Types of chimneys used

Various materials are used to build a chimney, all of them have their own characteristics in manufacturing and operation. There are four main options:

- Fire brick;

- Metal;

- Ceramics and glass;

- Asbestos cement pipes.

Coal and wood stoves, boilers and fireplaces were initially equipped with a chimney of often square or rectangular cross-section, made of refractory brick. They became widespread due to the availability of materials and a streamlined construction process. Actually, this is where its advantages end.

A square cross-section with right angles has a bad effect on the aerodynamics of the chimney. Parasitic vortices arise in the corners, which reduce thrust and contribute to the deposition of fuel combustion products on the channel walls.

Brick chimney from the inside

A brick chimney has enormous thermal inertia, that is, it takes a long time to warm up and then cools down for just as long. The inner surface of the channel is exposed to a temperature close to the dew point for a long time, which promotes the formation of condensation. In addition, the roughness of the brickwork and the presence of turbulence in the corners enhance the effect at other temperatures.

As a result of the combustion of solid fuel, a whole host of different chemical compounds and gases are formed, including water vapor. When any fuel is burned, carbon, sulfur and hydrogen react on the one hand, and an oxidizing agent, oxygen, on the other, and in addition there are necessarily non-combustible parts - ash.

The condensate water mixes with the ash, forming a durable sediment. Together with the combustion products of sulfur and carbon, water forms acids. Under the influence of these substances, the chimney quickly collapses, forming a thick layer of black, oily deposits, which impairs draft.

Which chimney is preferable?

Of all the above options for solid fuel boilers burning wood, coal or briquettes, it is best to use chimneys made of stainless steel and ceramics. Brick chimneys require too much effort to maintain proper performance and integrity of the duct.

A good chimney for solid fuel boilers should have the following properties:

- Operating temperature from 300 to 1000°C;

- Round channel cross-section;

- Smooth inner surface;

- Ability to quickly warm up along the entire length to reach operating mode;

- High resistance to corrosion and acids.

