What is ecowool?

Ecowool is a natural, environmentally friendly insulation material. Made from virgin paper. Contains boric acid (antiseptic) and sodium tetraborate (fire retardant). The first component fights fungal plaque and black mold. The second repels small insects, rodents, and resists the direct effects of flames. With prolonged contact with fire, cotton wool only smolders. Along with thermal insulation, it creates a sound barrier and absorbs noise with a power of 15-60 decibels. Superior to basalt insulator, polyurethane foam, polystyrene foam, and other analogues. It is used not only in Russia, but in Europe, Scandinavia, the Finnish Republic, and other countries. Read on to learn about the rapidly growing popularity, advantages, disadvantages, and features of insulating houses with ecowool.

History of ecowool creation

The first mentions of the product announced in the current article date back to the end of the nineteenth century. English engineers came up with the production technology in 1893. For thirty years the patent lay on the shelf. Then Germany bought it. In 1928, the Germans established production at the Berlin plant. Then the insulation did not gain much fame. A sharp increase in demand occurred in the fifties of the twentieth century, when the passenger terminal of the international airport in Frankfurt was insulated with ecowool. Having learned about this news from the newspapers, residents of the villages and provinces closest to the city rushed to insulate their buildings with it. Seventy years have passed since then, and the popularity of the advertised material continues to grow. How can we explain this? Find out in the upcoming paragraphs.

Ecowool production

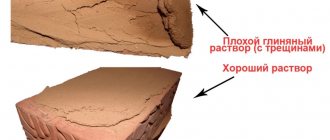

It is made from ordinary paper. The plant purchases waste paper. Shop workers sort newspapers, magazines, and books. Remove paper clips and centimeter staples. The sheets ready for processing are loaded into a hopper, where they are shredded by high-speed auger knives. The result is a loose brown mass containing dust and typographic pigment. Passing through a dust collector, it is cleaned, then high-polymer components are added - borax and boric acid produced in Turkey and other regions. Then it is packaged in vacuum-type plastic bags of 15-20 kilograms, sent to a warehouse, from where it is delivered to interested builders, as well as private homeowners. In Russia, the products of four brands are in demand: Ekovata Donskaya (Tula region), Vateko (Sergiev Posad), Extra (Kolomna), Ekowool (Latvia).

Ecowool insulation: material characteristics

The material is also called thermoflock and uniol. Cellulose in its composition occupies the predominant share - 81%. This material has excellent thermal insulation characteristics; its use allows you to create a seamless monolithic layer. But in its pure form it cannot be used in construction work, since it is very flammable, easily ignites, and is susceptible to the influence of various biological factors.

Adding useful fillers helps correct these characteristics. It is 7% borax and 12% boric acid. What do these components provide?

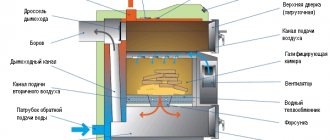

Borax is a reliable fire retardant, helping to reduce the flammability and fire hazard of the base material. Of course, to a certain extent. It is, of course, not recommended to insulate chimneys and heating boilers with such an insulator, but it is extremely good for interfloor coverings and walls.

How ecowool briquettes are packaged

Boric acid has a different function. It ensures that the material loses its attractiveness to various micro- and macroorganisms: rodents, fungi and mold. Its use guarantees ecowool protection from rodents better than that of mineral wool or polystyrene foam (it must be said that they even like the latter). The material also contains a certain amount of lignin, thanks to which the smallest particles of ecowool tightly bind to the surface of the insulated structure when moistened.

In what form is ecowool produced for insulation? This is a loose, unshaped mass consisting of cellulose fibers. It is compressed to a density of 110 kg/cubic meter. meter and briquetted, facilitating loading, transportation and storage. To be used, the material must be unpacked and fluffed to such an extent that its volume has approximately quadrupled.

Main performance characteristics:

- Flammability class - G2, moderate;

- Thermal conductivity coefficient – 0.037 – 0.042;

- Vapor permeability indicator – 0.3 mg/g;

- Mounting density – 26-95;

- Density – 40 g/meter cubed;

- Smoke generation – moderate D2;

- Flame spread over the surface – 0.

Technical characteristics and advantages of ecowool

- thermal conductivity coefficient – 0.032-0.041 W/meter*Kelvin. This is much cooler than polystyrene foam, as well as mineral wool based on basalt (igneous rock) or glass with the addition of sand, limestone, and borax.

