Industrial boilers operating on gas fuel are in great demand today due to the high assessment of their efficiency, taking into account the rising cost of various energy sources. Such autonomous heating systems are capable of heating not only large-scale objects with large areas of interior space, but they are also suitable for heating houses with all their outbuildings (baths, garages, barns, poultry houses, etc.). It is worth studying in more detail the general characteristics of such boilers, as well as examples of several models that are considered popular on the market today.

Conditions: centralized main gas

Industrial equipment operates on centralized main gas, which is supplied from central direct gas supply systems in the city or locality. Such installations are most often used in the premises of the following facilities:

- warehouses;

- workshops;

- utility central heating points;

- administrative buildings, offices, buildings;

- indoor training grounds, playgrounds and other wide areas of premises.

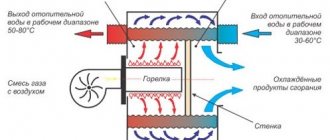

Gas fuel is considered the most inexpensive than all others, which is why the equipment is more economical than solid fuel or other installations. The device has a special gas burner that directly supplies gas, and also has a special heat exchanger made of high-quality copper.

The design also includes a pump for supplying water (steam) , a pressure gauge for measuring pressure indicators, a thermometer showing the optimal heating temperature and, most importantly, a tank into which the coolant liquid – water – is supplied. To this it is worth adding a security system, which is now supplied to almost all models of modern industrial gas boilers.

Types of boilers: hot water, steam pyrolysis

Depending on whether the device will heat a hangar or a small warehouse, two heating supply options are provided - steam or hot water. To heat indoor production areas, hot water boilers are most often used. And the steam pyrolysis option is well suited for residential buildings and small premises. Which of them is more economical and which is more expensive should be calculated individually, based on the parameters of the area, principle and design of each model separately.

Heating boiler Protherm Bizon NO 100

Boilers with water circuit

Solid fuel boilers with a water circuit are a new approach to solving two problems: organizing heating and hot water supply. Essentially, this is a single-circuit unit with a boiler installed inside. As in the first case, the boiler can be installed either on top of the firebox or on the side.

The simplest variety is titanium

Hot water moves inside the heat exchanger, heating the building's heating system. Its outlet circuit passes through a heat exchanger installed inside the boiler. This is how the water inside the tank is heated for household needs.

Since the technology used inside this type of equipment has some features, this affects the efficiency of two systems at once (meaning heating and hot water supply). That is why manufacturers make sure that firewood or other types of solid fuel burn completely inside the firebox, releasing as much thermal energy as possible, which would be enough for two human life support systems.

And one more point for information. If you want the solid fuel boilers installed in your own home to operate efficiently, use only fuel with a low moisture content.

Additionally: automatic boiler control, automatic fuel filling

The improvement of gas industrial boilers lies in the fact that they have automatic control, as well as automatic “filling” of fuel.

Automation consists of the following elements:

- Control block;

- elements that control the operation of the boiler - sensors, valves, control with a built-in microprocessor;

- elements safety system - warn of leaks, pressure drops, temperature increases, etc.

Thanks to this system, it is possible to control the supply of energy, shutdown, ignition of the flame, stability, and uniformity of pressure distribution in the system. And other. This also achieves significant savings in gas consumption.

Features of solid fuel devices

Advantages of a water heating unit:

- Almost autonomous - does not depend on electricity or gas , but runs only on solid fuel. Long burning models do not require intervention for up to 7 days.

- Low cost. Solid fuel boilers are much cheaper than gas or liquid fuel models.

- Heating a large area. Depending on the power, the device can heat an area twice as large as an electric boiler.

- Purity. During operation, the device produces substances that are negative for the external environment , but their level is much lower than from liquid fuel. But more than gas or electric.

- Efficiency The boiler produces more heat than a conventional furnace .

Flaws:

- Fuel storage. For the heating season, consumption is from 6 to 10 m3 , but reserves are planned depending on the heated area and the power of the device.

- No automatic control. The power of the unit can be adjusted only using a single sensor that monitors the temperature of the coolant in the system. All other processes for servicing the boiler and monitoring its operation must be done with your own hands . There are models on the market with automatic fuel supply from a special department, but this function is only available in pellet units that operate on peat or wood briquettes.

If the disadvantages of a solid fuel unit are considered insignificant, it becomes the best option for a local heating system.

Advantages and disadvantages

The advantage of using industrial gas boilers in areas such as agriculture, production, administrative or residential buildings is easy installation and long-term operation without major repairs. But there are other advantages, which are as follows:

- The heat transfer coefficient is high , more than the consumption coefficient.

- The coolant in such boilers does not need to be brought to a boil, which eliminates the risk of compromising the integrity of the heating system itself.

