Combustion process

When considering the operating principle of condensing boilers, it makes sense to start with what generally causes the heating of the coolant in this equipment - fuel combustion. The main chemical elements involved in the combustion process of any hydrocarbon fuel:

- Carbon (C), hydrogen (H2), sulfur (S) are contained in fuel. The sulfur content can be quite high in diesel or solid fuels (wood, coal). For natural gas, the maximum hydrogen sulfide content according to the standards is 20 mg/m3; the actual content is usually much less.

- Oxygen (O2), nitrogen (N2) are found in the air. There are also other gases in the air, but they are either inert or their percentage is extremely small.

Next, we will consider combustion using the example of the simplest hydrocarbon - methane (CH4). Strictly speaking, this reaction is a rather complex chain with the formation of intermediate compounds; we present the final formula:

CH4+2O2 ? CO2+2H2O+Q

The reaction occurs with the release of energy and the formation of carbon dioxide and water. The important point here is that if there is a lack of oxygen in the reacting mixture, in addition to carbon dioxide, carbon dioxide (CO) is also formed, which is dangerous for humans even in relatively low concentrations. In addition, this reduces the amount of energy received. To prevent this effect, there are certain features in the design of boiler elements, which we will discuss later.

Another important group of reactions during the combustion of methane in air is the oxidation of nitrogen and sulfur:

N2+O2 = { NO | NO2 | N2O}

S+O2 = { SO2 | SO3}

The nitrogen oxides NO and NO2 are usually referred to by the common name NOx. When reacting with water, they form nitric (HNO3) and nitrous (HNO2) acids. When released into the atmosphere, the latter become one of the main components of acid rain. Nitrous oxide N2O does not form acids, but is involved in the destruction of the ozone layer. Naturally, in the design of modern boilers, measures are taken to reduce these emissions. We will consider these measures when discussing individual hardware components.

Sulfur oxides react with water to form sulfuric acid. But their content in combustion products is extremely small, so they are not considered as a factor in environmental pollution. But they can have a strong impact on the elements of the condensing boiler.

Principle of operation

In any heating boiler, in addition to the electric one, the energy released when burning fuel is used, followed by heat transfer through a heat exchanger. However, not all the heat released by combustion is used. Some of it is scattered aimlessly, some of it is needed to maintain natural draft, that is, it simply flies down the drain. Even a closed combustion chamber and forced exhaust removal does not particularly help improve heat transfer efficiency. The average efficiency value for a gas boiler is 92%. It is almost impossible to increase the coefficient; this is the ceiling for the classic design of a gas boiler.

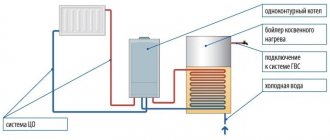

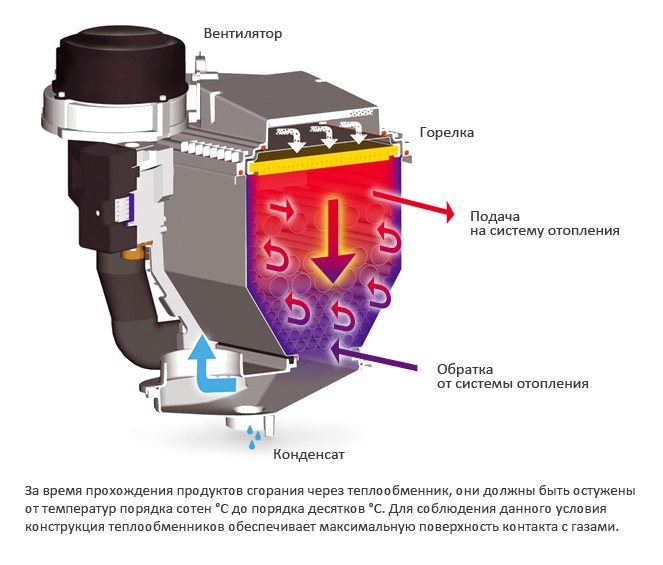

Boiler operation diagram

However, it is possible to use heat sources previously ignored by designers and developers of boiler equipment. In the exhaust, in the exhaust gases after the combustion of natural gas, there is a fair amount of superheated water vapor and other inclusions (ash, tar, etc.).