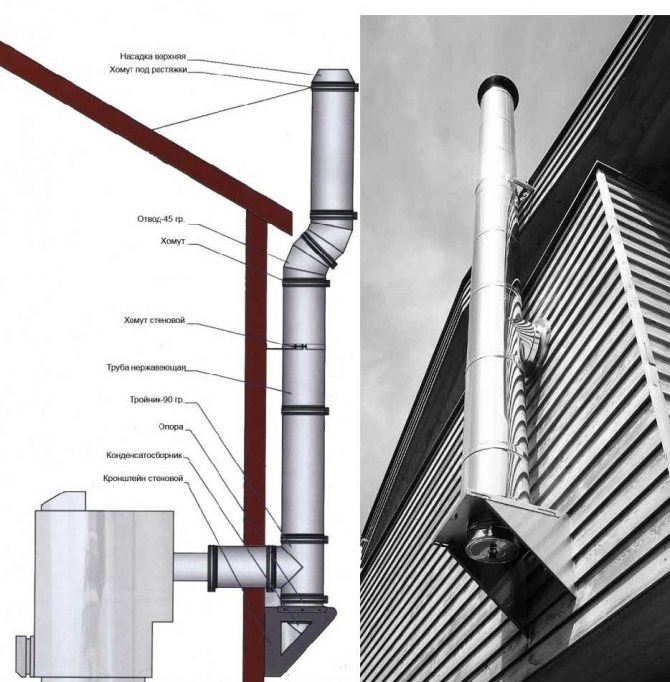

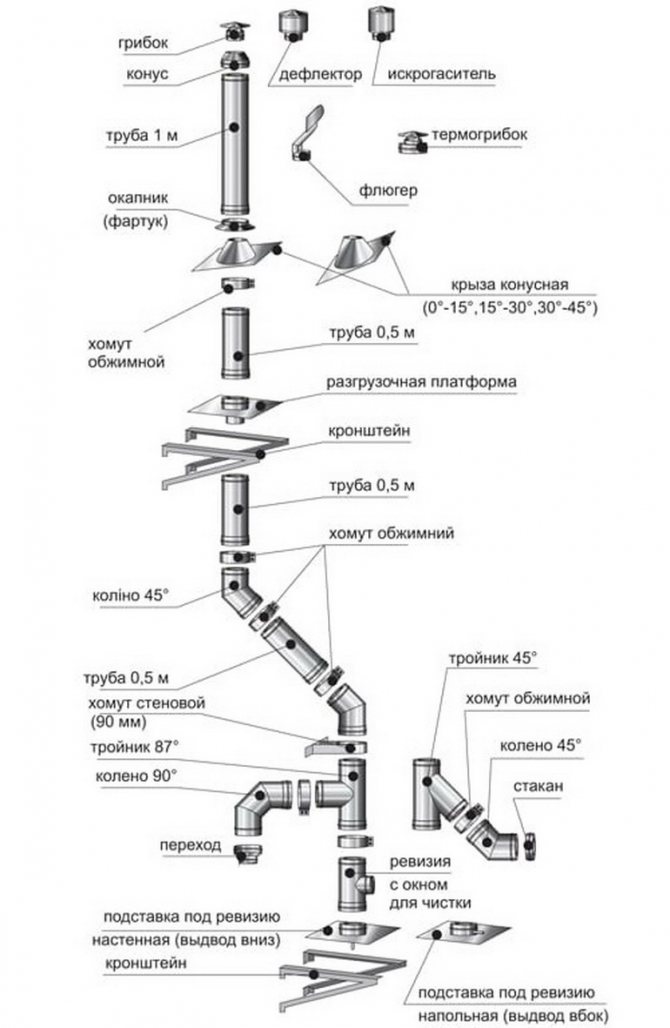

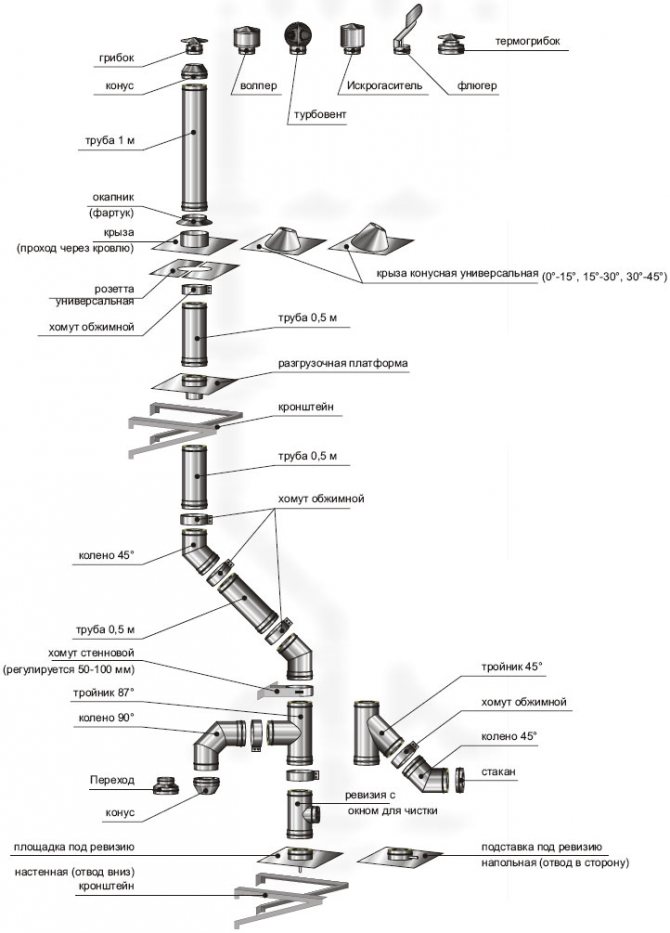

Stainless steel chimneys have all this. In addition, they are much lighter, which simplifies their installation and maintenance. The industry produces individual chimney elements, such as:

- Pipes;

- Tees;

- Knee;

- Fastenings;

- Heads;

- Audits, etc.

With their help, you can assemble a chimney in accordance with the task, any available configuration that will allow the boiler to work with maximum efficiency.

What should you consider when installing a chimney?

- How fast does free fall accelerate?

- What is the length of the chimney?

- Average external/internal temperatures.

- Height.

- Sectional shape of the structure.

- Total channel area.

- How smooth the walls are (measured in coefficient of friction).

- What is the speed of the flue gas?

Chimney installation for a wall-mounted gas boiler

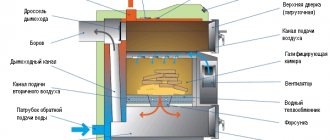

The operating principle of a coaxial chimney is as follows.

The products are removed from the combustion chamber through an internal, smaller diameter pipe During the exhaust process, flue gases are cooled by cold air in the outer pipe, which reduces the fire hazard.

through an outer, larger diameter pipe. Due to the temperature of the exhaust gases, the air is supplied to the burner already heated, which increases the efficiency of the heating unit.

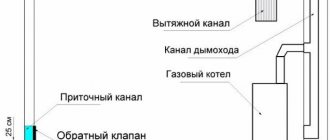

The main difference between the chimney of a wall-mounted boiler and the smoke exhaust system of a floor-standing boiler is the absence of a vertical chimney . This is due to the fact that the burners of wall-mounted boilers with a closed combustion chamber are equipped with fans. To maintain the combustion process, no additional draft is required, which in floor-standing boilers is created due to the length and diameter of the chimney.

An important advantage of a heating system based on a wall-mounted gas boiler over a similar one with a floor-mounted one is that there is no need to construct supply and exhaust ventilation . As a result, a wall-mounted one with a closed combustion chamber can be placed, for example, in a kitchen, the parameters of which satisfy current standards and regulations.

The standard delivery of a smoke removal system for a wall-mounted gas boiler usually includes:

- coaxial pipe of 2 segments : one for the vertical section from the boiler, the second for the horizontal section , for outlet through the wall;

- swivel elbow 90 degrees, 1 piece;

- sealed gaskets, crimp clamps;

- decorative overlays as an option.

In some cases, it may be necessary coaxial pipe extensions a second 90 or 45 degree swivel elbow , or a tee to connect two boilers to one chimney.

Coaxial tubes and connecting elements to them are made of steel and painted with white heat-resistant enamel . Some manufacturers make the outer element from plastic for better thermal insulation. The most common standard size of coaxial is: the diameter of the outer pipe is 100 mm, the inner one is 60 mm . Larger diameter pipes are found on condensing boilers, which have the highest efficiency and low exhaust gas temperatures. Increasing the diameter in such boilers is a measure to reduce the amount of condensate formed.

Types of chimneys

Designs are classified depending on the material used for manufacturing:

- brick;

- ceramic;

- steel.

Let's look at the features of each option.

Brick chimneys

Such designs are much cheaper than their more modern counterparts. At the same time, the chimney of their bricks perfectly withstands elevated smoke temperatures, and also perfectly withstands cases when soot accumulated on the surface ignites.

Another design feature is its impressive weight. The chimney requires the construction of a solid reinforced concrete/brick foundation; the installation procedure requires specialized skills, which is why it is advisable to entrust it to a professional mason. The surface of the walls of the structure is rough, so that soot accumulates on them; this, combined with the rectangular cross-section, sometimes creates serious difficulties during cleaning.

Note! This type of design is ideal for solid fuel boilers as it can only operate with high temperature flue gas!

It is also worth noting the fact that today pyrolysis-type boilers emit harmful condensate along with smoke, which will soon destroy the walls of the chimney.

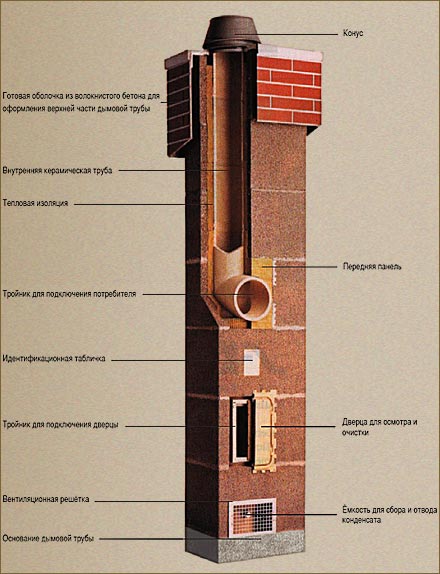

Ceramic structures

A chimney for a solid fuel boiler, made of ceramics, can be used for any of the existing boilers. This material is characterized by increased strength and resistance to both aggressive environments (which often accompany smoke) and high temperatures. In addition, this is the most durable design of all described in the article.

There is a gradation of ceramic pipes depending on the maximum permissible temperature. We won’t delve into it - we don’t need it - we’ll just note that products with a temperature rating of 600-650°C are suitable for solid fuel equipment.

The fact of ventilation of the outer part of the pipe is also important - the fact is that the material is able to absorb moisture. The surface itself is smooth and even, so soot does not settle on it. This is known to greatly simplify the cleaning procedure.

