Rating of pipe sealants

Poor quality compounds can lead to leakage. To avoid such a situation, a rating of the best pipe sealants was left. It is based on consultations with plumbers, sellers and customer reviews.

The following parameters were taken into account during the selection:

- Type – acrylic or silicone;

- Composition – acidic or neutral;

- Volume and type of packaging;

- Drying time;

- Resistance to UV rays, moisture, bacteria, fungi, vibrations, high pressure;

- Color and consistency;

- Smell;

- Application area;

- Maximum and minimum operating temperature;

- Processing material – metal, plastic, wood, ceramics, glass, concrete or stone;

- Chemical resistance;

- Possibility of contact with drinking water.

Another important criteria were versatility and value for money. More than 30 applicants took part in the selection. After detailed analysis and comparison, 10 sealants were selected. For convenience, they are divided into 2 categories: for metal and plastic structures.

Types of sealing compounds, their characteristics and methods of application

Based on the place of use, sealants for heating systems are divided into compositions:

- for external use - applied to the site of damage to the pipeline from the outside and, after curing, restores the tightness of the system;

- for internal use (liquid, volumetric action) – they are introduced into the circuit and seal damage from the inside;

- sealing - applied to gaskets and threads to improve the tightness of connections.

The choice of sealant type depends on the degree of damage and accessibility of the repair site. In addition, the choice of sealing composition determines the method of preparing the heating system for the upcoming repair.

Let's consider sealants in relation to common types of damage and connections of heating system elements.

Sealing compounds for external use

These sealants are produced as one or two component sealants.

Considering that the coolant in the pipes of the heating system is not only hot, but also under pressure, damage to the pipeline should be sealed with particular care. First of all, the sealant must be designed for operation at high temperatures, which is indicated on its packaging in the form of the “heat resistant” marking and the operating temperature range.

Important! Acrylic-based sealant (acrylic) is used only for sealing cold water pipelines. Acrylic glue is not suitable for repairing pipes of heating and hot water systems, since after curing it is not plastic and therefore collapses due to thermal deformations of the base.

Among the one-component compositions for repairing water heating systems, silicone-based sealing adhesives are common.

Heat-resistant silicone-based sealants

To restore the tightness of heating systems from the outside, the most common use of sealants based on various types of silicone, including rubber.

To repair steel pipes, it is necessary to use neutral types of silicone (a mark with this parameter is available on the packaging), because “acidic” silicone adhesives that are also produced, which form acetic acid during curing, react with the metal.

If the material meets the required temperature requirements, it is necessary to enhance the effectiveness and reliability of its application with additional means to ensure success. As a rule, the manufacturer recommends such sealants for use as a filler for cracks or holes. If the material indicates another application, but its characteristics and potential are high, the adhesive is quite suitable for use. For example, a composition recommended for sealing components on an engine can easily cope with the same task in a home heating system.

And yet, taking into account the responsibility of the application, it is necessary to apply silicone sealants to the pipes of the heating system in combination with a reinforcing mesh, for which striped fiberglass tape “serpyanka” is successfully used.

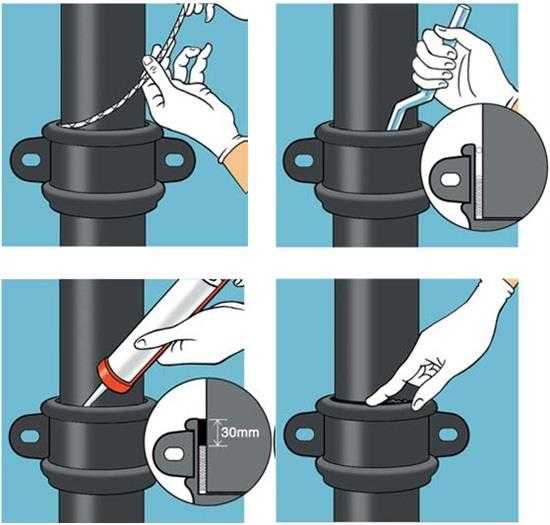

Sealing method

A layer of sealant is applied to the prepared surface of the pipe (drying, cleaning, degreasing), on top of which coils of serpyanka are laid end-to-end, then sealant again, after which the tape is wound in turns with an overlap of 1 cm. The number of layers of serpyanka with glue between them should be 4-5 , it is necessary to prevent the formation of air bubbles or loose areas between them. The last 2-3 turns of the serpyanka are made on a section of the pipe without glue and are tightly attached to it with a nylon clamp, which, after the silicone has cured, will be removed along with the excess turns of the tape. The top repair layer is made of sealant and smoothed out.