- Work on different types of liquid energy without significant losses.

- Fluid movement is straight forward.

- Climate change regulators control the operation of the system.

- A control and measuring set of instruments is included in the boiler package.

- Perfectly mounted in a block-modular boiler system .

- There is protection against scale.

- Compact dimensions.

- Availability on the market.

- There is no need to connect to a power supply, which significantly reduces the cost of using the equipment.

The disadvantages of gas industrial installations are the following indicators:

- They consume fuel quickly and intensively.

- The price on the market is too high. You have to look for cheaper options from a direct supplier.

- Accidental extinguishing of the burner can lead to accidents and gas explosions. You need to choose a model with a built-in self-diagnosis and safety system - for example, thermostats that regulate the intensity of the flame.

Industrial hot water boilers

Industrial hot water boilers are heating equipment designed to heat water, which is subsequently used for heating and/or hot water supply purposes. Industrial hot water boilers are designed, as the name suggests, to prepare hot water to meet the needs of an industrial enterprise. Of course, from the point of view of heat supply, such enterprises include not only facilities that house production facilities, but also any facilities in general intended for human economic activity.

►See Industrial hot water boilers in our catalog

FEATURES OF INDUSTRIAL FACILITIES

So, an industrial facility is not necessarily just a production site or a factory floor. From the point of view of selecting a hot water boiler, such objects can be:

- administrative buildings, for example, plant management;

- warehouses, hangars, garages;

- dining rooms, showers and other premises for household purposes;

- free-standing commercial buildings (shopping centers, business centers, car dealerships, service stations);

- detached buildings for social purposes (hospitals, schools, kindergartens, etc.);

- objects of the hospitality industry - hotels, sanatoriums, recreation centers;

- various production facilities and technological lines

What unites them into the “industrial facilities” group, and what is the difference from residential facilities? After all, the tasks of heating and hot water supply in these areas are not fundamentally different. From a heating engineering point of view, there is no difference. Both residential and non-residential premises will be described by the same construction characteristics: wall thickness, area and type of glazing, thermal insulation properties, etc.

However, industrial facilities differ in terms of approaches to the selection of water heating equipment:

- firstly, they have quite large volumes, which means they require more thermal energy;

- secondly, as a rule, for such objects it is possible to build a clear schedule for hot water consumption, which is determined, as a rule, by technological factors (or behavioral - for hotels, sanatoriums, hospitals, etc.)

LET'S CONSIDER WHAT THESE FEATURES MEAN IN PRACTICE

Large volumes of consumption require the presence of an energy service or position. In some cases, these functions are performed by a third-party contractor, but in industrial enterprises, as a rule, there is a position of power engineer, chief engineer, who are responsible for tasks related to the energy supply of the facility.

The presence of such a service, on the one hand, makes it easier to solve problems of heating and hot water supply - after all, there is a responsible person. On the other hand, his area of responsibility includes not only hot water boilers, but also the entire energy sector as a whole - from lighting to technological equipment. Therefore, the main task of the energy service is the acquisition and installation of equipment that would:

- Effectively

- economical

- would not require constant attention

The second distinctive feature of industrial heat supply is the ability to quite accurately calculate the schedule of thermal energy consumption, especially with regard to the consumption of hot water. Any process of water consumption, in principle, can be formalized and calculated. This opens up opportunities for savings on water heating equipment through the use of storage tanks (we will return to this point).

VARIETIES OF INDUSTRIAL WATER BOILERS

There are many types of hot water boilers, but the most interesting is the division of boilers according to the type of fuel on which they operate. As a rule, it is this criterion that turns out to be the main one in the choice.

GAS INDUSTRIAL WATER BOILERS

Boilers operating on natural gas (less commonly, liquefied gas) are among the most common. In any case, where the consumer has the opportunity to connect to a gas pipe, preference is given to a gas boiler. It is generally accepted that gas is the most economical type of fuel available. Indeed, modern gas water heating boilers are technologically equipped enough to ensure automatic operation, have high efficiency, and are at an acceptable level of safety and environmental friendliness. However, gas boiler equipment also has many disadvantages:

- safety. No matter how high-tech the boiler is, its installation means both the supply of gas and the presence of a burner, that is, an open flame, which means that the risks of fire or explosion are in any case increased;

- installation of the boiler requires approval from the gas supplier. In this case, approval is only possible if a project is provided by a specialized organization - all this entails additional costs of both money and time;

- availability of a valid contract for servicing a gas boiler with a service company;

- higher investments in the purchase and installation of equipment: installation of a chimney, allocation of a separate room for a boiler or construction of a boiler house building.

And it is important not to make a mistake with the equipment - so that it is adapted to our reality in the form of unstable pressure in the gas transportation system.

