Many domestic consumers often have a question: how to insulate a Chinese iron entrance door? Metal doors from Chinese manufacturers are very popular, because they are of good quality and reasonable price. Their only disadvantage is the absence of a layer of insulation, which is simply necessary in our climatic conditions, otherwise you can buy construction doors in St. Petersburg . In order to understand how to insulate a Chinese iron entrance door, the video lesson will tell you quickly, and the article will tell you efficiently.

Material selection

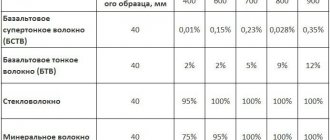

There are several types of insulation to insulate a Chinese door. Most often used:

- Liquid. These include polystyrene foam and penoplex. They are easy to install and have an affordable price. This is the best option for a country house or cottage.

- Soft. These include glass wool and mineral wool. This is an environmentally friendly and fire-resistant material. Designed for entrance doors in apartments and small spaces.

- Inflatable. For example, polyurethane foam. The main difference is high cost and decent quality.

It is also worth considering additional materials and tools for insulation.

What to do with one-piece fabric?

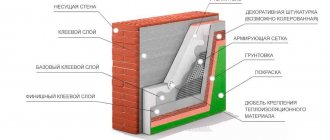

Of course, it would be nice if the Chinese-made iron door was initially insulated. Since this makes the final product more expensive, it is customary for us to take an economical option and improve it to the best of our abilities. In the case where the entrance door structure has one-piece panels, you need to be prepared to change the internal appearance of the door leaf and make a new overlay. But first things first:

- The door completely gets rid of the fittings located on the inside.

- An additional frame is made, as in the photo. To do this, wooden strips are fixed along the entire internal contour of the canvas with metal screws, the width of which should be similar to the width of the insulation. It will be better if the holes for the screws are prepared in advance in the metal base, and their diameter will be slightly smaller than the circumference of the fasteners themselves. At this stage, it is recommended to secure several cross slats, and all wooden elements should be pulled as tightly as possible to the metal base.

- Self-tapping screws must be screwed into the wood with a recess, the fixation points must be sealed with wood putty, after which all wooden parts must be painted or varnished.

- Then the Chinese door is filled with the selected insulation, which it is advisable not only to press well and squeeze into the newly created frame, but also to fix it with “Dragon” type glue.

- All this is covered with a sheet of fiberboard of the required dimensions, which, again, is attached with self-tapping screws or even nails to wooden planks.

- Foam rubber is placed on top, onto which high-quality leatherette is stretched. The latter is attached with specific nails with decorative or hidden caps. The entire process can be followed in more detail via video.

- Since after such insulation of the door leaf it becomes much wider, it is important to buy the appropriate fittings.

Related article: How to varnish a wooden door to return it to its original appearance

At the final stage, it is important to fill with foam all the cavities and gaps found between the box and the wall. After it dries, everything is cut off unnecessarily with a sharp stationery knife, and the joint is sealed with putty or cement.

Alternative methods

If you decide to protect a private home with a Chinese door, try to make sure that all its seams are tight. Then it will be possible to insulate the structure by filling the internal cavities with vermiculite or perlite. And one more thing: do not rush to get rid of the ancient entrance panel. Try living with two doors with an air cushion between them. It has excellent sound and heat insulating abilities, and is quite capable of replacing self-made insulation with hundredths and preserving the metal sheet from freezing.

Insulation of split doors, insulation of Chinese doors

One of the main features of split doors is that a spatial frame is already built into them. Therefore, insulating such a Chinese door will take much less time and effort, since they do not require preliminary preparation.

In this case, professionals use expanded polystyrene foam. Before its appearance, polystyrene foam or stone wool were often used, but they encountered a problem - over time, the material absorbs moisture and becomes painted. This material is still used today, since it is cheaper than expanded polystyrene.

Door with split frame

When insulating a hollow iron Chinese door, you need to pay attention to the choice of insulating material, since the heat and sound insulation of the room will largely depend on its quality.

Material selection

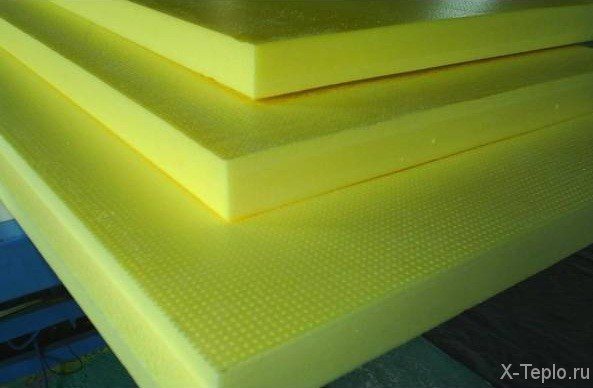

Firstly, it is better to prefer polystyrene foam to polystyrene foam, since it has a denser structure, which means it will last longer.

