School heating options

Central water heating

One of the most common types of school heating is low pressure central water heating. Such heating allows you to regulate and maintain the air temperature in the room at the same level throughout the day. The design of heating radiators should ensure easy removal of dust. The best in this regard are smooth, flat radiators, which, in addition, eliminate the possibility of injuries and bruises.

Radiant heating

Radiant heating, which has a number of hygienic advantages, is increasingly being used. With radiant heating, heat transfer by radiation is reduced, the possibility of radiation cooling is eliminated, thermal comfort is provided at a lower air temperature, which has a beneficial effect on muscle tone and human performance. This heating system makes it possible to provide extensive aeration of the classroom even during training sessions. Students experience a pleasant feeling of warmth and fresh air.

Air heating

Currently, there are schools with air heating combined with centralized supply ventilation. Atmospheric air is forced into the chamber by a mechanical stimulus and then conditioned, heated, purified and humidified in special chambers. The air treated in this way enters the classrooms. The supply openings are located above the chalkboard or in the opposite wall under the ceiling. There are no other heating devices in the premises, and there are no exhaust ventilation ducts. Thanks to constant pressurization, spoiled air is removed from the classroom through the cracks of windows and doors in the recreation area, and then into the exhaust ducts of sanitary facilities.

Thus, the temperature regime of classrooms with air heating is much better than in classrooms with conventional radiator heating. The supply of large volumes of heated air not only improves the physical and chemical properties of the air in classrooms, but also creates a positive pressure in relation to recreation and an open atmosphere, eliminating the entry of polluted air into classrooms and the infiltration of cold air through leaks in windows and panel joints.

Water heating

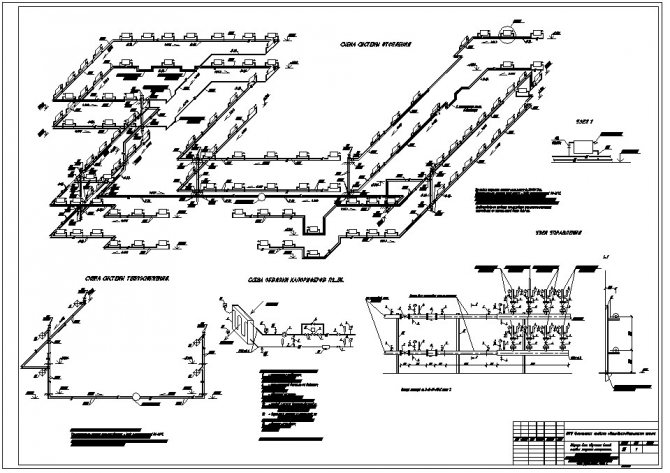

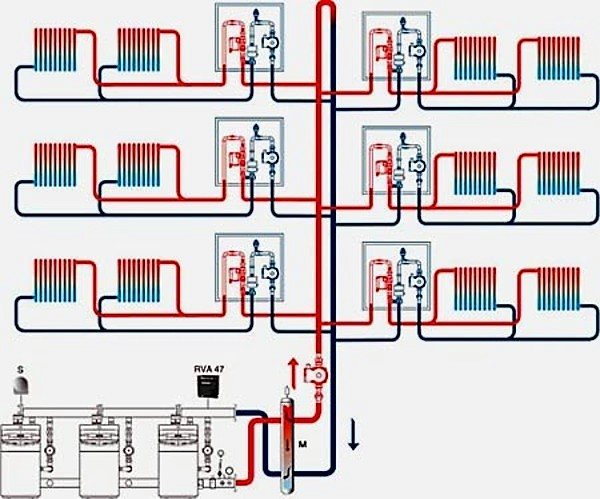

Water heating includes many individual elements: pipes, heating elements, pumps, radiators, etc. In order to design a heating system for a large facility based on such technical means, specialists must have extensive knowledge, experience and understand the current legislative standards.

Water systems in small buildings can be built without the use of electric pumps, since if properly designed, liquid can circulate through the pipes naturally. Schools are usually large in size, which is why it is necessary to organize water heating systems in which the circulation of liquids will be ensured by the operation of pumping equipment.

Electric pumps are powerful devices that can place significant additional stress on the internal electrical system. Due to power limitations in private homes, the use of pumps may not be possible. In schools, things are a little different; at such facilities, electrical supply projects rarely lack power, so almost any necessary electrical equipment can be used to ensure normal operation of the heating system.

