“Izospan B” - which side to lay towards the insulation, frame, floor

Although it is not a monopolist in the building materials market, it occupies the entire niche of vapor barrier films and membranes. Their products are a windproof, vapor-permeable, waterproofing membrane under the Izospan brand. Depending on the structure, density and scope of application, series A, B, C, D, E, F, K, etc. are produced. Basically, these are two-layer nonwoven materials, where one side is smooth, the other is fleecy and/or rough.

Using Izospan B film as an example, we will tell you which side to lay towards the insulation, how to lay it correctly and what they are generally intended for.

Basic information about the material Izospan AM

All types of Izospan are multilayer (two- or three-layer) polypropylene films or membranes. They are characterized by different mechanical properties of the material on the front and back sides: smooth and rough surfaces.

In stores and construction markets you can find more than 10 types of membranes of this brand. Manufacturers classify products by indices A, B, C, D, F, R, as well as combinations of letter indices, which makes it easier to select a particular product from the Izospan line for construction work. Depending on the marking, the membranes differ in individual technical characteristics and scope of application.

The entire variety of Izospan brand materials is divided into three groups:

- Waterproofing, windproof, vapor permeable membranes.

- Waterproof vapor barrier films.

- Roll materials with energy saving effect.

Izospan films are widely used in construction for waterproofing roofs and walls, for insulating floors, ceilings and attic floors, as well as for protecting wooden and metal structures from corrosion and rot. They make it possible not only to ensure waterproofing of the insulation, but also to prevent condensation of moisture entering the heat-insulating material along with steam through the walls of the house. Certain types of Izospan are produced with additional reinforcement, and may also contain non-flammable or other additives. Methods for installing Izospan films also differ depending on individual characteristics.

Why Izospan

This is not the first article we have devoted to the study of this material, so we will briefly discuss the main characteristics and scope of application.

Izospan B (V) is a two-layer non-woven material used to protect all types of structures, including floors, in any buildings. Prevents the formation of condensation and, as a result, the development of fungus. Retains dust and insulation fibers and serves as wind protection.

Membrane properties

Options

Indicators

Longitudinal stretch, mm

Transverse stretch, mm

Longitudinal tensile load, N/cm

Transverse tensile load, N/cm

It consists of two layers - the outer one is smooth for easy fastening, the bottom one is perforated to retain moisture. This difference in texture makes it easy to figure out which side to put Izospan to the insulation - with the bottom fleecy layer towards the place where condensation forms in order to constantly remove it.

Provided that a vapor barrier membrane is used, the structure is reliably protected from the formation of excess moisture, the accumulation of condensation on components and metal elements, rotting of wooden rafters and walls, etc. A side effect of using such a film is that it prevents insulation fibers, especially if it is mineral wool and especially glass wool, from entering the room.

VIDEO: Which side to lay steam and waterproofing

We understand the sides and fastening

Let us remind you once again which side to lay Izospan B - perforated towards the insulation, smooth outwards. Even if it is not possible to determine by touch which of them is rough, the marking - the name of the canvas is displayed on the smooth side, that is, when attaching it, you should see the name.

The inner side of the fabric is designed to absorb moisture

Front - smooth - side where the product name is printed

Installation of the Izospan material is carried out by one side or the other, depending on what material is used.

The membrane is always attached to load-bearing structural elements or to rough cladding or flooring. The canvas is secured with wooden slats or a construction stapler.

If lining, eurolining, plywood, etc. are used for finishing, the film is fixed with thin wooden slats parallel to each other. Insulation is inserted between the slats, in this case the smooth surface faces it.

When carrying out vapor barrier waterproofing of the roof, individual strips are attached overlapping each other (the overlap width is at least 10 cm) and fixed with double-sided tape, and the attachment point itself is additionally covered with vapor barrier tape. produces a whole line of adhesive tapes specifically for such needs.

Tape for gluing joints of vapor barrier Izospan V

It is clear that it is necessary to determine which side to lay Izospan in each specific situation, taking into account that its fleecy surface should absorb water, that is, it faces the place where the condensation will come from.

Application in certain areas

The use of a vapor barrier material greatly extends the service life of the insulation and, as a consequence, the entire building structure. Its main task is to prevent the penetration of condensate and the formation of fungus.

Insulated roof

A membrane or polyethylene film is a mandatory element when constructing an insulated roof. It is mounted on the elements of the supporting frame, less often - on the rough finish. It is necessary to ensure that moisture formed due to temperature differences does not get on the insulation. To enhance the characteristics of the joints (overlapping), Izospan SL is glued.

