Excellent performance

Firstly, the use of polyurethane foam is effective, because in terms of the degree of thermal insulation it can be compared with vacuum insulation. At the same time, our option is cheaper and simpler in terms of installation. Secondly, the coating based on this material is elastic, wear-resistant and resistant to deformation. In addition, polyurethane foam can be used in any climatic conditions regardless of the temperature range. Insulation with polyurethane foam received positive reviews due to the creation of a sealed layer impermeable to water and air. It is important that the insulation is environmentally safe, so its use fully meets the requirements of sanitary standards adopted in the construction industry.

Many owners of private houses prefer to insulate the attic with polyurethane foam. Reviews say that due to the cost-effectiveness and availability of the material, the construction process can be significantly reduced in cost. High adhesion guarantees that polyurethane foam will be well sprayed or laid on any material - glass, plastic, wood, frame or concrete, and can be used for finishing walls, ceilings and floors. Thanks to excellent adhesion, the use of fasteners is not required, which also greatly simplifies the installation process.

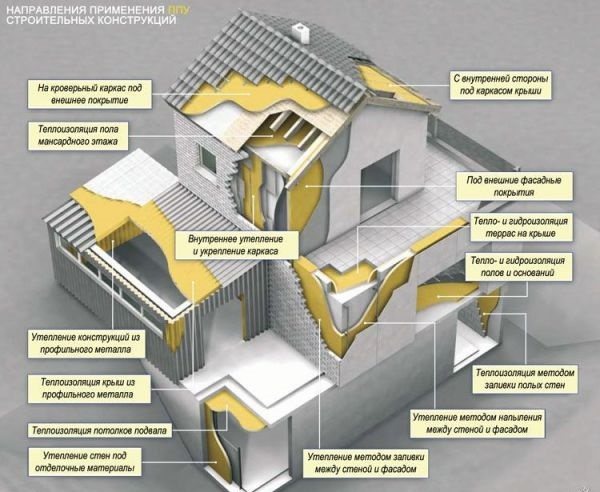

Today, insulating a house with polyurethane foam (reviews confirm that this technology is the most convenient) can be carried out using several of its varieties. In its toughest version, this material consists of closed cells that provide high levels of hydro- and thermal insulation. Most often, this type is used when finishing external walls, but this will require the creation of a ventilation system, since rigid grades of polyurethane foam are not vapor permeable. Thanks to this method of thermal insulation, several goals can be achieved:

- ensure high resistance of the coating to harmful substances and mold;

- ensure adhesion to any surface;

- protect the building from fire;

- use in any climatic conditions.

Ease of use makes it easy to insulate walls with polyurethane foam. Reviews from many of those who performed thermal insulation on their own indicate that this process can be handled easily and simply.

Why PPU

The feasibility of using polyurethane foam for insulating attics is ensured by its operational characteristics. The following properties of this material play a huge role:

- Minimum thermal conductivity, moisture absorption and vapor permeability of insulation based on polyurethane foam.

- The possibility of applying thermal insulation from the inside of the building with a continuous seamless carpet, eliminating the possibility of the formation of “cold bridges”.

- Insulation with polyurethane foam can be carried out both during the construction of a house with an attic, and during its reconstruction.

- A fairly simple technology for applying polyurethane foam to various surfaces is ensured by its high adhesion to various materials.

- High speed of work (up to 350 square meters per shift), thanks to which even a large attic can be insulated in just 1-2 days.

- PPU is a self-extinguishing material, so it is recommended for internal insulation to ensure fire safety.

- Unlike other insulation materials, polyurethane foam does not slide down inclined and vertical surfaces, which ensures reliable thermal insulation of the attic throughout the entire period of its operation.

- The price of the material and the cost of performing the work are quite affordable; certain savings can be obtained due to the minimum thickness of the insulation.

Thanks to all these properties of polyurethane foam, insulation of a house with an attic with this material is used both in private conditions and on an industrial scale.

