The building's engineering systems require maintenance and repair. Today we will get acquainted with malfunctions that you can fix yourself

The topic of this article is current and emergency repairs of heating and water supply systems. We are going to tell the reader about some of the typical malfunctions that the owner of an apartment or private house may encounter, and suggest ways to fix the breakdown in each specific case. The article will be structured in the form of answers to frequently asked questions. Let's get started.

Air jams

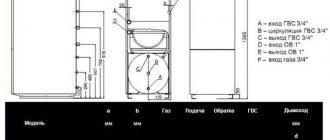

What should you do if in a house with a top fill (supply routed through the attic and return in the basement or subfloor) all the risers remain cold after turning on the heating?

Bleed air through the expansion tank vent. When heating is poured from above, it is always located in the attic, at the top point of the supply line laid with a slope.

Expansion tank with vent in the attic of a house with a top-fill heating system

How to start an airy riser in a lower bottling house (a heating scheme in which the supply and return are separated in the basement, and the heating risers are connected in pairs)?

The problem can be solved in one of two ways:

| Image | Description |

| If there is access to an apartment on the top floor, the air is vented through the Mayevsky tap located in it. Some types of vents require a key (flat, triangular, etc.), and some are opened with a screwdriver or pliers. |

| Sometimes the risers can be bypassed from the basement - provided that one of them is single (without heating devices) and is equipped with a dump instead of a plug. To expel the air lock, it is enough to close this riser and completely open the discharge on it. The air will fly out at the front of the water flow. |

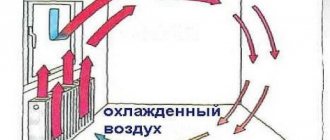

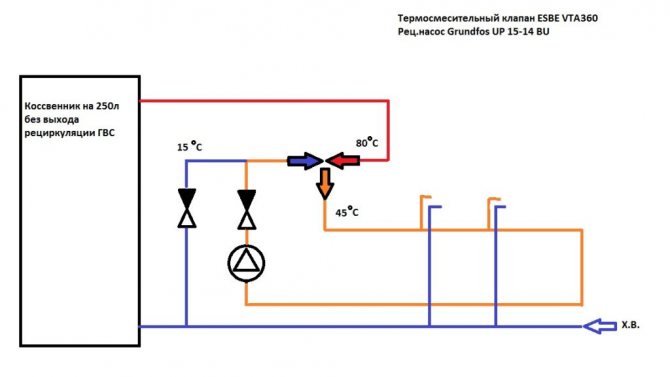

Why can a DHW system with recirculation make noise during normal operation?

Air in the water supply system of a private home is the cause of hydraulic noise. The circulation pump forces water through the air lock, but cannot expel air from the top point of the hot water supply. The problem is solved by installing an automatic air vent or a Mayevsky tap at the place where the plug forms.

One of the possible DHW schemes with recirculation. An air vent is needed at the top point of the circuit

Why don’t heated towel rails heat up in a house with a hot water circulation system?

The reason is the same - there is air in the jumper between the paired hot water risers. To drive it out, shut off one of the risers and open one or two hot water taps on the mixers along this riser to full capacity. Air will be forced through them.

In modern homes, heated towel rails heat up when water circulates in the hot water risers

Captain Obvious reminds: do not forget to open the valve in the basement after bypassing the risers.

The video in this article will help you learn more about how the water supply works in a high-rise building.

Replacing a water valve

To replace a valve in the water supply system of an apartment or other residential premises, it is necessary to shut off the water supply.

If you are replacing a faucet that is part of the wiring in the apartment, for example a toilet faucet or a washing machine, then you can turn off the faucet located on the riser.

How to turn off the water supply to an apartment

If it is necessary to replace the tap located on the riser, then the water supply must be turned off in the basement of the house. To do this, you will need the help of an employee of the management company or housing office.

Preparing for replacement

At the first stage you need to prepare:

- new valve;

It is more advisable to select a new valve in full accordance with the old device. Parameters such as valve diameter, capacity, diameter and thread pitch must match.

