Problems when building a mini-oven with your own hands

Amateur stove makers, due to inexperience, make mistakes, which then lead to problems. Let's look at the most common cases:

- Laying stoves with deviations from the design. As a result, there is no normal draft in the smoke ducts, and the walls heat up unevenly. The solution to the problem will be to disassemble the stove and lay it according to proven schemes.

- Laying stoves “by eye”, without using a level, frame, plumb lines, or rules. The device warps, the center of gravity shifts, and during operation the device collapses faster.

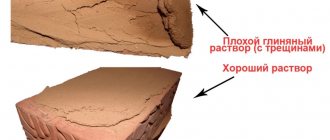

- Incorrect preparation of the solution. The masonry is cracking and crumbling. A temporary solution to the problem is to purchase a factory-made mixture and seal the cracks with a new solution. If the masonry cracks constantly and deeply, the stove will have to be moved.

- Firebox of a freshly built and wet device. This will lead to cracking of the masonry, which will need to be covered with mortar.

Types of furnaces

Based on the principle of operation, there are several types of brick kilns:

Russian – Large and multifunctional. It has an open firebox, which is closed with a damper; the chimney runs along all the walls of the stove. In addition to heating, you can cook any food in a Russian stove.

The disadvantage of the Russian stove is that it needs to be constantly heated, since when cooling, condensation forms in the stove, which remains on the bricks and the bricks crack the next time they are used.

Also, a Russian stove requires constant cleaning of the chimney.

Dutch - a stove with a vertical chimney. It has small dimensions and a fairly low price.

Bell-type - have wide straight channels. The smoke rises and lingers until it cools completely. Then it goes down, heating the walls of the furnace. The advantage of such furnaces is their low cost, simple design, and fast heating.