Work should be carried out at a temperature not lower than +5 °C, silicone should be at room temperature (20-25 degrees). Curing of the composition, which occurs due to contact of silicone with moisture, occurs depending on the type of silicone and amounts to several millimeters per day.

Products that have proven themselves abroad and in Russia are silicone sealants MakroFlex, Masterteks, Titan, MasterSil.

Two-component compositions for repairing heating and hot water systems are various types of adhesives based on epoxy resins and polyurethane.

These compositions are less common for pipeline repairs, since they require certain skills in maintaining proportions when preparing the mixture, have a short “survival” time of the solution after mixing the components, and have a high cost relative to other adhesives.

There are also one-component polyurethane sealants that cure upon contact with air. The quality of these mixtures is also high, curing takes a little longer than two-component compositions, and they are also much more expensive in price than silicone materials. The main disadvantage of polyurethane sealants is toxicity during work - there must be good ventilation in the room, and work must be done in protective clothing and gloves to avoid getting glue on exposed skin.

To guarantee success when using two-component compositions, it is also necessary to carefully prepare the section of pipe being repaired and use reinforcing tape – serpyanka – in combination with glue.

Sealants for metal pipes

Neutral or acid based silicone sealants are used to prevent leaks in metal pipes. They are easy to use, durable and have a wide range of applications. Acrylic products are very popular. Their advantage is their anaerobic properties, due to which no air is required for hardening. VyborExpert specialists carefully studied the characteristics of 20 nominees. After comparing them, 7 winners were selected based on the best resistance to atmospheric and mechanical influences.

Penosil Universal Silicone

One-component acid-type pipe sealant. It is resistant to a wide temperature range (from -40 to 100°C), does not deteriorate under ultraviolet radiation and prolonged exposure to water. Due to its versatility, the silicone product is suitable for processing joints for interior and exterior work. The product has high adhesion to wood, glass, plastic, metal and ceramics. Buyers appreciate Penosil Universal Silicone for its good range of colors: it is available in clear, white, black, gray and beige.

The silicone composition has proven itself in grouting ceramic parts in plastic and porcelain joints, sealing door and window frames, and sealing metal structures. Thanks to its thixotropy, it does not slide along the seam or spread; a dry film forms immediately after application. When treating surfaces, it should be taken into account that the product is prone to losing its original color when interacting with some organic elastomers (neoprene, EPDM).

Advantages:

- Final stretch 200%;

- The volume does not shrink during hardening;

- Low cost;

- Dries quickly - 10-12 minutes;

- The optimal volume is 310 ml.

Flaws:

- Strong smell.

For high efficiency, Penosil Universal Silicone is recommended to be used at temperatures from +5 to 40°C.

Stayer Master neutral

...I bought Stayer Master neutral for waterproofing a metal sewer pipe. I love that it applies easily, dries quickly, and creates a dense surface that doesn't crack under stress...

Expert opinion

Silicone sealant with a neutral composition is suitable for almost any surface, as it does not contain acids. It processes ceramics, concrete, plastic and porcelain, and qualitatively connects wood, glass, metal, rubber and stone structures. The product maintains operating temperatures from -40 to +100 °C, therefore suitable for indoor and outdoor use. It is often used for glazing doors and windows, when installing ventilation and repairing facades.

Stayer Master neutral is resistant to prolonged exposure to moisture. It is suitable for plumbing work, but only if there is no contact with food and drinking water. You can work with the sealant at air temperatures from +5 to +40°C. The composition hardens quickly, forming a dense and elastic coating that can withstand high loads and does not shrink.

Advantages:

- Affordable price;

- Odorless;

- Convenient release form - pistol;

- Protects against mold formation;

- Does not degrade under UV radiation.

Flaws:

- Not detected.

Kudo KSK sanitary

The advantage of plumbing sealant for sewer pipes is the presence of special antiseptic additives that prevent the formation of fungi and mold. This allows you to use it in rooms with high humidity: in the shower, kitchen, bathroom. The product is suitable for sealing joints when installing plumbing, for sealing the space between slabs, sealing seams around sinks, bathtubs and pools. It is available in clear, white and black.