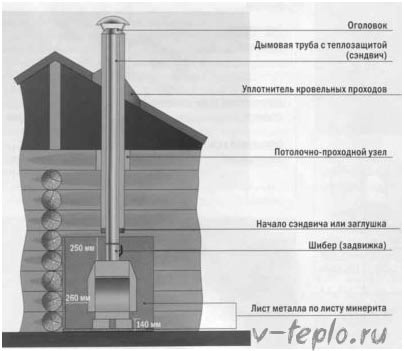

The structure of such chimneys

To install the pipe, a special vertical channel made of hollow bricks is often equipped. By the way, this channel can also be part of the general ventilation system, but not necessarily.

To protect the pipe from high temperatures, it should be insulated using mineral wool. Also, this measure will allow you to significantly increase the temperature of the gas, because if it is cooled, this, as is known, leads to the formation of condensation and deterioration of the hood.

Also, there should be a small gap between the walls of the channel and the pipe so that the insulation is ventilated during operation.

Note! Today the market even offers ceramic chimneys, “clad” in a steel body. They are distinguished by the fact that they do not require the installation of special channels and are mounted almost anywhere, open or closed.

You may also be interested in an article about the principles of operation of liquid fuel boilers

Steel structures

Steel chimneys are also different, but for solid fuel boilers only those are used in the manufacture of which heat-resistant steel approximately 1 millimeter thick was used. Such designs are characterized by a higher cost compared to previous options, and at the same time a shorter service life.

At the same time, installing such pipes is faster and easier; they do not require a special channel, which is why they can be repaired in the future. You can easily assemble it with your own hands; Moreover, the characteristics of its internal surface are the same as those of a ceramic chimney.

Chimney placement options

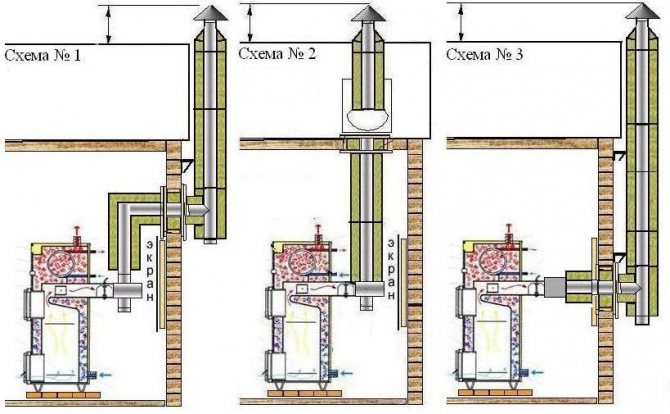

There are two options for installing a chimney:

…

- interior;

- outer.

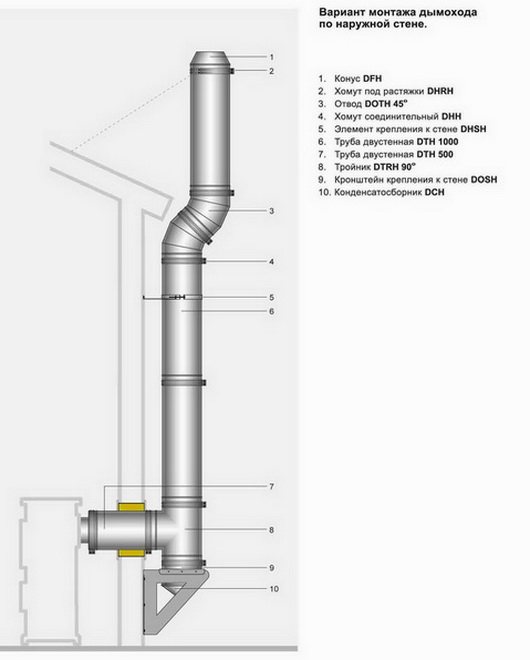

The second method is safer and easier to implement.

Depending on where the unit is installed and in which direction the pipe is routed, the selection of chimney elements is carried out. In any case, installation begins by connecting the adapter to the outlet pipe. According to the regulations, a drain pipe is installed. Some people use a corrugated channel, but this should not be done.

Relocation of a gas boiler - approval and stages

Find out more about installing a gas boiler on a loggia or balcony here

Chimneys for wall-mounted and floor-standing gas boilers

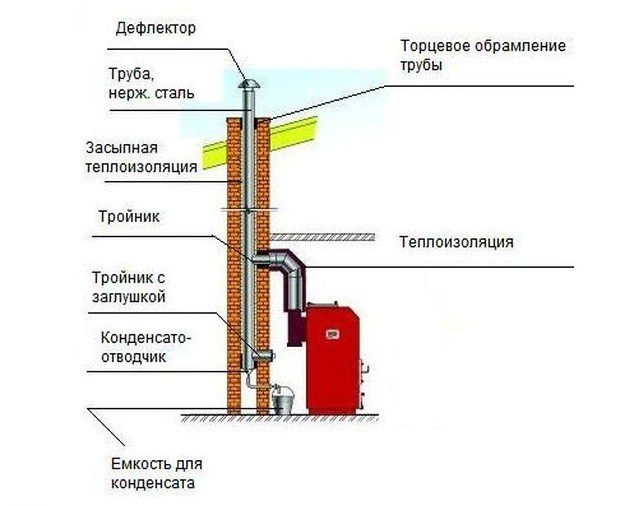

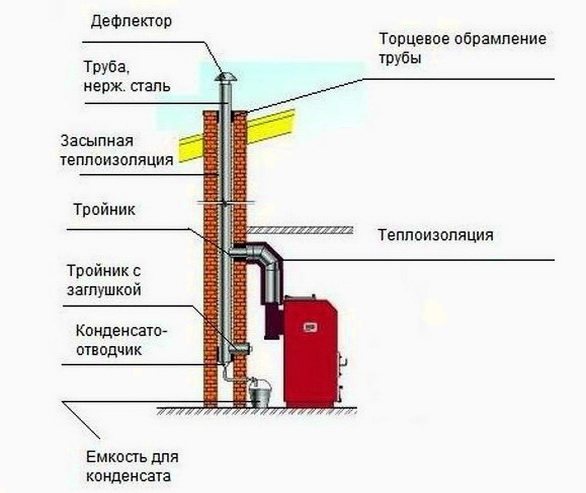

A tee is installed on the outlet element - this determines the beginning of the vertical part of the chimney. An element with a fitting for draining condensate and a plug for checking is connected from below.

…

The next stage is marking the floors along the pipe placement and making holes. After this, you can start building up vertical channels. At the chimney outlet from the roof, it is necessary to install a roofing metal box with insulation. The pipe outlet must be well sealed.

Installation of an external chimney is carried out in a similar way, but there is only one exit point from the wall. It is thermally insulated and sealed in accordance with building regulations.

Sandwich pipes are often used to construct an external chimney.

