Today, country houses and cottages are gaining more and more strength, and with them special heating equipment. Combination heating boilers are an excellent option for creating comfort and warmth in your home. The heating system is too important and expensive an element to acquire without prior knowledge. What are we going to do now?

Design Features

For the correct and efficient operation of such equipment, it is worth understanding its design. Universal heating boilers have several ways to switch to burning different types of fuel:

- Replacing burners

- Switching to different fireboxes

In the first option, the boiler kit has several burners for each type of fuel. To switch to another type of fuel, you only need to replace the burner. The second option involves several combustion chambers. One combustion chamber uses solid fuel, the second gas or liquid fuel.

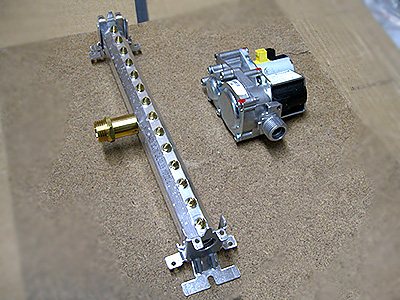

How to convert a boiler to liquefied gas

Theoretically, it is not difficult to reconfigure the heat generator; the main thing is to replace the jets responsible for the gas flow in the boiler. After this, you need to adjust the gas valve in accordance with the operating instructions. Plus setting up the controller in the case when the unit is automated. A good specialist with tools and equipment can do everything in half an hour - maximum.

The product instructions may include a section for service technicians, where everything is described in detail. But you need to have a pressure gauge to adjust the gas pressure. The first thing to do is change the jets on the burner ramp. To do this, you need to remove the front panel or open it. Next, the ignition group is unscrewed and removed, followed by the ramp. There are jets screwed into its inside that should be replaced.

Note. The operation of disassembling the burner and replacing jets in different models of units is carried out differently and can be much more difficult. In addition, when switching to another type of fuel, many boilers require intervention not only in the gas part, but also in the electronic part.

Further adjustment is made using a pressure gauge. You should know that the use of liquefied gas in gas boilers requires adjusting the pressure in the line leading from the automatic valve to the burner. Having carefully studied the instructions, you need to find the appropriate fitting and put the hose from the pressure gauge on it, and then, having started the heat generator, regulate the minimum and maximum gas pressure with a special valve. How to perform this operation on a BAXI Eco Compact boiler is shown in detail in the video:

Varieties

The following things you should know are the types of heating systems produced. The fuel you use determines the type of equipment. Combination boilers are divided into:

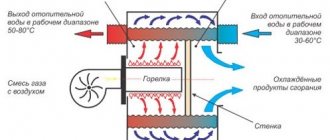

1. Gas and liquid fuel boilers

The operation of such boilers does not require much effort. To switch to another type of fuel you do not need to spend a lot of effort or time, and the power does not change at all. These home heating boilers use gas or liquid fuel to operate. Gas is often chosen as the main fuel because of its safety, environmental friendliness and low cost. The power of this equipment is quite large, which allows them to heat a large area.

2. Gas-wood boilers

They differ from the previous type - by the presence of a firebox for solid fuel. In addition to gas and liquid fuel, they also work on: coal, peat, firewood. Such equipment is popular due to its price and versatility, but in comparison with the previous type of boilers, gas-wood boilers have lower efficiency and a low level of automation. They are often used to heat small areas, since the larger the area, the lower its profitability. In addition to everything, universal gas-wood heating boilers require a high-quality chimney in order to function stably.

3. Boilers with electric heating elements

The above boilers differ only in the type of fuel used; boilers with heating elements can also operate on electricity to heat the room. They are ineffective for large buildings, but they have a high level of automation and frost protection. At temperatures below +5, the system automatically turns on the heater. Automation saves you from various interruptions and constant control over your work. Combined heating boilers using wood and electricity boast high efficiency and versatility.

Construction of a gas-wood combination boiler

Gas-wood heating boilers allow you to use one heating boiler for two types of fuel.

