Covering stoves and fireplaces with tiles is an ancient tradition that is gradually gaining lost ground. Not only Russian, Ukrainian and Belarusian, but also foreign manufacturers of tiles entered the market. Old recipes are being revived and new ones are being created.

However, making tiles is still a very labor-intensive process, most of which is done by the hands of a craftsman. That is why each fireplace and stove tile is a unique piece. As a single product, it has a high cost, which discourages most domestic consumers.

DIY tiles for stoves and fireplaces

How to make tiles with your own hands

A master class on making tiles will be of interest to those who decided to take on the task on their own. The work is not difficult, but painstaking and very exciting. Knowing the nuances of each operation will help you avoid disappointment and get a quality product.

Preparation for work includes: purchasing gypsum putty for making a mold and special clay for the product. Equipment you will need are knives or stacks and a muffle furnace for firing. Step-by-step instructions that will allow you to make a tile in accordance with the traditions of Russian craftsmen will not be superfluous.

How to tile a stove with your own hands

Decorating with tiles seems complicated. In fact, that's how it is. In the old days, two craftsmen were invited to lay tiles: a stove maker and a tiler. By doing the work at the same time, they created a beautiful and functional heating structure. Today, thanks to the fact that technology has stepped forward, it has become possible to finish the stove with tiles with your own hands.

Let us note right away that the work time from the moment the decision is made, development and approval of the stove/fireplace project to tiling is 3-4 months. And until the first full heating of the furnace is still 1 month.

Plus, a person who decides to make the cladding himself will be forced to play several roles: artist, designer, architect, ceramist and stove maker.

But, as they say, if there is a desire, step-by-step instructions for installing the tiles are attached.

Tiling - planning

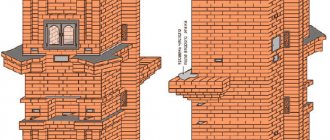

Tiled stoves are a specific type of firebox arrangement. Its peculiarity is that construction and cladding are carried out simultaneously (classic method). There is also a modern one, for those who want to cover an already working (old) stove or fireplace.

Thus, first, let's consider the first option - simultaneous construction and lining of the stove with tiles. As a rule, two specialists perform such work at once - a stove maker and a tiler.

Related article: What color to choose wallpaper for the kitchen: designer tips

Based on the essence of the stage, we can conclude that the decision to cover the stove with tiles is made simultaneously with the idea of building it. Considering that the weight of the tile is quite large (2 kg), due to its greater thickness compared to ceramic tiles, as well as due to the installation method, the stove needs to be provided with a powerful base - the foundation. Its area should be slightly larger than the planned size of the stove or fireplace. This will allow the structure to stand firmly and support the weight of the tiles without distortion. When choosing the type of foundation, it is better to give preference to a slab foundation, and its thickness will be determined by the weight of the future furnace.

Types of tiles

Fired clay tiles are distinguished by shape: they are flat (wall, straight), corner, shaped (cornice). Flat tiles, which have one flat front edge, are used to cover the side and front panels in places where there are no bends or turns.

At the corners, corner tiles are installed, in which two flat front faces are placed at an angle to each other.

For cladding cornices and ledges, as well as for artificially creating various decorative elements for finishing fireplaces, shaped tiles are used, the shape of which can be very different.

Based on the structure of the front surface, smooth and embossed tiles are distinguished; based on the type of finishing, majolica (glazed) and terracotta (unglazed) are distinguished. Very often, majolica tiles are decorated with paintings, relief patterns and bas-relief images.

What distinguishes tiles from ordinary ceramic tiles is the presence of an open box on the reverse side - a rumpa. Its purpose is to attach the tile to the surface of the fireplace or stove. In addition, massive pumps filled with a clay-based solution accumulate heat and increase the efficiency of the heating device.

Features of cladding

The front side of the tiles is similar to ceramic tiles, but on the back side it has a special protrusion (rumpu), reminiscent of a box. This configuration allows you to attach the tiles in a hinged way: using rods and wires, which are fixed in the holes of the tiller. The technology ensures the stability of this tile, regardless of temperature changes.

Advantages of tiled cladding:

- maximum heat transfer occurs from the fireplace to the room;

- good heat resistance gives the material strength and durability;

- Heat transfer occurs evenly over the entire area of the fireplace body and continues for a long time after the end of the firebox.

The latter characteristic is ensured by a thicker layer of tiles compared to, for example, ceramic tiles. It also makes the fireplace or stove more economical, allowing you to reduce the operating time of the firebox and, therefore, spend less fuel.

How to lay tiles on the surface of a stove or fireplace?

Already at the design stage of a heating fireplace or stove, you should decide on the advisability of using tiles in its cladding. The fact is that the total mass of these ceramic tiles, together with the protruding ramps and the clay mortar filling them, is quite high. Therefore, the entire plane of the fireplace or stove portal must rest on a solid foundation so as not to cause destruction of the fireplace structure. The weight of the facing material must be initially calculated when designing the foundation.