They are assembled on the ground and then secured to the house with clamps and brackets. The first fasteners are strengthened in increments of 2 m, and with brackets every 4 m. The price of such a chimney will be higher, but more reliable. After installing the external chimney, it can be painted with anti-corrosion paint. Note! It is possible to connect several gas boilers of the same type to one chimney - with a closed or open firebox.

When passing pipe through the roof, it is recommended to use a through pipe. An apron, a cone-shaped tip, is used for the top of the chimney to protect it from snow, rain or debris. After installation is completed, all joints should be treated with sealant.

Steel chimney pipes for solid fuel boilers

Steel chimneys are very popular due to several significant advantages:

- Low price for a chimney - compared to ceramic and even brick analogues (if you take into account the cost of consumables and building materials), the cost of construction is much cheaper.

- Simple design - it’s quite possible to make a chimney for a solid fuel boiler with your own hands. For assembly, you will need to calculate the required pipe height and purchase components or a ready-made kit. Installation takes place using the “father-mother” method. The joints are treated with sealant.

- Aerodynamics of the chimney - steel pipes are produced in round or oval shapes, which provides better draft performance. The absence of internal sagging reduces the settling of resins on the walls. You can use chemical fuel briquettes for cleaning.

- Availability of components and materials of all required sizes. Thanks to the wide range of segments, choosing the configuration and diameter of a stainless steel chimney for a solid fuel boiler is quite simple.

Manufacturers offer several modifications of steel pipes, with different technical characteristics.

Insulated sandwich pipes for TT boilers

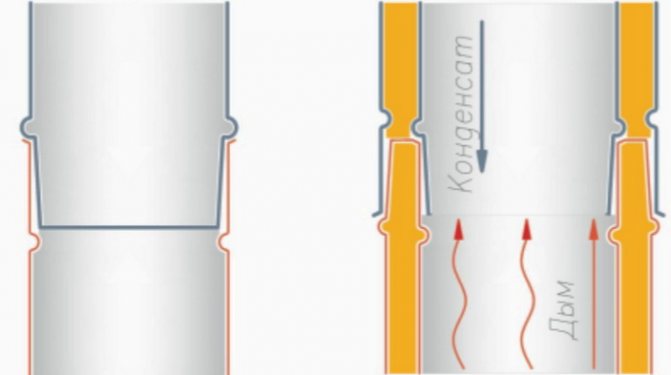

Sandwich pipes have two circuits, between which there is non-combustible insulation. For production, the stainless steel grades AISI 316 L and AISI 321 are used. Other characteristics of sandwich chimneys:

- The wall thickness of the chimney sandwich pipe for a solid fuel heating boiler is 0.8-1 mm for the internal circuit, 0.5-0.6 mm for the external circuit, depending on the manufacturer.

- Insulation – basalt wool with a thickness of 30-40 mm is used.

- Assembly - the pipe is assembled using condensate from bottom to top. A mandatory requirement for solid fuel units is the manufacture of a special glass (condensate collector) installed at the foot of the pipe.

- Service life of sandwich chimneys - manufacturers assure that stainless steel will last at least 20-25 years. The design uses acid-resistant steel to withstand exposure to aggressive environments.

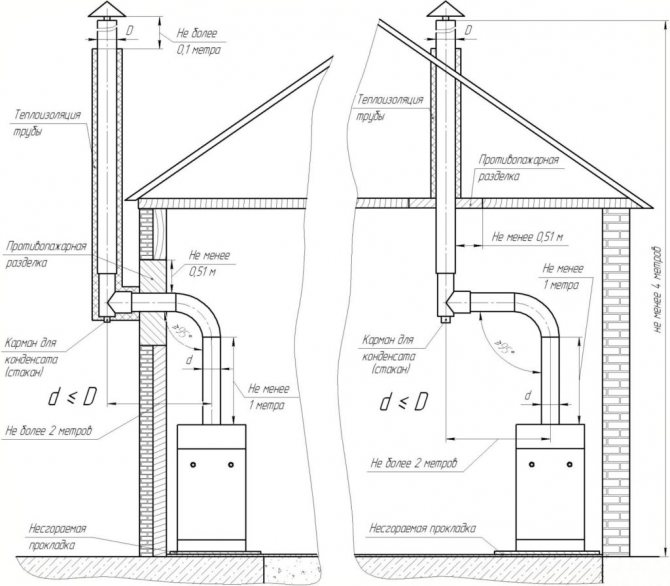

Regulatory design requirements

The following requirements apply to the chimney design:

- Pipes must be vertical without narrowing. The permissible slope of the chimney is up to 30ºC with a side deviation of up to 1 m.

- Laying pipes through residential premises (living rooms, bedrooms, children's rooms) is prohibited.

- Gas boilers are connected to chimneys using roofing steel.

- The permissible number of pipe turns is no more than 3.

- Below the junction of the outlet channel there should be a condensate outlet from the chimney.

- Chimneys passing through unheated rooms can be insulated with insulation.

- The height of the pipe and its diameter must correspond to the characteristics of the gas unit.

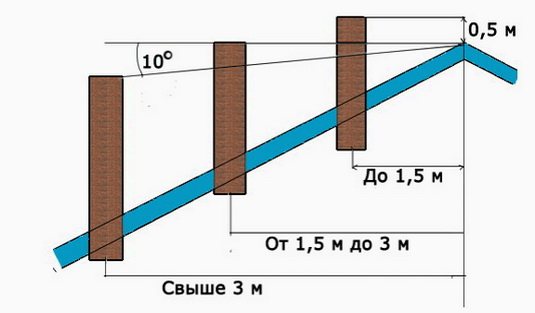

- The chimney must be at least 50 cm higher from the roof ridge.

- It is unacceptable to install pipe joints in areas where walls and ceilings pass through.

- It is advisable to place a deflector on the head of the chimney.

- The pipe should not be closely adjacent to the material of the walls or ceilings. The gap should be at least 2-3 cm.

The best shape of a chimney for removing combustion products is a cylinder, square or oval.

Fire safety technology

It is allowed to install a chimney in accordance with the requirements:

SNiP 2.04.05–91U.

DBN B 2.5-20–200.

NAPB A.01.001–2004.

Installation should only be carried out by professionals. The cross-section of the chimney must correspond to the value specified by the manufacturer in the instructions supplied with the boiler.

The required chimney height is usually recommended by the manufacturer, or it must exceed 5 meters.

If there is a horizontal section, its length should not exceed one meter.

The design must provide for the possibility of draining condensate, as well as cleaning the smoke exhaust channel.

How to connect a chimney

All connections of parts to the nozzle of a solid fuel boiler are made with a heat-resistant sealant that can withstand temperatures in the range of 1250-1500 degrees.