The steam for the most part does not come from air coming from outside, but is obtained as a result of combustion itself, and therefore it contains a significant supply of energy. Direct heat exchange in this case is not particularly useful, but if you force water vapor to condense, a significant amount of heat will be released, comparable to the combustion energy of natural gas.

It turned out that it is easy to condense steam from the exhaust of a gas burner. It is enough to install a heat exchanger on the path from the combustion chamber to the chimney with a surface temperature of no more than 55 ° C, which approximately corresponds to the dew point value for natural gas combustion products.

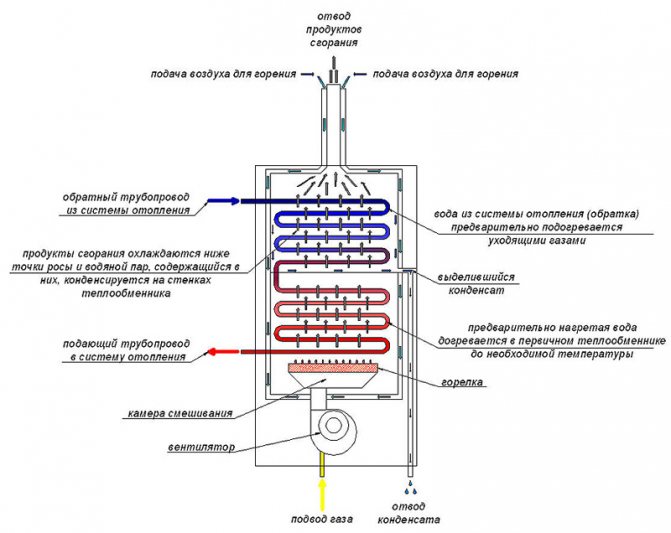

Operating principle of a condensing boiler:

- Natural gas is burned in the combustion chamber.

- The heat from combustion is transferred to the main heat exchanger.

- An additional chamber with a heat exchanger is installed in the upper part of the boiler, which heats up to no higher than 55°C.

- The steam from the exhaust condenses in the second chamber and gives off additional heat.

If we take the classical heat of combustion of gas as 100%, then due to condensation we get an additional 15%. Taking into account the output of conventional boilers - 92%, we obtain 107% efficiency for a condensing boiler.

To ensure normal operation of a condensing boiler, the coolant in the heating system should not heat up above a certain temperature of 50-55°C. The return flow coming from the radiators is first supplied to the condenser, and only after that to the main heat exchanger.

Operating principle of condensing boilers

Now let's move on to considering the use of thermal energy generated during fuel combustion. The chain of energy transformations in the boiler can be conditionally expressed as follows:

Burning? Energy output? Energy use

? At the first stage, the resulting heat can be divided into three parts:

- Radiation;

- Heating of combustion products;

- Evaporation of water contained in combustion products.

? At the second stage, respectively:

- Coolant heating;

- Losses through the boiler body;

- Losses with flue gases.

The main goal of the boiler unit is to ensure maximum heat production at the first stage (combustion quality) and its transfer to the coolant (reduction of losses).

The main idea of the “condensing boilers operating principle” is that the heat spent on evaporating water at the first stage, from the point of view of further use, is fundamentally different from radiation and heating of combustion products. The fact is that heating of the coolant using radiation or contact with heated gases occurs in any case, albeit with different efficiency. At the same time, in order to use the energy contained in water vapor, it is necessary to provide conditions under which a phase transition will occur: the transition from vapor to liquid (condensate). This happens when the steam is cooled to the so-called dew point, which for methane under normal conditions is approximately 55 °C.