To ensure that the water system works properly and smoothly, schools can use various heating boilers. Heating can be provided by gas equipment, technical devices running on diesel or solid fuel. When it comes to public schools, such buildings rarely use only electrical equipment, since it can be too expensive given the large size of the heated premises. In private schools, it is not uncommon to find heating systems that use electricity as the main source of energy.

design separate pipelines with individual thermal energy metering units for each

groups of premises.

6.1.2 The heating supply of a building should be designed, as a rule, taking into account heat consumption and

automatic control of coolant temperature for internal heating systems

buildings according to a temperature schedule depending on changes in outside air temperature. Systems

heat supply without automatic control can be designed at the design flow rate

heat energy of the building (including heat consumption for heating, ventilation, air conditioning and hot water

water supply) less than 50 kW.

In buildings with central water heating systems with pipelines made of polymer materials

automatic regulation of coolant parameters should be provided in individual

heating points for any heat consumption by the building. Coolant parameters (temperature,

pressure) must not exceed 90 °C and 1.0 MPa, as well as the maximum permissible values specified in

documentation from manufacturers.

6.1.3 Heating of residential buildings should be designed to regulate and account for flow

heat for heating each apartment, groups of public and other premises,

located in the house, as well as the building as a whole.

To determine the heat consumption of each apartment (taking into account the readings of the common meter) in residential

buildings should provide:

— installation of a heat consumption meter for each apartment when installing apartment-by-apartment systems

heating with horizontal (radial) pipe distribution;

— device for apartment-by-apartment heat metering with heat consumption indicators at each heating station

device in a heating system with common risers for several apartments, including in the system

apartment heating;

— installation of a general heat consumption meter for the building as a whole with the organization of apartment metering

heat in proportion to the heated area of apartments or other indicators.

6.1.4 Internal heating systems for buildings should be designed to ensure

hydraulic and thermal stability. Service life of heating devices, equipment and

pipelines must be at least 25 years old for residential multi-apartment, public,

administrative, household and industrial buildings.

6.1.5 For internal heating systems it should be used as a coolant, as

usually water; other coolants may be used if they meet sanitary and hygienic standards

requirements and explosion and fire safety requirements.

For buildings in areas with a design outdoor temperature of minus 40 °C and below (parameters B)

It is allowed to use water with additives that prevent it from freezing. Not as additives

Explosion and fire hazardous substances should be used, as well as hazardous substances of classes 1 and 2

hazards according to GOST 12.1.005 in quantities (in case of an accident in the internal heating system),

exceeding the lower concentration limit of flame propagation (LCFL) or maximum permissible concentration in the air

premises. Substances of hazard classes 3 and 4 may be used as additives,

approved for use in internal heat supply systems by the Russian State Sanitary and Epidemiological Supervision authorities.

When using polymer pipes as water additives, you should not use substances that

which the pipe material is not chemically resistant.

6.1.6 Heating and internal heat supply of buildings with direct electricity

transforming it into heat can be used according to the technical specifications. Supply of electricity

should be agreed upon with the energy supply organization in accordance with the established procedure.

6.1.7 Equivalent roughness, mm, of the inner surface of steel pipes of heating systems and

internal heat supply should be taken at least: 0.2 for water and steam and 0.5 for condensate.

When directly connecting internal heat supply systems to the heating network, as well as

when reconstructing them using existing pipelines, the equivalent roughness, mm,

should be taken at least: 0.5 for water and steam and 1.0 for condensate.

The equivalent roughness of the inner surface of pipes made of polymeric materials, as well as

copper and brass pipes should be taken at least 0.01 and 0.11 mm, respectively.

6.2 APARTMENT HEAT SUPPLY SYSTEMS

6.2.1 Apartment heat supply systems are used for heating, ventilation and hot water

water supply to apartments in residential buildings, including those with built-in public premises

appointments.

6.2.2 As heat sources for apartment heating systems, it is necessary to use

individual heat generators - automated boilers of full factory readiness at various

types of fuel, including natural gas, operating without permanent maintenance personnel.

For multi-apartment residential buildings and built-in public premises it is necessary

use heat generators:

— with a closed (sealed) combustion chamber;

- with automatic safety system that ensures that the fuel supply is stopped when the supply is interrupted

electricity, in case of malfunction of protection circuits, in case of burner flame extinguishing, in case of pressure drop

coolant is below the maximum permissible value, when the maximum permissible value is reached

Heating design for schools

Functional and safe heating systems are needed not only for private houses and country cottages, but also for any other premises. The school heating project must be drawn up by professional specialists with extensive experience in the field and the necessary qualifications.