- specific density - 35-65 kilograms per cubic meter, makes it possible to produce thermal insulation with optimal structural load. For the ceiling and floor you need 35-40 kilos per cubic meter. For roofs with a slope - 45 kg, for vertical floors 65 kg/m3

- vapor permeability – 0.3 milligrams/m*h*Pa. In the west it is determined by the index “MU” with a numerical value. Gives the thermal cushion a breathable function, which automatically eliminates the formation of condensed deposits.

- acoustic barrier with a sound wave absorption potential of 63Db. For noise reduction, a layer of 5-10 centimeters is enough. With such a density, people in the room will not hear the roar of an airliner taking off nearby.

- fire resistance class "G2". Under the influence of a temperature of 800-1500 degrees Celsius, a reaction occurs in ecowool, characterized by the release of crystallized particles, which slow down combustion and form slow smoldering.

- excellent adhesion (coupling) with any building materials, including red and sand-lime brick, foam concrete, sand block, wood when installed wet or dry, by blowing with a special machine.

- relatively low cost of building insulation. is 250 rubles per square meter of floors, walls, under-roof space. Simple installation provided that the work is carried out by craftsmen with specialized education.

- minimum shrinkage - 0.1% over 12 months, is achieved by following the thermal frame installation technology and an almost unlimited working life. The average service life of ecowool insulation is 50 years.

Pros and cons of using ecowool

Having considered the main properties of ecowool, we can determine the positive and negative aspects of its use.

The advantages undoubtedly include:

- Good thermal insulation properties, even superior to those of the most popular insulation materials - mineral wool and expanded polystyrene.

- Can be used in any construction technology

- Good vapor permeability and ability to retain its thermal insulation properties when moistened

- Quite a high degree of environmental friendliness

- Durability of the material - the service life of mineral wool without loss of heat-insulating properties is estimated at 50-60 years

Low cost - after all, 80% of ecowool consists of waste

The disadvantages of using ecowool include:

- Limitation of its use for application to vertical surfaces

- Fragility of attachment to vertical surfaces even when applied using a wet-adhesive method

- A high-quality insulation layer can only be installed using expensive equipment and with sufficiently qualified builders

- The quality of ecowool very much depends on the quality of the source material, usually waste paper, which is difficult to control even for the manufacturer

The use of ammonium sulfates and phosphates as fire-fighting additives leads to an unpleasant ammonia odor

Ecowool can smolder even at 50 degrees Celsius, and it must be protected from sunlight and not installed near sources of high temperature (furnaces, heaters, etc.).

Negative aspects of ecowool

Disadvantages manifest themselves in the event of a clear violation of the method in order to save money or when directly ignoring the manufacturer’s recommendations. Problems arise due to banal carelessness, bordering on the irresponsible attitude of the consumer towards the process of thermal insulation of a frame house, dacha, cottage. Greed and the desire to save money by reducing the density from 65 to 35 kilograms per cubic meter turns into discomfort for the homeowner when it is already cold outside. To prevent the disadvantages from making themselves felt, buy materials from the best manufacturers working according to a recognized state standard. Don't try to blow it out yourself. Entrust the work to persons with engineering education and confirmed qualifications.

Comparison with other insulation materials

Expanded clay stone, basalt and glass wool, polystyrene foam, and foam boards weakly compete with ecowool. They are inferior to it in thermal productivity, ability to retain and transmit steam, density, and flammability class. Iron-containing basalt and fiberglass as part of their analogues also resist fire, but emit toxic chemicals into the atmosphere, in particular formaldehyde, which is dangerous to the human body. These insulators themselves are safe, but when heated they release gas that can damage the larynx, trachea and pulmonary system. Some substances, when ignited, release vapors that, when they enter the body, provoke the growth of cancer cells and the development of oncology. Ecowool is made from paper that has gone through several stages of sorting. An important feature in production is maintaining the humidity of the raw materials - no more than 12%.

Rodents avoid it. Why? Because it contains multicomponent Lewis acid insecticides. They have neither taste nor smell. Prevents the appearance of mice, rats, gophers, as well as red ants and bark beetles. These chemical compounds are safe for humans and animals, since ecowool is located in the walls between the beams, if we are talking about a wooden structure. Unlike the analogues briefly listed above, the insulation in question has a certificate of compliance with the ISO 14001 standard for complete environmental safety. Mineral wool and polystyrene, on the contrary, create an environment favorable for rodents and insects. They smell bad. Over time they cake, depriving the structure of its thermal insulation properties.