Due to the fact that combustion products contain a certain amount of nitrogen and sulfur oxides, when condensation occurs, they react to form the corresponding acids. In addition, under certain conditions, carbonic acid can be formed as a reaction product of carbon dioxide and water. But this acid is quite unstable and quickly disintegrates in the atmosphere.

Accordingly, two terms are used for the energy produced by combustion:

- The higher calorific value (Qs) is the total thermal energy.

- Lower calorific value (Qi) is the total thermal energy minus the energy contained in water vapor.

Condensing boiler efficiency

In accordance with what was described above, the concept of efficiency is introduced - the efficiency of the boiler as the ratio of the heat transferred to the coolant to the heat of combustion of the fuel. In this case, usually, unless otherwise indicated, it is the lower calorific value that is used, that is, without taking into account the energy of steam condensation.

Generally speaking, any boiler can be placed in conditions where it starts operating in condensing mode - it is enough that the coolant temperature is below a certain value. But equipment not designed for such work is extremely sensitive to the acidic composition of the condensate and quickly fails. Therefore, the documentation for non-condensing boilers usually limits the return coolant temperature to “not lower than 60 °C”. The exception is cast iron boilers from some manufacturers, where due to the thickness of the metal, even at low coolant temperatures, the flue gases do not cool down to the dew point. However, this factor greatly affects the efficiency of such boilers.

To increase efficiency, you need to take action in several related directions:

- Improving combustion quality.

- Reducing heat losses from flue gases.

- Increasing the amount of heat transferred to the coolant.

- Reduced heat losses through the boiler body.

The measures related to the last point are quite obvious - thermal insulation of the body and individual elements, so we will not consider it separately.

In solving problems related to the first and second points, the design of burner devices plays an important role.

The design of the boiler heat exchanger is primarily responsible for increasing the amount of heat transferred to the coolant.

Now let's look at the main design features of boilers that allow them to operate in modes with condensation and aimed at increasing efficiency.

What are gas convection boilers

Their work is based on the principle of convection. It involves transferring the internal energy of a heat source (natural gas) to a coolant (water) through a heat exchanger.

Features of the heat transfer process

Part of the energy of the burned gas is not used and evaporates into the atmosphere along with the products of its combustion. This is the heat from the energy of water vapor that can be released when it condenses.

For convection boilers, vapor condensation on the surface of the heat exchanger and combustion chamber is unacceptable. Acidic components will certainly lead to their premature failure.

Therefore, in order for convection boilers to work properly for a long time, they must be used in high-temperature heating systems. Here the temperatures of the supply and return lines of the coolant do not have much difference.

For example, the supply line has a temperature of about +80°C, and the return line has a temperature of +60°C. It is important that the temperature of the returned coolant does not reach the dew point - this is +57°C. Below this value, the process of water condensation may begin. As a rule, these are radiator-type heating systems.

Ensuring normal operation

To do this, convection boilers need constant renewal of the air in the room where they are located. This provides natural ventilation. It implies, firstly, the installation of chimneys using natural draft to remove gas combustion products. Secondly, ventilation ducts for fresh air.

To achieve high-quality and safe combustion of 1 m3 of natural gas, at least 10 m3 of air is required. If there is less air, the process of incomplete combustion of gas will begin. It negatively affects both its heat transfer and the safety of using the convection boiler.

Therefore, the requirements for ventilation and smoke exhaust systems are very high. They require proper design and operation.

How do gas convection boilers work?

They consist of several main technological units, control automation and safety.

Internal structure of a convection gas boiler

The gas burner unit consists of a gas supply pipeline, a control system, a main gas burner, an igniter, and an electric ignition. Its purpose is to deliver gas to the boiler elements and put the device into operating mode. Next comes the preparation of the gas-air mixture in the required proportion of gas and air for its effective combustion.