It is laid with the smooth side against the insulation, regardless of its type - polystyrene foam, polystyrene foam, mineral wool, etc.

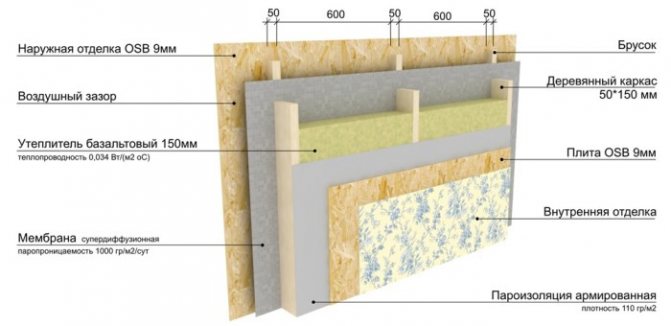

External wall insulation

The structure of the product is such that it is equally successfully used for both external and internal insulation. The main thing is that the film should not be exposed to direct sunlight - they significantly reduce the service life and generally have a negative effect on the canvas. For exterior finishing, the smooth side also faces the heat insulator.

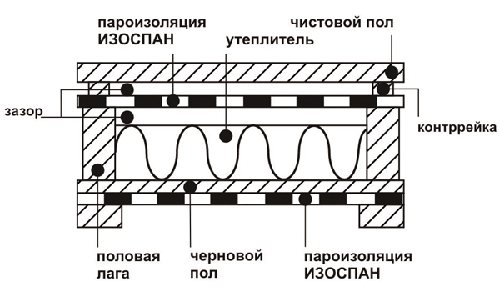

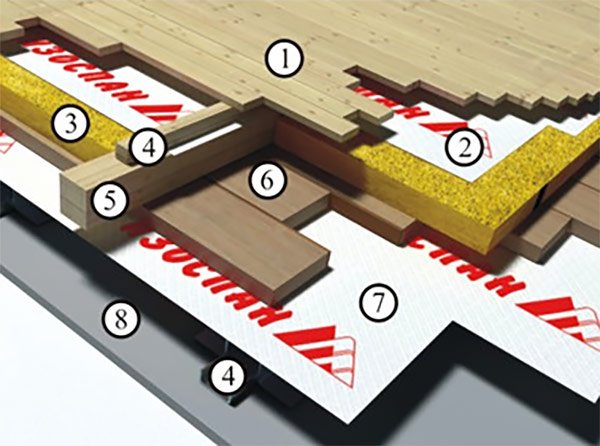

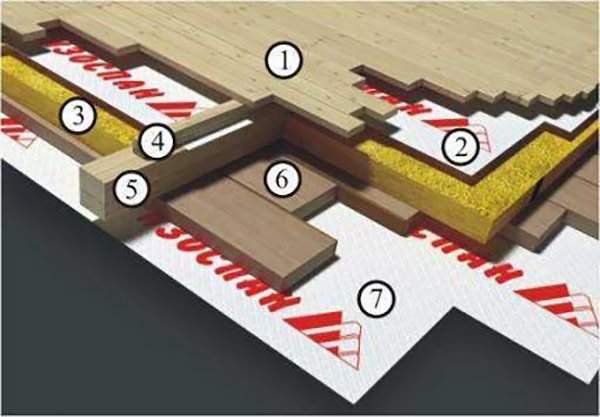

Floor structures

Installation of Izospan is recommended when arranging interfloor and basement floors to isolate the insulation from moisture and at the same time to prevent its fibers from entering the living space.

Polyethylene is laid between the cladding and the rough ceiling with the perforated (reverse) side down and directly above the insulation itself, with the rough surface facing it.

Be sure to make a ventilation gap of 40-50 mm between the vapor barrier and the insulation for air circulation.

To ensure the tightness of the joints, it does not matter whether they use series B or FX; when they are laid end-to-end, they are glued with KL or SL tape.

Flooring

When laying any floor covering on a concrete, brick, cement or other base (with the exception of wood and its derivatives), be sure to lay a layer of vapor and waterproofing to compensate for temperature differences and absorb condensation. They lay the canvas directly on the screed, they can lay it with insulation if the decorative coating is thin, or they can immediately lay parquet or laminate on the base.

Installation instructions

In houses and premises where work is being done to insulate walls and roofs, the membrane sheet is attached to the supporting frame between the insulation and the rough finish, with the smooth side facing the insulation. For fixation, it is permissible to use galvanized nails with large heads so as not to tear them, or use a stapler - this is much more convenient and faster.