Kudo KSK sanitary with acetoxy curing system is used for structures made of ceramics, glass, metal, wood, PVC and plastic. Materials can be processed both indoors and outdoors. The product is characterized by a wide operating temperature range (from -40 to +180°C) and thixotropic properties that do not allow it to spread and slide along the seam. It is characterized by the rapid formation of a surface film - 10-20 minutes.

Advantages:

- Does not collect dust;

- High deformation mobility (up to 25%);

- Resistance to cleaning agents and detergents;

- Optimal cost;

- High curing speed – 2 mm/day.

Flaws:

- Unpleasant smell.

Buyers write that Kudo KSK sanitary is not subject to destruction by UV radiation.

Fome Flex Thermo

Acid-type silicone is suitable for processing joints on aluminum, PVC, PS, cast iron and galvanized surfaces. It also works on glass, raw wood, ceramic tiles and stainless steel. The one-component product retains its properties under the influence of increased vibration and at temperatures from -65 to +260°C. After its application, the film is formed within 5-30 minutes, and the curing speed is only 2-3 mm/day. Before use, it is recommended to store the product at a temperature of 15 to 25°C.

Fome Flex Thermo will prevent water leaks from the heating system, sewer pipes, and seal joints in coolers, motor pumps, power supplies, ovens and car engine heads. The liquid requires moist air to cure and is therefore not suitable for use in completely enclosed spaces. Before applying it, the surface to be treated should be degreased with detergent, ethanol or acetone. Application temperature ranges from +5 to +40 °C.

Advantages:

- High adhesion;

- UV resistance;

- Good elasticity and chemical resistance;

- Compliance with EN-ISO 11600 standards;

- Low shrinkage.

Flaws:

- Available only in red.

For high-quality adhesion to specific surfaces, you can use a backing.

Remontix

Silicone acid based mixture suitable for glass, construction and renovation work. It adheres to wood, ceramic, metal and glass surfaces. Remontix has proven itself in sealing water supply, sewerage, air conditioning and ventilation systems, and in sealing door and window frames. The formed elastic compound retains its properties over a fairly wide temperature range - from -40 to +100°C.

Sealant for sewer pipes is packaged in a cartridge and is released from a 310 ml cylinder using a gun. It is highly resistant to ultraviolet radiation and has an optimal drying time of 25 minutes. The recommended temperature for using silicone is from +5 to -40°C. It comes in 2 color options: white and clear.

Advantages:

- Versatility;

- Suitable for rooms with high humidity;

- Low price;

- Fits well;

- Maximum stretch – 200%.

Flaws:

- Unpleasant smell.

Vertical joints should be handled with extreme caution, since silicone is quite liquid.

Tangit Metalock

A specialized adhesive-sealant designed for high-quality sealing/connection of fittings and structures with metal threads. Its advantage is the ability to cure without oxygen. This allows the surfaces to be treated to be connected as tightly as possible. Buyers appreciate the acrylic composition for its suitability for application to stainless steel.

Tangit Metalock is characterized by a highly resistant coating that can withstand strong shocks, increased vibrations and temperature changes ranging from -55 to +150°C. The product is approved for the treatment of drinking water pipes. It is suitable for both cold and hot water supply. Before curing, the substance has the form of a yellow paste with high viscosity. Due to its thixotropic nature, it does not run off from the application site. It takes 24 hours to achieve full strength.

Advantages:

- Does not require preliminary activation of surfaces;

- Convenient to use;

- Suitable for gas pipes;

- High efficiency;

- Good elasticity.

Flaws:

- Somewhat high price.

Glue is not recommended to be applied to products with oxidizing properties and added to mixtures with oxygen.

Efele 133

Another representative with an anaerobic composition that does not require oxygen for curing. It ensures tightness and fixation of standard (up to M80) and non-standard (up to 0.5 mm) metal threaded connections, including disassembled ones and those with a protective coating. The peculiarity of Efele 133 is 100% efficiency in sealing pipes even in the case of incompletely tightened or damaged threads. The product extends the service life of joints, protecting them from moisture penetration.