When the diameter of the chimney does not match the size of the chimney outlet, an adapter is installed to create a tight joint.

How the parts are assembled

Any single-walled, as well as sandwich, with insulation, are assembled in only one option: “pipe is inserted into pipe.” The connection points of the chimney parts do not require the installation of additional clamps.

If the structure is made of special stainless steel, assembly is carried out only using condensate. In this case, condensate, as well as the resulting tar deposits, will never get out; they will flow along the walls of the pipe directly into the condensate drain.

If a revision is used in the chimney and tees are installed, all parts are assembled “according to the smoke.” The assembly of vertical parts extending from the tee is carried out “using condensate”.

If it is necessary to line the channel, the gap formed between the pipe and the channel must be more than 4 cm. It is necessary when the metal expands when heated.

To ensure that the chimney sandwich parts have a more rigid fastening, rivets are installed or screws are screwed in.

Fixing the chimney

The pipe is attached to the wall only with special materials.

The single-wall structure must be fastened with a fastening step of 1.5 meters on all vertical sections of the pipe.

If the sandwich chimney does not have a supporting structure, it is necessary to secure each element.

If the system uses a 45–87 degree tee or a 45–90 degree elbow, installation is carried out in such a way that the load on the rotating parts of these parts is completely eliminated.

If installation requires additional support, use a floor stand installed under the inspection.

When the chimney pipe is raised above the roof by more than 1.5 meters, a bracket must be installed under the brace.

Passage through floors

To make a passage through the wall of a house or its ceiling, it is necessary to use the building codes that are in force in Ukraine today.

If a sandwich chimney with insulation passes through wooden walls, a liner must be installed and another layer of thermal insulation is applied.

When a chimney pipe is installed through the roof, builders must install a special additional pipe part, the so-called “roof”. Another additional layer is created, consisting of fireproof insulating materials.

The final stage of construction

When a brick chimney is lined, its upper part is covered with an additional part - the end.

Usually the top of the pipe is covered with a baffle or a beautiful fungus.

If the building's roof covering is made of a fire-hazardous material, such as bitumen shingles, a special spark arrestor is mounted on the top of the chimney.

If a gas boiler is installed in the house, installing a deflector is strictly prohibited. According to current regulations, the upper part of the gas device pipe is always kept open.

Why is a brick chimney for a gas boiler ineffective?

Recently, 99% of modern chimneys are made only from durable materials that can withstand high incandescent temperatures and resist corrosion due to the collection of condensate from vapors.

Previously, during the USSR period, most chimneys in rural areas and beyond were made exclusively of brick. Why? – Low cost of work, materials and installation were the determining factors in the installation of equipment for removing gas from the premises.

However, over time, practice has shown that brick is not an effective option, since the constant “hot state” inside the pipe (due to gas and smoke) does not allow the chimney to cool. Moreover, the condensation that collects on the walls of the pipe soon causes destruction, deformation, splitting and the likelihood that the complete structure will begin to ineffectively remove harmful gases and vapors from the room. For this reason, the unit, made of brick, gradually began to be taken out of use.

IMPORTANT: Let's look at the advantages and disadvantages of a brick chimney today

Advantages:

- Inexpensive service

- Cheap cost

- Fast production and installation

Flaws:

- The accumulation of water on the walls will soon cause cracks and deformation

- Short service life without repair (relative to stainless steel and asbestos cement)

- Morally outdated type

Many houses in villages and villages are still heated using brick chimneys. As an example, we can take the immortal concept of “Russian stove,” which perfectly identifies the design of this type of exhaust unit.

Making and installing a chimney with your own hands

In the current age of standardization and high-quality factory materials, it is better not to take risks and not make a chimney yourself.

What materials are best to use?

Brick chimneys require certain skills, a foundation, and a lot of time - they are usually built during the construction of a house (or modernizing old stoves, if possible).

Ceramics is a rather fragile material, and you should only undertake its installation yourself if you have experience in installation work on the roof and have already worked with ceramic structures.

Installation of steel chimneys is quite simple.

Single-layer pipes are cheaper, but during installation they will have to be insulated on the roof of the house, so the best option would be three-layer “sandwich” pipes.

Drawing and diagrams

Before connecting the chimney, you need to study the instructions for the heating unit - it indicates the diameter of the outlet pipe to which the chimney will be connected. Then measure the height of the pipe inside the house, attic, and determine the height of the roofing part; consider the placement, fastening and shape of the pipe - will there be inclined sections, etc.

Then we advise you to draw a detailed diagram or drawing - they will help determine the number of pipes, connecting elements, fasteners, and other components for the chimney.

Size calculation

The length should be determined in accordance with building regulations (see above).

The internal minimum diameter is determined according to the instructions for the boiler.

Chimney installation and installation features

On sale there are a large number of pipes of various lengths, elbows, tees, revisions, brackets, clamps, elements with unloading platforms for supporting the pipe on the roof or ceiling.

Installation begins with installing the boiler. When the pipe is positioned horizontally, a tee is attached to it - a container (the so-called “glass”) for condensate is attached to the bottom of the tee. For boilers with an upper branch pipe, a pipe 1 m long is installed, then an elbow with revision, then a tee - and all elements are similar to the first option. Then the actual chimney elements are mounted from bottom to top. They are connected using special clamps. The elements are carried through the ceilings in a casing made of a steel pipe of larger diameter, the gaps are insulated with mineral wool. Special elements with unloading platforms are mounted so that they rest on the ceiling or roof and serve as additional support for the chimney.

In places where the box bends, it is necessary to install revisions with special hatches for cleaning.

The structure is secured to the walls using special clamps with a distance of 500 mm.

A cone and deflector are mounted on top of the chimney. If the roof is made of flammable materials, install a spark arrestor. If the roof is non-flammable, you can do without it.

Which heating boilers are perfect for installing modern chimneys?

If you are convinced that the brick chimney is left far behind, it’s time to figure out that the version of the gas and steam exhaust unit you like may not always fit quickly and “well” with certain heating boilers. Below we will provide a detailed breakdown of the correspondence of some brands of room heating units with chimneys that are popular today.

Senor Duval gas boilers are a French production of one of the world's leading brands in the field of space heating. These devices are distinguished by very reliable quality, long service life, and the presence of additional accessories, the purchase of which is not required when installing the chimney.

Today, the design of chimneys is generally approximately the same. However, some models may differ slightly. That is why we will present the “pros” and “cons” in favor of why it is necessary to choose “Saunier Duval” as your reliable “friend” for supplying heat in terms of ease of installation of chimneys.

