A standard radiant heating system for a private house or apartment building is an organization of heating the internal space through several circuits with individual connection to an already installed pipeline of separate, rather than sequential, devices.

This option allows for optimal heat transfer and also prevents significant losses of thermal energy.

Modern heating systems

In modern apartment buildings and in private buildings, regardless of the number of floors, horizontal heating systems are usually used.

The main design feature of the scheme, in this case, is the presence of one or several vertical risers with branches for arranging heating for each individual room.

The pipeline connection to the radiators is carried out horizontally.

Currently, both open and hidden pipeline laying is practiced, but the second option is the most preferable:

- in a branched dead-end heating system, it is assumed that the minimum length of pipes and hydraulic resistance are leveled by mutually crossing the pipeline, which becomes the main reason for increasing the thickness of the screed;

- the perimeter wiring of the heating system provides for the laying of the pipeline along the walls along the perimeter of the entire room, and it is also possible to carry out hidden installation in the floor structure;

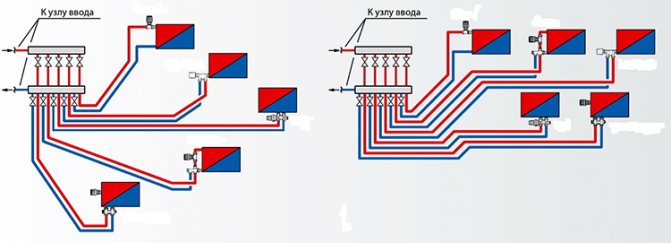

- The collector circuit provides for parallel connection of all heating devices to the supply and return pipelines.

It is the latter method that is optimal for arranging a combined type of heating, that is, a combination of traditional radiator heating with a “warm floor” system.

The most budget-friendly and easiest-to-implement option is the traditional single-pipe system, in which all heating devices are sequentially filled with coolant, which does not guarantee uniform heat distribution.

Requirements for heating systems

Water heating should be used in health care facilities. The use of other liquids and solutions as a coolant is not allowed. The maximum temperature of the coolant in heating systems is taken equal to:

- 85 °C - in ward departments, intensive care units, intensive care units, maternity hospitals and inpatient clinics;

- 95 °C - in other rooms of health care facilities, wards of psychiatric and narcological departments.

Heating appliances must have a smooth surface that allows easy cleaning, is resistant to daily exposure to cleaning and disinfecting solutions, and prevents the adsorption of dust and the accumulation of microorganisms. Such devices are installed in operating rooms, preoperative rooms, intensive care rooms, anesthesia rooms, labor rooms, electrolight therapy rooms, rooms in psychiatric hospitals, wards, manipulation rooms - toilets for newborns, wards for premature, injured, infants and newborns, wards for patients with infectious diseases, burn patients, boxes and half-boxes, rooms for storing, preparing and classifying blood, for storing sterile materials and preparing medications under aseptic conditions, X-ray rooms, laboratory premises and experimental biological clinics (vivariums).

Heating appliances are placed near the outer walls of the room under windows without fences. Heating devices are not allowed near interior walls.

In wards and medical, diagnostic, and preventive rooms, tubular and panel radiators without fins are used. At the same time, it is allowed to use other types of radiators and convectors in lobbies, stairwells and corridors, except for the corridors of ward rooms, intensive care units, maternity wards and intensive care units.

The premises listed above are equipped with water wall or floor heating systems. Wall-mounted heating panels or registers made of polyethylene pipelines embedded in the wall structure are used as heating devices.

If the power of the underfloor heating system is insufficient to create the required microclimate, it is advisable to use combined heating in these rooms.

The temperature on the underfloor heating surface in the area where people are constantly occupied should be no higher than 26 °C. It is allowed to form boundary zones along external fences with a width of 1 m and a surface temperature of 31 °C.

To improve the operation of the automatic control system, the length of the circuits should be no more than 80 m. With this heating, the wall surface temperature should be no higher than 50 °C. For floor and wall heating systems, an automatic temperature control system is provided in individual rooms.

During the warm period of the year, it is advisable to equip the premises listed above with heating system pipelines for cooling in order to remove excess heat in the work area and reduce air exchange to that required by sanitary standards. Wall heating systems and ceiling systems are used as cooling systems.

To avoid moisture condensation on the surfaces of walls and ceilings, the temperature of the water in the supply line must be taken 1-2 °C above the dew point temperature, while the temperature of the surfaces of the walls or ceiling should not be lower than 20 °C.