As a rule, a gas heat source is consumed at the time of day when automatic operation of the heating system is necessary: at night, when everyone is sleeping, during the day, when family members go to work or study. Wood heating operates mainly in the evenings and on weekends.

Most often, combined heating boilers provide heating using solid fuel (wood) and then maintaining the temperature using gas. The design of such boilers is equipped with only one combustion chamber, in which different fuels can be burned.

Combined gas-solid fuel boilers with two combustion chambers are a complex consisting of two furnaces.

When solids burn, they release gas, which also releases heat when burned. This is exactly the operating principle of a pyrolysis boiler. Read about industrial pyrolysis boilers here.

Such a boiler is more expensive to produce and sell, but at the same time it guarantees the reliability of the heating system, operating with the main and reserve types of fuel. The design of such boilers includes a combustion chamber for solid fuel and gas burners.

Gas/wood boilers are characterized by large sizes.

Advantages and disadvantages of universal boilers

Taking into account all of the above, it is possible to determine their strengths and weaknesses. Strengths include:

- fuel availability and low cost;

- a wide choice of fuel helps to maintain the unit in working condition, even in the absence of one of the types of fuel;

- the ability to regulate the operating mode, while saving fuel;

- environmental cleanliness;

- automatic operation, and the possibility of compatibility with the Smart Home system;

- reliability and ease of use.

Long-burning solid fuel combination boilers also have weaknesses:

- limitation in the scope of application - only residential buildings;

- requires a separate room in the house for storing fuel and installing equipment;

- the need for regular inspection and maintenance.

Despite all the disadvantages, long-burning combination boilers show excellent economic and performance indicators, which supports the demand for them.

Disadvantages of a universal gas-wood boiler

- The boiler design is automated only to a small extent, so its operation requires human control. Without visual supervision, the boiler may be unsafe.

- The weight of the combined boiler (gas-solid fuel) and the complexity of its piping make it impossible to install the device in living rooms, so it requires a separate room.

- Operating time on one stack of firewood, according to manufacturers, averages about 3 hours. This means that every 3 hours it is necessary to monitor the combustion of fuel and, if necessary, add a new batch to the combined heating boiler. Reviews about this process somewhat do not coincide with the data stated by the manufacturer: in the winter season, in windy weather, it is sometimes necessary to perform a bookmark every 1-2 hours. True, in the evening the boiler is set to temperature maintenance mode, in which one bookmark is often enough for the whole night. Recently, long-burning boilers have appeared on the market, which are capable of operating on one bed for several days. This option is certainly very convenient, but the cost of such boilers is incomparably higher than conventional ones.

- The combustion tank and ash pan must be regularly cleaned of combustion products.

- Independent decision on the issue of providing firewood for heating boilers (combined). User reviews about universal boilers are in some cases overshadowed by the need to regularly purchase firewood and build a room for storing it. Some are burdened by the need to bring firewood into the room and load the firebox with firewood. This is especially true if the owners of the house are elderly people. These nuances should be kept in mind when choosing a heating system.

More on this topic on our website:

- Combined heating boilers - wood/electricity What are the advantages of combined heating boilers - wood/electricity? In what situations are they best used? What can you use to heat...

- Italian double-circuit gas heating boilers Beretta - reviews and characteristics The Beretta company was created in the 50s of the last century by Italian engineer Angelo Beretti. During this time the company has developed into a huge...

- Electric - wood heating boilers - combined boilers Wood heating in suburban houses is very rare, but in rural areas it is completely common. However, the wood-burning system...

- Siberia floor-standing gas boilers - technical characteristics and reviews The Siberia gas boiler, reviews of which are becoming more and more common, is a Rostov brand. This Russian manufacturer produces heating…