When working with inclined surfaces, cut the required size sheets in advance and fasten them horizontally from bottom to top with an overlap of 10-15 cm.

For further finishing with lining and other wooden panels, the film is fixed with wooden slats with an edge of 40 mm, pre-impregnated with an antiseptic.

When plasterboard is used for rough finishing of walls, the membrane is secured with staples or galvanized nails, with its smooth side facing the insulation and fitting as tightly as possible to it.

In case of excessive humidity, roof insulation or external wall insulation, the joints are additionally fixed with double-sided tape Izospan KL or single-sided SL tape.

It is prohibited to use ordinary stationery tape - it will not last even a day on the surface of the membrane.

To insulate floors, foundations and basements, Izospan V is laid between the subfloor and the decorative coating. The panels are also laid overlapping, but there must be a ventilation gap between the outer side and the insulation for air circulation - 40-50 mm is enough.

Working with floor slabs and floor insulation on concrete screed

The same applies when laying the floor on a cement or concrete screed. In this case, be sure to use adhesive tape or connecting tape for the longitudinal seam of the panels to prevent even the slightest wetting of the parquet or laminate.

Scope of application of individual series

- A – membrane for the under-roof surface to protect against moisture and wind;

- B - vapor barrier

- AS – “breathing” diffusion membrane;

- AM - “breathing” diffusion membrane;

- AQ - professional line of protective equipment;

- FS – reflective with foil layer;

- D – vapor and waterproofing membrane;

- KL, SL, FL, FL – double-sided and single-sided connecting tapes

In general, we figured out which side to put Izospan on insulation, supporting frame, subfloors and some types of finishing. If you have any questions, you can ask them in the comments to the article. The company's specialists will answer them as soon as possible.

VIDEO: Condensation on the roof + incorrect vapor barrier

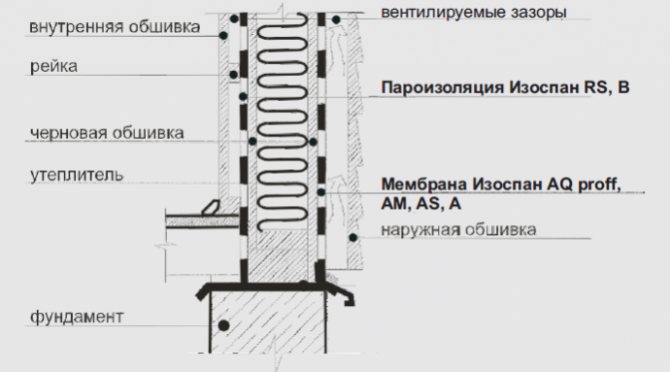

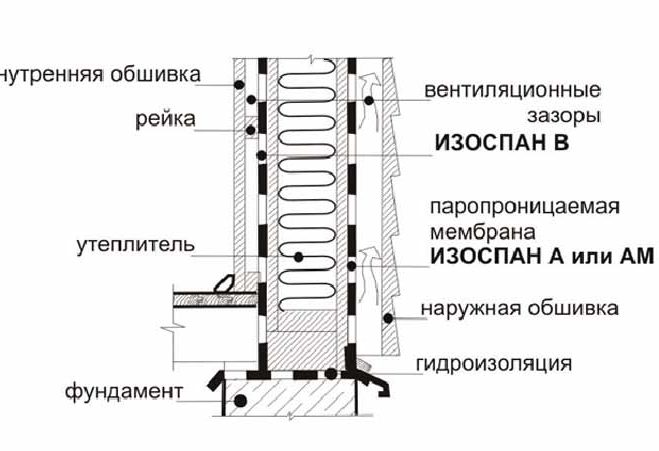

Vapor barrier for frame walls

On the outside the insulation is protected with hydro-wind protection, and on the inside with vapor barrier. Therefore, for work you will need two types of membranes:

- Izospan A (or AS, AQ Profi, AM);

- Izospan B or RS.

General scheme of a wall pie:

- External cladding.

- Cottrogrid.

- Hydro-wind barrier – Izospan A.

- Thermal insulation layer.

- Vapor barrier – Izospan V.

- Internal finishing.

Izospan A is mounted on the frame on top of the insulation, the side of placement is not important. If the brands AS, AQ Profi, AM are used, then the white side faces the heat insulator. The panels are placed from top to bottom, horizontally with an overlap of 10 cm at the joints. They are fixed to the frame with a construction stapler.