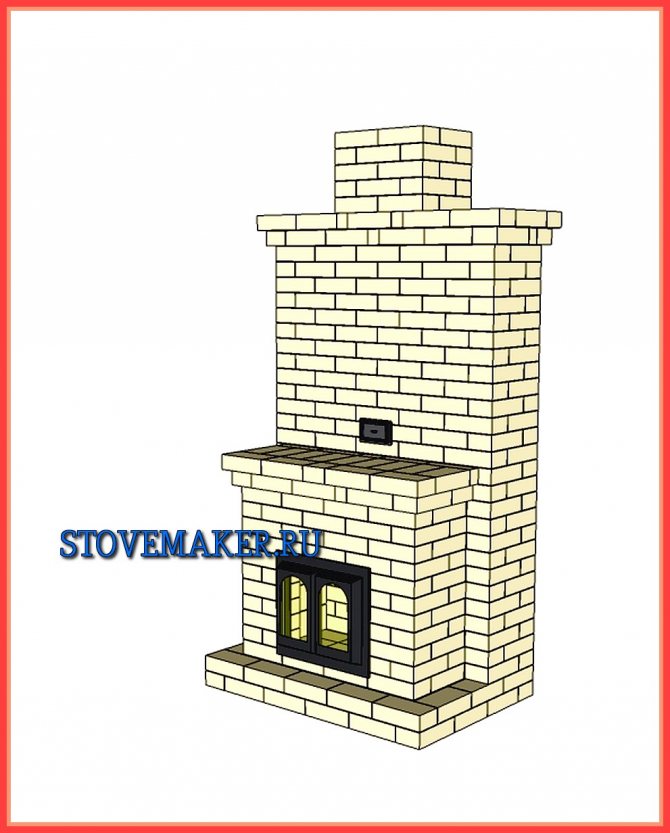

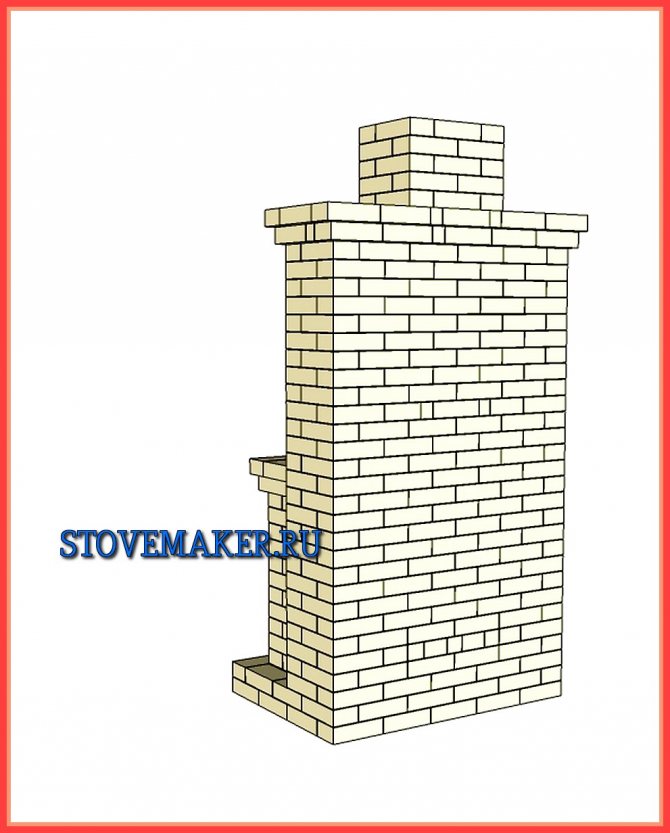

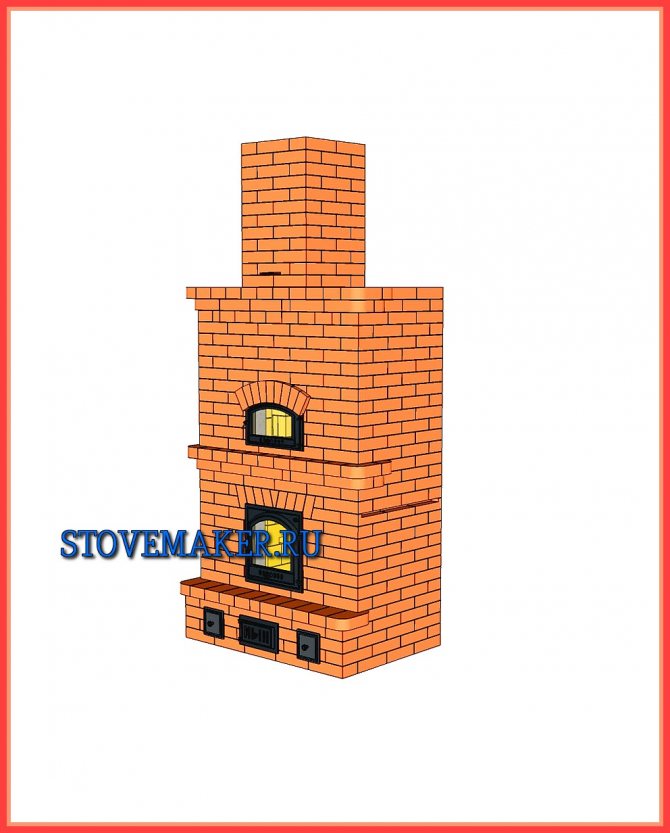

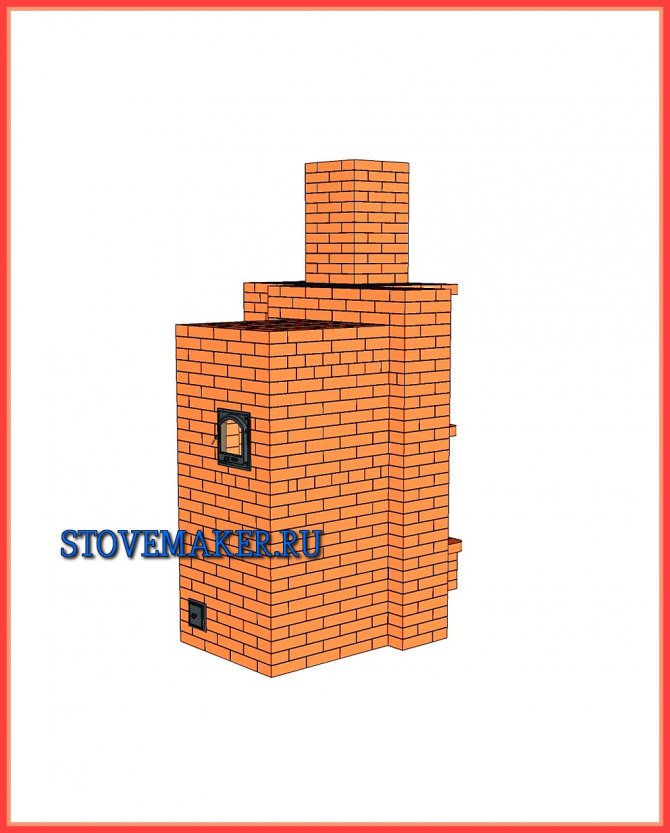

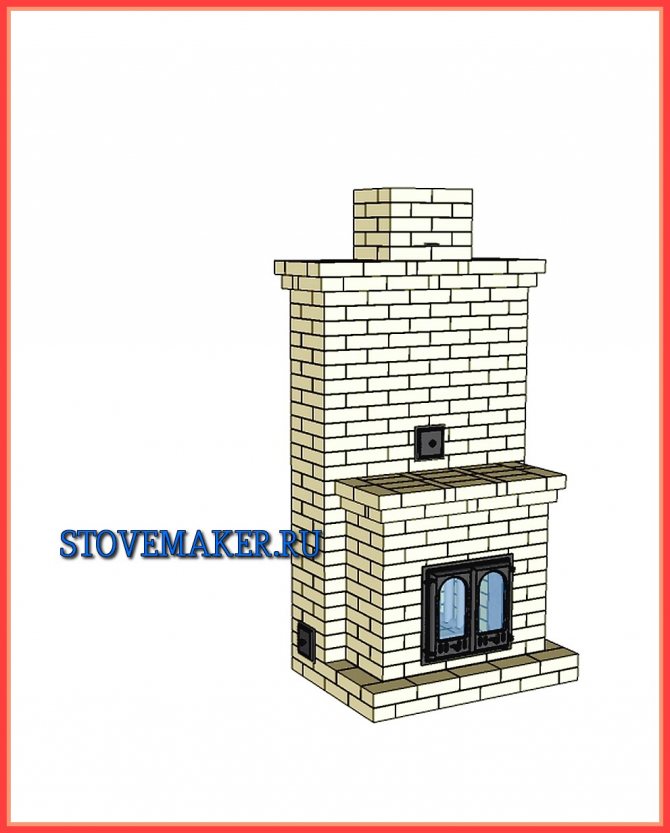

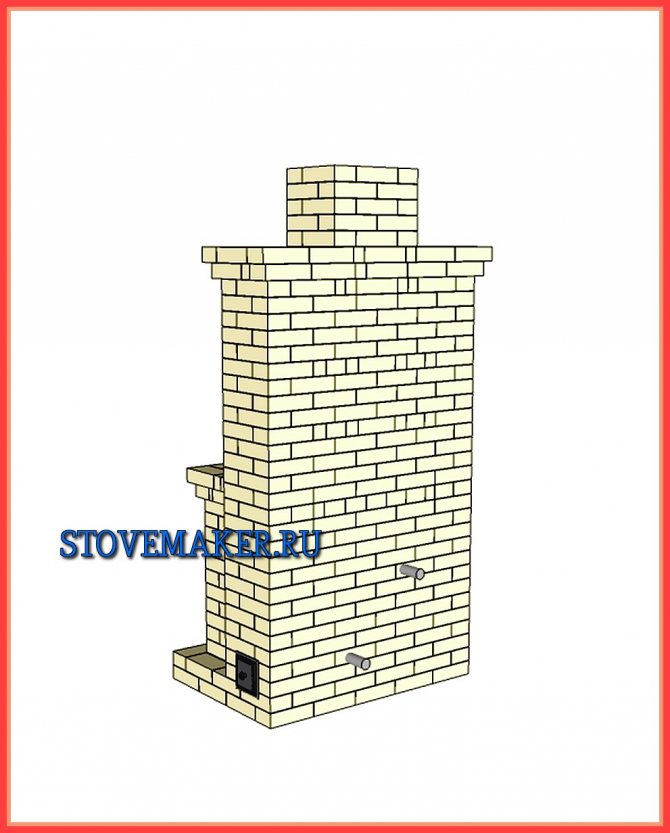

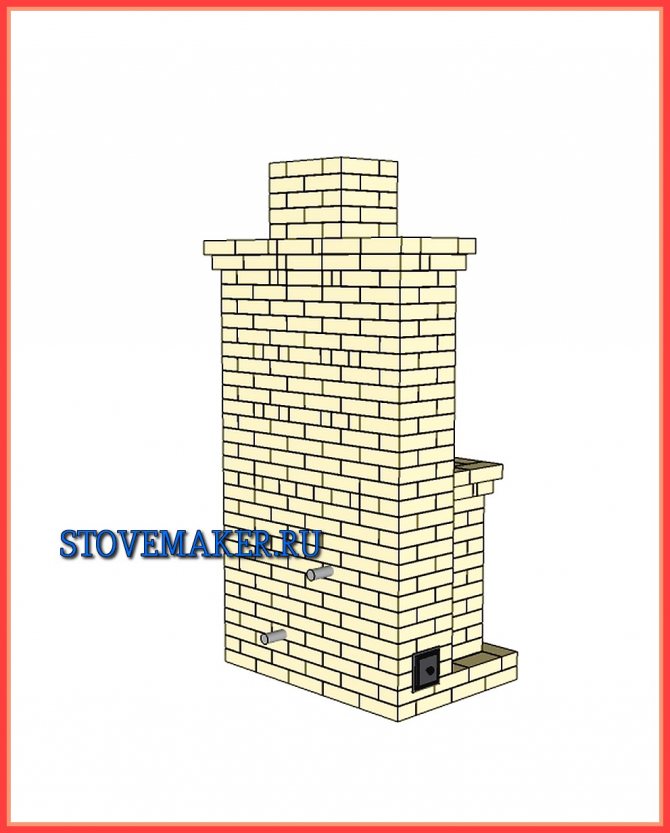

Fireplace stove

Heating, 5 channels

- Sides: 117cm*82 cm (designed for brick ША-5, ШБ-5; 230cm*114cm*65cm)

- Heating: 25 sq.m.

- Brick: 600 pcs.

- System: channel

Possible difficulties and problems

When building stove walls, inexperienced craftsmen do not use a frame made of wooden beams and a plumb line, which leads to the walls deviating from the vertical.

If during the construction process a distortion of the walls is discovered, the masonry should be dismantled and repositioned.

After finishing the work and natural drying, the mini-oven begins to be heated with small portions of firewood.

In this case, the stove walls become covered with cracks due to the fact that shrinkage processes are taking place in the heating structure. To eliminate cracks, dilute the solution and cover the seams.

a07ff0f2bc47417ca4e38dc4d992141a.jpe

Improper sealing of the door fasteners can cause the door to move. To avoid skewing the door, do not leave it open until the fasteners are completely sealed into the seams. If displacement is discovered during construction, the rows are dismantled and the fasteners are sealed again.

Preparation of the solution

To prepare the solution, you need to stock up on a suitable container, as well as a sieve with 3x3 mm cells. To work with the mixture you will need a shovel, a drill mixer and a small board. The solution will include water, sand and clay. The harvested water must be clean, without the smell of mold and with a minimum amount of mineral additives.

If the tap water in your area is contaminated, try to bring it in advance in the right quantity. Its volume depends on the number of bricks that the masonry will contain: for example, for every hundred there are from 15 to 20 liters of liquid. The solution requires fine sand. It is sifted through a sieve to remove pieces of crushed stone and gravel. In addition, you need to purchase high quality clay: the strength of the solution depends on it.

Preparation of the mixture begins by mixing water and clay in such proportions that the mass is not too liquid, but not too thick, homogeneous mass.

After it becomes plastic, add sifted sand in a ratio of 1 liter per bucket of water. You can check the readiness of the solution by lowering a board into it: the thickness of the mixture adhering to it should be at least 2 cm. When the desired result is achieved, stop adding sand.

Buslaevskaya stove: projects

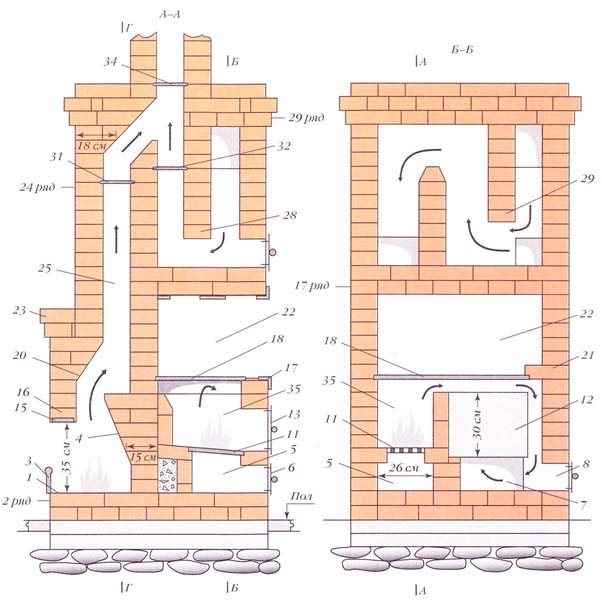

projects of houses with a stove For installation you will need the following materials:

- doors - firebox (0.2x0.25 meters), VK (0.39x0.5 meters), blower (0.14x0.14 meters);

- refractory - 43 pieces;

- solid brick – 382 pieces;

- oven-cabinet 28x33x50 centimeters;

- cast iron stove 0.7x0.4 meters with burners (removable rings of different diameters);

- valves - steam exhaust (12x13 centimeters) and smoke (12x25 centimeters);

- grate - grate 30x20 centimeters;

- corner - three equal-flange blanks 1 meter long and 45x45 millimeters in size;

- steel - piece 0.3x0.28 meters;

- strip - 4 pieces of meter (4 graph paper), 0.25 meters (2 graph paper), 0.35 meters (3 graph paper);

- cast iron plate – 0.4 x 0.25 meters; 40x15 centimeters.