- two adjustable wrenches or wrenches. When selecting wrenches, it is important to choose the correct size (in accordance with the size of the fixing nuts);

- sealing material. For water, FUM tape or Tangit Unilok thread is most often used.

Thread sealing tape

Replacement procedure

Replacing the valve on the riser or water supply distribution is carried out according to the following scheme:

- after shutting off the water supply, it is necessary to open all the taps in order to drain the remaining liquid from the pipes;

- the old valve is dismantled:

- if the tap is installed on a threaded connection, then using wrenches it is necessary to loosen the fixing nuts;

- if a valve with a flange connection is installed, then to remove the device it is necessary to loosen the bolts securing the mounting flanges;

- if the faucet is soldered into pipes, then during replacement you will need additional equipment for cutting pipes, since it will not be possible to dismantle the faucet in any other way;

Plastic pipe cutting tool

- the pipes at the valve installation site are cleaned of various types of contaminants;

- a new locking device is installed:

- if the threaded method is used during installation, then before installing the tap it is necessary to seal the thread;

How to wrap sealing tape around a thread

FUM tape or Tangit Unilok thread is wound clockwise. To seal with tape, it is enough to apply 3 – 5 turns. To seal, the entire thread is covered with thread.

- if a flanged valve is mounted, then additional sealing is not required;

- the welded valve is installed using a special apparatus for soldering pipes;

Installation of valve by welding

- The tightness of the resulting connections is checked.

How to replace a tap installed on a thread, watch the video.

Radiators

What problems can you expect from heating devices?

Leaks

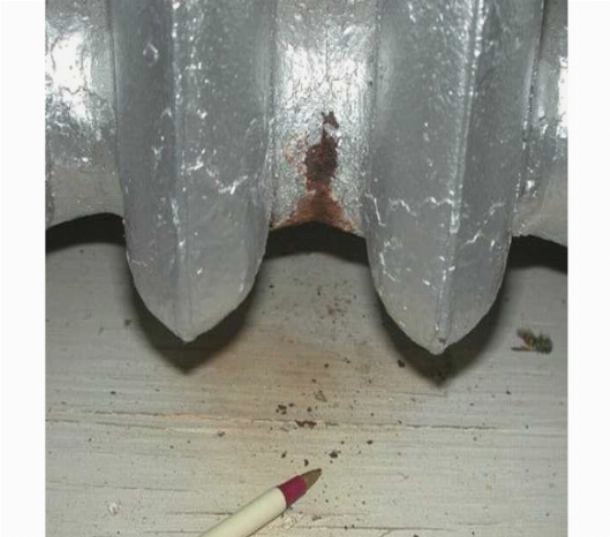

Why do cast iron radiators leak at the joints between sections and how can you fix the leaks with your own hands?

The reason is in paronite (made from hard heat-resistant rubber) intersectional gaskets. With each heating and cooling cycle of adjacent sections, they compress the gasket and relieve pressure on it.

As a result, sooner or later, with the next drop in temperature, the paronite gasket, which has lost its elasticity, ceases to block the gap between the sections, and the connection begins to leak.

Leaking between sections is a common problem with Soviet-style cast iron radiators

Please note: modern aluminum and bimetallic sectional devices suffer from leaks between sections much less often due to better gaskets. Even despite the coefficient of expansion of aluminum when heated, which is twice as high as that of cast iron.

A radical solution is to overhaul the heating device and replace the problematic gaskets. It is better to replace them with rubber ones (purchased or cut from an old car inner tube) or silicone ones (their heating life lasts for decades).

Sectional radiator bulkhead with replacement of gaskets

As a temporary solution, you can simply reset the riser with problematic batteries in the summer: when the heating starts in the fall and the accompanying heating, the sections will expand, compress the gasket, and the leak will stop.

However: resetting the heating circuit laid with a black steel pipe for the summer will significantly reduce the service life of the latter. When in contact with moist air, corrosion of the walls of the pipes and riser will be much more active than when in contact with water.

Siltation

Why don’t the sections of the radiator farthest from the connections heat up? The reason is banal silting of the sections. Sludge (suspension contained in process water) settles in areas of the circuit with a minimum flow velocity.