Vertical slats are attached on top of the hydro-windproofing film - the basis for the outer cladding. The lower edge of the membrane is fixed to the drainage drain of the base.

Instructions for use of Izospan B:

- Installation of the canvas from inside the room, on top of the insulation. Fixation to the supporting beams of the frame.

- The order of installation is from below, with an overlap of horizontal panels of 15 cm.

- Izospan B is placed with the smooth side facing the heat-insulating layer, the panels are fastened with connecting tape.

- The interior decoration is mounted on a slatted frame (lining, plywood) or galvanized profiles (plasterboard) - a ventilation gap of 4-5 cm should be obtained.

Insulation problem

Thus, each person releases on average about 100 grams of water vapor per hour when breathing, which is 2400 grams per day. In addition, steam is generated as a result of everyday activities - washing, drying clothes, cooking, taking water procedures (about 3000 grams in total).

In total, per day of living in a house, a family of 3 releases more than 10 liters of water into the air. If this moisture is not removed outside the house, it can condense on building structures and roofing. Moisture saturation also harms the building’s insulation, reduces its efficiency, increasing thermal conductivity.

Moisture that is not removed from building structures in a timely manner promotes the proliferation of mold fungi and putrefactive bacteria, house dust mites and other pests. Gradually, the walls are destroyed, mold spores are released into the air of the interior space, and the atmosphere in the rooms becomes harmful to health.

How to protect your home from excess moisture?

There are several ways to protect your home from the harmful effects of water vapor. Firstly, ensuring good ventilation, in which moist indoor air will be constantly released into the street, and fresh, drier air will begin to replace it.

Secondly, the use of water- and vapor-tight barriers that do not allow moisture to pass through, but allow it to slowly evaporate.

With this method of protection, water does not get into the insulation and onto the walls, and the resulting condensate evaporates directly from the protective coating.

What is Izospan?

Among the materials presented on the construction market, the leading role is played by the products of Hexa - Nonwoven Materials LLC, produced under the Izospan trademark. The company has its own production base in Russia, not far from Tver, and operates a research laboratory.

Izospan materials are special films and membranes made using modern polymer materials and having special properties. The thickness and strength of the films, their dimensions are selected in such a way as to make installation simple and convenient. The line of materials under the Izospan brand is represented by the following groups.

Ruler

The first group is waterproofing membranes with properties of vapor permeability and resistance to wind loads. They are designed to protect buildings from external wind and rain. The property of vapor permeability allows moisture released by the walls of the house to evaporate into the external environment. Such materials are designated A, AF, AF+, AM, AQ proff, AS, A with OZD.

The second group is energy-saving heat, steam, and waterproofing materials. These are airtight films coated with metal foil, which reflects electromagnetic radiation in the infrared part of the spectrum. Due to this effect, more thermal energy remains in the room, and heating costs are reduced. Film designations - FS, FD, FX, FB. Materials of this group can be used for saunas and steam baths.

The third group is waterproof vapor barrier film materials. They perform two main functions: the first is to protect the wall insulation from condensation and the penetration of moisture into it from the rooms of the house, the second is to isolate the interior of the home from harmful emissions of insulation and walls (for example, mineral wool fibers, cement dust from concrete blocks). Their designations are RS, B, C, D, RM, DM.

The fourth group is tape connecting materials. Designed to eliminate leaks at the junctions of films and membranes. Presented under the designations KL, KL+, SL, FL, FL termo, ML proff, SUL.

Connecting tapes and tapes

To fix, connect and seal films during installation, the manufacturer produces its own range of adhesive tapes and adhesive tapes:

KL . Double-sided adhesive tape for sealing overlaps of vapor barrier materials Izospan, one side is metallized;

KL+ . Reinforced double-sided adhesive tape for sealing and fastening overlaps of Izospan material sheets, as well as their fastening to other surfaces (wood, concrete, metal, plastic);

S.L. _ Butyl rubber connecting tape for sealing and fastening overlaps of Izospan material sheets, as well as their fastening to rough surfaces (building stone, wood).

Izospan FL tape is designed for sealing and connecting panels of Izospan RF, FS, FD, FX materials. At the same time, Izospan FL creates a solid heat-reflecting surface. Can also be used to repair minor damage to Izospan RF, FS, FD, FX materials.

Izospan FL termo tape is similar, but can be used in rooms with elevated temperatures: baths, saunas, etc. (Temperature resistance from -40° C to + 180° C).