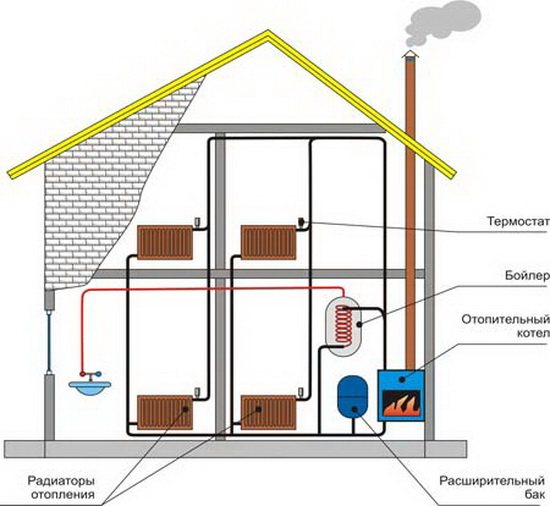

Installation

The reliability of the heating system will depend on the correct and high-quality installation of the equipment, therefore it is necessary to treat the installation with full responsibility and ensure the correct installation and connections of all components and components.

When installing equipment such as pellet combi boilers, there are special requirements

The best choice for installation would be a floor-standing boiler, since its installation does not require unnecessary structures. Before installation, check the strength of the floor; place a fireproof material, for example, asbestos and a sheet of steel, in the place where the stake is installed. Make sure that the boiler is installed as level and motionless as possible; if necessary, place non-flammable material under the legs of the unit for balancing. Also remember that you may need to dismantle it, so when installing, expect easy dismantling.

When connecting the equipment, you must strictly follow the instructions and correctly connect the boiler to the chimney. The room for the boiler location must be selected in advance. It should be well ventilated to ensure ventilation.

You can do the installation alone, but when connecting, it is advisable to have a specialist present.

Operation of universal boilers

Before installing a long-burning combination boiler, you should take into account that such equipment is heavy and requires a fairly strong foundation. Another equally important point is the purchase and installation of a chimney sufficient to provide boiler draft. It is also necessary to pay attention to cleaning the ash pan. The degree of contamination will depend on the type of fuel and the intensity of the boiler operation.

The boiler room is an important point that you should not forget about when purchasing universal boilers. The chimney should be purchased with non-flammable thermal insulation to prevent fire upon contact with the heated surface of the pipes. Next, it is necessary to place a steel sheet in front of the boiler firebox to protect the floor from possible sparks or burning particles. Also, do not forget about fuel delivery and loading; some boilers need to be loaded every 4 hours. The moisture content of firewood should not exceed 20%.

Universal boiler design

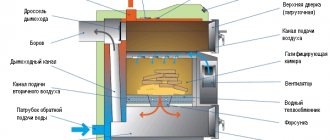

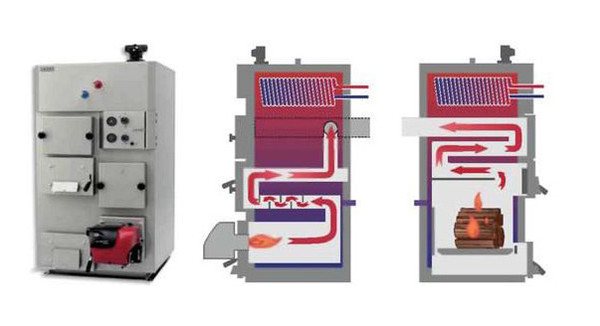

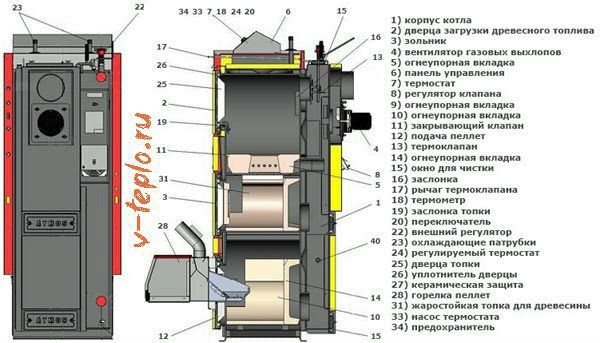

In general, the diagram of a combined boiler looks like this:

- At the bottom there is a combustion chamber.

- Directly above it is a nozzle.

- Between the upper and lower doors there is a fan that blows combustion air.

- Next to the nozzle there is a space for loading solid fuel.

- are located behind the solid fuel chamber .

