Properties

This material is successfully used in the construction of temporary and permanent buildings, as well as in the construction of summer cottages. In addition, it is necessary to highlight the following important properties of mineral wool:

- excellent fire resistance (does not allow all materials in contact with it to ignite, and does not ignite itself);

- non-hygroscopic (excellently prevents intensive penetration and absorption of moisture);

- vapor permeability (this is an important property, since in some rooms it is necessary to regulate the level of moisture and thus create a suitable microclimate);

- high sound insulation (does not allow sound waves to pass through itself, therefore it is actively used in the construction of nightclubs, discos and other noisy establishments);

- chemical and biological resistance (excellent protection against harmful and aggressive substances);

- environmental friendliness (consists exclusively of natural rocks that do not carry any harm, tested by specialists);

- corrosion resistance (does not create corrosion to metals that come into close contact with it).

Chapter 3. THERMAL INSULATION MATERIALS AND PRODUCTS

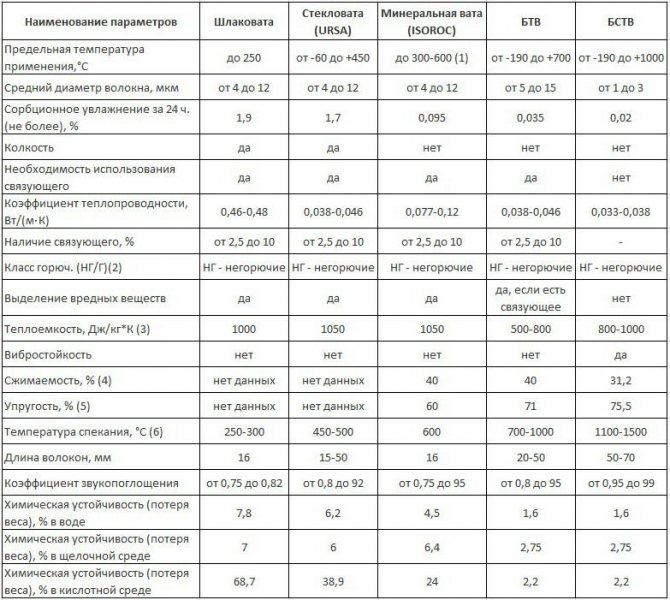

When producing melts in bath furnaces, the following raw materials are used: marl with limestone, blast furnace slag with mountain sand (in a ratio of 1: 0.33 or 1: 0.18 parts by weight); marl with dolomite (Germany), melt acidity modulus 1.3-1.86.One of the main criteria that determines the quality of mineral wool is the acidity modulus, which takes into account the content of four main oxides (SiO2, A12O3, Fe2O3, CaO, MgO). With an increase in modulus, in some cases the chemical and thermal resistance of mineral fiber increases. In accordance with GOST requirements, the acidity module must be at least 1.2. The main oxide in the raw material for the production of mineral wool is Si02, with an increase in the content of which the melt viscosity and chemical resistance of the fiber sharply increase. Increasing the A1203 content also increases viscosity, simultaneously causing a decrease in the temperature range of change in melt viscosity, and leads to an increase in the chemical resistance of the fiber. An increase in CaO content, on the contrary, reduces the viscosity of the melt and reduces the resistance of mineral fiber to temperature and various aggressive environments. With an increase in the MgO content due to a decrease in the CaO content, the thermal resistance of the fiber and its elasticity increase.

An increase in the content of iron oxides (FeO and Fe2O3), Kr and Nap reduces the melting point and viscosity of the melt, and in the process of fiber formation has a different effect: Fe oxides increase surface tension, K and Na oxides reduce it.

The diameter of wool fibers in most factories meets the requirements of the current standard - up to 8 microns. Good quality cotton wool is produced at the Voskresensky plant "Krasny Stroitel" (it has the smallest volumetric mass, the smallest number of non-fibrous inclusions with a diameter of over 0.25 mm (up to 1.4%)). At most domestic factories, the content of beads with a diameter of more than 0.25 mm ranges from 14 to 25%, and in foreign countries it does not exceed 9%. In Sweden, Germany and the Czech Republic, fiber with a diameter of 5-7 microns is produced, the mass of mineral wool is 50-75 kg/m3, and in the USA, France and England - 50-120 kg/m3.