Engineering systems for schools are usually subject to increased safety requirements, since the main users of the facility will be children.

Today, there are various methods and methods for organizing internal heating systems in any buildings and structures. In schools, it is possible to organize the same heating systems as in private homes. The difference between such buildings lies only in their size and layout features. Schools are large facilities with a large number of separate interior spaces, inside of which it is necessary to maintain comfortable temperature conditions throughout the school year.

Types of pressure in the heating system

There are three indicators :

- Static , which is taken equal to one atmosphere or 10 kPa/m.

- Dynamic , taken into account when using a circulation pump.

- Working , consisting of the previous ones.

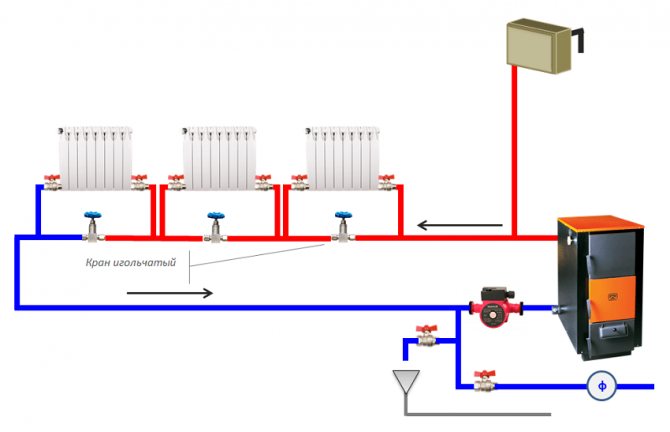

Photo 1. An example of a wiring diagram for an apartment building. Hot coolant flows through red pipes, cold coolant flows through blue pipes.

The first indicator is responsible for the pressure in the batteries and pipeline. Depends on the length of the harness. The second occurs in the case of forced fluid movement. Correct calculation will allow the system to operate safely.

Working value

It is characterized by regulatory documents and is the sum of two components. One of them is dynamic pressure. It exists only in systems with a circulation pump, which is rarely found in apartment buildings. Therefore, in most cases , the working value is taken to be 0.01 MPa for each meter of pipeline.

Minimum value

Selected as the number of atmospheres at which water does not boil if heated above 100 °C.

| Temperature, °C | Pressure, atm |

| 130 | 1,8 |

| 140 | 2,7 |

| 150 | 3,9 |

The calculation is made as follows:

- determine the height of the house;

- add a margin of 8 m , which will prevent problems.

So, for a house with 5 floors of 3 meters each , the pressure will be: 15 + 8 = 23 m = 2.3 atm.

Air organization and supply

In buildings under Khrushchev, it was noted that wooden windows were quite leaky, allowing both clogged and clean air to pass through. The ventilation was not done thoughtfully and without a special professional approach. With the advent of SNIP standards, the equipment of window openings and ventilation ducts became very organized and aimed at the correct installation of air exchange.

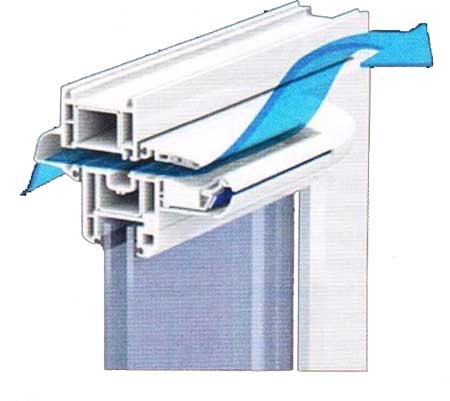

Lack of airtightness and poor air flow from the street can be corrected by installing metal-plastic windows with built-in aerators, which are built-in valves that regulate the air supply to the room. The aerator can be installed on top of the window so that fresh air enters the ceiling and mixes with the existing warm air.

However, you might consider installing a valve under the window sill, this way the air will mix with the existing flows in the floor area. The need for this type of valve is due to the fact that it is necessary to regulate the humidity of the entire room. In addition, they are able to ensure the preservation of heat in winter; if the room is 15-20 sq.m., then it is necessary to install one valve, which will automatically work in a room with ceilings up to 3 meters, but with an increase in area it is worth increasing the number of valves .