Depending on the temperature and humidity conditions of the room, when choosing the wall surface temperature, it is advisable to check the possibility of moisture condensation on the surface of the enclosing structures. The water radiation cooling system is made of lightweight gypsum concrete ceiling panels with pipelines embedded in them. Rooms with the highest relative humidity are equipped with a dew point temperature sensor and connected to the automation system.

During the cold season of the year, the water temperature in the supply line should be no higher than 40 °C, and the ceiling surface temperature should not be higher than 24 °C. In operating rooms for various purposes, the thermal regime should be maintained by an air conditioning system.

Beam wiring: features and elements

The radial type of heating system wiring is a well-thought-out and effective design, consisting of several main elements, presented:

- A boiler designed to transfer coolant through pipes to heating radiators. The power indicators of the installed equipment must be taken into account with a percentage increase for heat losses in the gas radiant heating system.

- Circulation pumping equipment that allows forced movement of the coolant through a closed heating system. In the process of choosing the model and design of the pump, the height and length of the pipes that create hydraulic resistance, as well as the design and type of radiator batteries, must be taken into account.

- Comb and collector. The installation of gas radiant heating requires the mandatory installation of combs or a collector, which is responsible for the process of distributing the coolant throughout all heating devices in the system.

Horizontal radial heating distribution diagram

Modern brass, steel or polymer manifolds used in radiant heating systems are often equipped with additional elements of thermostatic or shut-off-regulating properties, which allows the individual flow of coolant to be distributed over each individual circuit.

Equally important is the presence of an automatic air removal mode and standard thermometers that facilitate the operation and maintenance of the heating system.

In recent years, the installation of special external and internal, so-called built-in cabinets, within which elements of the radiant heating system are mounted, has become very relevant.

Classification of water heating systems

Classification of water heating systems is carried out according to the following main characteristics [11].

1. According to the method of creating circulation, water heating systems are divided into systems with natural circulation (gravity) and artificial circulation (pump) . In systems with natural circulation (Fig. 4.3), the movement of water is carried out under the influence of the difference in the densities of cooled water after heating devices and hot water entering the heating system. In systems with artificial circulation, water movement occurs under the action of a pump.

2. According to the scheme for connecting heating devices to a riser or branch, water heating systems are divided into two-pipe ones in accordance with Fig. 4.3 (devices are connected in parallel along the coolant) and single-pipe (devices are connected in series along the coolant).

3. In the direction of combining heating devices, both two-pipe and single-pipe heating systems can be vertical in accordance with Fig. 4.3 (heating devices on different floors are connected sequentially to a common vertical riser) and horizontal (heating devices on the same floor are connected sequentially to a common horizontal branch).

4. Based on the location of the supply and return lines, water heating systems are divided into systems with an upper supply line in accordance with Fig. 4.3 (through the attic or under the ceiling of the upper floor, and return lines through the basement) and with the lower location of both lines (through the basement or above the floor of the first floor).

5. Based on the direction of water movement in the supply and return lines, water heating systems are divided into dead-end ones in accordance with Fig. 4.3 (hot and cooled water in the mains move in opposite directions) and with parallel movement (hot and cooled water in the mains move in the same direction).

To understand the structure and principle of operation of a water heating system, consider the system diagram [11] shown in Fig. 4.3.

Water heated in a heat generator (boiler) K to a temperature t

g enters through the heat pipe - the main riser

1 into the supply main heat pipes 2 . Hot water flows through the supply main heat pipelines into the supply risers 9 . Then, through the supply lines 13, hot water enters the heating devices 10 , through the walls of which heat is transferred to the air in the room. From the heating devices, cooled water with a temperature t

o through the return connections

14 , return risers 11 and return main heat pipes 15 returns to the heat generator K , where it is again heated to a temperature t

g, and then circulation occurs in a closed ring.

K – boiler; 1 – main riser; 2 – supply main heat pipeline (hot water); 3 – signal tube; 4 – expansion tank; 5 – overflow pipe; 6 – circulation pipe; 7 – valves; 8 – tees with a plug, the upper ones – for admitting air into the disconnected riser, the lower ones – for draining water; 9 – supply risers (hot water); 10 – heating devices; 11 – return risers (chilled water); 12 – control valves for heating devices; 13 – supply lines; 14 – return connections; 15 – return main heat pipeline (cooled water); 16 – shut-off valves for regulating and shutting down individual branches of the system; 17 – pipe for filling the system with water from the water supply; 18 – drain pipe

Rice. 4.3. Scheme of a two-pipe water heating system with top wiring and natural circulation

The water heating system has an expansion tank 4 , designed to accommodate the increase in the volume of water when it is heated, as well as to remove air through it into the atmosphere both when filling the system with water and during its operation (in the case of an open expansion tank). To regulate the heat transfer of heating devices, control valves 12 .