Advantages:

- Simplicity of the device. If you decide to use asbestos-cement or stainless steel options for exhaust units, this choice will only be beneficial. Along with the already complete set of heating boiler, the general set includes several important parts for attaching the chimney to the heating boiler, which you will not need to buy.

- The diameters of the hole for fastening the gas and smoke exhaust pipe are available in different sizes. You do not need to worry that the selected model has a non-standard “cut” for fitting a combustion waste exhaust pipe. The company offers several possible diameter options.

- Excellent sealant when fastening. Unlike some domestic (CIS countries, example - Signal gas boilers) manufacturers, in whose boilers you can find gaps after attaching the chimney pipe at the “pipe-boiler” junction, the French perform their units strictly and responsibly. You will not see any extraneous holes or cracks.

Flaws:

- Relatively high cost of goods. French quality, like German, meets the standards of time and reliability. Like most European brands, the products require serious financial investments for purchase.

- Expensive maintenance. All the spare parts required as replacement material are also not cheap.

Gas boilers Termobar is one of the few companies offering truly worthy products and services in the field of heating houses, apartments and industrial premises. Together with Thermobar heating boilers you:

- Get an excellent price-quality ratio

- Easily install equipment in the right room

- Do not spend a lot of time attaching the chimney pipe to the neck of the heating unit

IMPORTANT: Receive additional parts for installing the chimney and boiler completely FREE

Gas boilers Termotechnik is a joint concern of Ukraine and Germany, which supplies heating equipment mainly to the CIS and European markets. These products have proven themselves very well as space heating units.

Comparing this company with those described above, it is worth noting that the set of Termotechnik heating boilers does not contain significant important components necessary to simplify the fastening work of the exhaust unit pipe. In other words, this heating boiler will not provide you with devices for boiler-pipe joints. For this reason, it will be necessary to contact specialized centers or sales points for heating boilers of this brand in order to separately purchase the necessary components.

In general, simplicity of design and reliability in use have a positive effect on the final choice of this room heating unit. The low price compensates for the lack of necessary fasteners in the main kit, since the cost of the connecting devices is low.

How to calculate the dimensions of a chimney

To build the correct chimney for a solid fuel boiler, you must maintain its main dimensions:

- height;

- length of the acceleration section;

- hole diameter.

It is important to make the chimney for a solid fuel boiler insulated in order to shift the dew point. In thin-walled chimneys, cold and heat “meet” inside the pipe, condensation forms. It promotes the adhesion of soot particles to the walls, clogging the outlet channel with soot. Moisture reduces fuel combustion efficiency and impairs traction.

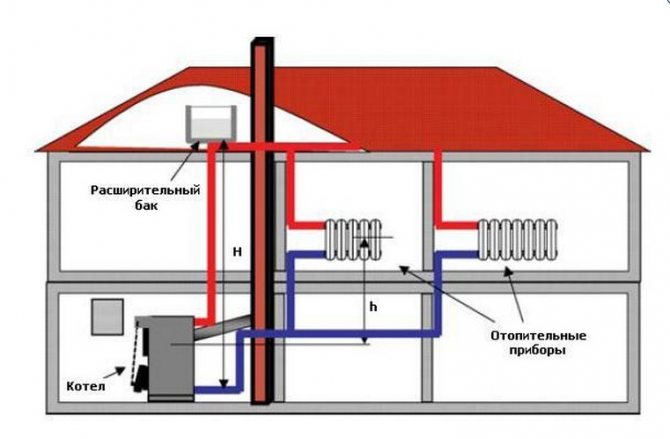

The minimum chimney height for a solid fuel boiler is indicated in the technical data sheet. It is advisable to make it higher; you cannot reduce it. The greater the length of the vertical section of the exhaust system, the greater the difference in the pressure of the air leaving the firebox and that located outside at the end of the pipe.

It is also impossible to make a very high chimney for a solid fuel boiler. The air leaving the combustion zone and rising upward gradually cools down.

Cold masses can begin to sink, bringing soot and carbon monoxide back into the room. The intensity of fuel combustion at this moment decreases due to the limited supply of oxygen. The diameter of the chimney for a solid fuel boiler must be the same as the smoke outlet on the heating equipment. If the exhaust duct is square in shape, then the diameter size is the determining factor between the walls of the pipe.

Basic principles of operation and design of a chimney

The main purpose of the chimney is to remove smoke that is formed during the combustion of solid fuel. Its effective operation depends on a number of factors that must be adhered to, it should be noted here:

- for the normal functioning of the system, a certain amount of air is needed to be supplied to the solid fuel boiler;

- sufficient draft, which is the speed at which gases are removed from the structure;

- the temperature difference inside and outside the pipe is an unstable indicator, but it has an impact on the draft and operation of the chimney as a whole.

Often, solid fuel boilers have special equipment that does not make it possible to maintain a permanent temperature. All this is explained by the fact that when burning various types of solid fuel, the output is smoke waste of different temperatures. So, when mining coal, the gas temperature can be from 500 to 6000C, but if firewood is used, the smoke temperature will be from 100 to 3000C.

These temperature ranges are quite high, which means that the chimney must be resistant to them in order for the solid fuel boiler to operate smoothly.

Tip : When choosing the best chimney, you need to pay attention to the number of narrowings, expansions, as well as horizontal sections. The fewer such bends there are, the more stable the operation of the solid fuel boiler will be.

This is explained by the peculiarity of the process of raising smoke, which resembles the shape of a spiral. The smoke spiral tends to break as it passes through each turn. In this case, the smoke is mixed and can change direction. The pipe walls also create problematic movement. Therefore, you should opt for a round chimney with smooth walls. It has been proven that the draft in rectangular pipes is much worse.

All structural elements of the chimney are indicated in the image.

To install the equipment, you need to consider several parameters:

- gravity acceleration level;

- total length of the chimney pipe;

- external and internal temperatures;

- pipe height;

- shape and cross-sectional diameter of the system;

- chimney area;

- wall friction coefficient;

- thrust or speed of gas movement.

Each of these parameters must be taken into account when choosing an installation and the necessary calculations must be made. Next, we will consider what types of pipes there are, their disadvantages and advantages.

Frequent errors and problems during installation

The most common mistake is the lack of insulation of a single-layer pipe. Inside the house, this can lead to fire of flammable structures and objects and burns to people. In the open air, the lack of insulation causes many very unpleasant consequences:

- flammable gases cool very quickly, draft decreases, combustion products or even carbon monoxide can enter the room and cause poisoning of people. During frosts, reverse draft may even occur - an extremely dangerous phenomenon;

- A very large amount of condensate settles on the walls, which leads to rapid failure of the pipe.

You cannot install a flue without a deflector or at least a cap - snow and rain should not get into the head and channel.