Cotton wool from rock melts is mainly acidic in its chemical composition and is more resistant to use. With similar acidity modulus values, mineral wool produced at different plants can have significantly different strength, water resistance and durability.

Binders and methods for their introduction into mineral wool Binders hold the fibers together, fix the structure and bulk of the product. Moreover, in hard and rigid mineral wool slabs, the pore-filling binder significantly limits the mutual movement of the fibers, and in soft and semi-rigid products, the binder holds the fibers together mainly at the points of their contacts, as a result of which the elasticity of the product is imparted due to the elasticity of the hardened binder, and most importantly - due to elasticity of the fibers themselves.

The physical and mechanical properties of products (density, strength, elasticity) and their safety during operation (durability) are influenced by the quality of both mineral wool and the binder after it has cured in the product frame. All these factors together affect not only the strength and elastic properties of products, but also the durability of the thermal insulation layer in the enclosing structure.

The binder is introduced into the mineral wool carpet both by spraying (dispersion) at the moment of wool formation in the fiber-deposition chamber, and by soaking the layer of wool with an aqueous solution of polymer substances flowing through it, followed by suction of part of the solution during vacuuming - the method of “impregnating the carpet using the spill method.”

The introduction of binders into a mineral wool carpet should ensure their uniform distribution throughout the volume of the product and exclude the possibility of premature curing not at the points of fiber contact.

Due to the imperfection of domestic industrial equipment, when spraying the binder in the fiber deposition chamber, in some cases its premature curing is observed (the temperature in the fiber deposition chamber reaches 60–130 ° C). In this case, the binder does not participate in the formation of the frame; the “products” have low strength.

By impregnating the carpet with a binder, this drawback can be eliminated, but at the same time, energy costs for drying a carpet with high humidity increase. Using existing equipment, the “wet” process (impregnation of the carpet with a binder) makes it possible to obtain more durable products with increased performance properties than similar products in which the binder is introduced by spraying in a fiber deposition chamber.

Technical characteristics of mineral wool

The density of mineral wool can be different - from 20 to 350 kg/m3. The required density must be selected based on its intended purpose. For example, if you plan to insulate the walls, then you need to choose a material with a higher density, but if you are insulating the ceiling, then you can get by with a less dense option.

Technical characteristics of mineral wool may also vary depending on the type of material.

Each type has its own technical characteristics, so you can indicate the average indicators for the material as a whole:

- maximum heating temperature is up to 700 degrees Celsius;

- thermal conductivity coefficient varies from 0.03 to 0.1 W/m*K;

- hygroscopicity is high.

You can see a photo and video review of mineral wool on our website. All of the above varieties are presented here.

Harmful substances in slag wool

Phenol-formaldehyde resins, which are part of slag wool, negatively affect human health. Some experts believe that such substances are very dangerous for humans. However, manufacturers claim that the concentration of harmful substances is very small and cannot pose any danger. In order not to risk your health, it is better to buy material only from well-known and trusted manufacturers.

According to reviews of builders who use this insulation, they say that slag wool is a practical and inexpensive material with a long service life. The main thing is to comply with all technical conditions and safety measures during installation.

Related publications

- Read

Kaolin wool

- Read

Basalt wool

- Read

Glass wool

- Read

Minvata

- Read

Greenplex

- Read

Flaws

But there are also disadvantages: it has increased fragility, quite often crumples and becomes compacted, it can wear into dust, and mice feel good in it.

In general, reviews of mineral wool are quite positive. Many builders use it to insulate their buildings, even though it has minor drawbacks. This material is still popular due to its advantages. It will be used in construction until a more profitable and convenient alternative appears.