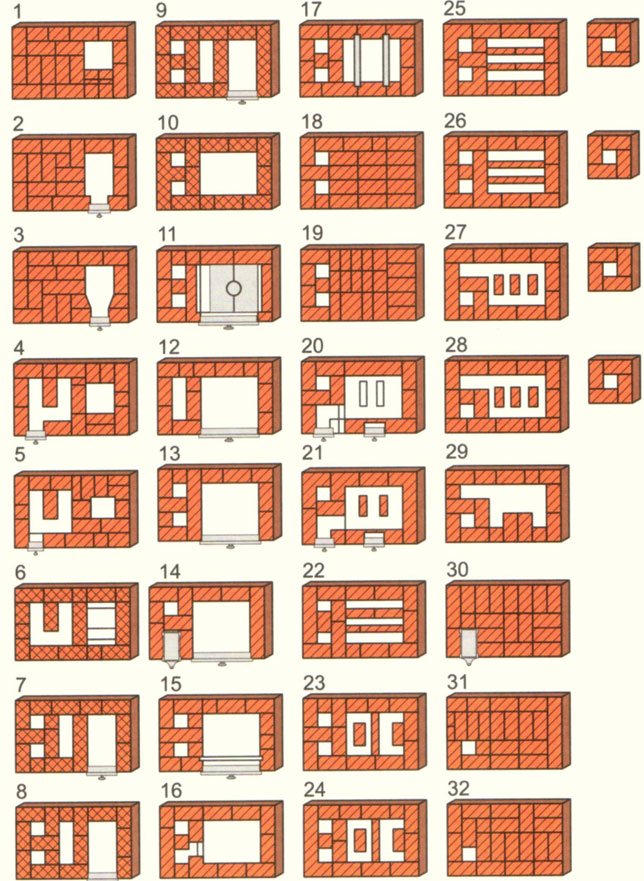

Projects for brick stoves of this type look like this:

- Full row.

- Blower door.

- Window opening for cleaning.

- The bottom of the oven is lined with refractory, three sides are lined with iron.

- Installation of the combustion door, grate, refractory under the firebox, cleaning cover, ash door.

- Installation of DS.

- Laying refractory on the edge around the door.

- Laying according to the scheme.

- The oven is top coated with clay (1 centimeter), the heater is covered, and a stove with burners is attached.

- Installation of smoke circulation with cleaning windows, the stove is not laid. Subsequently, the brick is placed on its edge.

- The cleaning is overlapped, channels are created, and 25-centimeter strips are laid.

- The cleaning is completed and the fastening wire is installed.

- The cap is installed.

- Installation of the VK ceiling, while the hoods remain.

- The stoves are laid out according to the diagram.

- The small stove ends in sheet iron, the masonry is done in the same order as a brick stove.

- The cleaning hole of a large stove is laid out, the edges of the side walls of the channels are cramped.

- Laying protrusions.

- The projections are duplicated and the corner is installed.

- The BP chimney is closed in the same way as row 19.

- A three-row neck is made, the size of the chimney is reduced to a section of 26x13 centimeters for the top valve.

- A chimney is created with grooves on this and subsequent rows.

Masonry

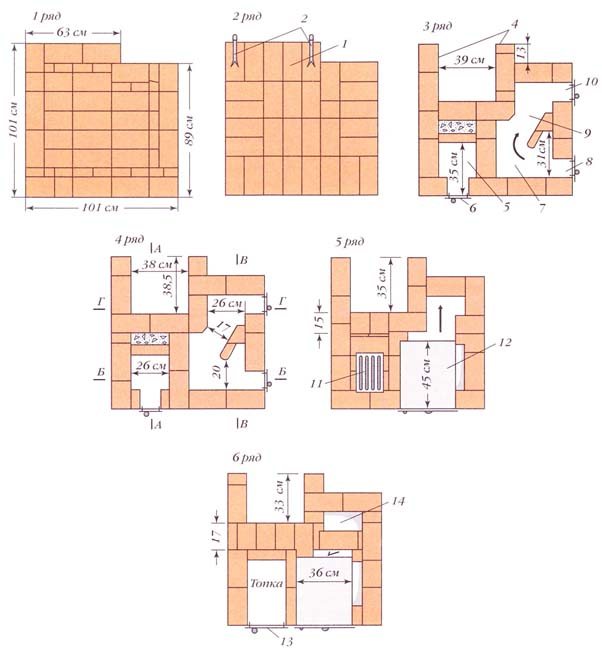

The Swedish brick stove is installed according to a project, a specific scheme, and order. Each part of the structure has its own characteristics and purpose.

The “Swedish” must be laid on a pre-prepared foundation. For the foundation, crushed stone and broken brick are taken as a basis, which must be filled with concrete layer by layer. It should be taken into account that its size should be larger than the size of the stove itself. The last layer of the foundation is subject to waterproofing, after which bricks are laid.

When laying, it is necessary to ensure the evenness of the structure. Also pay attention to the seams of the stove so that they do not contain voids or excess mortar. It is important that the seams are not too thick; 0.3 to 0.5 cm is allowed. Using a building level will help control the evenness of the seams.

Before you begin laying out the oven, you must complete the following steps:

- Soak the bricks in water for a day so that the pores of the material are filled with water, so that it will not absorb water from the clay mortar in the future.

- Prepare a clay solution from ground clay, sand and water. The proportions of the components are selected according to the quality and characteristics of the clay to produce a solution of uniform plasticity and structure.

The layout of the future stove is carried out in accordance with a special scheme. There are standard designs and layout schemes; without the skills and experience of building stoves, it is advisable to use one of them. As a rule, standard procedures are simple and clear; they indicate the necessary materials and the stages of their use.

