Why should you choose insulated coating?

The popularity among consumers and the first position in the market of this flooring are ensured by its performance characteristics, ease of installation and general availability. As a rule, the question of using this type of flooring arises when there is a need to insulate floors efficiently, quickly and not so expensively. This material can be laid on any surface made of concrete or wood, but it is recommended to comply with certain requirements for the base.

Warm linoleum is divided into two types, one of them is made on a warm base, and the other is made as an insulated coating. There are very important differences between them not only in the structure of the canvas, but also in quality characteristics.

↑ Choosing warm linoleum

When choosing insulated linoleum, you need to take into account some features:

- for rooms with high humidity and rooms on the ground floor of the house, it is recommended to choose linoleum on a foam basis, since it is resistant to moisture and has increased thermal insulation properties compared to conventional insulated linoleum on a felt or jute basis;

- It is not recommended to glue ordinary household linoleum on a jute or felt basis due to a violation of the thermal insulation characteristics;

- When laying linoleum on a “warm floor” system, it is recommended to use ordinary insulated linoleum due to its greater naturalness.

Description of the main types of insulated linoleum: foam-based material

Insulated linoleum can be made on a foam base. It is used when there is a need to insulate floors without additional costs. This coating is especially often used when it is necessary to cover a concrete base, which is quite cold. This linoleum is also used for wooden surfaces.

These types of linoleum have significant thickness, so their use is justified in cases where the rough surface is not ideally even, has height differences and cracks, and there is absolutely no time to eliminate them. Insulated linoleum on a foam base has a rather complex structure. For example, the top layer is a decorative surface that can be any color. You can find similar material on sale that will have a special pattern and texture; these can be traditional or avant-garde options. The pattern is formed throughout the entire thickness of the layer, which ensures the preservation of an attractive appearance for a long time.

The next layer, which goes below, is foam rubber. It has excellent noise-absorbing and heat-insulating properties. The thickness of this layer is not so great: from 1.5 to 3 mm. However, this does not at all indicate that the effectiveness will not be as desired. In some cases, for additional rigidity, another layer is added, which is made of fiberglass.

A wear-resistant transparent film is applied on top, which is designed to protect the linoleum from mechanical damage; among other things, it prevents the penetration of contaminants into the structure. This flooring is not only practical, but also easy to maintain, it is easy to clean, and its durability is excellent.

Layers of linoleum on a foam base

The structure of foam-based linoleum is quite complex. The thickness of linoleum is large enough to provide the surface with heat and make it even. Linoleum with this type of base has a beautiful appearance, which contributes to its popularity among consumers.

One of the well-known types of linoleum, which is widely popular and has high-quality characteristics, is Tarkett.

This is linoleum with a heat-insulating surface, wear-resistant, durable and at the same time breathable. Its base consists of six layers, each of them performs its own function. Linoleum is thinner than felt-based flooring, but the addition of fiberglass makes it much stronger.

Foamed linoleum layers:

- Transparent layer for protection;

- Decorative;

- Foam layer;

- Primed layer;

- Bottom foam layer;

- Back layer.

This is the most practical type of flooring. It is easy to care for and wash. It is only important to remember that it is better to clean linoleum every day, and not just once after it becomes impossible to wash it from accumulated dirt and dust.

Description of warm-based linoleum

If you are interested in insulated linoleum, then you should pay attention to the material, which is made on a warm basis. It is a film that is glued to a felt or jute base during the production process. This type of coating is soft and resilient, making it pleasant to walk on. Laying this coating is quite simple, since it does not require labor-intensive gluing on the rough base. However, there are also disadvantages, which are expressed in the fact that the top layer is not very durable. Therefore, the material can be easily damaged, and during operation it requires careful handling.

In places where there is high traffic, such a coating can quickly lose its attractiveness. Among other things, linoleum on an insulated base cannot be used in rooms with high humidity, because under the influence of water the base can simply collapse, which is especially true for natural materials. But in a children's room or bedroom such a covering would be appropriate.

Types of linoleum

Based on wear resistance, they are divided into several types, regardless of the base:

- Domestic. Used in living rooms with low traffic. This is the most economical type. It is light, soft, and comfortable to lay on. Budget option - suitable for a country house, auxiliary premises. Coloring of this type is primitive. How to make household linoleum warm? Lay film under the linoleum. A thick film will do its job and retain heat.

- Semi-commercial. This type of linoleum can withstand increased loads. Used in residential premises and offices. If the floor is concrete, warm semi-commercial linoleum will help retain heat. The coloring is usually parquet or tile.