Cast iron sections with their large volume and, accordingly, slow water circulation are the first candidate for collecting sediment, but all batteries suffer from silting to one degree or another.

Sludge in the outer sections of a cast iron battery

How to deal with overgrowing of heating devices:

- Hydropneumatic flushing of the central heating system should be performed once a year. To do this, an air compressor is connected to the circuit, and the heating is discharged into the sewer. A mixture of water with air bubbles effectively breaks up silt deposits and carries them away through the dump;

Annual hydropneumatic flushing of the central heating system

- A separate radiator can be flushed through the so-called flushing valve - a valve embedded in the lower blind radiator plug. A regular garden hose is connected to it, directed to the street or to the sewer, after which the water from the heating system is discharged within a few minutes, taking with it deposits of silt;

- A radical solution to the problem of battery silting is to connect it according to the “bottom-down” scheme. In this case, the main volume of water circulates through the lower collector of the battery, preventing sludge from settling in it. The top of the sections is heated due to their thermal conductivity.

With this connection, the battery will always heat along its entire length

Uneven heating

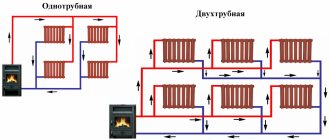

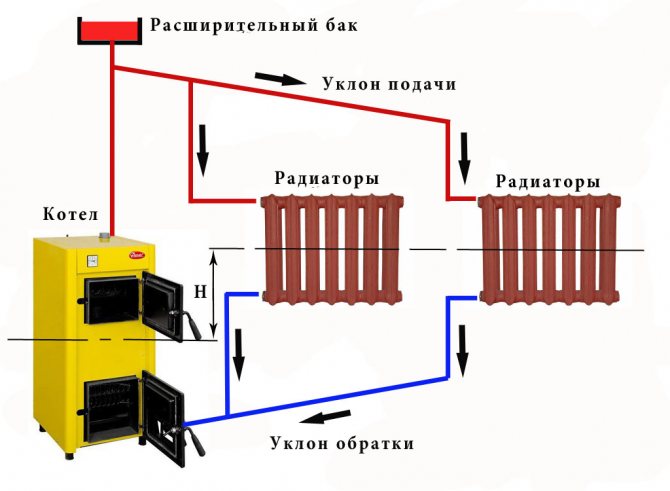

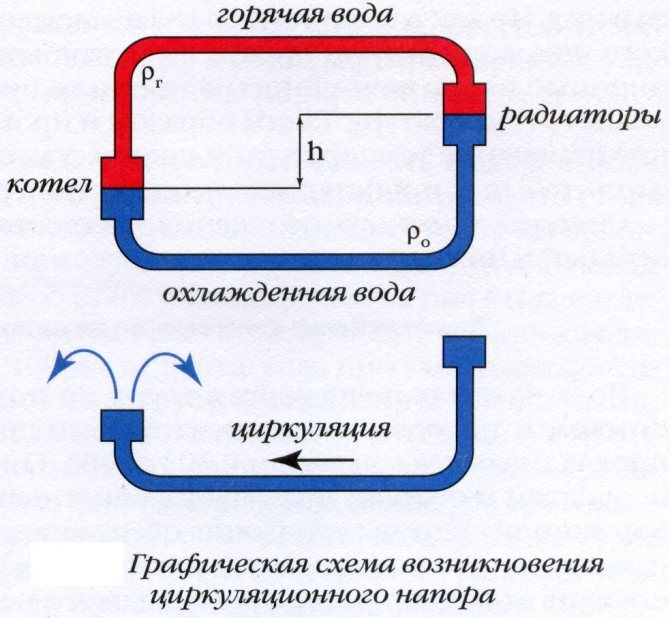

Is it possible to solve the problem of low temperature of batteries far from the boiler or other heat source in an autonomous heating circuit? The problem is typical of natural circulation systems, in which the coolant is driven only by the difference in density between the hot and cold media.