Features of home insulation

To make your country house warm, reliable in operation and energy efficient, and at the same time reduce heating costs, you need to competently approach the process of insulating it. One of the simple ways is to insulate the house with polyurethane foam, thanks to which the load-bearing structures will conserve heat indoors as much as possible. It is best to carry out external finishing to save usable space. Before finishing the walls, you need to do thermal calculations to determine the minimum thickness of the polyurethane foam layer. The calculations take into account:

- heat transfer resistance of load-bearing structures;

- wall thickness;

- region of residence.

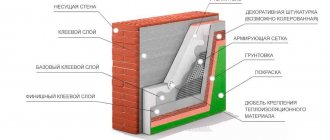

External insulation with polyurethane foam received positive reviews due to the fact that the work is carried out conveniently and simply. In this case, you can finish the attic, loggia, balcony. Insulation from the outside requires a number of works:

- The surface of the walls is being prepared.

- Polyurethane foam is sprayed.

- Reinforcement is carried out with a special screed.

- Finishing is in progress.

Polyurethane foam is applied only to a clean surface, and its thickness depends on the type of wall and its condition. Reinforcement is done using fiberglass mesh with small holes. Insulating a house with polyurethane foam has its own characteristics, which depend on the type of future finishing.

What should you look at before you start insulating your attic with polyurethane foam?

- Thermal insulator and its effectiveness - it should occupy a minimum area without placing additional loads on the supporting structures.

- In an ideal ratio, the insulation should have extremely low moisture absorption, and it is better if the attic insulation with polyurethane foam is used with insulation that does not absorb moisture at all. Thus, the dew point from the inside will constantly be shifted towards the insulating material, and if the vapor barrier layer is damaged or completely absent, moisture will reduce the thermal insulation of the room.

- If you decide to insulate the attic with polyurethane foam, it must be installed in such a way that there are no leaks or cracks. Proper insulation of the attic with polyurethane foam, reviews of the service indicate its popularity, allows you to save up to 40% of all space heating costs.

Siding or plaster?

If polyurethane foam is applied under siding, then the creation of a curtain façade based on a frame and brackets on the wall is required. When applying the material, you need to ensure that it gets under both the frame and the guide profiles. This will provide high protection and reduce heat loss. With this method, the frame should protrude a couple of centimeters above the facade.

If walls are insulated with polyurethane foam for further plastering, a slightly different technology will be required. When spraying, the texture and relief of the wall surface is partially repeated, so the application of polyurethane foam must be done carefully and evenly.

Attic insulation

Insulating a house with polyurethane foam has received positive reviews due to the fact that the materials can be used to decorate an entire country cottage. To reduce the level of heat loss, the attic or attic is most often finished with polyurethane foam. What is good about this method? Firstly, the seamlessness of the coating, which is ensured by the use of a low-pressure apparatus that sprays the mixture onto the surface to be insulated. The polyurethane foam hardens on the base within 10 minutes, and the operation is performed in several layers to achieve a smooth and neat surface. The material can be applied vertically and horizontally, and it is ideally attached to surfaces made of wood, concrete, metal or plastic. It is no coincidence that attic insulation with polyurethane foam is very often used. Reviews note that this is the simplest and most convenient way to provide additional thermal insulation.

This process must be approached responsibly, primarily because the attic is a living space that comes into contact with cold air more than other rooms. Accordingly, in addition to insulation, additional waterproofing will be required, carried out in accordance with environmental and fire safety standards.

The use of mineral wool and other tile materials is a process that is too long and labor-intensive, so insulation with sprayed polyurethane foam received positive reviews precisely for the simplicity and speed of the process. You can handle spraying yourself, and the service life of the coating will be about 50 years.

Work order

To protect window glass from contact with foaming material, they need to be covered with a special film. The peculiarity of polyurethane foam is that it sets very quickly, after which it is quite difficult to remove it from this or that object. Therefore, in order to prevent damage, it is necessary to ensure the protection of valuables, windows and doors.

The next step in preparation for surface treatment with polyurethane is to remove the old coating from the ceiling and walls. Remove, for example, worn chipboards, wooden slats. Of course, well-preserved material can be left untouched.