SOLID FUEL INDUSTRIAL WATER BOILERS

Solid fuel boilers are boilers that burn coal, wood, pellets and other solid fuels. Even modern solid fuel boilers cannot provide a satisfactory level of autonomy, so they are used, as a rule, either for heating/hot water supply of objects in which it is not possible to use other types of fuel, or for those objects in which regular maintenance of the boiler and maintaining it in working condition is possible. The main advantage of such a boiler is the simplicity and low cost of the design - there is little that can break in principle, and also, as a rule, the low cost of fuel. Of course, there are a lot of disadvantages, here are the main ones:

- the need for additional arrangement of a warehouse for a certain supply of fuel;

- need for constant maintenance;

- low level of automation;

LIQUID FUEL INDUSTRIAL WATER BOILERS

Liquid fuel boilers operate on diesel fuel, fuel oil, and kerosene. Taking into account the constantly rising price of fuel, which is a product of oil refining, this type of boiler is rarely used in its pure form. As a rule, such boilers are installed either as a reserve, or have design features that allow you to combine different types of fuel. Such equipment also has disadvantages:

- the need to equip a tank for storing liquid fuel; when using fuel from heavy fractions, it will be necessary to provide a heating system to maintain the fluidity of the fuel;

- the need to arrange a separate room (building) with a chimney;

- high and constantly rising fuel costs;

- the need for regular boiler maintenance.

ELECTRIC INDUSTRIAL WATER BOILERS

Water heating boilers powered by electricity have become widespread throughout the world relatively recently. Despite the high cost of electricity, the demand for electric boilers is steadily growing from year to year. The main advantages of electric industrial hot water boilers:

- autonomy and fully automatic control of the boiler operation;

- relatively low cost of equipment and capital costs. No chimneys or separate rooms are required (unless, of course, we are talking about megawatt installations);

- ease of operation;

- high efficiency at 98-99%;

- absolute environmental friendliness

In general, an electric boiler is a very convenient, least troublesome and effective solution to the problem of heating and hot water supply. Of course, you have to pay extra for these benefits. In the form of payment for kilowatt-hours of electricity.

In defense of electricity as a type of fuel, it must be said that, unlike other types of energy carriers, it is distributed almost everywhere in our country. And if allocated capacities and limits allow, then electric heating can turn out to be a very attractive and even profitable solution in industry.

►See Industrial hot water boilers in our catalog

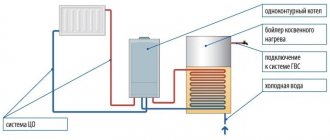

STORAGE INDUSTRIAL WATER BOILERS

The use of storage tanks (accumulation tanks) allows you to store hot water in advance, say, during the period of reduced consumption or at night. If electric boilers are used to heat water, then when using a two-rate or differentiated tariff for electricity, this allows the enterprise to significantly save money.

When using a separate storage tank, water will circulate along the internal circuit of the hot water boiler, gradually heat up and accumulate in a special heat-insulated container(s). Of course, such a container will have heat losses, but they will be insignificant compared to the savings on tariffs and the cost of heating equipment.

The use of a storage tank allows not only to provide the required volume of hot water during disassembly, but also to use a boiler of lower power. In this case, heating the water will take longer, but in the absence of analysis this is not important. But the savings on equipment costs can be manifold.

Therefore, industrial storage water heaters are becoming increasingly widespread. Most of the types on the market already include one or several standard storage tanks. However, some models can connect directly to a customer's already installed tank.

INDUSTRIAL WATER BOILERS TERMANIK

Among all types of electric industrial boilers, induction heaters stand out. On the pages of our website we have already studied in detail the differences, advantages and disadvantages of different types of electric heaters.

In short, an induction heater is a device that allows you to convert alternating current with an industrial frequency of 50 Hz into an electromagnetic field, which in turn heats up the heat exchange device through which the coolant (water) circulates.

The operating principle of an induction hot water boiler is demonstrated very clearly in the following video:

INDUCTION WATER BOILERS HAVE THE FOLLOWING DISTINCTIVE PROPERTIES:

- very high durability, reaching 30 years

- reliability due to the absence of loaded, high-temperature and mechanically wearing elements;

- ease of use;

- efficiency and economy; The efficiency of the installations is 98%, the power factor is 0.98.

Induction water heating boilers are used both for autonomous heat supply and hot water supply of any objects. But it should be noted that the manufacturer of TERMANIK brand heaters specializes in creating boilers intended primarily for the industrial market, and its model range is aimed specifically at this segment of consumers.