Schematic diagram of a gravity heating system

The reason for the temperature spread in this circuit is chalk circulation caused by:

- Long filling length;

- A slight difference in height between the boiler heat exchanger and heating devices;

The coolant drives the difference in height between areas with the same temperature in the boiler heat exchanger and in the heating devices

- Reduced filling diameter.

Seven troubles - one answer: electric circulation pumps can speed up the circulation of coolant in any case. The pump runs parallel to the filling; A ball valve or, which is much more reasonable, a ball check valve is mounted between the taps (unlike a spring valve, it operates with a minimum pressure difference).

Pump insert with ball check valve on bypass

How does this scheme work:

- In normal mode, the pump circulates water through the bottling system. The bypass between the taps is closed by a tripped check valve or a manually closed tap;

- As soon as the power supply stops (power outages are not uncommon in country houses), the circuit instantly switches to natural circulation mode. To do this, just open the bypass tap. If there is a check valve on it, the circuit’s operating mode will be switched without owner intervention, in a fully automatic mode.

And two more valves

Obviously, you need a valve to drain water from the system and a valve to let water into the system. Moreover, the second one will probably be part of the water supply system, not the heating system. This is described in more detail in the article about filling the heating system with water. Water can be drained through the emergency valve. He allows for discovery. But it’s better not to hope for this, because the stream of water through the open emergency valve is quite thin and draining will take a very long time and be very tedious. In addition, in this case the valve must be located strictly at the lowest point of the system, and this can be inconvenient.

valve

Screw valves are typical for apartment buildings and private buildings built in the 80s and earlier years of the last century. This design, which has become obsolete since the advent of ball valves, can present the owner with a number of unpleasant surprises. Fortunately, most problems are relatively easy to fix.

Old screw valves in the basement of an apartment building

Why doesn't the screw valve turn off the water?

Here are three main reasons:

- Wear or destruction of the rubber or paronite gasket on the valve. It is replaced with a new one, factory-made or cut from a car camera. To replace, the pipeline on which the valve is installed must be completely removed;

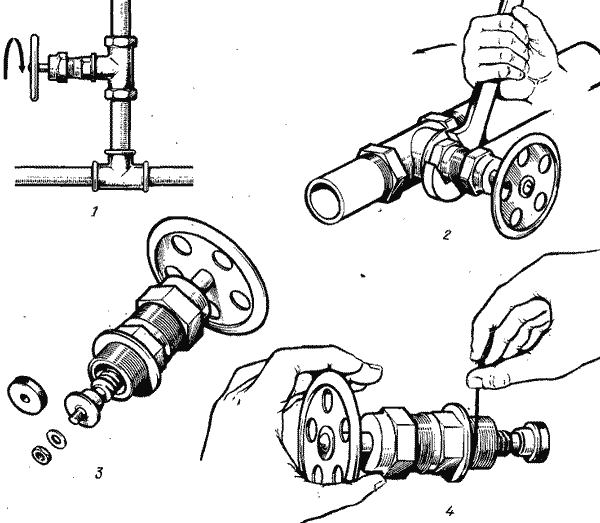

Replacing the screw valve gasket

- Valve destruction. This is typical for cast iron valves. In this case, heating and water supply repairs come down to replacing the valve head. The donor can be the same valve purchased at a plumbing store;

- Broken thread on the valve stem or head. And in this case, it is easier to replace the head of the shut-off valve element, rather than the entire body.

The valve head can be changed without replacing the body

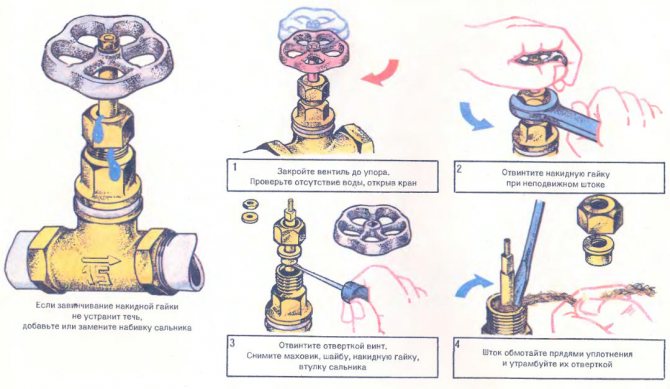

How to eliminate a leak on a screw valve stem?