The heat exchange unit consists of a combustion chamber and a heat exchanger. Here the process of transferring the thermal energy of the burned gas to the coolant of the heating system or for hot water takes place.

The combustion product removal unit is a place where exhaust gases are collected and passed into the chimney.

Types of automation

One of them controls the operation of the device. It consists of a block for issuing commands for the heating temperature of the coolant and hot water (for double-circuit boilers). With its help, gas convection boilers turn on or off the main burner at the right time.

Security automation is a unit for analyzing the operating mode of the device. The system issues commands for complete shutdown when emergency situations occur.

How does a convection boiler work?

This is an automated device for preparing heating fluid or hot water. Therefore, once it is started, constant intervention is not required for the boiler to perform these functions.

First of all, the boiler igniter is ignited manually (using a match, piezo or electric ignition). It burns continuously until the device is completely turned off by the gas tap for a long time.

When the water in the heating system has cooled down and requires heating, automatic temperature control is activated. The gas, mixing with air, enters the combustion chamber and ignites from the burning igniter.

Next, gas convection boilers turn on the main burner. The heating of the heat exchanger begins, and through it the coolant.

When the required temperature in the heating system is reached, the same automation turns off the gas supply. The main burner goes out and heating of the coolant stops. The pilot light continues to burn. The next time the heating system cools down, the process repeats automatically.

Condensing boiler heat exchanger

At the moment, there is a fairly wide variety of design solutions in this area from various manufacturers of boiler equipment. Both related to the geometry of the heat exchanger and the materials used. Upon closer examination, three main areas of development can be identified:

- Increased amount of condensate formed;

- Increasing the overall efficiency of the heat exchanger (transfer of radiation from burning fuel and heat from flue gases);

- Ensuring equipment resistance to the acid composition of condensate.

Previously, condensing boilers used two heat exchangers - one for primary cooling of flue gases (unresistant to condensation), and an additional one to ensure condensation of water vapor, the so-called economizer. This design is still found in high-power boilers (on the order of several megawatts) and in outdated models of low-power (up to 100 kW) and medium-power (up to 2 MW) boilers.

Modern boilers use one heat exchanger responsible for the first two points from the list above:

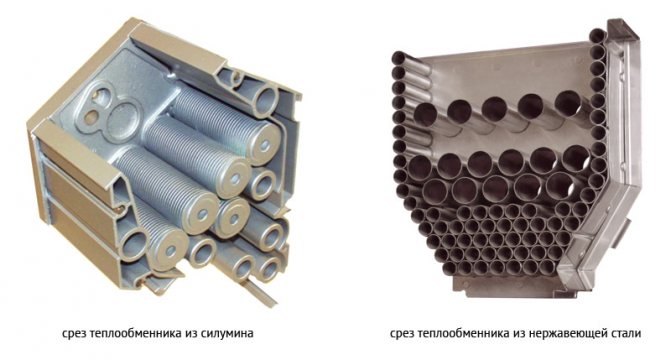

Resistance to acid condensate is ensured by the materials used. Today, two types of materials are used - high-quality stainless steels and aluminum alloys with silicon and magnesium as alloying additives (hereinafter, for brevity, we will refer to them as simply aluminum).

Each of these materials has its own strengths and weaknesses. The advantages of aluminum are high thermal conductivity, low density, and the possibility of molding by casting; The strengths of stainless steel are high mechanical strength, extremely high corrosion resistance to both acidic and alkaline environments, and smooth surface of parts.

From the point of view of resistance to condensate, aluminum heat exchangers perform well in interaction with nitric acid - upon contact with it, the surface of the aluminum is passivated, that is, a protective film is formed - just like when aluminum is in the air. But at the same time, such heat exchangers are extremely vulnerable even to low concentrations of sulfuric acid, and upon contact with it, the protective film is destroyed and interaction with nitric acid begins. In most cases, this factor is not critical due to the low sulfur content in the fuel, but in the long term it reduces the service life of the heat exchanger. Stainless steel of the corresponding grades is not susceptible to acids.