Tiles are a creative piece product and, unlike mass-produced ceramic tiles, they are quite expensive. Therefore, to cover a stove or fireplace with tiles, you need to have professional skills that are at the intersection of the skills of a master stove maker and a master tiler. The situation is further complicated by the fact that some rows of tile cladding must be laid during the process of laying bricks in the stove or fireplace body. Of course, you can take on this work yourself, but before that it is better to carefully study all the intricacies of the process.

Tiling process

The entire complex process of covering the surface of a stove or fireplace with tiles is carried out first dry, without clay mortar. The installation process begins from the bottom corner. After making sure that the tiles stand up straight, the structure is dismantled.

When installing a “clean” tile, half fill the tile with clay mortar mixed with small crushed stone or fragments of bricks. It must be remembered that the brick filler must match the coefficient of thermal expansion with the main design of the heating device. Therefore, it is preferable to use fragments of the same bricks that were used to lay the stove or fireplace.

Crutches are then inserted into the holes of the tile pile and when the till is completely filled, the tile is fixed to the surface. On top, the space between the rumps is a laid horizontal row with careful compaction with clay mortar with cobblestone or brick filling. Additionally, horizontal staples can be installed for temporary fixation.

Step by step, horizontal rows of tiles rise to the very top of the stove or fireplace. The ends of the twisted ends of the wire are embedded under the next horizontal row of tiles. In general, the procedure is quite complicated, but the end result will make you remember the best palace interiors - after all, stoves lined with tiles could previously only be found in luxurious mansions.

Selection of tiles for cladding

Master tilers have created many different tile configurations, allowing for the construction of a beautiful and functional tile stove. So, for example, smooth tiles are used when finishing planes; for cladding corners, corner tiles with a rum of the appropriate configuration are provided. Curves and decor are made by shaped parts (border, straight and corner cornice, grate, relief inserts, cover shelf, firebox frame).

Not only the types of tiles can be different, but also the method of making the front surface. Here there are relief, smooth, with and without patterns, glazed and terracotta surfaces. The method of applying the design and its color scheme determined entire schools of ceramists. Dutch, Spanish, and Russian tiles have gained popularity.

But the sizes of tiles, on the contrary, are unified and regulated by GOST 3742-47. The document contains information about the geometry of the tile and permissible deviations from the norm. The latter are no more than 1 mm. Standardization made it possible to avoid the lengthy adjustment of tiles to each other, which significantly reduces the tiling time.

How to check the quality of a tile

When buying a tile, you need to be guided not only by its aesthetic properties, but also pay attention to such indicators as:

- raw materials. Masters claim that durable tiles can only be made from white clay. Colored clays contain various impurities that affect quality;

- presence and size of pores. You don't need to break the product to see the pores. They are clearly visible at the ends of the tile. The larger the pore size, the more moisture the product can absorb. The percentage of moisture absorption determines the tile’s resistance to temperature changes and mechanical damage. Accordingly, the larger and larger the pores, the lower the quality of the product;

- method of making tiles. In industrial quantities, tiles are made in two ways: punching, pressing and casting. In the first case, wet clay is used, which simplifies the production process, but increases the drying time of the product. In addition, during the drying process, a wet product may move, which will violate the specified dimensions. The second option is more labor-intensive, but the finished product is more durable and has identical dimensions. The third method is used to obtain “tiles for tiles”;

- number (number) of firings. They can be determined by the quality of the front surface. If it is slightly cracked and has a duller shine, it means that the tile was fired once.

Article on the topic: Bed for the cottage. How to inexpensively make a bed with your own hands?

What are tiles?

If you plan to use tiles for cladding a fireplace or stove, it would be useful to find out the meaning of this word. It is interpreted in different ways, but comes from “to express,” which means “to cut out.” Tiles are tiles made from baked clay. It differs in configuration and the presence of a pump. The latter is a box-shaped protrusion that is located on the back side of the tile. The pump gives the product strength and makes the stove or fireplace more heat-intensive.

This part is somewhat smaller in size than the area of the product. This key feature makes tiles an ideal facing material for heating appliances. Hollow structures are characteristic of tiled decorative elements for finishing facades, walls, stoves and fireplaces.

Tiles are tiles that have many advantages, among them the following should be highlighted:

- strength;

- ability to withstand any temperature;

- high rigidity;

- resistance to temperature changes;

- environmental friendliness;

- heat storage;

- ease of care;

- fuel economy;

- long service life.

Due to the thickness of the product, the tile receives higher rigidity. This parameter is 2 times greater than that of ceramic tiles. If you want to understand what tiles are, you should know that they are capable of accumulating heat. If the stove is heated well, it will release heat into the room throughout the day.

This cladding is also environmentally friendly, which can be achieved through the use of clay in the production process. This feature is also due to the presence of glaze on the surface, which does not retain dust. It does not burn and does not emit substances harmful to human health during operation of heating equipment.