It occurs due to partial depletion of the omentum. The simplest instructions will help solve the problem: open the valve all the way. In this case, the thread of the rod with the help of a thrust washer will tighten the oil seal, and the leak will stop.

However: when the stuffing box is completely worn out, it will have to be refilled. To do this, you need to drain the pipeline after the valve (the direction of water flow is indicated by an arrow on the body), unscrew the union nut on the rod and pry off the gland with a screwdriver. The graphite oil seal is sealed with a screwdriver after laying each turn.

Sequence of packing the stuffing box on a screw valve

Advice from professionals

When installing a heating system in a house or apartment, shut-off and control valves are installed. Craftsmen install various taps on heating radiators.

Of all the designs, the most practical is considered to be a product with an “American” type connection, equipped with union nuts. In addition, cranes of this type can be used repeatedly, which confirms their high reliability and durability.

Let's consider the sequence of replacing a faucet in a bathroom or kitchen with your own hands. After you have purchased a new faucet, proceed to install it:

- Shut off the water supply using ball valves or riser valves.

- Remove the old faucet.

- Clean the threads on the pipes and wrap flax tow around it clockwise, coating it with a special sealant.

- Screw on the new faucet, making sure the nuts are evenly tightened.

- Turn on the water and see if there are any leaks. If necessary, tighten the nuts.

Water dripping from a tap is a bad omen, which is considered a sign that the owner’s wallet is empty. Watch a short video that shows the process of doing the faucet repair work yourself.

In any residential premises, several valves are installed to enable emergency shutdown of the supply. Valves are present on plumbing, heating and gas systems. The valve of any system can be replaced independently or with the help of specialists. Read on to learn how to do the work yourself.

Fittings for various pipelines

Ice jams

Why can pipes freeze inside a house?

Building engineering systems freeze in two cases:

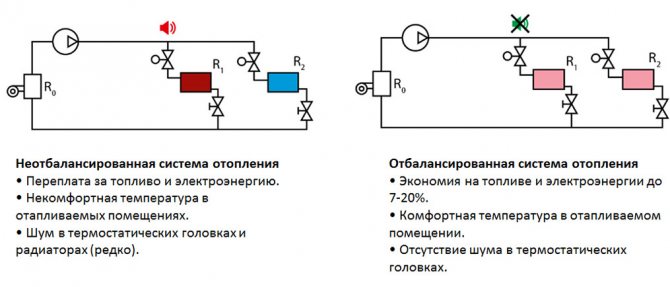

- In case of gross errors in heating design. A typical example that the author encountered first-hand is a two-pipe system without balancing: with the onset of cold weather, the heating registers farthest from the elevator unit froze and were torn by ice;

A two-pipe dead-end heating system requires mandatory balancing - limiting the permeability of the connections of the devices closest to the boiler

- During a long shutdown of the heating system, which is not accompanied by a complete discharge of water from the circuits.

Captain Obvious suggests: if the temperature in a building for any reason can drop below zero, its engineering systems - heating and water supply - must not only be turned off, but completely drained. To do this, you need to drain the water from the spills and all the brackets, and also open the vents or vents at the top of each circuit to allow it to suck in air and prevent water from hanging in the pipes.

To drain your water supply, open all faucets and allow the pipes to suck in air.

How to defrost the water supply system in a private house if it is made of metal pipes?

The easiest way to warm steel, copper and stainless steel pipes that are stuck by ice in certain areas is with a blowtorch or a hair dryer. Before heating the connections or pouring, open the taps on the nearby mixer: the pressure difference in the water supply will help you break up the partially melted ice plug.

A small section of the water supply can be heated even with a regular hair dryer.

Please note: if the pipes are frozen along their entire length or if the water supply is laid with plastic (or, alternatively, metal-polymer) pipes, attempts to warm them with a local heat source are doomed to failure. In this case, you need to heat the entire room. The heat source can be not only a standard heating system, but also an electric heater or a gas heat gun.

Is heating defrosted in the same way as water supply?