Before putting into operation, each system will be filled with water from the water supply 17 through the return line to the signal pipe 3 in the expansion tank 4 . When the water level in the system rises to the signal pipe and water flows from the pipe into the sink located in the boiler room, close the tap on the signal pipe and stop filling the system with water.

If the devices are insufficiently heated due to clogging of the pipeline or fittings, as well as in the event of a leak, water from individual risers can be drained without emptying and stopping the operation of other parts of the system. To do this, close the valves 7 on the risers. From the tee 8 installed in the lower part of the riser, unscrew the plug and attach a flexible hose to the tee fitting, through which water from the heating pipe and heating devices flows into the sewer. To make the water drain faster, remove the plug 8

The scope and advantages of various water heating systems are presented in table. 4.2 [11].

Table 4.2 – Scope and advantages of various water heating systems

| Water heating systems | Advantages | Application area |

| Vertical two-pipe systems with an overhead supply line with natural water circulation. | 1. Large natural circulation pressure. 2. It is easier to remove air from the system. 3. Higher heat transfer from heating devices. 4. Supply of water with the highest temperature to each heating device. 5. Minimum area of heating devices. | In buildings with up to 3 floors inclusive. |

| Vertical two-pipe systems with a lower location of both lines with natural water circulation. | 1. Less heat loss. 2. Installation and commissioning of the system can be carried out floor by floor. 3. The system is more convenient to operate. 4. Greater hydraulic and thermal reliability of the system. 5. Supply of water with the highest temperature to each heating device. 6. Minimum area of heating devices. | In low-rise buildings with double adjustment taps on heating appliances. |

Continuation of Table 4.2

| Vertical single-pipe systems with closing sections on risers and natural circulation of water. | 1. Lower cost. 2. Simple installation and shorter length of heat pipes. 3. Beautiful appearance. | In multi-storey industrial buildings. |

| Single-pipe horizontal system with natural water circulation. | 1. Less pipe consumption. 2. Possibility of switching the system on floor by floor. 3. Standardity of nodes. 4. Installation is easier | In production premises. |

| Vertical two-pipe heating system with artificial circulation and dead-end system. | 1. Large difference in pressure loss in individual circulation rings. 2. Uniform heating of all heating devices. | In production premises. |

| Single-pipe system with bottom laying of lines with artificial circulation. | 1. Smaller pipe diameter. 2. Large range. 3. Easy installation. 4. Stable thermal and hydraulic operating conditions. | In production premises. |

Advantages and disadvantages of radiant heating

Unlike traditional heating circuits, the radial layout does not follow the sequential principle, so it can effectively solve cooling problems.

The coolant is distributed as evenly as possible throughout the heating devices, so there is no sensation of temperature difference on radiators at different degrees of distance from the heating device.

Among other things, using a two- or three-way valve, there is an excellent opportunity to set an individual heating level of the coolant for each individual circuit.

If it is necessary to carry out preventive or repair work, there is no such mandatory condition as turning off the entire heating system. The possibility of reducing hydraulic losses due to the minimum number of bends can also be regarded as an important advantage.

Pipe routing - beam system

To make a final decision on the advisability of using a radiant heating system, it is also important to familiarize yourself with some of the disadvantages presented:

- Significantly increased consumption of pipes for supply and return. It is especially important to take this disadvantage into account when arranging large households with complex room geometry.

- Increased labor intensity of installation work, which always affects the final cost of installing a heating system.

- The need to carry out only hidden installation, since it is not possible to install a significant number of pipes along the walls.

- Increased costs for installing a heating system using screed or laying under the floor covering.

- The need to design and install the entire piping heating system under the floor with a minimum number of joints or completely without them.

It is at the design stage that it is necessary to determine the number of circuits of the radiant heating system. If it is intended to use several heating circuits with different temperature conditions of the coolant, then each must be equipped with an individual circulation pump.

It is important to remember that the joint areas always pose a certain risk of leaks and system failure, so it is advisable to entrust all stages of the hidden installation of radiant heating to professionals.