TERMANIK brand equipment intended for hot water supply tasks is supplied with storage tanks and are fully equipped and ready-to-connect hot water supply installations. However, there are also modifications designed for flow-through heating, as well as separate heating units connected to the customer’s tank.

►See Industrial hot water boilers in our catalog

INDUSTRIAL WATER BOILERS: SELECTION FEATURES

Selecting boiler equipment is not an easy task, requiring consideration of many factors, such as the construction characteristics of the facility, consumption schedule, tariff system, electricity limits, etc. To obtain a balanced solution, we advise you to seek help from the specialists of Scientific and Production Enterprise “Thermal Technologies”, who have the necessary experience and knowledge to find optimal solutions for heat supply to industrial facilities.

If you are ready to formulate the tasks that your company is currently facing, send a description. You can also use standard TOR forms on our website, in the “Contacts” section. Calculations on the composition, characteristics, quantity and power of industrial hot water boilers produced by NPP "Thermal Technologies" are made for customers free of charge.

TOP – Description with characteristics and prices of three boilers (for an area of 1000 sq.m.)

We will describe the capabilities and main parameters of some industrial-grade gas boilers.

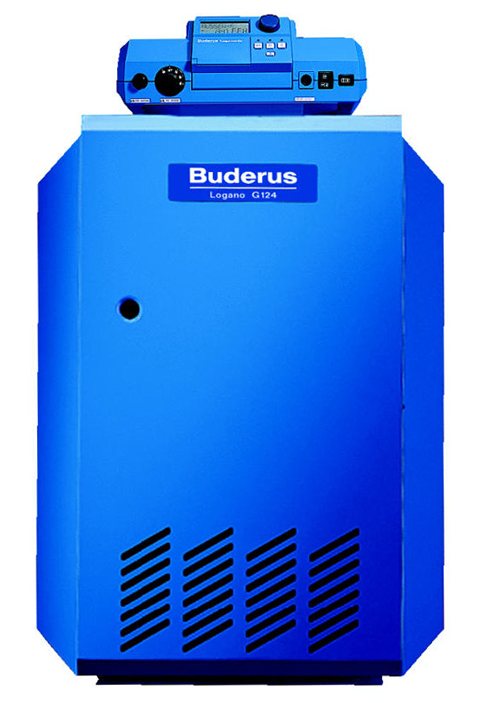

Floor-standing boiler Buderus Logano (2 boilers come in pairs)

- Heat exchanger – cast iron.

- The combustion chamber is closed.

- Power modes – 4 options.

- Control – intelligent, automatic.

- Burner type – atmospheric.

- Ignition - electric.

- Thermal power – 159-296 kW.

- Pressure – 4 Bar.

- Efficiency – 93%.

- Pressure thrust – 3 Pa.

- The chimney diameter is 250-360 mm.

- Manufacturer – Russia.

- Dimensions (LxWxH) – 1264x1420x1610 mm.

- Warranty – 2 years.

- Price – 776,550 – 950,000 rubles.

Gas industrial boiler VAILLANT atmoCraft

- Type of equipment – sectional.

- Installation - on the floor.

- Heat exchanger – cast iron.

- The combustion chamber is open.

- Control – LCD display, intelligent, automatic.

- Burner type – atmospheric.

- Ignition - electric.

- Thermal power – 157 kW.

- Pressure – 4 Bar.

- Heat transfer – 95%.

- Pressure thrust – 3 Pa.

- The chimney diameter is 250-375 mm.

- Dimensions (LxWxH) – 1145x1730x1012 mm.

- Manufacturer – Germany.

- Warranty – 2 years.

- Price – 550,000 – 750,000 rubles.

Industrial gas boiler PROTHERM NO-3500 Bison

- Heat exchanger and housing – steel.

- The combustion chamber is open.

- Association – cascade.

- Power modes.

- Control – intelligent, microprocessor-based.

- Burner type – atmospheric.

- Burners - there may be several variations.

- Different variations of energy carriers.

- Ignition - electric.

- Thermal power – 3500 kW.

- Thermal load – from 10 W.

- Heat transfer – 93-100%.

- Pressure thrust – 3 Pa.

- The chimney diameter is 250-360 mm.

- Dimensions (LxHxW) – 2146x390x1870 mm.

- Manufacturer – Russia.

- Warranty – 3 years.

- Price – 1.9-2.2 million rubles.

In conclusion, I would like to note that the selection of the optimal boiler model should be carried out with accurate calculations, and not approximate ones. Only in this case is its high level of functionality possible. A special formula is used for calculations: 1 kW (heating) per 10 sq. m. premises with excellent thermal insulation and a ceiling height of no more than 3 m. The boiler may have 1-2 circuits. You should also pay attention to the dimensions, weight and equipment of the equipment with all the necessary measuring instruments.