Advantages of slag

In general, the advantages of using slag wool as a heat insulator are the same as those of all other fibrous insulation materials. The advantages include the following factors:

- Good thermal insulation

. The material has good heat-saving properties. Slag wool is slightly inferior in this parameter to stone and glass wool, but when installed correctly it also reliably protects the structure from cold winds and freezing. - High sound absorption coefficient

. As a soundproofing material, slag wool can be laid both on external walls and on interfloor ceilings. It will reliably protect against the penetration of extraneous sounds from the outside thanks to its own fibrous structure, in which air is retained and sounds are suppressed. - Low price

. Slag wool is a fairly inexpensive material. This is explained by the fact that waste from the metallurgical industry is used for its production. - Easy to install

. Insulation can be laid on both flat and curved surfaces. It is also easy to cope with the installation of heat insulation on round objects. It's quite flexible. In addition, the weight of the slag wool is small, so even one person can do the installation work. - Long service life under optimal conditions

. If slag wool does not get wet and is exposed to high temperatures, then it can maintain excellent sound and heat insulation characteristics for 50 years or more.

What factors destroy mineral wool?

At industrial facilities, even during major repairs, cotton wool cannot be replaced, because the material itself as a whole does not deteriorate, break down or decompose. Breakdowns can occur when steam under pressure forms a hole in the pipe (fistula) and, escaping, sweeps away the insulation. During insulation work, the old insulation is not removed.

Mineral wool insulation is able to withstand a new operational period until the next major overhaul, so it is reused. New material is applied where it has become smaller for various reasons. Only those sections of the insulating layer that, being open, become clogged with dust, dirt and turn to stone, must be replaced. Thus, the first enemy of mineral wool is dust and dirt.

Water

The next enemy of this porous and breathable insulation is moisture in the absence of air. If water or condensate gets into the thermal insulation layer, but does not have an exit, it violates the thermal insulation properties. Vata stops breathing and retaining heat. Therefore, when installing thermal insulation, technological holes are provided through which air enters the thermal insulation layer and moisture is removed.

Mineral wool absorbs moisture well

Some manufacturers impregnate mineral wool with water-repellent substances, and this material is suitable for thermal insulation of roofs and external walls of a house.

Mechanical impact

From the above, the conclusion also suggests itself that the service life of mineral wool is reduced by mechanical influence from the outside. This

- fistulas on pipelines;

- wind that can sweep away loosely secured casing on above-ground pipes;

- workers fixing pipe leaks;

- rodents living underground and in houses.

Industrial thermal insulation is mainly subject to mechanical destruction.

Rodents

Whatever the manufacturer says, practice shows that rodents make nests in almost all types of insulation. They are not even afraid of the prickly and irritating glass wool. They gnaw passages, make nests, thereby destroying the insulating layer.

Thus, in order to extend the service life of the thermal insulation layer, it is necessary, first of all, to comply with all the requirements for thermal and vapor insulation at the installation stage, and to eliminate factors that destroy thermal insulation.

Disadvantages: slagging

In addition, the disadvantages of slag wool include the following:

- Poor resistance to sudden temperature changes

. Insulation may lose its thermal insulation properties if it is frequently exposed to temperature fluctuations. - Good ability to absorb water

. This factor provokes a number of negative aspects. Thus, when wet, slag wool ceases to function as a heat insulator. In addition, when moisture gets on the material, acid is formed, which corrodes metal parts, fasteners and elements. - Limited scope of use

. Slag wool is not recommended for laying as insulation on buildings where there is a high level of humidity (baths, saunas), building facades due to the risk of getting wet. In addition, wooden houses should not be insulated with this material either. If it gets wet, the wood under the heat insulation layer will rot. - High fragility and thorniness of fibers

. Like glass wool, it has sharp and brittle fibers that are dangerous if they come into contact with exposed skin and mucous membranes. Therefore, it is necessary to work with the material with the mandatory use of protective equipment. - Low vibration resistance

. Under strong vibration loads, the slag will settle, and its thermal conductivity will increase. - Presence of harmful substances in the composition

. Many insulation materials that are not of very high quality contain volatile chemical compounds, such as phenol-formaldehyde.