If you look at the history of the construction of residential buildings in cold regions, insulating walls with sawdust began to be practiced not so long ago. Sawdust has only been used as wall insulation in the construction of houses for the last 300 years.

At the same time, over the past 50 years they have been increasingly replaced by highly effective wall insulation materials such as polystyrene foam and basalt wool. Construction progress does not stand still. And just as the insulation of a house with sawdust is becoming a thing of history, over time the insulation of facades with mineral insulation will also become a thing of history. They will be replaced by completely synthetic effective insulation materials.

Sawdust as insulation for walls and ceilings

What distinguishes sawdust as wall insulation, and why are they still used in private low-rise construction?

- Firstly, insulating walls with sawdust is an extremely simple process that does not require specialized tools or any specific knowledge.

- Secondly, sawdust as insulation for walls and ceilings is virtually free. This is the so-called “sharely free” building material - you spend money only on its delivery and preparation for laying in the walls.

- Thirdly, sawdust is an environmentally friendly insulation material; it does not emit harmful substances at the “production” stage and at the stage of installation and operation.

However, it has several very significant disadvantages:

- Sawdust is a flammable material prone to spontaneous combustion. Sawdust in its free form is susceptible to the accumulation of static electricity.

- Sawdust as wall insulation must be well protected from external and internal moisture.

- This is a bulk material that can cake or fall out through defects in the façade or ceiling cladding.

- The sawdust layer can harbor pests - insects and rodents, for which the sawdust layer is an excellent refuge.

These disadvantages in modern construction completely outweigh the main advantage of sawdust - its “free” nature. Therefore, sawdust is used as insulation for walls and ceilings only when the financial component of the process of insulating the walls of a house is extremely important.

Using sawdust for do-it-yourself insulation

Using sawdust to insulate a house

Often, shavings can be used for the purpose of thermal insulation of one-story buildings. If you plan to assemble a heat insulator from sawdust yourself, you should prepare the following types of materials and tools:

- Cement.

- Lime.

- Sawdust.

- A shovel.

- Stirrer.

- Antiseptic.

The thermal insulation layer can have a thickness, the size of which is determined by two factors:

- Conditions of the area.

- Multifunctional purpose of insulated rooms. A thermal insulator with a width of 25 cm will be sufficient to install ceilings up to 15 cm wide for walls.

For this purpose, a special stand is mounted on the main frame, which creates space for the purpose of filling it with sawdust.

Scheme of wall insulation with sawdust.

To properly perform insulation using sawdust, you need to know the following points:

- It is imperative to take into account the presence of objects that have a risk of flammability, which include sockets, wiring, switches, insulated with material that cannot ignite.

- The electrical wiring and chimney pipe must be connected.

- Electrical wires are usually hidden in steel pipes 3 mm thick.

To prevent the cement from absorbing excess water, insulation must be provided. Please note that new sawdust contains special substances that prevent cement from adhesion to water. The consistency of the solution is not strong, so this difficulty can be prevented by wetting the sawdust before using it.

How to prepare a sawdust-based mixture for thermal insulation of buildings

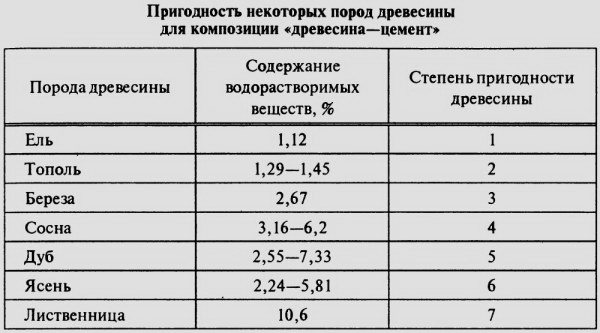

To create a heat insulator using sawdust and cement, you should prepare the following materials: for 10 buckets of sawdust, take one bucket of cement and lime. All these components should be mixed for ideal impregnation of sawdust with the prepared composition, insulating the roof or attic. Then you should dilute the antiseptic in water, pour this composition into a watering can to irrigate the mixture.

The test is done by taking a small amount of the composition and squeezing it in your hand; if no water appears and the lump does not crumble, then this means that the solution is correct. The next step is to backfill the composition with sawdust and cement and tamp it layer by layer. You should wait at least two weeks for the blocks to fully mature.

When insulating the ceiling, floor or walls using a composition with shavings, all work is carried out in a well-ventilated area. After two weeks, those places that were filled up must be inspected, which will reveal the presence of voids that arise during drying. If there are voids, they are filled with a composition containing shavings.