The composition with a chemical base in the form of dimethacrylic polyester is resistant to vibrations, does not crumble or weaken under high pressure. It does not cure on external surfaces and does not run off when applied. Due to these properties, it perfectly replaces sealing (tapes, windings) and locking (grovers, lock nuts) elements. Often, sealant for water supply pipes is used to lubricate the threads, which greatly facilitates the process of assembling products. Connections can be adjusted within 10 minutes after application. Their full strength is achieved within 24 hours.

Advantages:

- Wide range of activities;

- Operating temperature range – from -60 to +150°C;

- Suitable for products in contact with food;

- Resistance to thermal expansion;

- There is practically no smell.

Flaws:

- Expensive.

Efele 133 is resistant to aggressive alkali, acid solutions, oil products and gases.

Silicone sealant

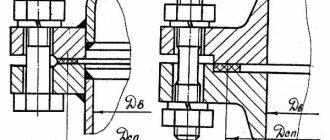

Sealing of joints is carried out using silicone adhesives made in accordance with TU 6-15-1822-95, GOST 6-02-4-53-96.

All plumbers have a weakness for this type of sealant. Meanwhile, silicone compounds have good sealing ability, allow you to seal seams and cracks in plastic and cast iron pipes, dry quickly and are easily removed from the surface.

There are two types of silicone compounds.

- The first type, neutral , allows you to work with any surface and does not come into contact with water and other substances. Features a higher price tag.

- The second sealant, acidic , is used only for PVC pipes and other plastics. Although it is a cheap substitute, it destroys metal and cement-containing materials. In the presence of water, it breaks off acetic acid, which can damage the inside of pipes. Therefore, for cast iron and steel pipes we choose only neutral sealant.

Silicone insulating material is a rubber-based composition consisting of a filler, a hardener and a catalyst. The vulcanization temperature of the material ranges from +60 to +200˚С.

Stages of sealing cast iron pipes with sealant

Silicone sealant for repairing PVC pipes in the sewerage system has a density of 2.0 g/cm³, dries at a temperature of +20˚C in 150 minutes. The tensile strength characteristics are even more varied, ranging from 16 to 20 kgf/cm² and depending on the grade of material.

The peculiarity of the sealant is that the vulcanizer has high adhesion to steel, copper, aluminum, silicate glue, and concrete. Silicone sealant is resistant to adverse weather conditions, solvents, synthetic and mineral oils.

When repairing a pipe, there is no pollution of the environment with toxic substances, since silicone materials belong to class 4 of low-hazard products. The sealant is used for gluing and sealing joints and connectors when repairing sewer pipes.

Sealants for plastic pipes

For plastic pipes, silicone sealants with the acetoxy curing type are mainly used. Acidic compounds form a durable and elastic connection and can be used both for sealing and insulating individual surfaces. The editors of Vyborexperta.ru tested 10 candidates. 3 winners received the highest score and many positive reviews.

Bostik Sanitary Silicone A

The advantage of Bostik Sanitary Silicone A is its high resistance to moisture, mold and fungi. Thanks to these properties, the silicone product can be applied to seams in rooms with high humidity: showers and bathrooms, washrooms, laundries. It is used to seal joints in swimming pools, toilets, washbasins and bathhouses. The product also works well with plastic products in which cold and hot water flows, as well as with grouting ceramic tiles.

The sanitary product with acetoxy curing type is characterized by high adhesive properties and excellent elasticity when working with ceramics, glass, PVC and plastic. It can be applied without a primer. The sealant does not deteriorate at temperatures from -40 to +180°C and has good ultraviolet resistance. On average, product consumption is 11 m.p. The film forms within 15 minutes.

Advantages:

- Optimal volume (280 ml);

- Low price;

- Transparent color;

- Easy processing;

- Tensile strength – 1.3 MPa.

Flaws:

- Not suitable for aquarium.

To clean the hardened substance, you must use a tool, since it is insoluble.

Kim Tec 101e / Kim-Tek 101E Silicon Acetat

One-component silicone-based rubber with an acetate curing system. When exposed to air and moisture, it forms an elastic seal that can be used as an adhesive. Sealant for plastic pipes is characterized by excellent adhesion to wood, glass, PVC, ceramics, plastic and various painted surfaces. It is used for application to window and door seams, as well as for the treatment of plumbing fixtures.