Izospan B: description and application

To prevent moisture and water vapor from entering insulating coatings and walls from the internal volumes of the house, Izospan V is used. Its structure allows you to create a kind of barrier for steam: a surface for collecting and ensuring gradual evaporation of condensate. Another property of Izospan B is the protection of the air in the house from the penetration of particles from insulation and wall materials.

Scope of application are:

- internal surfaces of walls and ceilings in attics and attic floors;

- internal surfaces of living room walls made of any material;

- surfaces of interfloor and basement floors.

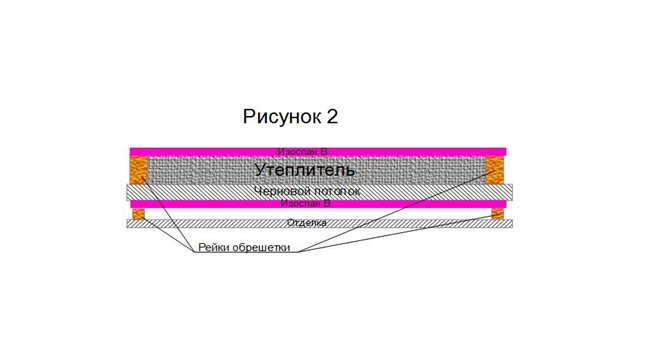

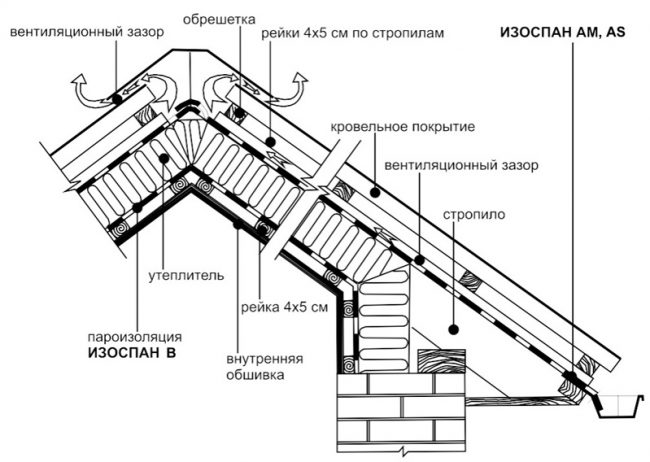

Vapor barrier of attic floor

Attic floor installation:

- Floor

- Hydro-windproof membrane Izospan AM , AS , AQ proff

- Insulation

- Countertrain

- Beam

- Rough ceiling

- Vapor barrier Izospan B, RS

- Interior decoration

Structure and parameters

Structurally, Izospan B is a polypropylene film with one smooth side and the other covered with a thin rough layer of fibers of the same material.

The smooth sealed surface of the film creates an impenetrable barrier to steam and water, and the fibrous coating is an excellent collector of condensation, which will remain on the film and will not get into the insulation of walls and ceilings.

The effectiveness of this protective coating depends on which side of the film is adjacent to the building structures or insulation.

Izospan B has excellent performance characteristics:

- vapor permeability not less than 7 mg/(m•h•Pa);

- water resistance is not less than 1000 mm. aq. pillar;

- tensile strength of at least 25 N/cm;

- operating temperature range from -60 °C to +80 °C.

The film does not lose its properties from exposure to direct solar ultraviolet radiation for 4 months. Izospan B is produced in rolls, strips 1.4 and 1.6 meters wide and with a total area of 35 m2 and 70 m2. What width and area to choose the material depends on the geometric dimensions of the protected surfaces.

Specifications

The described waterproofing wind protection is produced in canvases, the width of which is 1.6 m. The size can be 35 or 70 m2. Contains 100% polypropylene. You may also be interested in the maximum tensile force in the transverse and longitudinal directions. These parameters are 100 and 160 N/50 mm, respectively.

The water vapor flux density is 880 g/m2*24 hours. Ultraviolet stability reaches 3 months. Water resistance is 1,200 mm water. Art. Izospan AM can be used over a wide range of temperatures, which vary from -60 to +80 ˚С. The above data is based on laboratory test results.

General principles of application

The film is laid from bottom to top with the strips overlapping each other by 10-15 cm. The joints of the strips are glued with tapes such as Izospan KL, KL+. Izospan B is always mounted with the smooth side facing the insulation. The contact points between sheets and sheathing slats and air gap counter slats are sealed with a special sealing tape. The tape is pressed with the self-adhesive side simultaneously against Izospan B and the abutment surfaces.