- Commercial linoleum is used in areas with high traffic. It has increased abrasion resistance. Where there are many people, shoes are not removed, so in these rooms there is no need to insulate the floor. And yet, sometimes warm commercial linoleum is also necessary.

The homogeneous type of linoleum is produced using a special technology. The homogeneous coating is painted with dyes to the entire depth of the working layer.

Even after prolonged use in trafficked areas, when the outer surface is abraded, the original pattern is retained. This type of coating can also be made with insulation.

The warmth and softness of linoleum with a backing is quite noticeable

This linoleum is often used in classrooms and auditoriums where there are often a lot of people. Homogeneous linoleum on a warm base will last a long time even under these conditions.

Reviews about choosing insulated linoleum

If you decide to purchase linoleum on an insulated base, then consumers recommend adhering to the general recommendations that apply to this type of flooring. Thus, for rooms where conditions are characterized by high humidity, linoleum on a jute or felt basis is not suitable. But in those places where a high load on the floor surface is possible, foam-based linoleum will feel better.

When choosing materials for different rooms, you should pay attention to the patterns and colors that should be combined. Consumers are advised to choose a covering material whose width allows it to be laid with fewer joints. Before purchasing, it is important to pay attention to the wear resistance class, which will determine the durability of the product.

Types of insulated linoleum (video)

Insulated linoleum allows you to significantly save on installing heated floors. It is usually used on cold concrete wood surfaces. Linoleum can have several bases, but they all differ in their heat and sound insulation function. This quality largely depends on the thickness of the coating. You need to choose the material very responsibly, taking into account the characteristics of the room in which the linoleum will be laid. Linoleum comes in three types: household, commercial and semi-commercial. When purchasing, be sure to check the product quality certificate.

Source: kitchenremont.ru

Warm linoleum on a cold floor

Reviews of felt-based linoleum

Thick insulated linoleum can be made on a felt basis. According to the manufacturers, it consists of two layers, the bottom of which is made of an antiseptic gasket. The top layer is made on the basis of polyvinyl chloride film. In order to lay such material, it is recommended to clean the base from debris and dust. The rough surface must be strong and smooth.

Experts say that it is important to prevent moisture absorption by the fibrous part of the material. To do this, it is important to make sure that the moisture content of the base does not exceed 5%. To do this, it is recommended to use a small piece of glass, which is placed on the surface and left for 2 days. If after this time you notice traces of moisture on the inner surface of the glass, then the base is not suitable for laying a felt base, since such linoleum may simply begin to rot after a while. Failure to dry the surface properly will result in additional costs in the future. In this case, it is necessary to treat the surface with special solutions that prevent the spread of mold.

Variety of linoleum depending on the type of insulation

What to put under homogeneous linoleum for warmth? When used on a floor that is dangerous from the point of view of dampness, it is advisable to take gaskets with a foil covering.

Before laying lined linoleum in a damp room, you should think carefully

These substrates can be synthetic, such as polyester, padding polyester, or made from materials such as flax, wool, jute. The use of natural materials for this layer allows you to achieve a good thermal insulation effect.

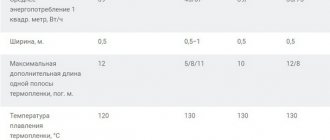

Linoleum thickness required for warmth varies depending on the type of insulation. This may affect the size of the coating itself. The minimum width of produced linoleum is 1.5 m, and then it can increase in increments of 0.5 m.

The widest canvas is made using foamed polyvinyl chloride insulation. Design features make it possible to produce a covering 5 m wide. This is the most popular size, especially in apartments with a traditional arrangement of rooms.

The convenience lies in the fact that there will be less waste and joints when installing the canvas.

When using felt as insulation, the width of the linoleum is up to 3 m. Felt is softer than the previous material and it would be difficult to lay a large covering.

Which linoleum is the thickest and warmest? With felt insulation, the thickness of linoleum can reach 5 mm.

Another type of insulation made from natural materials is jute fabric. But due to its specificity, the width in this case does not exceed 2.5 m.

The length of linoleum in a roll varies from 15 to 60 m. It is sold in the retail chain both in rolls and by linear meters.

Linoleum from different manufacturers: Tarkett brand material

If you are interested in the described material, then you can pay attention to the insulated linoleum “Tarkett”, which has been manufactured for more than 120 years. During this time, the company has established itself as a manufacturer of durable and safe flooring solutions. Today Tarkett is the number one brand in Russia, this title distinguishes it among analogue manufacturers of floor coverings. This linoleum is insulated, the price of which starts from 196 rubles. per square meter, ready to last more than 10 years with proper installation. It belongs to the KM5 fire safety class.