Kim Tec 101e / Kim-Tek 101E Silicon Acetat is distinguished by the durability of the connection due to its resistance to ultraviolet radiation and temperature changes in the range from -50 to +180°C. The composition contains inhibitory additives that help protect against bacteria and mold. Due to its thixotropic properties, transparent silicone can be applied to ceilings and vertical surfaces without fear of spreading. You can adjust the seam for 9 minutes until a film forms. The curing speed is 1 day.

Advantages:

- Multifunctionality;

- Convenient capacity;

- Easy to apply;

- Warranty – 2 years;

- Optimal cost.

Flaws:

- Strong smell.

Repair 100% universal silicone

The sealant has proven itself well in everyday life, in repair and construction work indoors and outdoors. The acid type silicone product is suitable for sealing ceramic, glass, wood and plastic products.

The repair is 100% characterized by good resistance to temperature (from -40 to +100°C) and ultraviolet exposure. It is often used to treat gutters, pipelines, air conditioning and ventilation systems. It is recommended to use it at temperatures from +5 to +40°C.

Advantages:

- Drying time – 25 minutes;

- Budget cost;

- Maximum stretch – 200%;

- Moisture resistance;

- Seam mobility – 20%.

Flaws:

- Not detected.

The product is convenient to use due to the presence of a gun for releasing from a cylinder.

Stove maker

Self-repair of heating leaks up to 30 liters per day. For systems filled with water with boilers running on diesel, solid fuel and electricity.

BCG 24 is manufactured in Germany. This is a liquid self-compacting sealant for heating systems filled with water without any additives. Eliminates water losses of up to 30 liters per day in all heating elements (pipes, radiators, heated floors, boilers). Suitable for all known plastic and metal materials. BCG 24 crystallizes when exposed to outside air. After crystallization, BCG 24 forms elastic, durable and age-resistant seals in leakage areas. Adding BCG 24 to the heating system is done in the same way as adding water normally. Since the sealant has a “jelly” consistency, when using a low-power “Malysh” type pump, it is advisable to dilute the sealant with distilled water before adding it.

Important! The system (coolant) should not contain additives such as antifreeze, anti-corrosion and saline solutions. In such cases, other types of BCG sealants are used. When used correctly, BCG 24 does not cause damage to pumps, control valves and other heating system mechanisms. If the heating system contains aluminum elements in contact with the coolant, then approximately 4 weeks after the leaks have been eliminated, the coolant must be drained, the system washed and refilled with water without sealant.

Instructions for eliminating heating leaks. Boiler leaks.

Disconnect the boiler room from the system. Set the operating temperature, then bring it to the maximum (safe) temperature. Shake the contents of the canister with BCG 24 thoroughly. The sediment at the bottom of the canister is part of the active substance of the sealant. It is necessary to thoroughly mix this sediment with the bulk of the liquid. Add sealant using a pump to the coolant in a ratio of 1:50. Bring the pressure to 1 bar. Carefully remove air from the circulation pump using the bleed valve. The boiler must operate with the circulation pump turned on for 4 hours. After the leaks have self-sealed, drain the coolant and sealant from the boiler, fill it with water in the usual way and connect it to the heating system.

Heating system leaks.

Filters, dirt filters and sensors must be removed or cut off from the coolant by taps. The system must be completely filled with water and the air removed. Set the maximum safe temperature. Open the main valves to allow the sealant to pass through the entire system. Drain the amount of hot water corresponding to the amount of sealant solution added. Shake the contents of the BCG 24 canister thoroughly until the sediment is diluted. Add sealant to the system using a pump. Make sure again that there is no air in the system. The system should operate with the circulation pump turned on and standard pressure for 7 hours. Self-sealing of the sealant and elimination of leaks occurs, depending on specific conditions, within one to several days. If the heating leak is located in an environment that prevents free access of air, the process of self-sealing of the sealant may take a little longer. During further operation, BCG 24 can remain in the heating system. You can check the concentration of BCG 24 in the system using a special determinant supplied with the canister. The pH value should be 10.5-11. It is recommended to check the concentration once a year. It is recommended that after carrying out the work, immediately remove any remaining BCG 24 from sinks, tiles, floors, etc., since once the sealant has crystallized, this will be difficult to do.

Precautionary measures.

When working with BCG 24, follow standard chemical safety precautions. In case of contact with skin or eyes, rinse thoroughly with running clean water. If swallowed, rinse your mouth with water, drink plenty of water and consult a doctor immediately! No special safety precautions are required when disposing of BCG 24. Neutralized by acid. When interacting with an acid, an exothermic reaction occurs!