With its coefficient of air and steam transmission, ecowool is twice as high as mineral wool and other building materials. It not only breathes, but removes excess moisture. The analogues mentioned above act in the opposite way. They accumulate suspended particles of liquid, creating conditions for the formation and further growth of areas of all-consuming mold and encircling fungal plaque. Foam polystyrene, advertised in stores, does not allow moisture to pass through at all and provokes microclimate disturbances. Red non-sinking stone (expanded clay) is too airy. Air masses pass through it unhindered. The room becomes cold and people are forced to use oil heaters to keep warm. All this is a small part of the advantages of ecowool over identical insulation materials.

In concluding this paragraph, I would like to voice another significant advantage of ecowool over fiberglass and basalt. The higher the density of the insulator, the higher, accordingly, its weight per square or cube. This leads to an impressive list of requirements for load-bearing elements of a wooden structure. The average density of ecowool (from 35 to 65 kg/cube) exceeds basalt (50 kg/cube) and glass (20 kg/cube). Slightly more weight. This minor minus is more than compensated by the advantages mentioned above. As you can see, there are no significant differences in the numbers. But there are other competitive qualities, and the main property of this list is permeability to steam and moisture. This helps regulate moisture and improves the microclimate in residential, office, industrial and commercial premises.

Construction of houses

110 votes

+

Vote for!

—

Vote against!

Due to the inevitable deterioration of the environmental situation on the planet, both beginners and experienced craftsmen, when choosing thermal insulation materials, began to pay attention to products characterized not only by a high level of heat and sound insulation, as well as ease of installation, but also made from natural environmentally friendly materials. The possibility of self-installation is also valued by consumers, since in this case they get the opportunity to fully control each stage of applying the material, which will not only save money, but also, in case of any damage, fix it themselves. One of these materials is ecowool, which, despite the above characteristics, has not yet received due popularity, which leads to the fact that consumers often prefer foam plastic, already tested and tested by many builders, as well as mineral wool. We are confident that after reading this article, you will be convinced of the undeniable advantages of ecowool, as well as the simplicity of its application technique, which we will also talk about in this material.

Content

- Ecowool: structural composition and feasibility of use

- Main advantages of ecowool

- Disadvantages of ecowool: what did you not know about the material?

- Ecowool application methods: manual and automated

- Equipment for the automated method of applying ecowool

- How to insulate with ecowool: basic application methods

- Dry method of applying ecowool

- Wet installation method of ecowool

- Wet-adhesive method of applying ecowool

- Recommendations from experts on how to apply ecowool yourself

Ecowool: structural composition and feasibility of use

The lack of popularity of ecowool, associated with its recent appearance on the construction market, as well as the long absence of the necessary equipment for its application, is a completely fixable matter, since its undeniable advantages cannot go unnoticed. Thermal insulation material ecowool is characterized by a loose structure, 80% consisting of cellulose, which has the highest thermal insulation properties and excellent mechanical characteristics, due to which, after its application, a homogeneous layer is formed, devoid of seams and irregularities. But, despite its characteristics, cellulose is not used in construction work in its pure form, due to its high flammability. In the composition of ecowool, these properties of cellulose do not prevent its use, since in addition to cellulose, its structure includes a fire retardant, which is borax, and an antiseptic, boric acid. The use of these components in the structure of ecowool makes it absolutely fireproof and can be used for thermal insulation of boilers and chimneys. The use of boric acid helps prevent damage to the thermal insulation layer by rodents and insects, as well as the appearance of mold and mildew.

Important! Unlike ecowool, mineral wool does not contain boric acid, and therefore it is often damaged by rodents and insects.

Main advantages of ecowool

- Despite the fact that ecowool is practically unable to transmit wet steam and heat, it easily absorbs large amounts of moisture, and unlike mineral wool, this does not affect its thermal conductivity in any way. The thermal conductivity of the previous one, when the humidity level increases by at least 1%, increases accordingly by 8-9%. In this regard, you get the opportunity to use ecowool for insulation of wooden frame houses, where it will help maintain an optimal level of humidity;

- Due to the fact that ecowool is a homogeneous loose mass, if all the rules for its application are followed, a seamless layer with high thermal insulation characteristics is formed, while the formation of voids and cold bridges, which contribute to a decrease in thermal insulation characteristics, is completely eliminated;

- Ecowool, in comparison with mineral wool, has higher sound insulation characteristics and, unlike foam plastic, has higher elasticity, which also allows it to more effectively dampen any external sounds;

- Ecowool contains no substances harmful to human health. Absolutely safe lignin is used as an adhesive, while the antiseptic and fire retardant, which do not spray or evaporate, also do not pose any harm, which cannot be said about the commonly used polystyrene foam;

- Ecowool is a bulk material that, in the case of industrial installation, is pre-moistened. The material can be used without preliminary moistening; then ecowool is pumped into the frame using a compressor. Laying ecowool can also be done manually, which is the most labor-intensive and time-consuming method of application.