Possible difficulties with establishing channels

With proper installation of ventilation, you can avoid a large number of problems, however, if you still fail to design the channels correctly, you may encounter a number of problems:

- Improper installation or the use of low-quality windows can cause the room to become unsealed, which leads to excessive humidity or dryness in the room. the main common difficulties may be the appearance of mold and mildew in living rooms;

- constant movement of extraneous “neighborhood” odors in your apartment. SNIP standards spell out how to properly create interconnected ventilation ducts so that clogged air goes directly into the main ventilation duct and is discharged outside. Violation of the rules for installing pipes or thinning the walls of the channels can lead to large amounts of polluted air or unpleasant odors from nearby apartments entering your home. Insufficient traction leads to this problem.

In the fight against these problems, you can fight only by attracting competent specialists who are able to detect a problem in any part of the system and eliminate its presence.

Ventilation schemes

To purify the air in a private home, it is customary to use supply, exhaust and supply and exhaust ventilation. Each of these schemes has its own advantages and features. Supply ventilation in a private house provides a dosed supply of clean air into the room. It consists of the following elements:

- removable grille to protect against insects and dirt;

- electric fan;

- step switch;

- porous liner to retain small mechanical particles;

- internal grille;

- pipes.

This ventilation system scheme allows you to change the air temperature by installing heating elements and combining them with air conditioners.

Exhaust ventilation of a private house is designed to effectively remove exhaust air. This design of the ventilation system allows you to remove gas combustion products, dust and small particles of debris from the living space, which can negatively affect the health of residents. The exhaust ventilation system also removes moisture from the bathroom and unpleasant odors from the toilet.

The supply and exhaust ventilation scheme provides an integrated approach to the issue of supplying clean air and eliminating exhaust air. The principle of operation of such a ventilation circuit is that the heat exchanger combines supply and exhaust channels. This makes it possible to pre-cool or heat the air without the use of additional energy sources.

What is important in calculating heating pipes?

Each heating system requires an individual approach. Already at the design stage, we must carry out many calculations that are aimed at determining the necessary characteristics of all circuit elements. Let's start with the basics, namely the requirements for heating pipes. Considering that polymer, especially polypropylene, products occupy the lion's share in heating systems for houses and apartments, we will consider the calculation of heating pipes made from this material.

There is a document developed and approved by state control authorities that regulates the production of heating pipes - GOST No. 52134-2003. The standard clearly states all the requirements for this type of product:

- scope of application;

- materials and the degree of their reliability;

- parameters and limit deviations;

- the fittings used;

- acceptance rules.

When calculating heating pipes, you need to take these rules into account. What characteristics should we calculate:

- thickness of heating pipes;

- coolant speed;

- load;

- water volume.

All these parameters are closely related to each other. Therefore, when choosing the thickness of the heating pipes, we automatically regulate the speed at which the water will circulate. And this, in turn, determines what the pressure in the heating system will be, as well as the volume of water in the heating pipe. Although the latter also greatly depends on the number of radiators.

So, let's start unraveling the tangle. To calculate the diameter we need:

- area of the heated room;

- degree of insulation of the room;

- water speed in heating pipes;

- heat loss of water during circulation.

We will not consider the calculation itself now, since we have devoted a separate article to this. Read about calculating the diameter and size of heating lines to understand the essence of the matter.

It should be said that the permissible coolant speed in the circuit is determined by SNIP 41-01-2003, Appendix “G”, and in practice the average value is about 0.6 m/s.

The load on the walls of the line is the operating pressure of the heating system. It comes in two types:

- static;

- dynamic.

Polymer pipes can withstand pressure up to 25 atmospheres

Static pressure is inherent in open-type gravitational systems, and dynamic pressure is inherent in sealed circuits with electric pumps, without which circulation is impossible. The maximum pressure is indicated in the marking and is designated by the letters PN. What pressure should be in the heating pipes? In autonomous circuits, water presses on the walls with a force of no more than two atmospheres, but in a centralized heating system this figure can reach eight atmospheres. The volume of liquid in the circuit also affects the calculation of the load on the heating pipe.

Knowing how much coolant is in the system is important when choosing an expansion tank or purchasing an antifreeze liquid. Calculation of water in a heating pipe consists of summing up the amount of liquid in:

- highways;

- radiators;

- heater

The volume of the circuit directly depends on the area of the heated room. Since in a large room there will be more batteries, as well as the length of the lines and their diameter.