Composition of BCG 24.

Alkaline silicates, cellulose fibers, special additives, which are the subject of a trade secret.

Mixing ratio BCG 24.

The sealant is mixed with the coolant in a ratio of 1:50 to 1:100, depending on the specific conditions. The optimal concentration of sealant corresponds to a pH level of 10.5-11. BCG 24 is heat resistant. Pressure resistant. Keep out of the reach of children! Do not store near food. Do not store near acid. When interacting with an acid, an exothermic reaction occurs (heat generation).

Retains all properties for 5 years from the date of manufacture.

Protect from frost during storage. Not flammable, not explosive. If the sealant is used outside our control, we cannot be held responsible for the consequences of improper use. Cost from 3450 rub. per liter depending on brand and quantity.

Go to the source site

Here you can watch a video on how to fix a leak.

How to choose pipe sealant

When choosing a pipe sealant, it is important to pay attention to its type, recommended processing material, packaging, and base composition.

Type

There are silicone (with neutral and acidic composition) and acrylic pipe sealants. The first type is an excellent option for those who value versatility. It has proven itself in sealing and compacting metal and plastic structures. The formed compound is elastic and resistant to deformation. This product is not suitable for painting.

The second type is suitable for those who want to obtain a high-quality connection of metal products that is not subject to increased pressure, vibration and temperature changes.

Processing material

Acrylic products are only suitable for metal. If you need to use a product for different materials, it is better to pay attention to universal types. Silicone mixtures meet this criterion. They work well with wood, glass, ceramics, metal and plastic, and some join stone and concrete.

Package

The packaging can be an aluminum foil tube or a cartridge. In the first case, the product is removed using your hands. The most comfortable use option is a cartridge. It is equipped with a movable bottom, which moves as the substance is released, and a special tip that facilitates application.

The basis

The product may be based on silicone or acrylic polymers. Acid-based silicone is suitable for those who want to insulate a specific area. But it should be borne in mind that it enters into a chemical reaction with some materials (neoprene, EPDM, etc.). A neutral type product is a good option for those who value versatility, as it adheres to almost all surfaces.

The acrylic-polymer base is suitable for those who want to obtain maximum resistance of seams to vibrations and high pressure. Its advantage is that there is no need for oxygen, the disadvantage is that it is only suitable for metal structures.

Peculiarities

Basically, sealants are suitable for both external and internal work. But there are compounds that specialize in a certain type. Thus, products for internal treatment use additional substances that protect seams from corrosion, bacteria and fungi.

It is important to pay attention to the color of the liquid, because if it is selected incorrectly, the appearance of the structure can significantly deteriorate.

If the sealant is used for connecting pipes in difficult conditions, it is necessary to have heat resistance, frost resistance, elasticity, resistance to vibration, UV rays and pressure.

Types of sealants for heating systems

The choice of sealant is determined not only by the material of the pipes, but also by the type of coolant used and the presence of a heat exchanger. If you choose the wrong product, pipes can become clogged anywhere in the heating system. Various substances can be used as a coolant, and the sealant should not react or be destroyed by contact with them. Based on this criterion, agents are divided into those that can come into contact:

- with water (regular, softened with complexons or magnetized);

- with antifreeze;

- with oils;

- with gas or steam.

A separate line includes sealant for cold water pipes, which is also applied to the threads of faucets and is used to seal joints. The consistency of sealants can be fluid or paste-like. Pipe sealant can also be classified according to its physical properties:

- Drying compounds. As they polymerize, they become completely dry. If the application and drying technology has been violated, the products may shrink and quickly crack.

- Non-drying compounds. Ideal for removing small leaks and sealing threads, although they can be squeezed out at joints under pressure.

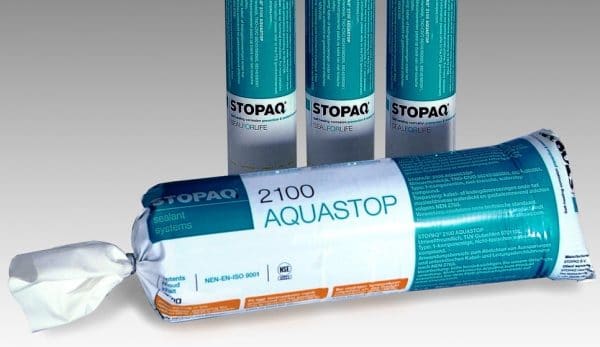

Among the popular brands of sealants are Aquastop 2100, BCG, Block Seal 100. Based on their composition, the products are divided into several groups, which are described below.