To ensure better adhesion to the surface of this heat insulator, they must be cleaned of dust, dirt, and various debris.

Basically, attic spaces accumulate a lot of dust and dirt. The best option would be to insulate the attic before installing the interior cladding of the house. It must be remembered that this foam material is applied from the inside.

How to carry out the spraying process?

It is important to determine the thickness of the spray. It is determined depending on the thickness of the walls, room temperature and other factors. On average, this figure is no less than 10-15 cm. It is advisable to spray immediately at this thickness. Make a layer of 10-15 cm in one pass. If it is necessary to create a greater thickness of insulation, it is applied in several layers.

It must be remembered that spraying is carried out only on a clean and dry surface. The temperature during spraying should be between 10°C and 15°C. If it is low, the material will not fit well on the walls. High humidity will lead to various defects - open pores, bubbles. In some cases, peeling of this material may occur. The technology of its application itself is similar to painting surfaces using a spray gun.

When processing walls with this material, it is recommended to move the gun from top to bottom, gradually moving from side to side. It is necessary to ensure uniform application of the material on the walls, to ensure that the layer is the same everywhere, and the surface does not have significant protrusions. After completion of the work and complete hardening of the material, you need to paint it to protect it from exposure to UV rays.

Methods

Attic insulation is done in several ways. Only insulation of the attic floor can be carried out: polyurethane foam is sprayed between the wooden joists. If the attic is not intended to be used as a living space, insulation is applied only to the base of the floor. In this case, it is necessary to organize an effective ventilation system.

Features of roof insulation

PPU is also widely used for finishing roofing systems, since thanks to spraying, the material adheres well even on an inclined surface, repeating complex reliefs and shapes. Insulating a roof with polyurethane foam allows you to achieve high thermal insulation, but will require a thinner layer of material that will protect the surface well from the cold. Thanks to its durability and good noise and heat insulation properties, polyurethane foam is a good solution for any roofing system.

Comparative characteristics

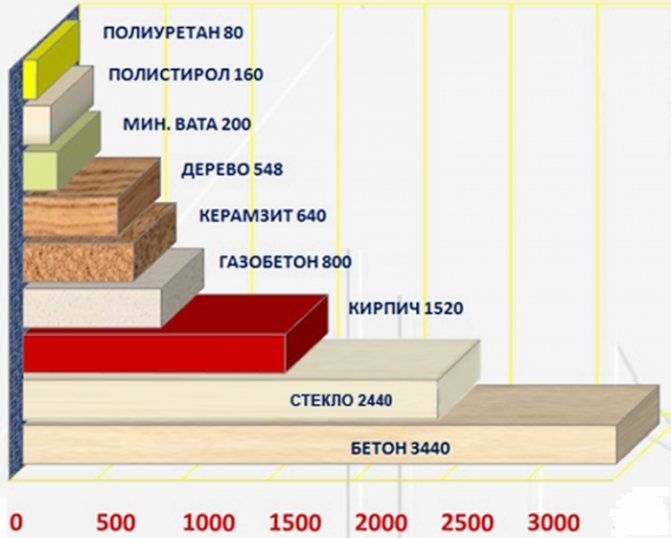

The properties of polyurethane foam are most clearly visible in comparison with similar thermal insulation materials:

Polyurethane foam is one of the most commonly used materials in construction. Its unique properties provide high-quality insulation and further strengthen the structure. Moreover, with the help of polyurethane foam you can treat rooms both inside and outside. Additional evidence of its effectiveness are numerous reviews from professional and non-professional builders.

Filling with polyurethane foam

Polyurethane foam is a unique material that is installed using only two technologies. Thus, in most European countries, insulation with polyurethane foam has been popular for many decades (reviews of the technology are only positive), which is poured into cavities up to 10 cm wide. Gaps are left specifically to fill them with foaming materials that provide a high level of heat and sound insulation. The entire insulation process comes down to performing several types of work:

- Holes with a diameter of up to 12 mm and a set pitch of 60 mm are made outside or inside the walls.