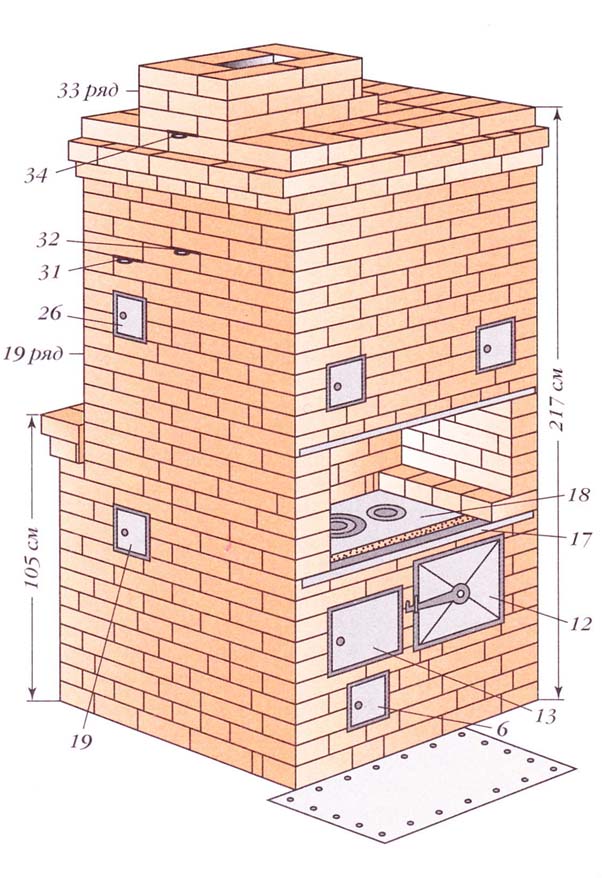

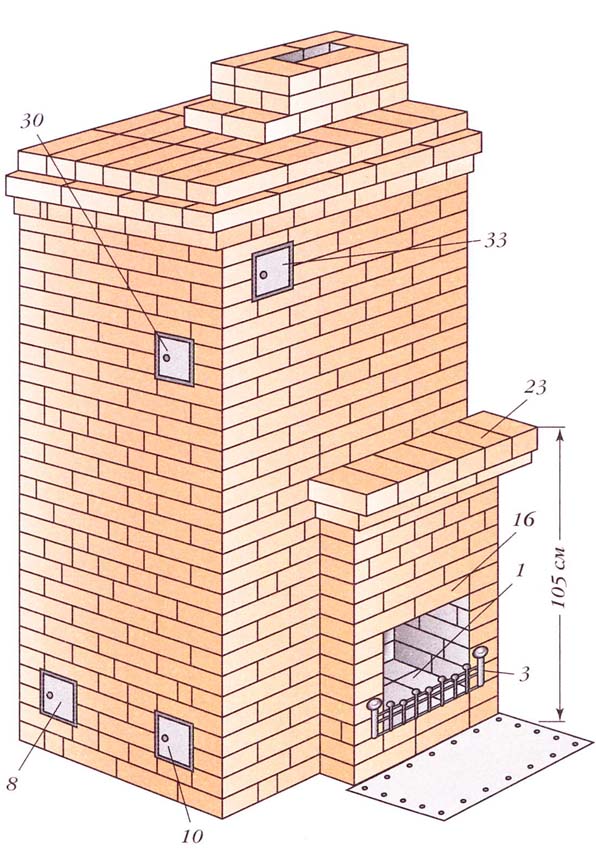

Rows 1-2 of the furnace masonry are very important, since they are responsible for the reliability and strength of the entire future structure. Therefore, the laying of the first and second rows must be carried out with maximum accuracy and evenness.

On rows 3-4, it is necessary to form an ash chamber with a door, and also install a door for the ash pit and cleanout hatches. On the reverse side of the "Swedish" it is necessary to lay out the smoke circuits in a vertical position.

From rows 5 to 10 there is a firebox and an oven, between which a partition made of refractory brick is laid. It should be taken into account that the brick is laid on its edge.

On the 10th (11th) row, a steel corner is placed on the front part of the structure, which is secured with wire and clay mortar, as well as an additional cast iron plate.

From rows 12 to 16, cooking compartments and vertical flue ducts with smoke holes are laid out.

Rows 17-18 are occupied by a ceiling above the cooking compartment, made of sheet steel and angle iron.

On rows 19-20 there are hatch doors for cleaning gas exhaust channels.

Rows 21-28 are occupied by chimney channels with a valve on row 27. It is necessary to leave a technological opening above the smoke valve through which the gas ducts will interface with the air ducts.

On rows 29-30 the overlap of the chimney ducts is laid out. At these stages, it should be taken into account that the width of the masonry around the perimeter must be increased.

A chimney is laid out on rows 31-32. This is the final stage of laying out; if desired, you can finish the structure with finishing materials.

Properly executed masonry of a Swedish stove will allow you to heat several rooms at the same time with minimal wood consumption.

Where is it more efficient and safe to place a small-sized stove?

In order for the heating stove to efficiently release heat, it is placed in the middle of a one-room dwelling or built into interior partitions. Small heating and cooking stoves are placed in the center of the kitchen or against the wall.

The heating structure will be safe if the ceiling is properly cut. A spark arrestor is placed on the chimney.

The combustion chamber is a source of increased danger. The stove is placed so that coals and sparks do not fall on walls, doorways, or furniture. If necessary, walls are protected with non-combustible materials (flat slate, ceramic tiles).

Schemes of small brick stoves

Compact stoves do not take up much space, which is especially important for small spaces. Heaters have a rectangular cross-section at the base

The height of the stoves depends on the height of the building and the chosen model. A brick chimney is often replaced with a factory-made steel pipe.

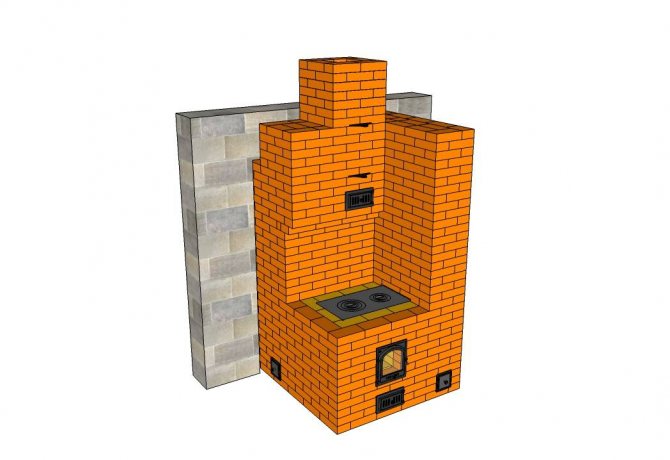

Heating and cooking mini-oven

In small stoves designed for heating the home and cooking, a niche for the stove is built in.

An oven or water heating container can be built into another niche located above the firebox. Niche space is often used for drying things.

bbf7fb962a830ba83a9417eeb9ffbf86.jpe b906bdd2e27548d30c2db6edec3f39da.jpe

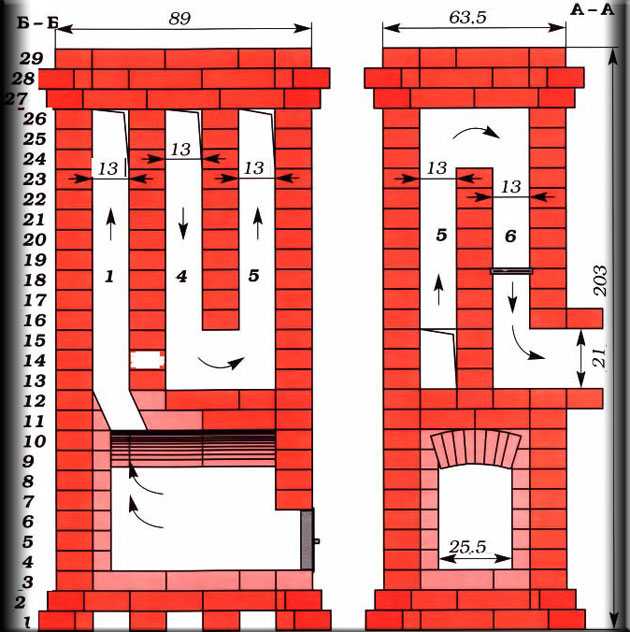

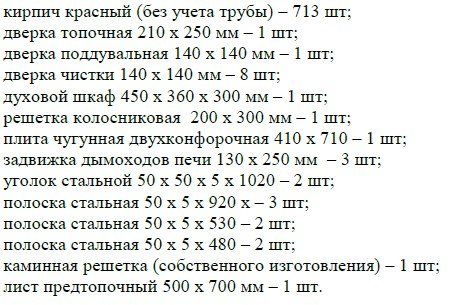

Let's consider a specific diagram of a compact stove with a base size of 0.64 x 0.51 meters (2 x 3.5 bricks) and a height of 2.15 meters (32 layers of masonry).

This heater model is designed to heat small and medium-sized houses with an area of 25 to 40 square meters. Ceramic solid (ordinary) brick is suitable for masonry.

The oven is built in the kitchen (in the middle of the room or against the wall). The furnace of this model contains the following structural elements:

- combustion chamber;

- blower;

- smoke ducts;

- hole for cleaning smoke ducts;

- hole for building a chimney;

- niche with cooking floor;

- niche for installing an oven or hot water tank.

Metal elements for the heater are purchased at a hardware store. The list of factory parts includes:

fire door measuring 20 x 20 cm (solid cast iron or with fireproof glass in a metal frame);

Photo 1. Fire door measuring 30 by 30, made of polished cast iron and fire-resistant glass. It is possible to regulate traction.

- door for the blower (14 x 14 cm);

- 2 doors for cleaning smoke ducts (20 x 14 cm);

- grate (45 x 25 cm);

- cooking floor measuring 20 x 35 cm (with or without hole);

- 2 valves;

- steel corner profile 50 cm long (attached between the firebox sheet and the stove wall);

- pre-furnace metal sheet measuring 50 x 60-70 cm.

The oven and hot water tank are welded from steel sheet. Asbestos cardboard of the same size is placed under the firebox sheet. For furnace work you will need:

- 222 units of solid red brick;

- ready-made masonry mixture for fireplaces and stoves (or a solution of sand and ordinary clay taken locally in a quarry).