- Low chemical activity, due to which corrosion processes do not form at the points of contact between the heat-insulating coating and metal parts of fasteners or the building frame;

Important! Due to the random arrangement of cellulose fibers included in the ecowool structure, it eliminates shrinkage of the material in the case of vertical application. This contributes to the long-term preservation of the thermal insulation properties of the coating.

Disadvantages of ecowool: what did you not know about the material?

- Despite the fact that ecowool is an absolutely non-flammable material, it can smolder when exposed to high temperatures. In this regard, when insulating objects subject to heating, basalt or asbestos is additionally used;

- Application of ecowool is a process, the complexity of which depends on the method of its installation. To carry out installation activities correctly, sufficient experience and the use of specialized equipment will be required;

- During the process of insulation with ecowool, a large number of dust microparticles of cellulose and borax are formed;

- In the case of wet application of ecowool, subsequent installation activities can be carried out no earlier than a day later;

- And, perhaps, one of the most important disadvantages is the fairly high cost of ecowool insulation, which is several times higher than thermal insulation using traditional polystyrene foam and mineral wool.

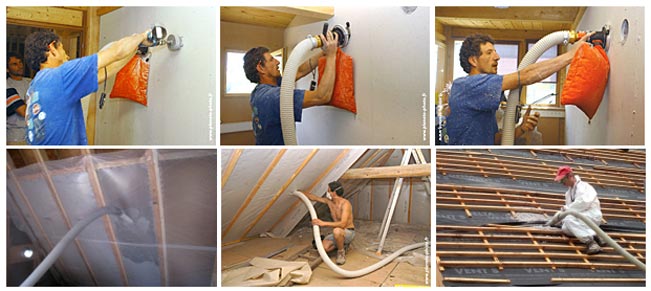

Ecowool application methods: manual and automated

Installation of ecowool can be carried out in several ways, each of which is intended to achieve different purposes and is characterized by its own advantages and disadvantages. One of the simplest ways to insulate ceilings and floors is to manually apply ecowool. Despite the fact that this method is characterized by a number of advantages, there is a more modern - semi-automated method, which involves applying the material using a sprayer.

The manual method involves performing the work in stages, the first of which consists of pouring the required mass of insulation into a container of a certain volume. You can use bulk boxes or a bucket as this container. Taking into account the fact that ecowool is supplied to the retail network in compressed form, the next stage of work consists of “fluffing” the material. To do this, you will need a drill or a specialized attachment for mixing paints and varnishes. It must be remembered that after this activity is completed, the volume of material will increase at least three times. Having carried out the above steps, experts recommend proceeding with the direct installation of ecowool, which involves filling it into vertically oriented structures or floor coverings. In the process of manual laying, it is important to know the packing density of the material for each insulated element, which is, first of all, determined by the material consumption. So, for example, in the case of insulating floors, the optimal density of insulation is 35-50 kg per cubic meter. In the case of wall insulation, the required material consumption is 60 kg per cubic meter, and for roof insulation - 50 kg per cubic meter.

Important! If you need to insulate houses with a large area or cottages, the manual method of installing ecowool is unsuitable for this, since in this case you will have to resort to the use of specialized blowing equipment.

Equipment for the automated method of applying ecowool

To install ecowool using an automated method, you will need the following equipment for applying ecowool:

- An automatic blowing installation equipped with a specialized agitator, with the help of which you can produce a more uniform supply of heat-insulating material to the place of its direct installation;

- Corrugated hoses, which will be used to supply insulation to the work site;

- Water-adhesive installation of ecowool involves the use of a set of specialized foams;

- Wet spraying is carried out using an additional kit;

- A more modern version of specialized equipment involves additional equipment with blowing nozzles and electric trimming rollers, which will be required to remove excess material.

How to insulate with ecowool: basic application methods

Answering the question: “How to insulate using ecowool?”, we consider it necessary to consider all the main methods of insulation using this thermal insulation material. If we talk about applying ecowool using specialized equipment, it is necessary to consider three installation methods, such as dry, wet and wet-adhesive installation of ecowool, each of which will be discussed in detail below.

