mixed to achieve a uniform shade of the coating .

There is no need to remove the protective film in advance; this is done gradually during the installation process. The installation procedure is as follows:

- An underlayment carpet is laid on the base of the roof .

- Ventilation vents are sheathed with special passage elements and carefully coated with bitumen mastic .

- Cornice and pediment strips are attached along the edge of the slope . Ridge-eaves elements are laid on top of them. If there are no special types of tiles, you can cut off the petals from the ordinary ones. The tiles are attached using a backing and nails 2.5 centimeters from the edge.

- Next, they begin to lay rows of tiles with each next row overlapping and offset by one petal. The edge of the second row of tiles should coincide with the edge of the previous one.

- The outermost tiles along the slopes are trimmed , the vertical row laid along the pediment is coated with mastic.

- The ridge is covered with a Technonikol and ridge tiles.

When laying it, pay special attention to the roof components and ventilation holes in the roof.

IMPORTANT! Professional builders advise starting laying rows from the middle of the slopes.

Roll material

How to cover a garage with Technonikol ? TechnoNIKOL roll roofing types are laid in one, two or three layers. The number of layers depends on the angle of the flat roof: the smaller the angle, the more layers will be required. Installation consists of the following steps:

- The cleaned and leveled surface is covered with a bitumen primer and dried.

- Laying the rolls begins from the bottom , heating them with a gas burner as they roll out.

- After the strip is completely rolled out, it is rolled with a roller . The edges of the strip are rolled especially carefully. If the material rises in some places, it is additionally heated with a burner before rolling.

- The next strip is laid with a side overlap of 8 cm, an end overlap of 15 cm. All overlaps are made in the direction of the surface slope.

- Funnels are insulated with double squares of 0.7x0.7 meters.

- At parapets, the covering must be turned up . The bottom layer rises by 25 cm, the top by 5 cm. The junction is insulated using a special tape.

ATTENTION! If the weather is hot outside, do not keep the material in the sun. Under such conditions, the protective film may stick to the material and be difficult to remove.

TechnoNIKOL roofing materials requires compliance with certain rules and work skills. However, you can handle it yourself and get a reliable and durable coating.

Read about how to make racks, shelves, a workbench and a car lift in your garage.

Storage and transportation rules

When storing rolled fused waterproofing, a number of rules must be observed - the rolls must be installed in a vertical position, access to moisture and direct sunlight must be blocked. The heat source should be more than a meter away from the rolls.

Waterproofing material is transported in covered transport, preferably in a vertical state. When installed vertically, the number of rows in height is no more than two. For horizontal transportation, no more than five rolls in height are allowed.

Which fused roofing material is better?

Fused materials for roofing are selected according to the following criteria:

A single-layer solution is ideal for roof reconstruction. Our recommendation is Icopal Syntan Solo Vent material.

On the Baurex company website you can use filters to compare materials for choosing waterproofing.

specializes in the supply of materials for flat roofs and performs roofing work using fused materials and PVC membrane roofing material. We are ready to offer you rolled fused materials (rolled roofing, fused roofing) from all major manufacturers:

| TechnoNIKOL | RKRZ | Icopal |

| Technoelast | Gidrostekloizol | |

| Uniflex | Elastobit | |

| Linocrom | Elastoizol | VillaTex |

| Rubemast | ||

| Steklomast |

Roll roofing: weight of binder

In different rolled fused materials, the weight of the binder (bitumen or bitumen-polymer) can vary from 1.5 to 5.5 kg.

Roll welded materials have the following markings:

HPP, HKP, TPP, TKP, EPP, EKP

The first letter indicates the type of base:

- X – fiberglass;

- T – fiberglass;

- E – polyester.

The second and third letters indicate the top and bottom layers of the membrane:

- P – low-melting film;

- K – slate or other protective fill.

We also install roll roofing.

Carrying out waterproofing requires an integrated approach that will affect absolutely all parts of the building. Only in this way can the maximum level of protection against external moisture penetration into residential and administrative premises be ensured.

Fused waterproofing seems to be one of the most optimal methods, since it allows you to get good results with a relatively small investment of time and effort. With its help, you can only process vertical surfaces, since it will be impossible to work with horizontal ones due to technological features.

The evolution of roll roofing

In order to solve the problem of inelasticity and premature aging of bitumen binder, APP and SBS modifiers began to be added to raw bitumen. The percentage of modifiers can range from 5 to 25%. SBS and APP modified bitumens have significantly improved performance characteristics. The heat resistance of roll roofing materials reaches 110 degrees, the material has become elastic, which allows it to be used on a flexible base, and its service life can reach 25-30 years.

SBS (styrene-butadiene-styrene)

- a highly elastic polymer (artificial rubber), which gives bitumen excellent flexibility at low temperatures. Its heat resistance is somewhat worse than APP, however, when using a high-quality SBS modifier, it can reach 100 o C. SBS coatings have excellent adhesion and excellent resistance to cyclic alternating loads. The elasticity of SBS bitumen reaches 1500-2000% (without base). When modifying bitumen for roll roofing materials using SBS, a polymer matrix is created, which is a three-dimensional network formed through the interaction of polystyrene blocks into so-called polystyrene domains. Bitumen is distributed within this elastomeric mesh in the form of a fine dispersion.

APP (atactic polypropylene)

— according to physical and mechanical characteristics, it belongs to thermoplastics. Having a high melting point, APP provides roofing materials with high heat resistance, resistance to ultraviolet radiation, and good flexibility. Being plastic, APP materials have low elasticity, but fatigue resistance under cyclic loads, thanks to the use of polyester bases, is quite high. Roll roofing based on APP modified bitumen is optimally applicable in hot climates.

The following materials can be used as a base for welding: Fiberglass (X), Fiberglass (T), Polyester (E).

Fiberglass is a non-woven bioresistant material consisting of randomly arranged glass threads. Fiberglass has a relatively low tensile strength of 294N, low elasticity of 1-2%. Fiberglass is recommended to be used in combination with fiberglass; in this case, the two-layer roofing membrane acquires the high tensile strength characteristic of fiberglass.

Fiberglass is a base consisting of interwoven glass threads. Fiberglass has a very high tensile strength (about 600N), but the material is practically inelastic. If the linear dimensions of the roofing surface change, the roofing membrane is simply torn off from the base without losing its waterproofing properties. The fiberglass will simply tear.

Polyester is the most expensive and reliable base. Consists of randomly oriented polyester fibers. The material has high tensile strength (up to 725N) and elasticity up to 50 percent.