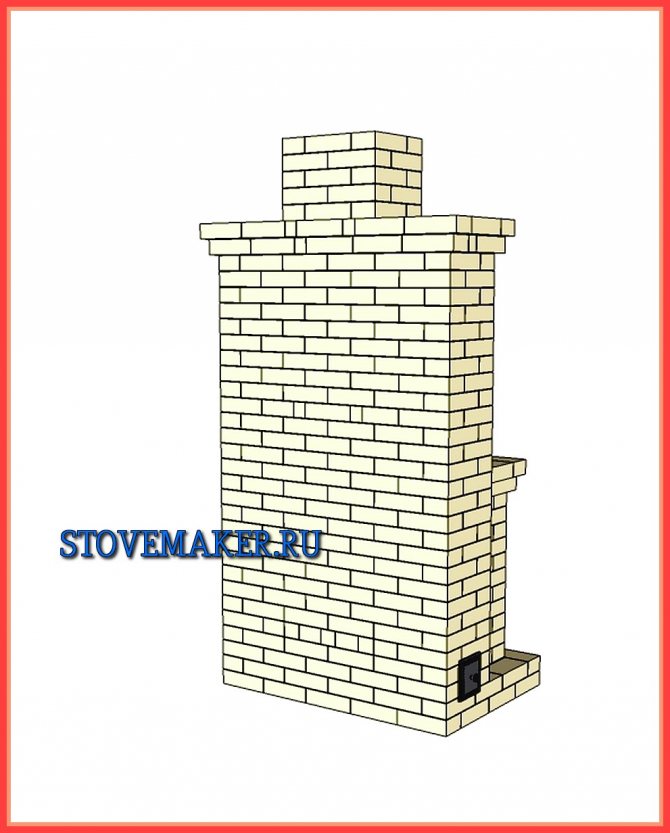

Small heating device

Let's consider a specific heater circuit. The base of this model has the shape of a rectangle measuring 0.89 x 0.51 meters (2.5 by 2 bricks). The height of the stove is 2 meters 38 cm.

Compact dimensions allow the heater to be installed in a corner or in the center of the room. If the dacha has a kitchen and a couple of living rooms with a total area of up to 40 square meters, the heater is built into the wall openings (interior partitions).

The main elements of this model:

- firebox;

- blower;

- smoke channels;

- outlet to the chimney.

A door with heat-resistant glass in a metal frame or a solid cast-iron door is built into the firebox portal. The furnace is built on a solid foundation buried in the ground. The foundation is made solid or columnar.

Important! The stove is made of ceramic and fireclay bricks. The firebox is made of fireclay bricks, and the lower and upper parts of the heater are made of ceramic bricks.

The masonry is done using sand-clay and fireclay-clay mortars.

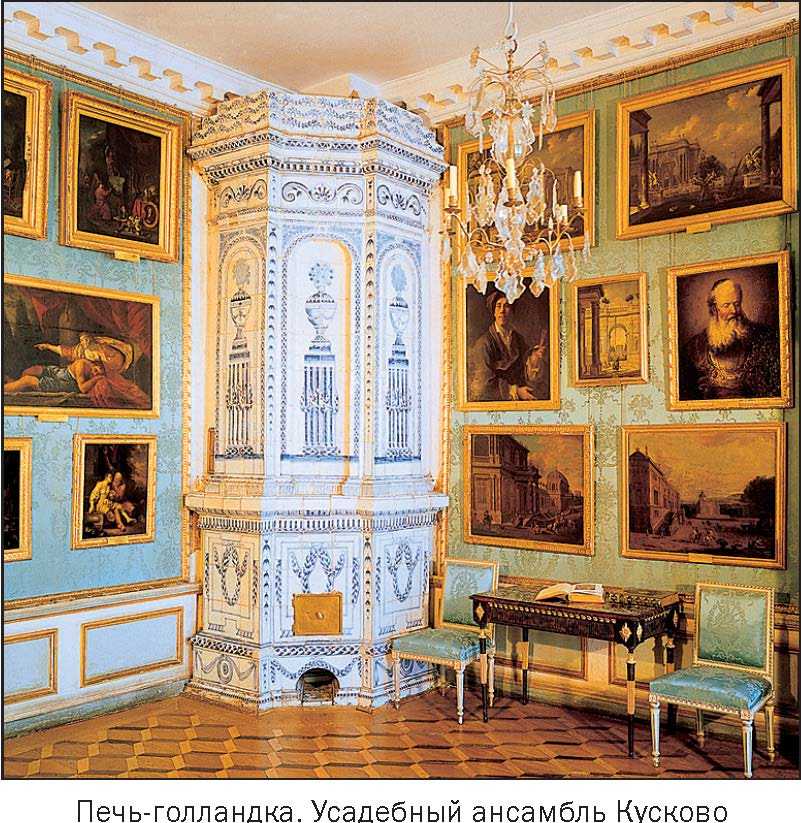

General structure of a Dutch oven

In the classic version, the Dutch oven is purely heating, with a wall of one brick, has a rectangular shape, and long chimney channels are built above the firebox. That is why, with low fuel consumption, it heats well: hot smoke warms up the bricks of the internal channels and, already significantly cooled, exits into the chimney. Initially, these stoves were lined with tiles.

This is what classic Dutch stoves look like from the inside without a grate or vent.” A feature of any stove of this type is the presence of smoke channels in the upper part

In the same classic Dutch oven, the exit of the smoke channel is located on the side: the Dutch paid a tax on smoke, so several stoves were led into a common pipe. Moreover, problems with smoke in less heated stoves do not arise: long smoke channels are not easy to blow through even with reverse draft.

This is what modern Dutch ovens look like, lined with tiles (a prototype of tiles)

All this, and even the plasticity of the design, led to the appearance of many forms of Dutch ovens: in addition to the traditional rectangular and square ones, there are triangular, trapezoidal and round. There are no fewer options for use: pure heating, heating and cooking, with a stove bench, on one, two or three floors, with a fireplace, a tank for heating water and a tank for water heating. It's no surprise that this design is popular. Moreover, everything is so simple that anyone who has laid a brick wall with a bandage at least once can fold a Dutchman with their own hands. If you are planning to try your hand as a stove maker, choose the Dutch pattern and get to work.

You might be interested in learning about the Swedish stove.

Advantages and disadvantages

Let's start with the pros:

- Laying a Dutch stove requires little material - about half as much as a similar Russian stove. The consequence is low weight, which almost all types of floors can withstand without any problems.

- Its design is such that it can be “customized” to the required dimensions without much fear of a significant deterioration in performance. The minimum size of a Dutch woman is 50*50 cm.

- It is undemanding in terms of the quality of materials: the safety margin and design are such that Dutch ovens are not afraid of possible thermal deformations. It is advisable to use high-quality fireclay bricks for laying the firebox; for the body you can take any more or less normal solid ceramic one.

- Flexibility of the design: a water heating tank or oven can be built into the smoke duct area.

- The channels above the firebox can be extended over several floors: two or even three floors is not a problem.

- After the Dutch oven has been idle for a long time, it does not need to be warmed up slowly. You can immediately heat it to warm up the room: there will be no cracks. Moreover, it heats up quickly, and cools down (if you remember to close the damper) slowly.

This is a corner Dutch oven in the Kuskovo Museum

There are many advantages, and they are all significant. But there are no shortcomings. This miracle of heating technology also has them:

- Demanding on fuel quality. In the sense that you need to heat it with wood or coal, and not with waste fuel or garbage. It is optimal precisely in the mode of smoldering, and not burning, and when burning with sawdust, brushwood or straw, there is nothing to smolder.

- If you forget to close the view after heating, it cools down very quickly: the heat is carried out through the channels.

- Low efficiency - about 40%.

- Since there is not much brick used for it, the heat capacity is also small. Therefore, to maintain a stable temperature, it must be heated at least twice a day. Moreover, you cannot overheat it: carbon monoxide may even escape.

- If you use wet, low-quality fuel, the channels quickly become overgrown with soot and have to be cleaned frequently.

As you can see, the main disadvantages are related to the operating features. If done correctly, a Dutch oven is an excellent heating appliance.

And this miracle is also a galanka heating stove in the Metropolitan’s chambers

Types of stoves

In the past, houses were built “from the stove”, that is, it was installed first, and then the walls and ceilings were erected. Nowadays, it is not necessary to do this, but it is advisable, especially when you plan to position the stove in such a way that it heats several rooms at once.

454581eb825c7405a99754f8687d5b66.jpe

9c05dcdd6e25fb34fe8fcae867d33ffb.jpe 72d6731b9b342a72d16bb6ae4cf3b6f7.jpe

e1cf46657f7d139dbcb2f33aebb6bdc3.jpe

The most common types of stoves are Russian, Swedish and Dutch. At the same time, the Russian one must be erected before the construction of the house begins, and besides, it requires a separate foundation. In general, any kiln consisting of 500 bricks or more needs a foundation that is separate from the base of the building. It's easier with Dutch and Swedish ovens. They are compact, can be installed in an already constructed building and do not require an additional foundation.