Dry method of applying ecowool

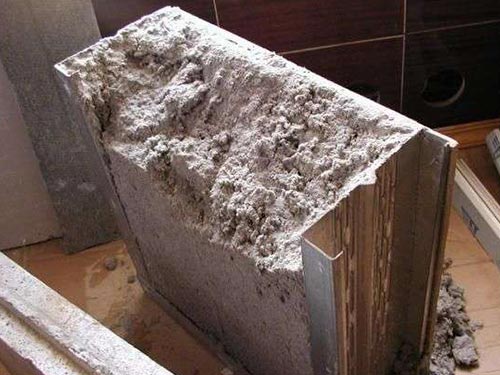

This method is especially relevant in the case of cellulose insulation of horizontal and inclined surfaces, as well as for carrying out installation activities in interfloor ceilings, and filling voids that represent closed spaces in the walls.

Installation of ecowool using the dry method looks like this:

The initial stage involves the organization of holes in confined spaces limited by membrane waterproofing, which will subsequently be filled with insulation. It is important to remember that the diameter of these holes must completely coincide with the diameter of the corrugated hose or spray nozzle, with the help of which the automated installation of the heat-insulating layer will be carried out. Subsequently, the newly installed hole is connected to a hose, which facilitates the flow of ecowool mixed with air to the place of its installation. The presence of air in the composition of the heat insulator contributes to its more efficient delivery to its destination, as well as to the maximum filling of the free space with ecowool particles with the subsequent formation of a durable cellulose plug. Free cavities are filled until they are filled with the required insulation density.

Applying insulation to surfaces located in a horizontal plane is done in a similar way, however, the only difference is that before applying ecowool there is no need to arrange preliminary insulation.

Wet installation method of ecowool

If you need to insulate vertical planes characterized by free access, wet application of ecowool will be the most optimal way to carry out thermal insulation measures. The fundamental difference of this method is that ecowool, pre-moistened with water, is applied to open surfaces that are freely accessible and limited by frame structures. Ecowool is moistened with the aim of maximizing the filling of the free space with insulation, which, due to the inclusion of lignin in the ecowool structure, which acquires stickiness upon contact with water, adheres tightly to the frame. If, after applying ecowool, you notice excess material clearly protruding above the frame, you need to resort to using an electric trimming roller, with which you can remove excess cellulose material.

Wet-adhesive method of applying ecowool

This method is in many ways similar to the previous one, but is characterized by one distinctive point, the essence of which is the addition of an adhesive substance to the structure of the heat-insulating mixture, which gives it a number of undeniable advantages. The most outstanding of them are the following advantages:

- Low probability of deformation of the cellulose material after it dries;

- Higher level of elasticity of the thermal insulation material;

- No harmful impurities in the material.

Applying ecowool using this method is most relevant in the case when it is necessary to insulate surfaces located in a horizontal plane and characterized by a lack of free access to their lower part. Typical examples of such structures are ceilings, structures located in a suspended position, as well as other thin-walled structures.

In the process of implementing thermal insulation by applying ecowool with your own hands, you can solve several installation and technological problems at once:

- Implementation of high-quality sound insulation;

- At the same time, you solve the problem of condensation in a room insulated with ecowool;

Recommendations from experts on how to apply ecowool yourself

- In order to correctly calculate the required number of ecowool packages, the weight of which is 15 kg, you can use online calculators on any construction site or make the necessary calculations yourself. To do this, it is necessary to multiply the area of the insulated surface by the technological consumption of material presented in our article;

- Experts recommend being guided by the following parameters. The recommended insulation thickness for the floor is 15-20 cm, for a pitched roof - 15-20 cm, for interfloor floors this parameter is 10-15 cm, for attic floors - 20-30 cm;

- When purchasing ecowool, do not forget that the consumption of thermal insulation material may exceed the calculated values by 10%, and therefore it is important to purchase material with a reserve;

- Initially, the characteristics of ecowool are such that it is intended for insulating wooden structures. In this case, it is applied directly to the surface, without the use of insulating materials. In the case of insulating surfaces made of metal, brick and concrete, before directly applying the insulation, it is necessary to “isolate” the ecowool from the surface being treated using an insulating material. This will prevent the formation of condensation in the room;

- During the installation of ecowool, it is important to take into account possible shrinkage of the material under the pressure of its own weight. This most often occurs in the case of insulation of high vertical cavities. To prevent this, horizontally oriented dividing partitions are installed in the insulated cavities during the installation of insulation, which help reduce the initial weight of the insulation;

- In case of roof insulation, it is also necessary to take measures to prevent the formation of sub-roof condensation.