Secondly, you need to purchase insulation of the required thickness and area. To determine the thickness, you should measure the width of the door at the end, taking into account the trim on both sides. We find out the area by measuring the door horizontally and vertically.

If you plan to insulate a Chinese iron door with missing inner lining, you should also purchase a sheet of fiberboard or hardboard to cover the insulation layer.

So, all the materials are prepared - you can get to work.

Removing the trim

We remove the inner door trim or prepare a new one from fiberboard or hardboard. If the area of the fiberboard sheet is larger than the area of the door leaf, we mark and cut out a part of the required dimensions. Next, we determine the location of the peephole, door handle, protruding parts of the lock and cut out grooves or drill and bore holes with a file. Do not neglect to “try” the fiberboard sheet onto the door leaf to ensure that all sizes match.

Inside, Chinese doors have metal stiffening ribs that divide the perimeter of the door leaf into cells. These are the ones that have to be filled with insulation.

Installation of insulation

Expanded polystyrene is cut into pieces according to the size of each of the cells between the stiffeners. If you were unable to buy a slab of the required thickness, you can reduce it to a suitable size with a hacksaw or hot wire stretched between two wooden handles. Expanded polystyrene is attached to “liquid nails” and lightly pressed against the metal.

Frame installation and sheathing

When all the cells between the stiffeners are filled with polystyrene foam, we proceed to attach the removed trim or prepared fiberboard sheet to the door frame.

It is more convenient to use a screwdriver with a magnetized bit or a magnetized screwdriver. In the case of fiberboard, you can also drill holes in the metal frame and the sheet itself. We screw in 3-4 screws on each side of the door leaf and on each stiffener rib. If the design of the ribs is such that it is impossible to screw self-tapping screws into them, first attach a corner to each rib.

The final stage is grinding the fiberboard sheet exactly to the edge of the door using a file or sandpaper.

Insulation of Chinese metal doors with liquid filler

Craftsmen often use liquid fillers to insulate a door with their own hands. But to ensure that the material does not crumble, it can only be used if the seams are sealed. Care must be taken as there is no guarantee that you will be able to completely fill the space. And this is one of the most important points.

Required materials and tools

In order to efficiently insulate a metal door at home, we need:

- insulation material;

- drill;

- liquid Nails;

- foam for installation.

These are the most basic tools without which you cannot get started.

How to insulate a Chinese door from the inside

Insulating the structure from the inside is more difficult, since the manufacturers initially did not provide for disassembling the fabric. It is assembled using electric rivets using resistance welding. But the painstaking work is justified by the fact that it allows you to maintain the attractive appearance of the product, which is so important for the apartment. You can disassemble a Chinese door using a grinder and a thin cutting disc, as well as a knife with a thick blade.

The process is performed in the following sequence:

- The bolts holding the hinge strips are unscrewed on the canvas and the sash is disconnected.

- It is placed on a table or other elevated surface for the convenience of subsequent manipulations.

- The structure has two steel sheets bent into a box shape and connected by contact welding every 150 mm. On the hinge side, you need to find one such fixation point and try to pass the disk between the sheets of iron to cut it off. You shouldn’t go too deep - 2-3 mm is enough.

- After practicing cutting tacks in a convenient place, you should do this along the entire contour.

- Then a knife is driven between the sheets and separates them. You need to act carefully, since the steel is very thin and easily deformed.

- It is enough to bend three sides, which will open access inside and allow you to insulate the Chinese entrance door.

After this, you need to remove the corrugated cardboard, fixed with glue. Mineral wool is placed inside the sash, the thickness of which is selected based on the depth of the canvas. If disassembly was carried out carefully, then the sheet of metal is returned to its place and fixed with short tacks using a semi-automatic machine with 0.8 mm wire at a minimum current. The end will then have to be repainted.

In case of severe warping of thin steel, the sheet on the room side is removed. Then you will need to lay a wooden beam around the perimeter inside the canvas, which is fixed at the ends with self-tapping screws. A couple more stiffening ribs are placed inside. Mineral wool is laid between them. From the outside, this is covered with an MDF panel, but no more than 6 mm thick, so as not to create excessive load on the points of fixation of the wooden part to the iron.