Felt base

Compared to the previous one, this base layer is more environmentally friendly and thicker (up to 5 mm). It is warm and soft, so it is an excellent solution for ground floors or private houses.

The thickness of the base also provides good soundproofing properties of linoleum.

The disadvantages of a non-woven base include low moisture resistance, susceptibility to rotting and the appearance of fungus, so the presence of a damp and unheated basement under your apartment will inevitably lead to rapid deterioration of the coating. Today, the felt used for this base layer is impregnated with special waterproof and antifungal substances, which gives it relative moisture resistance

Also, compared to foam, the main felt layer is less resistant to point and mechanical loads - in other words, dents left behind by furniture and other heavy objects never disappear.

Felt-based linoleum can shrink up to 10 mm, so before fixing it with skirting boards, you need to let it sit for some time. But you can lay it on a not-so-even floor - the main thing is that it is dry, if protection from moisture is not provided. This linoleum is ideal for a bedroom, living room or nursery, where it will provide the necessary softness and comfort.

As you can see, the answer to the question “What is the best base for linoleum?” directly depends on the type and characteristics of the room for which this flooring will be used.

Linoleum

You can insulate the floor with linoleum using material from, which offers its products from 181 rubles. per square meter. This material has a protective layer whose thickness is 0.15 mm. The coating belongs to class G4 in terms of flammability.

Fiberglass is used as a protective layer, and the abrasion rate is 35g/m2. According to tests, the change in linear dimensions can be 0.2%. The manufacturer indicates that the service life of the material reaches 20 years. This insulated linoleum, the price of which is acceptable for the average consumer, has the quality of moisture resistance and can be used for heated floors.

Coatings with base

Household linoleum on a heat-insulating base. “Budget” material for residential premises with normal humidity. The polymer layer is the same as that of thin household options. A glued heat and sound insulation (TSI) substrate made of jute or felt - natural or synthetic - increases the total thickness of the canvas to 5 mm. Thanks to the base, the finish retains heat well, is soft, elastic, and shows less unevenness in the subfloor. However, a heavy cabinet will certainly leave a mark on it. It is advisable to lay linoleum on a heat-insulating base without seams, otherwise when washing the floors, water will get on the felt and the coating will deteriorate.

Household linoleum on a foam base. There are many varieties of such material. In the simplest case, its structure includes two layers: decorative from dense PVC and insulating from foam. Products with an additional transparent protective layer retain their attractiveness longer. How much longer depends on the wear resistance and thickness of the protection (from 0.10 to 0.35 mm with a total coating thickness of 2 to 3.5 mm). Foamed polymer is generally more stable than felt and is not afraid of moisture. Summary: where frequent wet cleaning is required (kitchens, hallways, bathrooms), foam-based linoleum is preferable to felt linoleum.

- 1 of 1

On the picture:

Household linoleum flooring is intended for use in private houses and apartments.

Semi-commercial linoleum. Its structure is the same as that of a household foam-based one. The main difference is in the thickness and strength of the protective layer. The semi-commercial “armor” reaches 0.5 mm. Such linoleum floors last 5–10 years, depending on the location of installation. Manufacturers recommend their products for finishing offices, as well as kitchens and hallways in apartments.

Commercial heterogeneous PVC coating. Consists of at least 4 layers with a total thickness of 2–4 mm. Layers are made of different materials in various combinations. Let's consider the most typical option. At the bottom there is a non-moisture-absorbing elastic base that provides operational comfort and compensates for unevenness of the subfloor. Above is fiberglass - a load-bearing layer that prevents deformation. Above it are two more - decorative (with a pattern) and protective. The wear resistance of the coating depends on the thickness of the latter (up to 0.7 mm). The scope of application of heterogeneous linoleum is extremely wide. Such linoleum floors are used both in residential buildings and apartments and in public spaces: shops, cafes, offices, etc.

- 1 of 1

Laying thermal insulation under linoleum

Quite often, home craftsmen wonder how to insulate a floor under linoleum. In order to prevent the material from absorbing moisture, it is necessary to lay a waterproofing film on the concrete surface; simple polyethylene is suitable for this. Linoleum is laid on top of the film, and the joints are taped with construction tape. If you want to additionally insulate the concrete surface, then you must first apply heat-insulating paint to the base; it will act as liquid thermal insulation. After applying it, you need to wait until it dries completely, and lay plywood on top of it, on which the linoleum will be spread.