As noted above, reducing the temperature of the flue gases to the dew point is a necessary condition for the formation of condensate and the removal of the corresponding thermal energy. This reduction is achieved by supplying low temperature return coolant to the heat exchanger. However, one should not assume that if this condition is met, all the water vapor contained in the combustion products will condense. The fact is that condensation occurs only with direct contact of flue gases with heat exchange surfaces; accordingly, at an equal temperature of the return coolant, the efficiency of condensate formation strongly depends on the geometry of the heat exchanger.

Thus, the main engineering task when designing a heat exchanger from the point of view of increasing the amount of condensate formed is to increase the surface of contact with flue gases and ensure their high-quality mixing as they pass through the smoke path (to remove already dried gases from the heat exchange surfaces). In this case, it is necessary to adhere to reasonable aerodynamic losses in the heat exchanger. Maintaining a balance between all of the above requirements makes designing the geometry of a condensing boiler heat exchanger a rather complex and interesting task.

When manufacturing a heat exchanger from aluminum, these problems are solved by internal fins (along the smoke path).

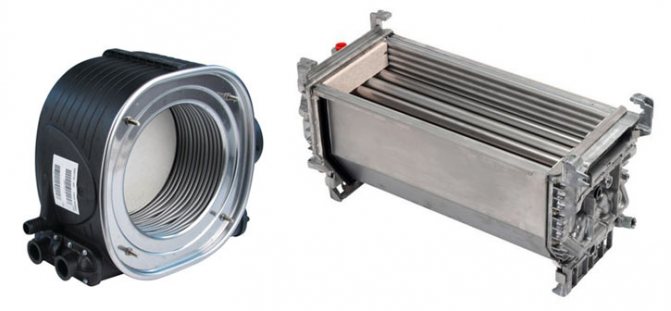

The main structural element of stainless steel heat exchangers is tubes. Made either in the form of a spiral or in the form of straight sections with collectors.

| The spiral design is the most common, but is prone to clogging when using insufficient quality coolant. This happens due to centrifugal effects as water moves through the tubes. Moreover, mechanical cleaning of such blockages is impossible, and chemical cleaning often does not lead to success. In both cases, the total surface area of the steel tubes is quite large. |

What are condensing gas boilers?

The concept of condensing units appeared not so long ago, but most owners of the unit understand the principle of operation of the device based on its name.

The design of the heating system uses thermal energy from the gas consumed, as well as from the generated steam, which in a conventional unit is discharged through a chimney outside the room.

In order to release as much heat as possible from the condenser, all types of devices are equipped with large heat exchangers.

In some versions of the system, an additional heat exchanger is built in. It, in turn, interacts only with water vapor. This design allows achieving high efficiency results.

Installing a boiler will be a real boon for those people who are not indifferent to the environment, but at the same time are accustomed to managing money rationally. Condensing gas boilers practically do not emit harmful substances into the atmosphere, therefore they have the right to be considered one of the most environmentally friendly heating systems.

One should also take into account the rationality of this equipment, which is capable of using the resulting thermal energy from the processing of liquid fuel with maximum efficiency.

There are not only gas, but also diesel devices. The system also collects heat from fuel combustion in order to provide the building with hot water supply. In this regard, the equipment requires less gas consumption to operate.

Burner Premix

The burner is also an important component of any boiler, including a condensing boiler. List of tasks for which she is responsible:

- Ensuring precise proportions of mixing fuel with oxidizer (air).

- High-quality mixing of gas components.

- Ensuring environmentally friendly combustion.

The first two points are necessary to increase the completeness of fuel combustion and, accordingly, the overall efficiency of the boiler. We will analyze them in detail below.