Repair of Chinese entrance door lock

As noted above, quite often the repair of Chinese metal doors is limited to replacing individual parts of the locking device or the entire lock. This work is completely doable without inviting professional specialists, that is, with your own hands. In such a situation, the following actions are performed:

- The linings with the door handles built into them are removed. To do this, you need to unscrew the bolts located in their upper and lower parts;

- The fastening elements are dismantled, most often the screws located at the end of the blade and holding the plate with crossbars;

- The filling of the lock is removed;

- Unscrewing the screws installed around the perimeter of the locking device body will allow you to remove this part of the mechanism;

- The vacated space is cleared, after which the moving parts of the lock are lubricated, faulty components are replaced, and the device is reassembled in the reverse order.

Obviously, repairing a lock, carried out in accordance with the step-by-step instructions provided, is not a technologically complex operation. In most cases, it is carried out by the direct owner of the property, which allows him to save money.

Insulation of doors along the internal perimeter

The final stage is insulation of the doors from the inside along the entire perimeter. Use polyurethane foam and rubberized insulation as materials.

To begin, remove the trim and fill the internal cavity evenly with polyurethane foam. Please note that polyurethane foam tends to expand 3 times. A few days after complete hardening, cut off any excess foam that sticks out with a knife. Secure the trims in place.

Get rid of cracks and gaps between the frame and the door using rubberized tape insulation glued to the door frame. Check that it does not make it difficult to open or close the door.

So, the insulation process has come to its final stage. There is no particular difficulty in doing the work. Therefore, there is no need to worry about possible failure. The knowledge gained will help you simply and quickly insulate a metal entrance door without outside help.

Selecting the right tools

The list of necessary tools depends on the type of insulation. The optimal and affordable option is mineral wool. For entrance doors, a material with a density of 35 kg/sq.m. is selected. m. Polyurethane is better; if you have limited funds, polystyrene foam is suitable.

Tools and materials for installing foam plastic:

- liquid Nails;

- cutter;

- construction gun;

- foil seal (additional insulation).

To install mineral wool you will need:

- waterproofing membrane;

- office stapler;

- scissors;

- protective gloves, glasses, respirator.

In the absence of internal stiffeners, a frame is made of metal slats and wooden beams. To do this you will need:

- welding machine;

- nails;

- hammer;

- screwdriver;

- drill.

Advice

To calculate the insulation, you need to multiply the width of the door by the height, and then by the thickness of the insulation. Mineral wool is sold in slabs of 610x1000 mm with a thickness of 50 mm. For a standard door you will need at least two. Similar requirements for foam plastic with an average dimensional grid of 600×1200 mm.

Options for increasing sound insulation

There are several ways to increase sound insulation in an apartment:

- Covering or upholstering the door leaf with specialized soundproofing materials. For these purposes, the following are successfully used: foam rubber, padding polyester, cotton wool and other porous structures. These materials are able to dampen sound waves without letting noise into the room or apartment.

- Ensuring a tighter fit of the door structure to the frame. For this purpose, sealing materials made of foam rubber or rubber are used. For better protection, sealing tapes are mounted on both the leaf and the door frame.

- Installation of the second door block. This solution is rational for increasing the sound insulation of entrance doors.

The professional services provided by our company’s specialists are guaranteed to improve the insulation of both entrance and interior structures. The cost of calling a specialist in Moscow is determined by the design features and the complexity of the upcoming work. The price for such services in our company is quite acceptable for any client.

Repair of hinges of Chinese metal entrance structures

Quite often, the decision to repair a Chinese door is made by the homeowner when unpleasant sounds are heard during its operation, for example, creaking or even grinding. In this case, it is also quite possible to fix the problem on your own, which will require lubrication of the hinges of the entrance structure, as well as adjusting the position of the leaf relative to the door frame.

To adjust, with the sash open at 90 degrees, slightly lift it using a wooden block placed underneath, loosen the fastening of the hinges, and then move the leaf slightly in the desired direction. The hinges are then securely locked again. Next, you should check the smooth running of the product. If the problem is not solved, you should repeat the procedure the required number of times, bringing the blade location closer to the optimal one, ensuring smooth and silent opening of the Chinese entrance structure.

Lubricating and cleaning the door hinges of metal doors made in China is carried out as follows. First, the sash also opens 90-100 degrees, after which it is raised and securely fixed with a wooden block placed underneath. As a result, hidden loops located inside the structure are revealed. They need to be carefully cleaned of adhering dirt and debris, and then thoroughly lubricated with special compounds, grease or chiseled graphite in the form of powder obtained from the lead of a simple pencil.