It is necessary to provide access to the required amount of air to the boiler - there must be a special window in the boiler room that is constantly open.

The chimney must be straight. If absolutely necessary, inclined and horizontal sections with a length of no more than 1000 mm each and the total length of their projections onto the horizontal no more than 2000 mm are allowed. The tilt angle is no more than 30° from the vertical (45° is allowed).

The length of the chimney increases by the sum of the lengths of the horizontal projections.

If the chimney passes in the same place with ventilation ducts, then it must be higher than the other ducts, the ventilation ducts must be covered with a cap located below the head of the gas duct. This protects against possible combustion products entering the room.

Chimney sandwich 150 for fireplaces, boilers and stoves

The main advantage is high-quality insulation: basalt fiber without phenol and glue, which does not burn out from high temperatures up to +900 degrees from direct fire!

Ease of installation and safety

If the question arises of installing a chimney, then today the most affordable solution is stainless steel chimneys. As a rule, single-wall chimneys are installed first, then an insulated sandwich chimney is installed.

The insulated pipe must pass through the floors, since this is required by SNIPs regarding fire safety. The sandwich chimney pipe itself consists of two pipes, one in one, and the thermal insulation material Basalt or Basaltine fills the space between them.

Maintenance and cleaning

The chimney must be periodically cleaned of soot. Better 2 times a year. It can be cleaned mechanically and chemically. The choice is yours. After cleaning, be sure to check the traction.

In winter, sometimes condensation or precipitation freezes in the upper part of the pipe - it is necessary to ensure that the channel is not blocked - this reduces draft and creates a danger of poisoning residents with combustion products.

Design, characteristics and assembly of the chimney for the boiler

The chimney is not as simple a design as it seems at first glance. Even experienced builders overlook the “little things.”

What should you pay attention to first when installing this system? What particularly important points cannot be violated? Let us consider in order everything that determines the reliable and long-term operation of the chimney.

What height will be required

You can come across different opinions regarding the height of the chimney. Of course, it is correct to calculate this parameter for each individual case. But this is quite rare when it comes to releasing smoke from a boiler. Basically, they use well-known, practice-tested recommendations: - the height of the chimney is at least 6 meters from the grate, from the combustion level.

How high should the chimney be above the roof? We also use well-known rules. It should rise at least 0.5 meters above a flat roof. And above a sloping roof, the “10 degree” rule should apply.

How far the pipe should rise above the roof is clear from the figure. Depends on the distance from the ridge - up to 1.5 meters - as well as above a flat roof, and then...

Pipe straightness

It is advisable to make the chimney straight and even, then it will have much less aerodynamic resistance to the movement of gases. When the pipe from the boiler is routed through the outer wall in a horizontal section, there is always a roof overhang above it, which you don’t want to destroy.

Therefore, it is not uncommon for another bend to be made on the chimney to get around the protrusion. In principle, this can be done, but you need to remember that every 90 degree turns (2 turns totaling 45 degrees) require an increase in the height of the chimney by 1 meter relative to the calculated height.

Therefore, you will need 7 meters. If you make 2 corners of 90 degrees (horizontal section), then this will require 2 extra meters.

Checking the evenness of the pipe is carried out using a mirror using a beam of light. There should be an even circle of light in the mirror. If there is already an oval there, then the move is considered crooked. This technique is used by regulatory organizations.

Presence of a horizontal section

The horizontal section occurs when connecting to an external chimney through a wall. This area is also necessary to prevent precipitation from entering the boiler (fungus is not used). There is a vertical acceleration pipe above the boiler, followed by a horizontal section of the chimney.

Its length should not exceed one meter. And this rule cannot be broken. Up to remodeling the entire house and building a separate chimney. The horizontal section should be as short as possible - no more than one meter.

Cross-sectional area

For a round chimney, its cross-sectional area is determined by the diameter of the boiler outlet pipe. The diameter of the chimney must be no less. Typically the boiler has an outlet pipe of 180 mm. Pipes are used with a diameter from 180 mm to 200 mm. But no less.

Problems arise when laying steel pipes in shafts made of brick. Builders forget about modern boiler chimneys and make a square shaft with an internal size of 260 - 270 mm, which corresponds to the length of the brick and the thickness of the joints.

But the chimney has an internal diameter of 180 mm, plus thermal insulation, plus an outer pipe, plus mounting brackets, as a result of this cross-section the shaft is small and the pipes have to be laid outside. Therefore, when building a house, you need to pay attention to the fact that the shaft must be of sufficient cross-section to accommodate all the necessary structures...

Chimney maintenance

The chimney must be equipped with inspection windows, closed with steel or cast iron doors, in order to allow cleaning and maintenance. The closure must be sufficiently tight to prevent excessive air leaks.

Typically, inspections are arranged in the lower part of the barrel, always below the boiler connection point in a horizontal section, as well as in those places where it is possible to clean the horizontal section of the pipe in which soot accumulates.

Condensate collection

Modern boilers have high efficiency and, accordingly, low temperature of exhaust gases. Consequently, the dew point will be located somewhere inside the passage through which the outgoing gases flow, and the resulting drops of water vapor will flow down through the pipes. Condensate is discharged into the sewer or collected at the very bottom of the shaft.

Due to the formation of condensation, it is unacceptable to use brick chimneys with modern boilers. More details in the section on materials.

Material

Chimneys are now mainly sold as complete sets of stainless steel pipes. If this is a branded design, then everything should be excellent - the material is of high quality. But if the equipment is cheap, then often... How to check the quality of a steel chimney?

Good stainless steel is not magnetic. You need to take a piece of magnet with you; if it is attracted to metal, then you need to look for another place of sale and other samples.

With stoves and fireplaces, as well as with solid fuel boilers with low efficiency, you can also use a chimney made of baked clay bricks. But with gas boilers, solid fuel pyrolysis boilers and other modern ones with high efficiency, brick passages cannot be used.

The brick will absorb condensation, get wet until it is soaked through, leave stains, peel off when frozen, and collapse. The phenomenon is unacceptable.

How to use an old chimney with a boiler

Is it not a rare situation when they want to adapt a modern boiler to an old chimney? How to connect a boiler to a brick chimney? Perhaps insert a steel chimney inside the brickwork, if size and straightness allow.

But also for this case there are also polymer flexible inserts into the old brick chimney. They are inserted, heated, and glued along the contour of the masonry, forming a continuous protection of the brick from condensation. In this case, the old chimney must also be equipped with a condensate drain... But this pleasure is not cheap - many people prefer to buy a new external chimney...

How to assemble new pipes

With branded high-quality chimneys, everything is simple - there are narrowings and flares, and all the parts fit together in a logical order without problems. It’s the same with ceramic ones - there are protrusions and grooves on the joined parts.