How to insulate an attic, roof, floor, ceiling and walls with sawdust

Using sawdust, warm plaster is made, which will serve as a heat insulator not only for interior finishing work, but will also allow for insulation of the roof or attic. The solution is used to create slabs that are perfectly compacted and dried. If the chips are used in their pure form without various impurities, then only for creating slabs. At the end they must be thoroughly compacted and dried.

During the construction process, clean sawdust is not used, since this material is highly flammable and burns out very quickly.

Using shavings, various thermal insulation materials are produced, such as pellets, ecowool, and wood concrete. They can produce high-quality insulation of attics, attics and other rooms.

Preparing sawdust for use.

You can insulate a floor using ecowool using a special device for one-time use. Therefore, it is not recommended to insulate the floor with ecowool yourself, since the device is expensive. It is better to entrust the solution to this problem to professionals, and if you work manually, you can spend 40% more insulation.

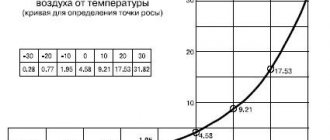

To insulate the floor in an area where the air temperature does not drop below -20°C, you can use a layer of thermal insulation, the width of which is 15 cm. At low temperatures, any 5°C frost requires adding a thermal insulation layer of about 4 cm.

When planning to insulate the roof with sawdust, you can create blocks from shavings. If you add cement and copper sulfate to the composition to moisten the sawdust, they will replace the antiseptic. Then cement is added in a ratio of 1 to 10, which ensures uniform coverage of the chips.

If there is thermal insulation, the roof and other structures allow heat to pass through, which is about 20%. Ceiling insulation with sawdust should be carried out by following the basic steps:

- Place glassine on the ceiling surface.

- Treat the boards with a fire-retardant compound.

- Prepare a solution of cement and water (1 to 10), adding 10 buckets of sawdust and 1.5 buckets of water.

- The mixture should be poured in a layer 2 cm thick over the entire ceiling and compacted.

It is better to insulate the ceiling with sawdust in the summer, since in this case everything will dry out very quickly. After drying, the mixture will not sag, but will only crunch underfoot. If you use sawdust as a heat insulator for walls with partitions, roofs, then the composition should contain lime and dry sawdust, which are taken in proportions of 1 to 10.

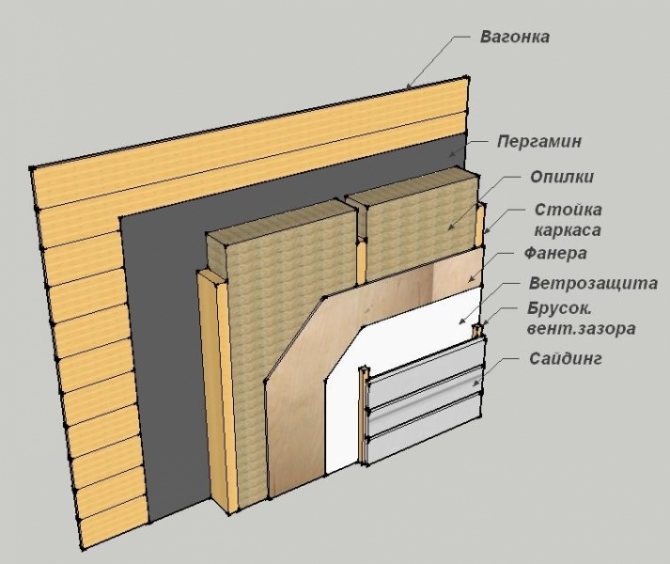

Insulation of walls with sawdust - technology

Since sawdust is a fill-in insulation, to install it on the walls you will need space between the load-bearing wall and the facade.

A sheathing is mounted on the wall, to which the outer rough facade is attached. Or, a space is immediately created between two layers of frame cladding, in the case where the frame house is insulated with sawdust.

Sawdust is poured into this space, prepared to serve as insulation for the walls of the house. To eliminate the possibility of spontaneous combustion of sawdust, it is mixed with clay, after which the output is actually sawdust-expanded clay. This material is poured into the wall of the house when insulating.

Or, when sawdust is poured into the space between the walls, it is compacted with the addition of a solution containing cheap fire retardants - chemical or natural.

In addition, it is possible to pour sawdust into the walls and subsequently pour it with a liquid clay solution. In this case, always leave a space at the top of the gap, through which the moisture from the resulting solution of clay with sawdust will gradually evaporate.

Dry filling of the clay-sawdust mixture can be carried out at any time of the year, and all work associated with spilling sawdust with solutions can only be done in the warm season, when the outside air temperature is above 0C.