Which finishing material to choose

For additional sound insulation, the finished metal door leaf can be trimmed with leatherette lined with foam rubber, isolon or padding polyester. It can be sheathed with wooden slats, eurolining, plywood or fiberboard. Wood is an environmentally friendly material, but requires additional processing to protect it from fire and extend its service life.

You can use laminated panels or MDF panels. These materials are beautiful and have high performance qualities. They can be used to decorate the entrance and interior doors, silence will be ensured.

What materials are doors made from?

Typically, wood and steel are used to make entrance doors. Both materials have features that determine the performance characteristics of the finished product.

Steel

The entrance metal structure is the most common option. Its design features ensure high performance characteristics, subject to compliance with technological requirements and the use of high-quality metal.

Steel doors

At the very first stage of production, a steel frame is welded, inside which insulation and material with good soundproofing characteristics are inserted. Often this is the same material, which has both noise and heat insulation properties (foam or mineral wool).

In addition to the material placed inside the metal frame, finishing materials help improve the soundproofing characteristics of the door. Upholstering the steel sheet with MDF panels or vinyl leather simultaneously improves the appearance of the door structure and enhances the sound-absorbing properties. Powder coating will help prevent mechanical damage. It is extremely difficult to damage, but it makes the door leaf look more attractive.

Finishing option

Tree

Wood is used to make doors, the sound insulation characteristics of which reach 32 dB. Conifers, cherry, oak, ash and walnut have these characteristics. The choice of the appropriate option depends on the financial capabilities of a particular family. If a wooden door is additionally finished with natural veneer, this improves sound insulation and gives the door a presentable appearance. The ability to apply paint and varnish allows you to choose the appropriate shade for any structure, regardless of where it is installed.

Wooden door

The thicker the door leaf, the higher its characteristics. Considering that wood is an environmentally friendly material, many install such structures at home, taking care of their health. Made from high-quality raw materials, the canvases are not afraid of mechanical stress and reduce the noise load on the home. In addition, wood helps ensure optimal temperature and humidity conditions inside the house.

How to soundproof a door yourself

In order to make the door more solid, it is necessary, first of all, to replace its internal filling. To do this, you can choose regular polystyrene foam or mineral wool.

Info!

Mineral wool is an excellent fireproof material. It will prevent the spread of fire

In order to lay the new filler, the door must be opened, so this option is only suitable if you have such an opportunity. To do this, it is laid in a horizontal position, and the door leaf is very carefully opened with a knife. Then you need to pull out the filler that is already there and replace it with the selected material.

The joints of the panels are cleaned of dust, thoroughly coated with glue and everything is glued back.

5.00/5 (2 ratings)

In this article, we will look at such an important detail as soundproofing the door and doorway with our own hands.

Using modern, strong and durable materials. We will also pay attention to the aesthetic component, so that your Hand made (made by hand) pleases the eye. When the front door has good sound insulation, then no extraneous sounds penetrate to you from the side of the doorway.

But what should you do if persistent, alien sounds creep into your home from the landing, or from the street (if you have a private house).

You can hear a neighbor closing the door, someone swearing and shuffling their feet, cats meowing or someone talking, in a word, extra decibels prevent you from enjoying comfort.

Soundproofing process - stuffing the doors!

You don’t need any special tools to soundproof your entrance doors yourself. An ordinary screwdriver, scissors and a knife will suffice. And you can find the necessary soundproofing materials in any decent building materials store. Of course, you can get by by gluing self-adhesive sound insulation directly to the surface of the door on both sides, but if you still care about the appearance of the product, then you will have to place all the layers of materials inside. By the way, it is also more effective.

If you are determined to disassemble the structure, you can also stuff it with all sorts of electronic devices: a peephole, a lock.

So, you have disassembled the door frame. To begin, cover the inside of the doors with self-adhesive vibration and sound insulators. By the way, for good quality gluing, the door surface temperature should be at least 20 °C. Then fill the remaining space with mineral wool or foam rubber. To prevent materials from settling, create additional stiffeners from scraps of tin or wood. Calculate the amount of materials so that they rest against the surface - this will prevent them from becoming loose. Having assembled the door frame, you will feel a huge difference, both in the level of thermal insulation and in the silence in the room.

Soundproofing material

To ensure the required level of sound insulation characteristics, various materials are used. Preference is given to polystyrene foam, polyurethane, mineral wool and corrugated cardboard. The latter material is popular among Chinese manufacturers. However, this option is not suitable for the realities of the Russian winter: the house will be quiet, but cold, since the insulating properties of cardboard are low.