Precisely. Short sections of metal connections and spills can be heated with blowtorches by opening the vent or vent; Heating systems - water supply systems made of polypropylene or metal-plastic are thawed entirely by heating the room with an external heat source.

A heat gun will help you quickly warm up a frozen house

Installing a tap on a radiator

Currently, apartment owners are massively carrying out repairs and reconstruction of heating systems in their apartments. Installing shut-off valves, at least a tap on a heating radiator, becomes necessary for all users. The fittings used for the normal operation of the heating device consist of various devices:

• a straight-through ball valve (faucet), which has two threaded fittings (sometimes tapered) and a union nut, called “American,” allows you to turn off the heating radiator and dismantle it;

• radiator thermostat, which allows you to create comfort in the room and saves heating costs;

• a special valve for removing air from the radiator (Mayevsky valve);

• end caps.

These complex, modern and sometimes expensive devices must be installed by reliable hands, controlled by a competent and sober head. If you hire crooks and instruct them to install a tap on the battery, expect problems in the near future.

Most likely, you will be installed with a stolen 30-year-old BU cast iron valve, which was “rebuilt” by local “masters” from the housing and communal services sector. Many words will be said, and the valve will go down in three months, but you will no longer find these would-be masters, and you will not recover from them.

Summer is the best time to inspect the entire heating system in your apartment or office. It becomes possible, without much hassle, not only to install a faucet on the heating radiator (a modern butterfly valve), but also to replace pieces of pipes, weld radiators, in a word, prepare for winter.

Leaks

How to eliminate a leak on a smooth section of a steel pipe?

If the fistula is small, apply a bandage made of an aluminum clamp and a rubber gasket, after first cleaning the surface of the pipe from rust and paint.

Installing a bandage on a fistula in a water supply riser

If an electric-welded pipe leaks along a longitudinal seam, alas, the problem can only be solved by welding or replacing a section of the water pipeline.

By the way: a section of a steel pipeline at a bend can be replaced with compression fittings, without involving welding and threading. The fitting design ensures that the connection is sealed with a rubber seal when the union nut is tightened.

Compression fitting for steel pipe

How to fix a leak in the exhaust? In the vast majority of cases, the cause of the leak is the destruction (burnout, rotting) of the winding between the locknut and the coupling or other threaded fitting.

A typical place for a leak is the hose on the radiator line

To rewind the connection, you need to:

- Turn off the water and make sure there is no excess pressure in the pipeline. It is not necessary to reset it completely;

- Loosen the locknut 3-4 turns;

- Remove the remnants of the old winding;

- Apply a new winding;

Rewinding the squeegee with sanitary flax

Tip: rewind the threads with thread sealant (for example, Tangit Unilok) or plumbing flax impregnated with paint or silicone. Such winding will last much longer than pure flax, which is afraid of dampness and high temperatures.

Linen impregnated with paint lasts several times longer than organic fiber without impregnation.

- Tighten the locknut with moderate torque.

Why do connections of metal-plastic pipes with compression fittings leak in hot water supply and heating systems?

The reason is due to incorrect assembly of the connections. For homemade installation, the pipe is cut with a hacksaw and pulled onto the fitting without removing the internal chamfer or calibration. As a result, it tears off the sealing rings on the fitting that are responsible for sealing, and when the union nut is tightened, it compresses the fitting with its inner shell.

Compression fitting for metal-plastic: a rubber O-ring on the fitting is responsible for sealing the connection

Further occurrence of a leak is a matter of time: cyclic heating of the connection, accompanied by expansion of the parts, gradually squeezes the plastic out of the gap between the fitting and the pipe core.

Repairing a water supply and heating system made of metal-plastic pipes comes down to rebuilding all connections. Pipes are calibrated with mandatory removal of the internal chamfer; O-rings are installed in standard grooves and, if necessary, replaced with new ones.

The photo shows pipe calibration with simultaneous removal of the internal chamfer

Tip: when assembling the connection, it is advisable to apply a little neutral lubricant to the fitting - silicone or ordinary liquid soap.

Lubricant will help you assemble the connection without moving the O-rings on the fitting