Insulating the ceiling of a house with sawdust

Often in village houses or bathhouses you can see attic floors covered with a layer of sawdust. In this way, the insulation of the ceiling of a house with sawdust has been carried out for several hundred years.

However, in order for the insulation layer to last longer and be fireproof, you should impregnate it with a fire retardant or use sawdust mixed with clay.

In this case, of course, you need to consider how much weight the ceilings can withstand for two possible extreme states of sawdust:

- Dry sawdust with a minimal amount of moisture.

- Wet sawdust, saturated with external moisture after heavy, prolonged rains.

Since sawdust, even when mixed with clay, remains a fairly hygroscopic material, it absorbs moisture from humid air. This greatly increases the weight of the entire insulation layer and increases the load on the floors.

Insulation materials

A fairly large number of materials are used to insulate the ceiling:

- bulk (sawdust, expanded clay, earth, etc.);

- fibrous (all kinds of cotton wool);

- polystyrene foam insulation (extruded polystyrene foam, polystyrene foam).

Bulk insulation materials are naturally used for external insulation of ceilings.

When insulating the interior, either polystyrene foam or mineral wool in the form of slabs are used.

Sawdust

This is the cheapest insulation known for several hundred years.

This method is considered outdated, but sawdust is still used quite often.

This is an environmentally friendly material that is mixed with clay and lime.

And the effect of sawdust is often higher than that of modern synthetic materials.

Expanded clay

The second bulk insulation is expanded clay.

It is obtained by firing foamed clay granules in special drum units.

The thermal conductivity of expanded clay is not the lowest, but it is very easy to use, it is an environmentally friendly material, it does not burn and is quite affordable.

But it is a very good sound insulator!

Expanded clay has high moisture and frost resistance.

It is very important that rodents and insects ignore it.

Extruded polystyrene foam or polystyrene foam

One of the most popular insulation materials.

The material has a cellular structure and consists of oval or round granules filled with gas.

It is these granules, which are very tightly soldered together, that provide the foam with low thermal and sound conductivity, good moisture resistance, reliability and practicality.

It is very easy to install on the ceiling both outside and inside.

Yes, and it is very affordable.

Polystyrene foam is flammable, but polystyrene foam is a fire-resistant material.

It is for this reason that it is used to insulate the ceilings of baths and saunas.

The material does not rot and insects do not breed in it.

Mineral wool

Mineral wool is a fibrous insulating material.

It is made from fibers of various natural raw materials: glass, slag, volcanic rocks.

This insulation is produced in the form of rolls or mats.

The thermal conductivity of mineral wool is quite low.

Installing this insulation is easy.

This is a reliable, fire-resistant and environmentally friendly material.

Perhaps the only drawback of cotton wool is its low moisture resistance.

If moisture gets on the material, over time it will wrinkle and lose its heat-protective qualities.

Therefore, if cotton wool (in any form) is used as insulation, then special attention is paid to waterproofing.

Insulation of a wooden house with sawdust - features

Sawdust as wall insulation has one excellent feature - it is actually free. This means that virtually any thickness of insulation for walls or attic floors can be made.

You can insulate the walls with sawdust 0.5 meters or 1 meter thick. Well, what other insulation can a home owner afford to lay in such a thick layer?

Therefore, not the best thermal resistance of sawdust in a wet state can be compensated by the thickness of the insulation layer.

Technology for insulating wooden house walls with sawdust

Supports for the external rough facade are mounted on the load-bearing wall of a wooden house. The supports regulate the thickness of the future backfill layer of sawdust.

The external rough façade is mounted to the supports. This can be any sheet material - plywood, OSB, DSP, etc. The board or slab is not used for these purposes for the following reasons:

- Through possible gaps between the boards, sawdust will spill into the space between the rough and decorative facade.

- The process of attaching the board is longer and requires more fasteners. The initial cheapness of the board as a material will be offset by the longer duration of work and the cost of hardware.

Next, sawdust is poured into the space between the load-bearing wooden wall and the rough facade. As mentioned above, insulation of a wooden house with sawdust can be done either in a mixture with clay, or by pouring a layer of sawdust with liquid solutions of fire retardants.