The general rule of assembly is that the top pipe is inserted into the widened bell of the bottom pipe. And not vice versa. Then the resulting condensate flows down, as it should, to the branch or to the collector along all pipe joints.

This is the so-called “condensate” chimney assembly. There is also an invention - assembly by smoke, i.e. in the direction of smoke movement, in reverse order. But this cannot be done on any system.

In a multi-layer chimney structure with insulation, it is all the more important to collect everything “by condensation” so that the condensate does not wet the insulation. But the outer casing is assembled in the reverse order - the lower part is inserted into the upper one, because rain should also not wet the insulation, water from the outside should flow past the joints.

Several installation and maintenance rules

- When purchasing cheap chimneys at “difficult” points of sale, it is important not only to check the stainless steel “magnetically”, but also to join the insulated pipes - the inner pipe is inserted into the lower one, the outer pipe is put on the lower one. If for some reason it goes wrong, but the other way around, then you need to change the seller.

- An umbrella is not installed at the top - the pipes must be washed with sediment, as well as with industrial designs. A certain amount of precipitation must fall into them per quarter, per year, which is discharged along with condensate, according to the flushing calculation.

- The chimney must be installed with a horizontal outlet elbow so that precipitation and condensate do not fall directly into the boiler. A horizontal section is made above the accelerating part, also for this reason, and below it in the vertical shaft there is a condensate collector.

- Assembling a chimney “by smoke” is unacceptable. It is not correct to fear that smoke will be released into the room at joints or leaks. The design often has expansion holes (fungi) located directly in the room, which help create draft in the pipes. The smoke will be drawn by rarefaction to the outlet above the roof.

Why insulate a chimney for a solid fuel boiler?

Why do you need to insulate a chimney for a solid fuel boiler? To ensure that the flue gases leaving the boiler do not cool too quickly. Modern TT boilers are already devices with the highest possible efficiency. This means that the boiler design ensures maximum “recovery” of thermal energy from the flue gases as they “travel” through the boiler heat exchanger.

This means that the outgoing flue gases, entering the chimney, already have an extremely low temperature. And if they continue to give off heat through the walls of the pipe into the surrounding rooms or street air, then their movement will slow down more and more. This means that again there will be no normal draft in the chimney.

To prevent this from happening, the chimney pipe for a solid fuel boiler or stove must be insulated. For this purpose, the easiest way is to use ready-made sandwiches, which are double cylinders made of stainless steel, the space between which is filled with basalt insulation or vermiculite.

The better the sandwich is insulated, the less temperature the outgoing flue gases lose, and the better the draft in such a chimney compared to an uninsulated one.

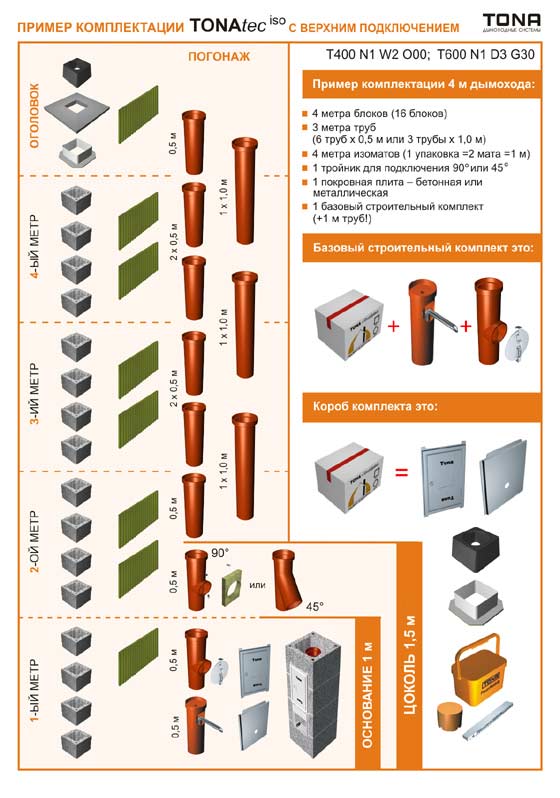

A chimney pipe for a solid fuel boiler, assembled from sandwiches of 1.0 and 0.5 meters, has a number of other advantages, in addition to the main one - improving draft:

- Easy to assemble, because easy installation of sections of 0.5 and 1.0 meters is possible

- Corrosion resistance of stainless steel to external precipitation and condensate in the pipe

- Convenient removal of condensate from the chimney using a drain valve on the tee

- Attractive appearance, you can run a pipe made of sandwiches along the facade of the house

In addition to using sandwiches, an insulated chimney for a solid fuel boiler can be obtained in 3 more ways:

- Insulate the old chimney with basalt insulation or vermiculite.

- Use an old brick pipe from a boiler or furnace, lining it with stainless pipe inserts.

- Install an insulated ceramic chimney

The first two methods belong to the budget category. The third method is the most expensive. But it will make you forget about the “chimney issue” for many years.

The chimney structure for a solid fuel boiler made of ceramic sections is clearly visible in the diagram below.

Such a chimney is not afraid of condensation and is not subject to corrosion. In addition, a ceramic pipe is extremely fire resistant and does not burn out like steel.

More on this topic on our website:

- What are the rules and regulations for installing a wall-mounted gas boiler? Installing a heating boiler is not an easy task. The boiler cannot be hung somehow, because it depends on how correctly the wall-mounted boiler was installed.

Installing a solid fuel boiler with your own hands - correct connection and piping Here, three opponents in the comments are telling me that installing a solid fuel boiler with your own hands cannot be done. What.

We choose a backup power supply for the boiler - generator, UPS, inverter. Winter, frost, smoke from the chimney. The picture is like a postcard. A good owner prepared in advance, the boiler was installed in the fall, it works perfectly and heats.

Chimney topic - which chimney to use for a boiler Today we’ll talk a little about how flue gases can be removed from boilers, what a chimney pipe should be for a gas boiler.

How much to hang in grams, or choose the height and diameter of the chimney

Let's start with the first two points. The height of the chimney for a solid fuel boiler is a critical parameter. What does it mean? This means that if your chimney is not high enough, the draft in the boiler firebox will also be insufficient. This can lead not only to poor combustion of fuel, but also to “draught reversal”, when, instead of being discharged outside, flue gases will penetrate indoors.

This is fraught with the release of carbon monoxide into living spaces, which is deadly to humans.

Carbon monoxide has neither color nor odor. Therefore, you can get burned out unnoticeably and die without waking up.

Have I convinced you that there is no need to save on the “extra” meter of pipe?