Oligomer based

Depending on the functional group used in production, such products are divided into polysulfide and polysiloxane. Sealants made from polysulfide oligomers are used much more often for heating systems. They have a unique set of properties: oil resistance, gasoline resistance, gas impermeability, weather resistance, and the ability to operate for a long time in different temperature ranges.

Acrylic

Most acrylic products are not suitable for repairing CO in a private house or apartment. Only some brands are able to withstand temperature changes and boast heat resistance. For example, anaerobic sealants are suitable for sealing pipes and radiators - a type of acrylic compositions that, when released into an airless environment, fill the entire closed volume (crack, chip) and form a homogeneous polymer mass.

Such products can withstand high temperatures, they are very durable and elastic. Seams and joints can subsequently be cleaned with acidic and alkaline substances, since sealants are sufficiently resistant to chemicals. And yet they have one drawback: dismantling the structure will be very difficult, since it becomes monolithic.

Thiokols

Such materials can be used at temperatures of -20...+40 degrees, that is, they are not heat-resistant. Therefore, they are used only in construction for sealing interpanel joints, double-glazed windows, plumbing equipment and are not used for repairing CO.

Silicone

Such funds are considered universal and most in demand. Most silicone sealants are high-temperature and therefore suitable for work in CO environments. They can be liquid or paste-like, the latter having thixotropic properties (do not flow after application). The technical characteristics of silicone compounds are as follows:

- possibility of operation at -60…+300 degrees;

- penetration even into the smallest cracks and depressions;

- adhesion to any surfaces;

- hardening at room temperature;

- resistance to moisture and aggressive chemicals;

- elasticity;

- environmental Safety;

- strength;

- durability.

When purchasing silicone sealant, you need to pay attention to its specific type. The products are neutral and acidic, and the latter can cause corrosion of metals, so they are not suitable for metal pipes.

Polyurethane

Polyurethane-based products are produced in one- and two-component forms. The first ones are inexpensive, but they dry much longer. The latter, after reacting with the hardener, quickly undergo polymerization, resulting in the creation of a strong, elastic connection. Polyurethane compounds are suitable for all types of materials, including metals; they do not provoke corrosion; on the contrary, they protect parts from damage. Sealants are durable, resistant to aggressive chemicals and mechanical stress, and are characterized by low consumption.

Liquid sealant for heating system

Liquid sealant has to be used where there are hidden leaks and there is no access to the place where the defect appears. The material is poured into the damaged pipe along with the coolant. In the area of the crack, the sealant inevitably comes into contact with air and begins to polymerize, sealing the defect. Among the liquid options there are those that work in water, antifreeze, and are suitable for metal or plastic pipes.

Which pipe sealant is best?

The choice of pipe sealant largely depends on its resistance to temperature changes:

- For those who value versatility and the ability to operate connections at temperatures from -40 to +100°C, Penosil Universal Silicone or Stayer Master neutral are suitable.

- If there is a need for a temperature range from -40 to +180°C, it is better to pay attention to the multifunctional Kudo KSK sanitary with protection against fungi and bacteria.

- Fome Flex Thermo has the best heat resistance (-65 to +260°C), supporting a wide range of applications.

- Optimal temperature values (-40 to +100°C) are supported by the universal Remontix.

- For those who want optimal heat resistance, versatility and protection against mold and bacteria, a good option would be Bostik Sanitary Silicone A (-40 to +180°C) or Kim Tec 101e / Kim-Tek 101E Silicon Acetat (-50 to + 180°C).

- If the requirements for heat resistance are not high, you should choose Repair 100% (from -40 to +100°C), which processes a variety of materials.

- For those who want to buy a special composition for metal coatings, it is better to purchase Tangit Metalock (-55 to +150°C) or sealant for water pipes “Efele 133” (-60 to +150°C).

A high-quality sealant composition will ensure a strong and elastic connection for many years. The TOP presents the most universal products that are resistant to atmospheric and mechanical influences.