Areas connecting to windows, niches and openings for utilities (ventilation, sewerage, water supply) are sealed with Izospan ML proff tape material. The same tape is used to finish joints with concrete and wooden structural elements.

Vapor barrier of basement floor

The bottom of the basement floor must be protected with a layer of vapor-waterproofing. This must be done so that moisture does not penetrate from the ground to the insulation and other structural elements. The recommended type of Izospan for this purpose is D or C.

Scheme of vapor-waterproofing of the basement floor:

- Floor

- Izospan B (vapor barrier)

- Insulation

- Counterrail

- Rafters (beams)

- Subfloor

- Membrane Izospan D or C (as a hydro-vapor barrier)

Subfloors are laid Izospan D, C waterproofing film Next, beams and counter-battens are installed, between which the insulation is placed. The membrane is spread over the insulation, where the side with the rough structure faces the thermal insulation.

The rolled material is laid with a small spacing on the walls. The joints of the canvases are sealed with tape.

Installation plan

Installation of Izospan B has features depending on which element of the structure needs to be protected.

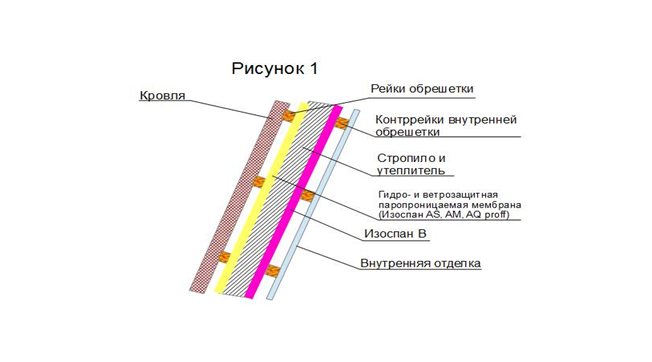

For attics and attic floors

The installation diagram is shown in Figure 1.

First you need to unroll the roll and cut the ribbons to size. To determine which size of panels is most convenient and economical for installation, it is necessary to measure and mark the walls and ceilings. Then you need to apply the first tape to the internal insulation of the attic or attic (from the ceiling side) with the smooth side and secure it.

The fastening method is chosen whichever is more convenient for the owner: it can be fastened with a construction stapler or on nails. The first tape in attics must be laid from below, parallel to the floor. For convenience, the tapes can be rolled into tubes with the desired side inward and unfolded as they are secured.

Next, you need to secure the following tapes in the same way, overlapping the previous one with an overlap of about 15 cm. Seal the joints with a special tape such as Izospan KL, KL+ and mount the lathing for cladding or finishing material on the coating. For ventilation and evaporation of possible condensation, the gap between Izospan B and the cladding should be 50 mm.

For interfloor ceilings

The installation diagram is shown in Figure 2:

Installation proceeds as follows:

- Unroll the roll and cut the ribbons to size;

- secure the first tape with the rough side to the rough ceiling (floor) using a stapler or nails;

- fasten the remaining tapes parallel to the first, with an overlap of 150 mm;

- seal the joints for sealing with the appropriate tape of the Izospan family;

- install the sheathing and lay insulation.

Next, you will need to lay another layer of Izospan B with the smooth side facing the insulation, secure it to the sheathing and seal the joints.

On top of the insulation, it is necessary to provide a ventilation air gap (gap) of 50 mm using counter slats on which the finishing cladding can be installed.

For interior walls of the house, interior partitions

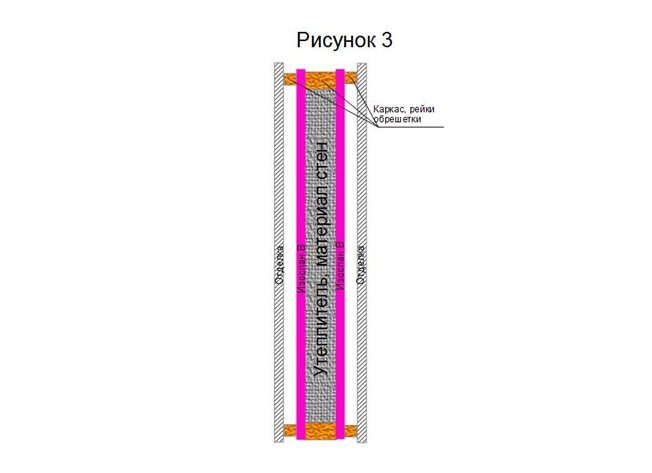

The diagram is presented in Figure 3.