- Polyurethane foam is poured through the holes under pressure, filling the cavity and rising along the height of the wall.

- Filling is carried out until the entire cavity is filled.

This is a convenient way to insulate your home with polyurethane foam. Many reviews agree that this technology makes it possible to create a seamless and sealed thermal insulation layer using high-quality and environmentally friendly materials.

Preparation of tools and materials

If you have hired specialists who will do everything quickly, efficiently and without your efforts, then you don’t need to do anything, since they have everything you need. All you need to do is prepare the premises and pay the workers for their labor and materials. Otherwise, to insulate the attic with polyurethane foam you will need:

- two separate containers that will contain liquid polyurethane foam and water;

- hose system and spray gun;

- pump or compressor to create pressure inside;

- special clothing for work: gloves, respirator, thick shoes and glasses;

- a spatula or rag to clean the inside surface of the attic;

- tool for removing excess polyurethane foam.

Advice! Before starting work, we strongly recommend that you familiarize yourself in more detail with the main action and stages of insulation work. However, the best results can be achieved if you entrust the work to a professional with their high-quality equipment.

Spraying: easy and fast

Insulation with polyurethane foam can be done by spraying it. This technology is widely used in most countries of the world. The essence of the technological process is the supply of two components to the sprayer under pressure. While stirring, the mixture is brought to the surface and applied in a thin layer to the surface. After just a few minutes, the foam sharply increases in volume, hardens, after which a monolithic thermal insulation coating is formed. Depending on the type of components selected, polyurethane foam of varying densities can be used.

The low density of polyurethane foam will lead to the fact that the coating will not be too resistant to mechanical impact, and therefore is only suitable for finishing with siding. A higher density allows the use of polyurethane foam for finishing surfaces that do not require additional finishing. The main advantages of spraying technology are manufacturability, economic feasibility and convenience. Based on this technology, the attic is often insulated with polyurethane foam - reviews say that this is the fastest way to cope with the insulation of this room.

Characteristics of polyurethane foam as insulation

First of all, we invite you to get to know this insulation material a little. It is completely different from the mineral wool or polystyrene foam we are used to. Why? It's all about the composition and appearance. PUF is in a liquid state and when its components are mixed and sprayed onto the surface, it begins to increase in size. And if you lay ordinary wool in slabs, then polyurethane foam must be applied using special equipment.

Nowadays, much attention is paid to the environmental component of materials. If we talk about polyurethane foam, it can be called one of the best in terms of safety and environmental friendliness. During operation, it does not emit harmful substances. This is very important for the attic, since it is exposed to the sun and heats up, and the insulation itself is applied from the inside.

Another important point is the adhesion of the material, i.e. its adhesion to the surface. When applied, it adheres perfectly to almost any type of coating: wood, metal surface, reinforced concrete. The only exceptions are the slippery polyethylene surface and fluoroplastic. But, when arranging an attic room, such materials are not used. There are many advantages regarding the method of applying polyurethane foam. The fact is that rigid insulation cannot penetrate into cracks and hard-to-reach places. But polyurethane foam penetrates everywhere, leaving no cold bridges. Moreover, after processing the coating becomes monolithic, without seams. These same seams can also act as cold bridges. This is not observed with PPU.

Insulating the attic with polyurethane foam occurs quite quickly. The structure of the material is porous, due to which there is air inside. Due to its characteristics, polyurethane foam is the best material for thermal conductivity. This is shown in the photo below.

Here are some more advantages of the material:

- moisture resistance;

- excellent property to make the room soundproof;

- PPU does not burn, which is very important in operation and for the safety of residents;

- it is not afraid of the influence of fungus, mold and microorganisms. And rodents do not damage it, since the composition does not contain substances that attract them;

- the material is quite light and does not load the attic rafter system.

Note! If you insulate the attic with polyurethane foam, you can save time, effort and money on creating a vapor barrier and waterproofing layer.