Insulation of houses with ecowool

Thermal insulation of houses with ecowool involves applying the material wet or dry. In the first case, cotton wool is mixed with water, glass or PVA glue. The peculiarity of the wet method is that ecowool can be applied only in sunny weather with the lowest ambient humidity. The maximum layer is 50 millimeters or 5 centimeters. Why? Because it needs to dry. Drying takes at least 14 days and increases if unfavorable weather conditions contribute to this. Considering that our weather is unstable, it is better to use dry blowing, which is described in detail below. The process involves the operation of an American-made Accu1-9218 blowing compressor or a domestic equivalent, UralEkoMash.

In a container with an average capacity of 15-30 kilograms, the cotton wool is loosened, then through a special hose it fills the space between the walls, under the roof, and floor boards. Crushed cellulose penetrates into hard-to-reach places, retains heat, and eliminates the formation of cold bridges. However, ecowool alone will not work. To minimize the risk of heat leakage and dew point, you need to follow the technology that you will learn about in the upcoming sections.

Areas of use of the material

Ecowool is a universal insulation material, which allows it to be used for insulating country houses, private houses, multi-storey residential and public buildings, industrial buildings, for arranging warehouses and retail outlets, as thermal insulation for saunas, baths and swimming pools. Due to its excellent soundproofing properties, this material is used in the arrangement of acoustic rooms and recording studios.

When insulating the walls of a house, dry and wet installation methods can be used. The attic, floors and roof are insulated using manual dry installation of insulation. To reduce heat loss in the attic, two methods of thermal insulation can be used: dry blowing of the walls with special equipment and manual laying of the material on the floor.

Dry plaster mixtures can be made on the basis of ecowool, which can be used to treat concrete, brick and gas silicate walls to improve their sound and heat insulation characteristics.

Thermal frame or how to prepare walls for insulation

Thermal frame system is an innovative technology for preparing walls for thermal insulation with dry cellulose. Includes installation of 200 grams per cubic centimeter engineering plastic retaining mesh. For better distribution of the material, it is necessary to ensure the release of excess air during blowing. The breathable membrane Izospan AM copes with this task perfectly. Installation of horizontal jumpers or slats made of wood at a distance of one to one and a half meters. Let’s say the ceiling height is three meters. Accordingly, it will take two or three cutoffs, maximum, to cover from the bottom to the top point.

The combination of a mesh and a diffusion membrane allows you to achieve the effect of pre. tension. When ecowool comes inside, the air leaves through the pores and is removed, the material remains and forms an elastic, springy pillow without seams or joints. Without these components, it is impossible to obtain an insulation density of 65 kilograms per cubic meter. You can read about the hidden capabilities and advantages of plastic mesh in a separate article on the website by left-clicking on the corresponding link. Now let’s look at the step-by-step preparation of a heating frame for insulating a frame house with ecowool.

First step

It all starts with sealing seams and joints. Craftsmen close them up manually using mineral wool or flax wool. Everything can be broken through with an ordinary chisel and hammer. The result is a tight seam under the heating frame. Some inexperienced builders use polyurethane foam, but it does not provide the necessary sealing.

Second

Upon completion of the above-mentioned manipulations, workers set cutoffs from the section board to 100 millimeters. Jumpers are placed every 1.5 meters when the ceiling height exceeds three meters. They support the cellulose in the space between the post beams of a frame house and prevent it from shrinking.

Third

At the 3rd stage of preparation, the master stretches the vapor-permeable membrane of the popular brand “Izospan” and secures it with an industrial stapler. The tension is done from bottom to top with an overlap. The bottom layer is laid first, then the top layer. The reference point is the red dotted line.

Fourth

The penultimate part of the preparatory work is stretching a plastic retaining mesh with a density of 200-250 g/cm3. It is laid on top of the membrane with an overlap of 20 centimeters and secured with the same stapler. It is imperative to leave a small splash on top of the counter bar - 3-5 centimeters.

Fifth

The final stage involves the installation of a counter block of natural humidity with a cross-section of 100-25 millimeters along the racks of the heating frame. It is advisable to mount the beams not with black, but with yellow screw-in hardware. This minimizes the risk of caps being torn off during the process of blowing ecowool into the prepared space. Want to know more? Watch the video.