Upgrading the system to save money

Any radiant heating system can be independently upgraded, which increases efficiency and makes operation more convenient. For this purpose, as a rule, it is sufficient to install additional valves with a thermostatic head on all radiator batteries of the system.

Using such a thermostatic head, you can set the values of the optimal, absolutely comfortable heating temperature of the heating medium.

The ability to regulate over a wide temperature range is especially important when there are rooms within the same building that have different purposes.

Alternative heating is not yet very popular, but many are in search of cheap and environmentally friendly energy. A do-it-yourself airborne solar collector is an excellent option for reducing energy costs.

A guide to installing a heating radiator with your own hands is presented at the link.

The efficiency of a heating system largely depends on the correctness of its design. An example of a hydraulic calculation of a heating system can be found here.

Types of building heating systems

Before designing and installing heating, nuances that affect the final result are taken into account: the client’s wishes, technical capabilities of the facility, state standards, safety.

An important point is the choice of heating method for an industrial or public building. Among the most popular types of heating systems are: electric, air, water heating and recovery. Each has its own characteristics associated with the type of coolant.

Air heating

Constant, uniform heating of rooms of hundreds and thousands of square meters requires the right engineering solution. An air heating system helps with this, when a heat generator is installed at the facility, heating and supplying warm air through air ducts to heated rooms.

Fans (less commonly, heat guns) and distribution heads direct warm flows evenly, avoiding overheating or underheating of individual zones.

Among the advantages:

- uniform heating;

- increased efficiency;

- savings on installation due to the absence of pipelines and radiators (air ducts instead);

- uninterrupted heating of large areas (indoor sports arenas, logistics complexes, etc.);

- Fire safety.

Disadvantages include large expenses caused by:

- purchase and installation of equipment;

- content and service.

Costs increase due to high electricity consumption. In some cases, productivity reaches several thousand cubic meters per hour, which entails an increase in utility bills.

Air is one of the safest heating methods

Water heating

This type of heating is rational to use in facilities located next to the central water supply system or its own boiler house.

Heat is generated by an industrial heating boiler powered by electricity, gas or solid fuel: coal, peat, wood products, etc. As a result, warm air enters the premises, mixes with the environment and heats it to the required levels.

There are two types of water heating:

- single-pipe.

Radiators are installed in series, which eliminates the possibility of temperature adjustment.

- two-pipe.

Radiators are placed in parallel, the temperature is controlled by thermostats.

Scheme of water heating through the boiler room

Advantages:

- uniform heat supply;

- stable air circulation;

- safety for people in a heated room.

Disadvantage: cannot be used on large objects.

The system is often used as an additional (“standby”) heating method.

Electric heating

Heating of industrial complexes using electricity is divided into two types:

- through portable devices - convectors.

The air passing through the heating elements maintains the set temperature, preventing overheating. However, this also causes a disadvantage: convectors dry the air.

- through electric boilers.

The operation of the system is automated, characterized by the highest (99%) efficiency and clean air, since the heater does not produce combustion products. The boiler, in addition to its heating function, can also serve as a source of hot water supply.

The disadvantages include the cost of paying for electricity.

Less commonly, compact electric furnaces are used as a device for heating small rooms.

The heated workshop ensures the safety of products and materials

Heat recovery from refrigeration units

Recuperation is one of the heating methods for large shopping centers, super- and hypermarkets.

Recovery (trans. “return”) - “return of part of the energy/material necessary for the technological process.”

Refrigeration units consume a lot of electricity, but at the same time produce large amounts of heat. With a simple exhaust system, warm air flows into the street through special equipment. When recycled, almost the entire volume of heat from refrigeration machines is used for air or water heating of the room.

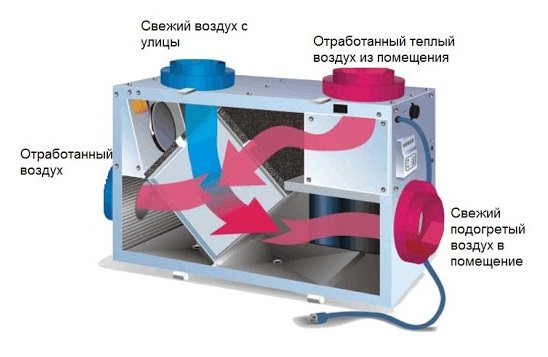

Heat recovery can also be used in ventilation systems, when heated exhaust air transfers its heat to the supply air.

Ventilation scheme with recovery