There is another wood-burning stove - a bell-type stove. Its advantage is its efficiency, reaching 70% compared to 50% for other types of furnaces. The disadvantage of such a stove is its complex design, which makes it almost impossible to assemble it with your own hands. Also, the stove cannot be equipped with a hob - the design is intended exclusively for heating premises.

Basic rules for arrangement

Unlike the Russian stove, which is very multifunctional, being both a source of heat, a stove bench, and a place for cooking, the Dutch stove was originally created only as a means of heating.

To maximize the functionality of an overseas hearth, domestic stove makers added a hob to it. This Dutch oven with stove and oven is ideal for a small home, and also if you do not want to clutter the room with a large oven.

The manufacturing technology of the unit is quite simple. The stove is placed in a niche of the structure, just above the firebox, approximately the third - fifth row. The oven is built parallel to the firebox.

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

If a hob is not needed, then the oven is placed directly above the firebox, but we still advise you not to ignore the stove: firstly, it will never be superfluous, and secondly, there are excellent design solutions for arranging the oven, where the hob perfectly complements the appearance Dutch women

Photo of Dutch ovens with stove and oven (located on the same level as the firebox):

Photo 1

Photo 2

Photo 3

Basic concepts for making your own brick kiln

To lay the furnace, you can contact specialists. But to save money, you can make a brick oven with your own hands. This will not be difficult even for a beginner, as it does not require special knowledge.

First you need to choose the type of stove, then find a masonry diagram. There are many DIY brick oven designs on the Internet for every taste.

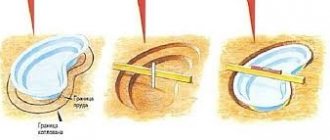

After the scheme has been found, it is necessary to make a foundation. It should be slightly larger than the oven itself on each side.

The chimney is also made of brick. After completing the laying of the stove, you can line it with finishing materials to give it a beautiful look.

It is also very important to choose the correct installation location. If the stove has a cooking function, it is better to install it so that the cooking part is in the kitchen and the heating part in the living room.

Fireplace stove 9

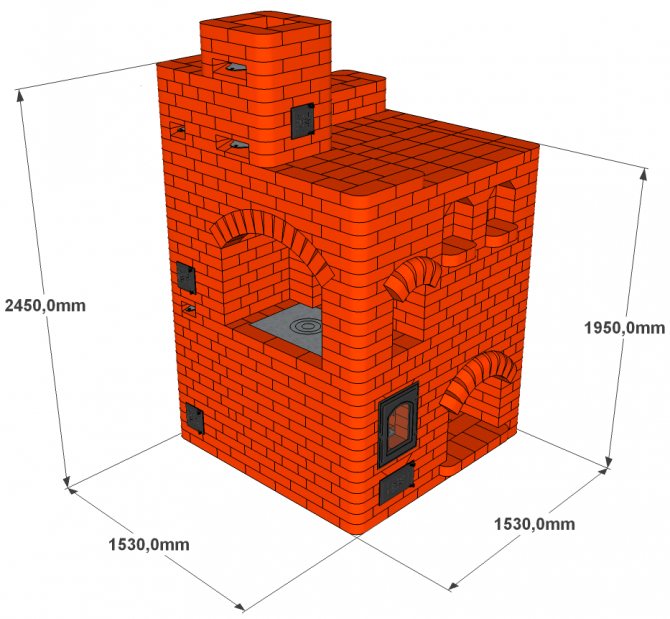

Oven with bread chamber and sauna oven

- Sides: 204cm*217cm

- Heating (fireplace stove): up to 40 sq.m.

- Heated steam room (sauna stove): 5-6 sq.m.

- Brick: 1800 pcs.

- System: combined

- Operating modes:

- - fireplace stove

- - bread oven only

- - sauna stove

- - both ovens at the same time

Russian stove: drawings of brick stoves

Russian brick stoves To lay the stove you will need the following materials:

- solid red brick – 1610 pieces;

- view for a valve measuring 0.3x0.3 meters - 2 pieces;

- dry clay solution in dissolved form;

- samovar 14x14 centimeters - 1 piece;

Heating stoves for a brick house - we do it ourselves. To work, you will need the following tools:

- trowel – for laying and leveling the mortar;

- pick - a multifunctional hammer with a blade located perpendicular to the axis of the handle. At its other end there is a square windshield;

- bubble level for masonry and hydraulic for the first row;

- rule - serves to align the bricks of each row;

- plumb lines - one of them must be permanently attached to the axis of the chimney (floor), and with the help of the second the verticality of the corners is checked;

- brush – needed for grouting joints;

- cord - it is pulled over each row of masonry.

Drawings of brick stoves for any type of home look like this:

- Cooking chamber. For masonry, 3/4 ground corner bricks with locks are used.

- Under. There is a slope from the back, for the purpose of which the space is filled with sand, on which the brick is laid.

- Covering the bottom. The structure is covered with bricks along rods, corners or sheet blanks.

- Vault with a castle. In some cases a central lock is used, in others the last two symmetrical bricks are used.

- Rows to the lower arch. The bricklaying of the stove is carried out in the usual way, then a vault template assembled from chipboard or springs cut from wood are installed on top of it.

- Wells. They are tied rows in which a hole is left leading to the underside.

- Sub-bake. Bricks are laid on a foundation mortar; hollow stones are not allowed.

- VK code. For convenience, the bricks are cut into a wedge-shaped shape.

- Covering the channel above the samovar. It is solid, only solid stones are used.

- The holes above the pole become smaller. The brick is cut in accordance with the drawing.

- Alignment of walls. At the same time, the over-pipe is reduced and the samovar channel is laid.

- Installation of a samovar. The structure is closed with a separate lid.

- Installing a view. To embed the structure, two rows are laid.

- Chimney. The height of the pipe from the bottom to the top must be at least 5 meters. The upper rows form a canopy that prevents precipitation from entering the chimney.

Advantages of the Swedish stove

Among the main features of the Swedish stove are the following.

Combined structure

It can be used not only for heating a room, but also for cooking. The design of the oven allows it to be equipped with additional functions, for example, to equip a place for an oven or for storing cooked food. In addition, the stove can be diversified as a place to relax: a lounger or other additional structures. Thus, the multifunctionality of the Swedish-type oven provides the opportunity to assemble a structure of different types with the addition of additional functions as desired.

Compact in size

The compact size does not consume too much space, but rather harmoniously complements any interior, being an interesting accent to the design of the room. If desired, the stove can be decorated with decorative materials.

High level of efficiency

The Swedish stove is an economical option in terms of fuel consumption. Firewood, peat and other solid fuel options can be used as fuel.

Simple masonry

You can install such a Swedish stove yourself, without the help of a specialist. You can get acquainted with the project, step-by-step instructions and order on the Internet. It is very important to understand the drawings, which indicate the serial number of the layout of each row of the structure and carry out everything according to the instructions. Of course, such a stove can be bought in a ready-made version, but the independent option will help save your budget.

Laying the furnace in order

During masonry, special attention will have to be paid to the strength and evenness of the surface. So, there should be no excess mortar or voids in the seams, and all channels from the inside should be perfectly smooth

In this case, they bandage it into half a brick.

Swedish stove stove When laying a Swedish stove with your own hands, special attention is paid to the cross-section of the smoke channel. It must remain unchanged throughout the entire laying of the furnace.

Otherwise, even with minimal narrowing, flue gases may escape into the room.

Once the first row is ready, you can install the blower door. Further work will be carried out based on the chosen order. To form the internal space of the main elements of the furnace, including the blower, the bricks used for them are somewhat cramped. Already on the next row the doors can be closed.

50e706ce2b402c827a19ce0e27a05ae1.jpe

Types of Swedes

Let’s say right away that it is extremely difficult for a Swede to assemble a stove with her own hands. To do this, you need to have some experience, understand something in the concepts of order, diagram, chimney ducts.

Without special skills, Swedish brickwork should not be done on your own. Otherwise, you risk simply wasting your money. To equip your dacha with a Shvedka, we recommend contacting specialists. Today, finding a good stove masonry specialist is not so difficult, but be sure to make sure that the person has experience in working with similar structures.

Your task is to determine which modification of the Shvedka stove you want to see inside your own dacha or country house. The functionality of your stove and the capabilities provided by new heating equipment depend on the chosen masonry.

- Heating and cooking models. This is an option for laying a stove with the simplest order, since there is only a cooking stove here. If desired, you can add an oven, a container of water for indirect heating and hot water supply, as well as niches designed for drying various products.

- Stoves and fireplaces. The peculiarity of this version of the Shvedka stove is that it goes through the wall. The heating and cooking element of the stove remains in the kitchen, allowing you to cook your favorite dishes over a live fire. The second part, located behind the wall, has a decorative heating function. A good option for those who value not only the high-quality operation of heating equipment, but also the aesthetics of traditional stoves.