The third point ultimately involves reducing emissions of harmful substances into the atmosphere. In the burners of modern condensing boilers, this is achieved due to relatively low combustion temperatures, which reduces the amount of nitrogen and sulfur compounds formed. To achieve the required power levels when the temperature drops, the flame area in such burners is usually quite large.

The most common are two options for organizing the combustion surface. Cylindrical: And flat:

|

|

| cylindrical premix burner | flat burner premix |

An increase in the combustion surface also provides a larger area of infrared radiation when the burner operates at low power modulation.

The surface material itself is a cellular structure made of metal or ceramic.

|

|

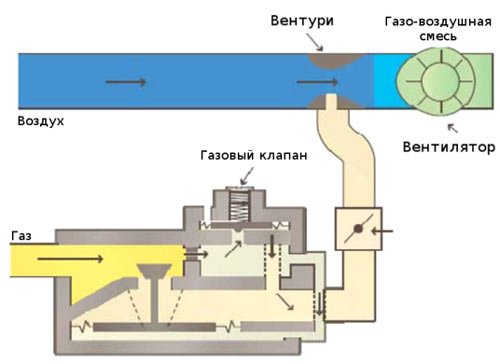

The cellularity ensures additional mixing of gas with air. But the main mixing and control of its proportions in modern boilers occurs before the burner - in the “gas valve / fan / Venturi tube” assembly. Its schematic image is presented below.

Such systems are generally called “Premix”, that is, a pre-mixed system. Precise maintenance of the air-gas proportion is ensured by approximately equal pressures at the mixing point. Moreover, this proportion is maintained over a wide range of mixture flow rates and boiler modulation.

Thus, the general scheme can be described point by point:

- The fan creates high draft, providing precise air flow according to the required power.

- The Venturi tube ensures equalization of gas and air pressures at the mixing point.

- The gas valve maintains the optimal gas-air ratio over a wide range of fan speeds.

- The resulting gas-air mixture enters the burner surface, where additional mixing occurs.

- The mixture enters the combustion area. Moreover, combustion occurs at a temperature low enough to ensure low emissions of harmful substances, but at the same time with a high total power.

To summarize, we can say that the design of a condensing boiler and the principle of its operation are not that complicated. However, each individual element requires great attention when designing. The correct choice of heat exchanger material, its geometry, and reliable components of the gas-air path are the key to efficient operation and longevity of the boiler. Compared to any traditional boiler, a condensing boiler provides greater efficiency in all operating modes. A heat exchanger made of stainless steel ensures a long service life of the equipment (up to 50 years) without loss of efficiency for any quality of fuel and coolant.

Let's look at how the principles and technical solutions described above are used in HORTEK gas condensing boilers.

The range of HORTEK boilers consists of three lines of equipment:

| HORTEK Q - domestic wall-mounted boilers with a capacity of 25-60 kW with options with a built-in DHW boiler | HORTEK XL - wall-mounted boilers of the industrial series 60-120 kW with the possibility of installation in cascade up to 960 kW | HORTEK HL - floor-standing boilers of the industrial series up to 910 kW with the possibility of installation in cascade. |

Design and principle of operation

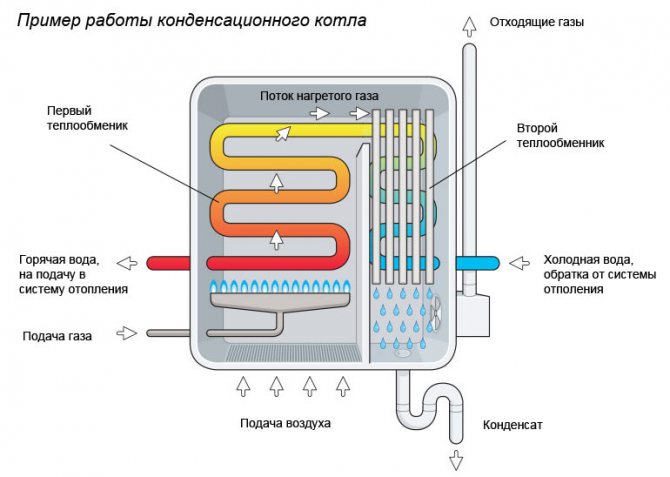

Condensing boiler design diagram

Condensing boilers were invented a long time ago, but have not been widely used for heating purposes for so long. Previously, the use of condensate for additional heating was impossible due to the lack of corrosion-resistant materials. Stainless steel and corrosion-resistant alloys have made such boilers available for widespread production and use.