Installation is carried out similarly to the option with interfloor ceilings, with the tapes being laid starting from the bottom, parallel to the floor, also with a smooth surface facing the insulation.

To protect the structures of frame partitions and walls inside buildings, instead of type B, you can use Izospan with the designations C, DM, RS. Installation of these materials is carried out according to the same rules.

Recommendations for installation and use

Vapor barrier film Izospan

B is placed indoors. It is used for insulated roofs, floors, attic floors, and walls. The manufacturer's instructions and information about the material give you an idea of which side to turn the panel towards the heat insulator during the fastening process. The smooth surface always adheres to the thermal insulation, while the fibrous surface remains on the outside and stops moisture from steam, preventing it from penetrating inside the structure.

The vapor barrier is laid with an overlap of panels of 15-20 cm, installation is carried out from the bottom up. The connecting places require good sealing; for gluing, a specialized adhesive tape produced by the company and marked FL is used.

Izospan tape is also suitable

SL. The areas adjacent to the structure, sheathing, utility holes and niches are sealed using self-adhesive sealing tape, which is simultaneously pressed against the protective sheet and the contacting surface.

Installation of the film when insulating a roof with an inclined surface is carried out according to the following scheme:

- the roll is cut into strips of the required size;

- the first strip is attached from below parallel to the floor, with the smooth part to the heat insulator;

- the next tape is installed, covering the fixed film by 15 cm;

- the panels are fixed with a stapler for construction work or with galvanized nails to the rafters of the building;

- the joints are covered with sealant using specialized SL tape;

- a frame frame is placed on top of the vapor barrier, forming a clearance of 40-50 mm;

- The cladding material is attached to the wooden slats.

Fastening Izospan B when insulating the floor (floor) occurs in stages:

- the canvases are laid with the rough side towards the base floor (ceiling);

- the places where they adjoin the surface of the walls and the joints of the tapes are coated with glue using SL tape;

- the heat insulator

lies on a smooth film surface; - waterproof Izospan C is laid on top;

- The floor covering is being installed.

When attaching a vapor barrier to internal walls and partitions, the panel is placed directly on the heat insulator

and is attached to wood slats. First of all, a frame frame is stuffed on top of the film, creating a gap for ventilation of at least 30 mm. During further gypsum cladding, installation is performed on a zinc profile.

Application of Izospan B, which protects the heat insulator

and the wall surface from moisture, extends the service life of thermal insulation and the entire structure of the building.

What is Izospan?

According to their intended purpose, all Izospan materials are divided into four categories:

- Waterproofing membranes. Used in insulated and non-insulated pitched roofs. They protect the insulation and attic from possible leaks and condensation from the inside, which forms on the inside of a cold roof upon contact with warm and humid air. The vapor-permeable properties of the membranes allow moisture to evaporate from the insulation, preserve its thermal insulation properties and do not create conditions for the elements of the supporting roof structure to get wet. Another function is protection against weathering of mineral wool fibers.

Waterproofing is laid under the roof sheathing

- Vapor barrier for the roof. A multilayer film in which one of the sides has an anti-condensation surface. Used in insulated pitched and flat roofs to protect mineral wool from the penetration of vapors with warm air from inside the building. Izospan materials are not an absolute vapor barrier, but they have a high enough resistance to vapor permeation to keep the insulation dry by ventilating moisture from it through the membrane to the outside (into the ventilated under-roof gap). Another function is to protect the attic from mineral wool fibers. Like any vapor barrier, Izospan films have high waterproofing properties (withstands the pressure of a water column with a height of at least 1200 mm), and they are used as moisture insulation for uninsulated roofs.

Vapor barrier, not counting the sheathing, is the outermost layer of the roofing pie

- Reflective vapor barrier. It differs from the usual one by the presence of a metallized outer layer on one side, which reflects some of the heat back into the room. Used in the roofing pie of a heated attic. Allows you to save up to 10% on heating costs.

- Connecting tapes. Used for joining adjacent sheets, extending them in length, connecting waterproofing and vapor barriers with adjacent surfaces, roof and drainage elements.

Connecting tapes are an essential element of hydro- and vapor protection

Uninsulated pitched roofs

According to the manufacturer's instructions, steam and waterproofing materials Izospan D (DM) are used in non-insulated pitched roofs. If you plan to insulate the roof in the future, then the best solution would be to choose a reinforced superdiffusion membrane from the Izospan AQ series (proff or 150 proff).