- Swede with a bed. The most seductive, according to many, modification of the Shvedka. The peculiarity of its design is the presence of a sleeping place. In winter, you can get real pleasure from relaxing on a bed. Experts have proven that resting on a bed provides enormous benefits for the body, normalizes blood circulation, and calms the nerves. It is difficult to overestimate the benefits of a warm bed. But you shouldn’t abuse it either. Especially when you overdid it with the amount of fuel and the sleeping area became overheated.

As you can see, the brick Swede can be varied. It depends only on you which modification of the Buslaev stove will end up in your home. You can rely on the photo if you are interested in the aesthetic component. But be sure to consider the basic selection parameters.

Recommendations for selection

Shvedka stove arrangement diagram

Before you begin laying your future Shvedka stove, listen to a few tips regarding choosing its parameters and who will be involved in construction issues.

- Building a Swedish stove with your own hands is difficult, so you should be prepared for this. It’s not enough to watch video instructions, although some craftsmen who have built stoves but have not dealt with Swedes can rely on similar video lessons. If you don’t have the slightest experience, trust the construction of the Swede only to qualified craftsmen.

- Power. Power is influenced by many factors. Your task is to lay out a stove that will provide warmth to your home. Due to its high efficiency and compact size, a stove with an area of 1 square meter is enough for approximately 30 square meters of heated premises. For a small dacha this is quite enough.

- Equipment and modifications. We have already discussed this issue and you know what Shvedka stoves can be equipped with. Their brick arrangement allows you to create ovens, dryers, beds, etc. Think about which of these you really need. The more oven elements, the more expensive the Shvedka will end up being.

- DHW. Hot water systems are a hot topic for many homeowners. Swedes make it possible to connect containers to them for heating water. Heating occurs indirectly due to the heat of the firebox or chimney ducts. This way you can get a certain amount of heated water. If the Swede is used only in the winter season, such a boiler will not hurt even if you have a regular electric one. During the heating period, you can switch to indirect hot water supply, thereby significantly saving on electricity.

- Appearance. It all depends specifically on your wishes and requirements. There are many options for decorating the Swede. Its big advantage is its appearance. In addition to the functions of space heating and cooking, such stoves create a great atmosphere. Many choose them precisely for their external parameters. Although the Shvedok’s functionality is at the highest level.

The Swedish order may cause problems for a beginner, but a specialist can handle the construction. The question is different - is the Shvedka really the optimal solution for providing heat to your home.

Selection of bricks and heating elements

For the construction of passages and heated elements of the furnace, refractory bricks are used. Ordinary brick is used to furnish parts that are not exposed to high temperatures. The dimensions of any type of brick are 250 mm in length, 120 in width and 65 in height. If necessary, brick blocks are broken.

Thus, a distinction is made between a three-quarter brick, the length of which is 3/4 of the whole, and a half-brick - with a length cut in half. Very small pieces of brick, equal to 1/4 of the whole, are called quarter bricks. The cutting of the material is carried out using a sharp steel knife and a squeegee - cutting a metal pipe. To build a furnace, you will also need metal elements, including:

- a door for the firebox, a door for the blower and a door for cleaning passages;

- view valve;

- grate

All listed details must be comparable to the dimensions of the brick blocks. The stove is waterproofed using roofing felt. The length of the sheets of this material depends on the dimensions of the structure. This factor determines the number of bricks. Typically, the amount of building materials needed is indicated in the project documentation or calculated individually. Knowing the number of rows, the size of the brick and the dimensions of the oven, this is done simply.

Step-by-step manufacturing instructions

A stove with a fireplace should be placed in the house so that its hob and firebox are directed towards the kitchen, and the fireplace faces the living space. It fits well between separate rooms.

In principle, it can be installed anywhere; if you do not plan to cook on the stove, then you can use it as a design element and decorate it with decorative material. It is better if the stove is planned during the construction of the house, it is easier to create a reliable foundation, because the mass of the entire structure is approximately 3 tons.

Furnace diagram

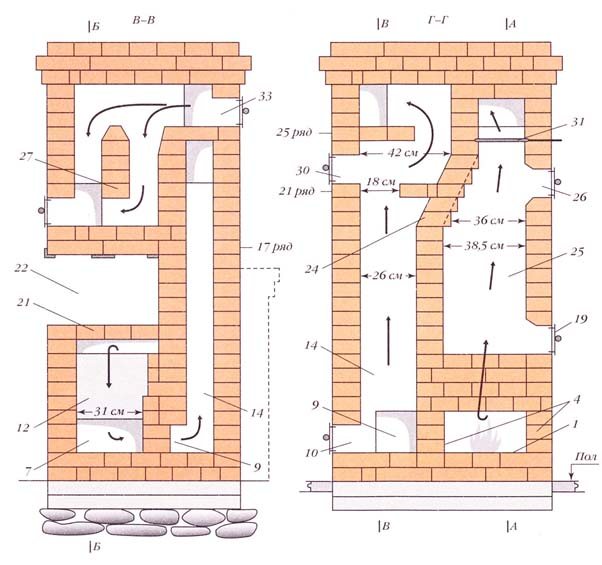

The Swedish stove with fireplace is shown in the diagrams:

Front view

Back view

Section #1

Section #2

Materials and tools

The required materials are presented below:

The materials used to prepare the masonry mortar are of great importance. Simple clay is not able to withstand high temperatures, you need to find fireclay clay. Anyone who wants to prepare it themselves needs to look for it in hollows near rivers or on their steep banks.

You need to prepare the tools in advance, of which you will need:

- Master OK;

- Rubber mallet and hammer-pick;

- Twine and plumb line;

- Rule;

- Tape measure, pencil.

Lay out the oven

If you wish, you can.

The order of the Swedish stove with a fireplace is presented below:

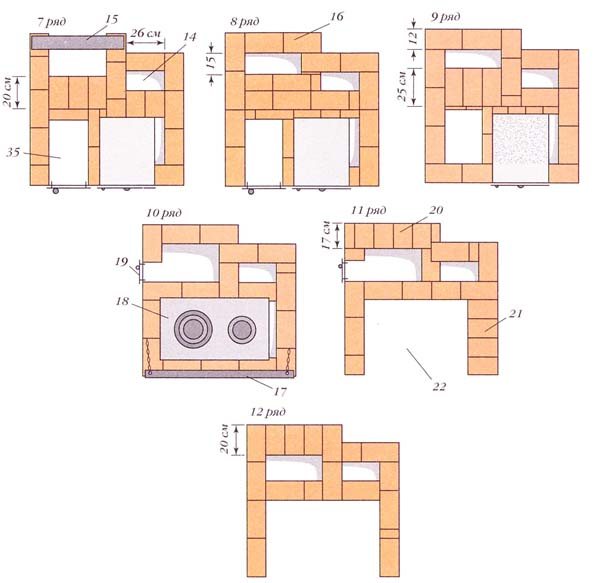

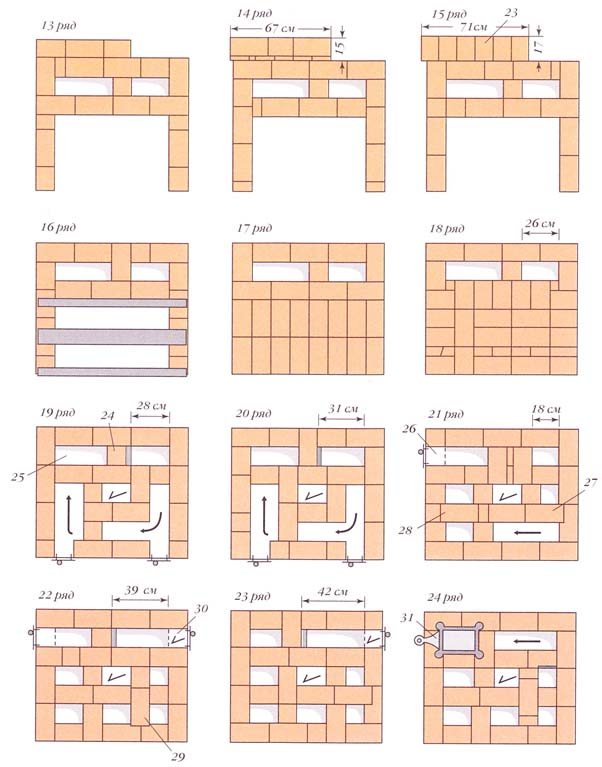

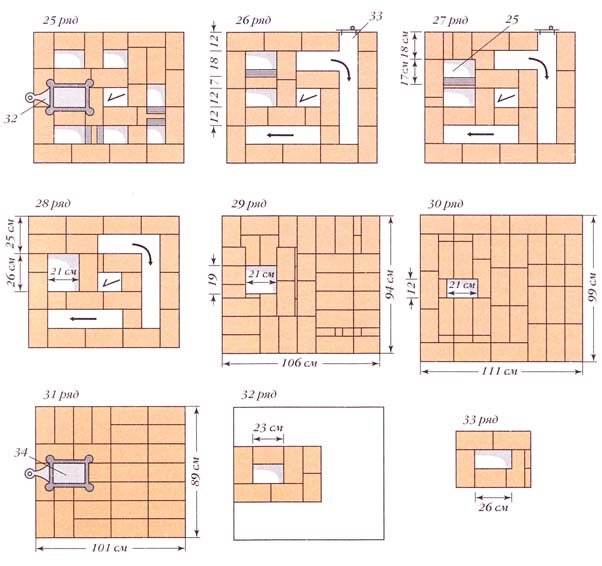

1-6 row

7-12 row

13-24 row

25-33 row

First of all, it is necessary to make a foundation for the stove. After this, the laying begins in order (images above).