- Not far from the arch there are flue dampers.

- On the front of the cover there is a controller that allows you to monitor the indicators.

Photo 1. Construction of a combined heating boiler using wood and gas. The internal structure and appearance are depicted.

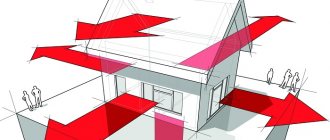

How does combined heating work?

Operating principle of the device:

- The device has two compartments : the lower one contains the burner, and the upper one contains firewood.

- When the heating device switches to gas, the remaining wood also burns out due to additional heat.

- If wood is already burning in the upper compartment, the gas is turned off, which allows you to reduce its consumption.

- Since both the main and secondary heat exchangers are located inside the device, the coolant (usually water) heats up faster.

- Heat loss is significantly reduced due to the insulation of the housing.

- Some models also have hobs and boilers , which allows them to be used for heating water and cooking.

Due to the complete combustion of unburnt wood, a heat-insulated body and internal heat exchangers, the efficiency of such a boiler can be more than 90% .

Firewood is the main fuel for the unit. The burning time is approximately 4-5 hours . As soon as the wood begins to burn out, the gas burner located below turns on.

It burns the remaining wood and maintains the set water temperature. To avoid unnecessary gas consumption, you need to load firewood as soon as the firebox goes out.

Sometimes there are models that can operate on low-pressure gas or liquefied fuel. Then the device is connected not to the gas pipeline, but to a special cylinder with propane or liquefied natural gas.

Attention! Such a boiler is to a certain extent dependent on electricity . When the lights in the house are turned off, the gas part will not work, and the device will switch to solid fuel power.

This will slightly increase the blockage of the chimney, so after a long blackout it is worth checking the chimney and cleaning it if necessary .

A few words about popular brands

Kiturami boilers, from South Korean manufacturers, designed for heavy loads and all weather conditions. Most equipment is designed for multiple fuel types. They are equipped with two circuits, and can be installed in both residential and industrial premises. The Kiturami KRM series has a durable two-chamber heat exchanger. The equipment is controlled from a remote control. The combination boiler for heating KRM 30 heats a room of 290 sq.m. and less, KRM 70 - up to 570 sq.m. m.

The next company is Ferroli. It specializes in special protection against low and high temperatures. The Italian company, thanks to new technology, reduces the toxicity of fumes and increases efficiency. Especially for Russian conditions, the company modifies its equipment. For example, for low-quality gas and water. Model Ferroli GN1, one of the most popular, cast iron shell and power from 22 to 92 kW. Uses liquid and gas fuel.

Zota is a Russian brand of heating equipment. Long-burning steel solid fuel combination boilers with a steel thickness of 4 cm and a power from 22 to 48 kW. Domestic equipment meets all reliability and safety standards. All models of this brand have increased operating pressure, due to which maximum efficiency is achieved. Reducing the density of smoke, increasing the rate of heat transfer and its quality, and this at a price lower than its Western counterparts.

Various types of combined structures

There are several types of heating combined equipment. They differ in the type of fuel used:

- A gas-wood boiler makes it possible to maintain continuous operation of the heating system when the gas is turned off. It is very popular due to the availability of solid fuel;

- Heaters using gas and liquid fuels are also widespread. But in order to store diesel fuel, additional containers have to be built and installed;

- Sometimes heating elements that use electricity are added to a heating structure that runs on gas and liquid fuel. This combination makes it possible not to interrupt the functioning of the heating system during interruptions in the supply of gas and diesel fuel;

- Devices that can operate on solid, liquid fuel and gas have even greater capabilities. They are often used when equipping a heating system in individual buildings;

- if we supplement the previous heating design with a device capable of operating on electrical energy, we will get a multifunctional, universal, autonomous unit. Its operation does not depend on the type of fuel used.

Combined gas-wood heating boilers are most often used in areas where there is a possibility of interruptions in the gas supply. As a backup option, it is much more convenient to use heating using wood or special granules (pellets). Solid fuel is convenient to store; it does not have a specific odor, such as diesel fuel.