Insulation of double timber

The fundamental feature of insulating houses made of double timber is solidity. The building material is filled with ecowool without a membrane or vapor barrier film. Blowing is carried out in stages, floor by floor. Craftsmen blow through the first part, then the second if the house is two-story. Cellulose enters the cavities through a special hose without a needle-shaped nozzle of standard density - 65 kilograms per cubic meter. As noted above, only ecowool can be used for thermal insulation of houses made of double timber. Other options are not provided and, as usual, are not considered. Why? It is simply impossible to lay rectangular mineral wool mats between the elements of a house kit.

When insulating a wooden structure with ecowool, there is no conflict between building materials, because what environmental insulation is is crushed cellulose obtained by processing wood. A dense ecowool cushion creates a vapor-permeable, breathing system inside the wooden block, which perfectly retains heat in any frost typical of the harsh Russian climate. It is not without reason that this type of insulation was first used by residents of the Finnish Republic, where environmental conditions are characterized by frequent winds, high humidity and other problems of this kind. A house made of double timber, clad in a fur coat of ecowool, is many times warmer than an identical structure made of rounded logs or bricks.

Insulation of brick houses

The process of thermal insulation of an eco-wool brick building is slightly different from what happens in relation to structures made of logs or timber. Since a building made of red or sand-lime brick does not have a frame base, ecowool fills the voids between the load-bearing wall and the facing building material. The master drills a hole from the outside of the masonry and inserts a metal needle connected to a 30-meter hose into it. The operator turns on the machine and, on command, supplies pulp under high pressure from the bottom up. The same blow-in holes are made in other places. They are drilled at a distance of one to one and a half meters.

The density of the ecowool thermal insulation cushion is 65 kilograms per cubic meter. The work is being carried out using the Accu1-9218 USA installation with a needle. Wealthy consumers are trying to insulate a brick house on their own and use an industrial vacuum cleaner instead of a blower compressor. A gross violation of technology leads to uneven distribution of cellulose throughout the internal space and, as a result, results in heat loss in winter. Experts categorically do not advise taking steps to insulate a brick house with your own hands.

Roof insulation with ecowool

Looking ahead, we note that the thermal insulation of the roof space is an attic or a cold attic. In the first case, we use a super diffusion membrane and a retaining mesh with a breaking density of 200 grams per square centimeter. We pump insulation with a density of 65 kilograms per cubic meter into the resulting cavity. In the second case, the horizons - the ceiling of the 1st or 2nd floor - are subject to insulation. When working with horizontal planes, the density of cellulose insulation will be 35 kilograms per cubic meter. As you can see, the technology is somewhat different. If in the first option, ecowool is injected into the cavity, then in the second situation, the cotton wool lies in a swollen mass, filling the cracks and joints.

The thermal insulation layer of the floor is from 15 to 20 centimeters, a kind of standard that operates in the Moscow region. Cellulose is poured by blowing through a 35-kilogram unit. The installer holds the hose and distributes the crushed cellulose into the existing cavities between the joists without additional compaction. When the stage is completed, the craftsmen lay the membrane on top. Vapor barriers are not used in the upper parts of the house. Moisture from the room passes through the insulation and exits through the membrane into the under-roof space or into the cold attic area. From there, the moist air escapes through the openings of the ventilation system.

Disadvantages of ecowool

Today there are practically no building materials that do not have negative reviews and shortcomings. For cellulose wool they are:

- Despite the excellent thermal insulation qualities, the material tends to lose them. To be fair, it must be said that this does not happen very quickly;

- for installation work, it is better to use special equipment, which makes it possible to achieve the required density of the insulating material;

- installation work must be carried out by a highly qualified specialist. Ecowool is considered a rather “capricious” material and the quality of installation will depend on the experience of the craftsman;

- When installing wool using a dry method, a large amount of cellulose dust is generated, and the work must be carried out in special protective suits and respirators. The wet method does not have this disadvantage, however, conditions are required for the treated surface to dry - a temperature of at least 15°C, drying time ranges from 48 to 72 hours, and sometimes more. However, preference should still be given to the wet installation method, since in this case good heat and sound insulation can be achieved;

- unlike expanded polystyrene, cellulose wool does not have such rigidity, which makes it impossible to install it in a frameless manner;

- when processing vertical surfaces, you must use at least 65 kg per cubic meter, otherwise the coating density will be insufficient, and voids may occur during shrinkage of the material;

- It is not recommended to use ecowool near open fire or very hot surfaces. Stoves, fireplaces, and chimneys cannot be insulated or insulated using such material, as there is a risk of slow smoldering of the insulation.