The first row of masonry must be placed on a waterproofing layer. In order for the masonry to be level, this affects the placement of the entire structure; markings must be made on a sheet of material for waterproofing - for this purpose, you will need a long ruler, a corner and white chalk. With the exact outlines of the future oven, it will be much easier to complete the work; according to the resulting markings, they begin to lay out the first row.

It is necessary to bandage the bricks. Check that the corners are laid out correctly and the structure is horizontal. These rows are necessary as the basis for the entire structure; you cannot make mistakes when laying them out. The rods on which the fireplace grate will rest must be walled into the masonry in the 2nd row.

A Swedish stove with a fireplace should be built in warm weather so that it can dry out from natural heat. During cold weather, you will have to remove moisture from the masonry by drying with small firewood. This is done for several hours, putting a few wood chips into the firebox. It takes at least a week to dry the stove; you can force dry the brick by installing a fan heater in the firebox and closing all the stove openings, leaving only the chimney open.

Progress of laying rows

The construction of the furnace begins with the installation of guide posts. The formwork is attached to them - a wooden box without a bottom. It is needed to ensure that the masonry is even. The formwork is designed for several rows: when they are completed, it is raised to the top. It is also used to create vaults and arches, although for this purpose semicircular formwork is used, and not in the form of a box. When the masonry is higher than the chest, you will have to work on platforms.

When everything is ready, you need to choose the ordering method for laying heating stoves and construction technology. There are two popular options for installing blocks - splice and spoon. They got their name depending on which part of the brick faces outward. There is another method - bed, when the bricks are installed on a spoon or a poke, but it is unreliable. To avoid problems, it is recommended to monitor the thickness of the seam: it should be at least 5 mm.

Laying stages

Let's take a closer look at the stages of laying a stove in a house using a Swede as an example. The first layer of brick is the most important; it is laid strictly in compliance with the level. Bricks are not placed in the place where the ash pit chamber is located. There will be a blower between the chamber and the front side of the furnace; the blocks behind it are cut at an angle to make it easier to remove the ash. A three-quarter brick is placed in front of the ash pit.

The second and third rows are placed after the ash pan is secured. Otherwise they are similar to the first

It is important that the height of the third row coincides with the height of the blower door. In the fourth row, a door is installed for cleaning the passages with your own hands, and the passages themselves are laid out directly behind it

A row of bricks from above blocks the door of the blower.

With each subsequent row, the opening of the ash pan is narrowed. A grate is installed on the fifth row of bricks. The combustion chamber door is mounted on top of the sixth row above the ash pit. It is necessary that its height coincides with the height of the ninth row.

The first ten rows are made of refractory bricks, the next superstructure is made of ordinary building material. A hob is placed on top of the bricks of the tenth row. In the next rows, the passages for the movement of heated air smoothly transform into a smoke outlet. A more detailed arrangement of the furnace is determined by the configuration and purpose of the structure.

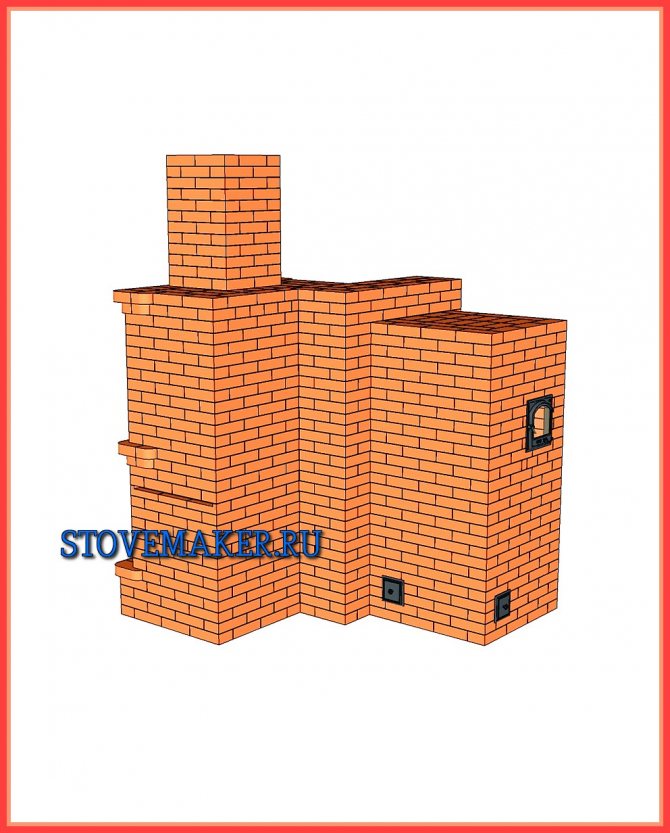

Fireplace stove B

Heating, 5 channels, boiler

- Sides: 118cm*82 cm (designed for brick ША-5, ШБ-5; 230cm*114cm*65cm)

- Heating: up to 200 sq.m.

- Brick: 580 pcs.

- System: channel

Furnace structure

The Dutch oven is a classic wood-burning channel stove. Its operating principle is based on the circulation of hot air along passages laid in the body of the furnace.

But installing a tank for heating water will not work: this will lead to a decrease in efficiency due to the accumulation of soot in the channels. In addition, even without a tank, the efficiency of the furnace barely reaches 40%.

In turn, the “Swedish” has an efficiency of 60%. It is considered the most advanced heating and cooking oven, where the oven serves as an air chamber. In the chamber part, the combustion gases burn out, and they go into the convector heated to 800°C. The convector itself is narrow, but has a large height, due to which the house is heated evenly.

The Swede can be equipped with a heat exchanger for the hot water supply system. The storage tank is placed on the roof or in a drying niche. As a result, the efficiency does not decrease: there is no feedback energy connection between the oven and convector on the one hand and the combustion part on the other.

f81d8331c0cbcabbffbacb2c82230306.jpe f33d6b7f2ad72e47625b790336eb38f8.jpe

Reasons for popularity

Photo of the Shvedka stove

Why exactly did the Shvedka heating and cooking stove, also known as the Buslaev stove, gain such popularity among owners of country houses?

- Environmentally friendly. The design features, masonry, layout and materials used make it possible to rightly call Buslaev’s stove an environmentally safe household item. And this is now in fashion.

- Economical. The masonry scheme and special order allow you to achieve excellent fuel saving results. At the same time, the stove effectively heats the room. With minimal fuel costs you get a large amount of heat. The same Russian stove cannot boast of such indicators.

- Functionality. Buslaev's stove can be equipped with three modes - a stove bench, a hob, and an oven. The presence of an oven allows you to expand your culinary capabilities, and with a hob you can create real masterpieces of culinary art. They enjoy the lounger while relaxing. It is the stove bench that makes Buslaev’s stoves and Russian traditional stoves similar.

- Compactness. The dimensions of the Swedish stove are quite small, but allow you to place three main elements. This is much preferable to a Russian stove, since it requires a much more impressive space to accommodate it. A model for a dacha measuring 1 square meter provides heating for 30 square meters. Only the part with the hob is located on the kitchen side, and the other part is taken out through the wall into the bedroom or living room. There the stove is equipped with a stove bench.

- Efficiency Despite the size, the brickwork pattern, the order, and the design features of the stove with a stove, a stove bench, and an oven make it possible to obtain high efficiency indicators.

- Oven with three operating modes. What are they? The firebox of the Buslaev stove allows you to simultaneously provide three types of fireboxes, which operate in summer, autumn and winter modes, respectively. Each mode has its own chimney channels. So in winter you can heat the entire house and cook food, and in summer you can only cook without raising the temperature in the whole house. With three modes, you can eliminate the possibility of smoke, which is a regular companion for homeowners at the beginning of the heating season.