During the combustion of any hydrocarbon fuel, hot volatile substances are formed. Traditional boilers do not use heat from them. They heat the boiler body and ventilation pipes, and most of it escapes into the atmosphere through the chimney. Part of the generated thermal energy is lost.

In condensing boilers, the steam produced by combustion of fuel is used to preheat water. For this purpose, the boiler is equipped with an additional large-area heat exchanger, which allows you to effectively use the energy of combustion products and return it to the system. It is a tube of complex cross-section with several spiral ribs. Made from oxidation-resistant metals. A fan is installed in front of the gas burner to create an optimal mixture of gas and air.

Main parts of a condensing gas boiler:

- Fan.

- Burner.

- Two heat exchangers.

- Condensate container.

There is a fan at the bottom that directs the air flow upward. There is a burner on top, the heat from which is transferred to the first heat exchanger, just like in a traditional gas boiler. Above it is a second heat exchanger, which uses the heat of water vapor from the combustion products. The steam condenses, releasing thermal energy to the water. It is this additional amount of heat that increases the efficiency of condensing boilers compared to conventional analogues. The condensate is removed from the system into a tank, where it is neutralized with magnesium and potassium granules, and then goes into the sewer system.

Heat exchangers for HORTEK boilers

The fundamental solution for all of the above boilers is to use heat exchangers only made of acid-resistant stainless steel AISI 316. From a design point of view, all heat exchangers are a set of smooth tubes communicating through manifolds. This solution made it possible to ensure high resistance to contamination both on the coolant side and on the flue gas side. In addition, the flow distribution in the heat exchanger is designed for high coolant velocities, which further increases resistance to clogging. Thanks to these factors, the efficiency of boilers with such heat exchangers remains at a constant level throughout their entire service life.

HORTEK boiler burners

As with any modern condensing boiler, HORTEK uses Premix system burners. However, the burner geometry is different for wall-mounted and floor-mounted boilers.

The Q and XL series boilers use flat ceramic burners located on top of the heat exchanger. This arrangement ensures the burner resistance to clogging and ease of maintenance.

HORTEK HL floor-standing boilers use a cylindrical burner, the surface of which is a mesh made of a refractory alloy. The burner is also located in the upper part of the boiler, which in the case of floor-standing boilers is a rather non-standard solution. But it is precisely this arrangement that ensures high compactness of boilers and a small occupied area in relation to thermal power, which is especially important for both roof-mounted and free-standing boiler houses of high power.

Advantages

Convection boilers are less efficient than condensing models. Such units heat the coolant only due to the heat obtained from gas combustion. At the same time, approximately 20 percent of the energy is lost along with combustion products into the atmosphere.

But despite this, such boilers have a number of the following important advantages, which determine their popularity among consumers:

- One of the most significant advantages is the significantly low price compared to condensation, one and a half to two times.

- The installation method can be either wall or floor. It has a cast iron heat exchanger, which is one of the most reliable and will last a long time.

- a small amount of acid condensate, which is formed during the operation of the boiler, the bulk of which goes into the pipe along with the combustion products.

- Having an open combustion chamber, it uses ambient air for the combustion process, due to which the air in the room where the gas boiler is installed is cooled.

- easy installation, repair and dismantling.

- simple design.

- low noise level during operation.

- a wide selection of models, both single-circuit and double-circuit.