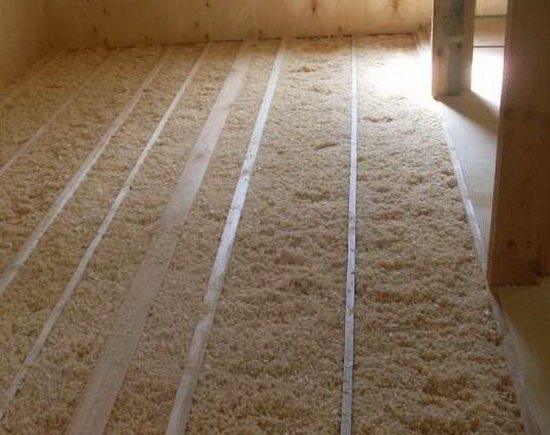

Floor pie during insulation

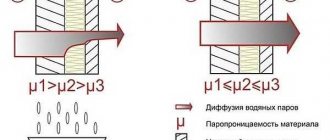

Insulating “pie” is a term used to describe the sequence of laying materials used for insulation. Using sawdust, materials are used for waterproofing and removal of excess moisture from the insulation layer. The location of the vapor and waterproofing layers differs for different floors.

For the lower floor, the order of layers is as follows:

- floor base;

- waterproofing film;

- insulation layer – sawdust;

- vapor barrier;

- clean floor covering.

The floor of the insulated attic floor consists of the following “pie”:

- floor structure (floor base);

- vapor barrier membrane;

- sawdust;

- waterproofing layer;

- attic flooring.

This is easy to remember - the vapor barrier should always be closer to the warm air of the room.

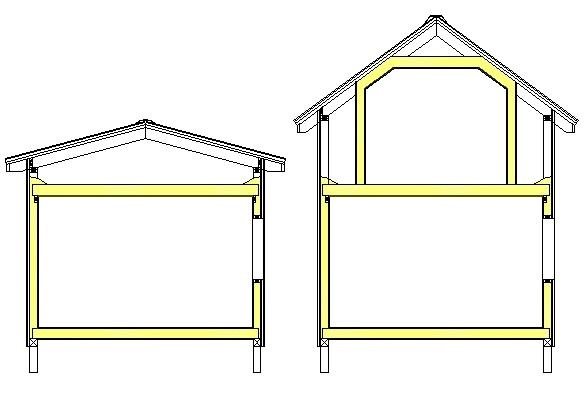

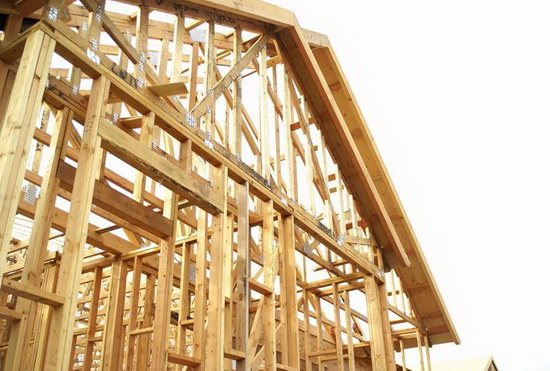

Insulation of a frame house with sawdust - features

Insulating a frame house with sawdust has its own characteristics. Sawdust is poured into the space between the two frame skins - external and internal. In fact, the thickness of the frame stud regulates the thickness of the insulation layer in a frame house.

And if for effective insulation such as basalt wool or polystyrene foam it is enough to use a board thickness of 150-200 mm, then for insulation with sawdust this thickness is clearly insufficient.

Using combined sawdust insulation technology

Therefore, insulation of a frame house with sawdust is carried out in a combined version. Sawdust is poured between the frame skins. This allows you to obtain a layer of sawdust insulation 200 mm thick.

Next, an additional frame is installed for external insulation with sawdust up to 300 mm thick using the same technology that is used to insulate a wooden house. This allows you to obtain a layer of sawdust up to 500 mm thick.

At the same time, the external frame for insulating the walls of the house with sawdust can be built up “indefinitely.” This way you can get warm walls at least 1 meter thick.

See more on this topic on our website:

- Construction of the walls of a frame house - pie diagram The simplest construction of the walls of a frame house is vertical posts connected by upper and lower frames and tied with jibs for additional structural rigidity. When using slab…

- Insulating the veranda of a wooden house from the inside Recently, natural wood has been one of the priority materials in the construction of country houses. The enormous popularity of this material is explained by the fact that buildings made of wood are erected…

- Insulating the walls of a wooden house from the outside with polystyrene foam Recently, people have begun to give preference to wooden houses. The first thing that attracts this natural material is its environmental friendliness. In addition to this, the tree is very good...

- Do-it-yourself insulation of the walls of a frame house from the inside Manufacturers of SIP panels and people who understand how the walls of a frame house are insulated say that well-installed walls can fully replace a half-meter…

- Insulation of a frame house with polystyrene foam or penoplex Today we will consider the issue of proper insulation of a frame house with polystyrene foam and penoplex….