It should be noted that almost all insulating materials have similar disadvantages. But synthetic ones are not particularly safe, since they contain various chemical compounds that can cause allergic reactions.

Cost of ecowool compared to mineral wool

In many ways, the cost of insulation depends on the policy pursued by the manufacturer. There are a great variety of firms and companies involved in the production of mineral water and stone wool, from budget-class products to premium-level products. If you analyze the market and go into detail, you can come to the conclusion that mineral wool paroc (Paroc) is the main, only competitor of environmentally friendly insulation. In practice it looks like this. Based on the classic insulation density of 50/50/30 kilograms - walls, roofing, floors. With an adequate comparison of these two insulation materials, you can achieve savings equal to 30 percent and this, mind you, is a minimum.

When laying mineral wool on wall panels, no special preparation is required. It is enough to insert the mats into the frame base, cover it with a vapor barrier membrane and sew it up with clean construction and finishing material. Before insulating a house with ecowool, careful preparation must be carried out. Due to the complex technological process involving the injection of wool under high pressure, the structure is at risk. To preserve it, we are building a thermal frame system, including a membrane and mesh - products that cost money. This is much more difficult than working with mineral wool mats, so the price for the work is added to the cost of ecowool insulation.

Accordingly, if we take into account all the preparatory work on ecowool, we will get 100 percent of the cost of insulating a house with mineral wool. What is the advantage of ecowool over mineral water, which results in the same price? Despite the fact that we announced the advantages to you earlier, let us remind you of the main advantage - solidity, as well as vapor permeability, seamless installation, and the absence of the human factor during installation.

Advantages of using ecowool

It’s worth listing the advantages in order to understand in what “special” cases this insulation is simply irreplaceable:

- High thermal insulation properties - this is the defining property of ecowool for insulation and deserves to be designated as a plus and a minus at the same time. The fact is that the initially high thermal conductivity of ecowool can be affected by installation and operating conditions, which will be more convenient to consider when talking about the disadvantages of insulation.

- Solidity of the insulating layer - with proper installation, an even layer of insulation, without seams and voids, is achieved; ecowool fibers fill the smallest cracks.

- High level of noise absorption - the insulation not only perfectly absorbs sound, but also does not allow it to penetrate through gaps, which simply cannot exist in a layer of ecowool. This material is a godsend if the house is operated in an aggressive sound environment.

- Breathable properties and moisture resistance - these properties are due to the vapor permeability and structure of the fibers of this insulation. The material absorbs excess moisture from the air in the room, and then, if ventilation is provided, it is able to release this moisture back without losing its insulating properties. In fact, ecowool simultaneously with insulation also functions as a vapor barrier.

- Eco-safety - thermal insulation does not harm the environment and humans, both during production and during installation and subsequent operation.

- Resistance to biodegradation - antiseptic additives do not allow the material to rot or mold even with a high degree of humidity and make the insulation unattractive to rodents and insects; such “neighbors” also cannot move and live inside a properly applied insulation layer.

- Fire safety - the material does not ignite or even melt, it can only smolder in the presence of a continuous source of strong heat; it does not emit toxic substances. If, for example, a roof or wall is insulated with ecowool, then fire will penetrate through the insulation for a very long time.

- Durability is considered as the totality of the integrity of a) the structure of the insulation and b) the “warm” layer made from it. The material itself, as already mentioned, is bioresistant, and when installed with a reserve and ventilation, shrinkage and caking will not occur. At the moment, in Europe there is experience in the successful operation of ecowool for 70 years.

- Cost-effectiveness - achieved due to the relatively low density of insulation, acceptable cost and lightweight, and therefore cheaper capital structures.

- Fast and safe installation - insulating a house with ecowool using a mechanized installation method can be done in 1-2 days, depending on the area, not taking into account the drying time of the insulation. The requirements for personal protective equipment are not as stringent as, for example, when working with mineral wool.

How to insulate the front door?

Here it would be appropriate to mention the main areas of application of ecowool:

- roofs, attic and attic floors;

- interior partitions, floor, ceiling;

- filling cavities during the construction of well masonry or box-shaped structures - the wall practically consists of ecowool, on both sides of the insulation - brick lining;

- insulation of external walls - log, foam concrete, aerated concrete, frame;

- correction of deficiencies of the previous thermal insulation without complete dismantling.

By the way, in the process of insulation with ecowool, virtually no waste is generated, and this insulation can be reused without any additional processing.

Thus, ecowool can be called an almost universal insulation material. All that remains is to find out why “almost”?