Mineral wool

In terms of price/quality, mineral wool takes the leading place. Thanks to its fibrous structure, this material absorbs external noise, preventing heat from escaping. However, laying mineral wool when making a door leaf can cause difficulties. When developing the design, additional partitions are provided that will help maintain the specified position of the mineral wool inside the frame.

If additional partitions are abandoned, during subsequent use the material will gradually begin to crumble and eventually end up at the bottom of the door leaf. If after some time the structure begins to let in the slightest rustle from the outside, disassemble the canvas. After this, you will probably see that there is no longer any heat- and sound-absorbing material at the top of the door. The reason is an unfinished design.

Before choosing a model with such insulation, it is recommended to think carefully. It is possible that the cotton wool will not be in place on the day of purchase, but this is impossible to verify. It will not be possible to determine the location of the mineral wool without opening the canvas.

Polyurethane

If you want to purchase entrance blocks that have no problems with sound insulation, this option will be optimal. This insulating material not only has suitable performance characteristics at any outside temperature, but also strengthens the door leaf. It does not burn, which becomes an important condition for a residential building. True, the high cost of such insulating material forces many to choose cheaper options. As a result, door structures with polyurethane are preferred by owners of luxury cottages rather than country houses.

Styrofoam

This is perhaps the most popular material for those who want to get a high-quality and affordable door with sound insulation. Due to its light weight, it does not place increased demands on the door frame and the fittings used.

Foam plastic is rigid, and therefore there is no fear that the performance characteristics will change over time. When choosing, pay attention to the density of the material used in the manufacture of a particular model. C25 foam is suitable for entrance structures.

Styrofoam

When you decide to install a door with good sound and heat insulation at an affordable price, you should first consider models that use foam plastic for insulation. If a door leaf that has been installed for a long time allows external noise to pass through, try to correct this by making a foam overlay.

Sometimes, the use of this material is refused due to its flammability and ability to release toxic substances. However, such a refusal is not always justified, since many thermal insulation materials have a similar property. Considering that the foam is usually located inside a metal frame or outside a wooden door, you won’t have to worry about the release of harmful substances.

Additional insulation

In order for the structure to acquire good sound-absorbing characteristics, an additional one is often used along with the main insulating material. Thus, isolon, laid on both sides of foam, will significantly improve the characteristics of the front door. For maximum effect, the isolon is positioned so that the reflective surfaces are directed in different directions. In this case, heat from the inside will not escape outside, and sound absorption will increase by 40%.

Additional insulation

Additional selection criteria

Even if a metal door is equipped with a door leaf made using modern insulating material, it may still be cold and noisy inside. The reason for this is the gaps between the canvas and the box. To ensure a tight fit, a seal of suitable size must be glued around the perimeter of the door leaf. If the inside of the house is uncomfortable, first check the condition of this element.

To begin with, we note that seals differ in geometric parameters and design features. Door manufacturers use seals with and without an air chamber. Each company decides which one to install independently.

It is better to choose models with two sealing contours. Considering the Russian climate and noise levels in cities, one is not enough.

If it turns out that the manufacturer decided to save money and refused to install a second sealing circuit, you can add it yourself. Such insulating material is always available in stores. Measure the fabric to get the right amount.

Attention! The thickness of the sealing material is determined in the compressed state. When choosing a suitable tape, compare the thickness of the seal and the gap between the sheet and the box.

After purchasing the required quantity, all that remains is to attach it around the perimeter of the box. Note that rubber seals lose their properties within a year or two after the start of operation. Therefore, if a rubber band is used for sealing, monitor its condition annually and, if necessary, replace it with a new one.

When planning to install entrance structures, be sure to choose a model with increased noise insulation. Manufacturers offer a wide range of these products. Based on the installation location, availability of available funds and finishing option, preference may be given to different modifications.

If the installation is carried out according to the rules, the door structure will provide the required level of sound insulation. At the same time, do not forget to monitor the condition of the seal and other insulating materials, and treat the door structure as a whole with care.

It seems that everything is clear: soundproof doors are needed in order to absorb sounds and not allow unnecessary noise into the room. Because if noise with a volume of 35 to 50 dB bursts into the room, then it will not be comfortable to be in such a room.

A sound-absorbing door is also needed to ensure that sounds do not leave the room. This is important for those people who like to listen to music loudly, watch TV or play musical instruments.

Special rooms are worth considering separately:

- Meeting rooms

Recording studios

Executive offices

Hotel rooms

Soundproof doors must be installed in them.