The structure of the roof in section looks like this:

- Rafter legs.

- Vapor and waterproofing Izospan D (DM) or waterproofing membrane Izospan AQ proff (150 proff), laid and fixed to the rafters.

- Rail on top of the waterproofing (to create a ventilation gap in the under-roof space).

- Lathing.

- Roofing covering.

Installation of waterproofing

Laying Izospan begins from the roof eaves, rolling it out on the rafters in horizontal sheets.

This is how the first strip of waterproofing is laid

The lower edge of the first row is lowered onto the drain drip and secured with Izospan KL+ tape.

Important! You need to remember how to lay Izospan on the roof: Izospan D (DM) - smooth side up, Izospan AQ - logo up.

The waterproofing is laid with a slight sag between the rafters - up to 2 cm. The upper panel should overlap relative to the bottom by at least 15 cm. If the length of the panel is not sufficient to cover the entire slope in length, then the extension is carried out along the rafter leg (the overlap size is similar - from 15 cm). All overlaps must be taped with Izospan KL+ tape.

On a ventilated ridge or ridge (when using Izospan D or DM), a gap about 10 cm wide is left in the waterproofing layer.

On a non-ventilated ridge or ridge (when using Izospan AQ proff or 150 proff), the waterproofing is laid with a bend on the opposite side of 15 cm and the joint is taped with Izospan KL+ tape.

The waterproofing of multi-gable roofs is more complicated than that of a gable, hip or half-hip roof. Here it is necessary to waterproof the valleys with a separate sheet.

Valley device

The film is rolled out along the entire length of the valley and fixed to the boards and rafters. The connection with the waterproofing of the slopes goes like this:

- the canvas of the left slope is placed on the right board of the valley with an overlap over its edge of no less than 15 cm;

- the canvas of the right slope is brought onto the left board of the valley with an overlap over its edge of no less than 15 cm;

- excess materials are cut off;

- fastening to the valley boards and along the rafters (at a distance of at least 30 cm from the valley axis) is carried out with a stapler.

The waterproofing is also fixed to the rafters using a stapler. The final fastening is carried out using a batten attached to the rafters. Before installation, sealing tape is glued to the surface of the rail facing the waterproofing.

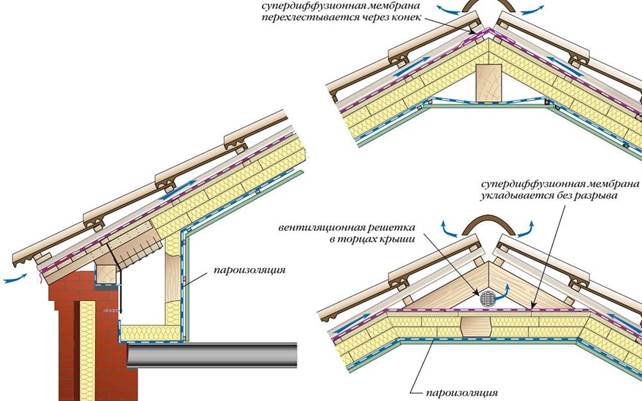

Insulated pitched roofs

The roofing pie of an insulated pitched roof looks like this:

- Coating.

- Lathing.

- Distance rail to create a ventilated gap.

- Waterproofing.

- Rafter legs.

- Insulation between rafters.

- Vapor barrier.

- Counterrail.

- Internal lining.

If additional insulation of the slopes is necessary from the inside, a counter-lattice is installed along the rafters for another layer of insulation.

Waterproofing

Izospan AQ (proff or 150 proff), AS 130, AS, AM, A membranes are used as waterproofing. The choice of a specific material depends on the type of roofing and the attic insulation contour.

So, for combined roofs with a U-shaped (or trapezoidal) insulation scheme, the roof of which has a relatively small insulation area, it is recommended to choose reinforced membranes with high vapor permeability (water vapor flow density) - Izospan AQ or AS. And, for example, Izospan AM, according to the instructions for use, has almost 2 times less tensile strength and 12% lower maximum water vapor flux density.

Features of waterproofing installation

How to properly lay waterproofing is described in the previous chapter. The only difference between the waterproofing of an insulated roof is that there is no gap left for superdiffusion membranes in the ridge area - the vapor-permeable properties of the materials are sufficient to ventilate moisture from the roofing pie.

Scheme of waterproofing with superdiffusion membrane

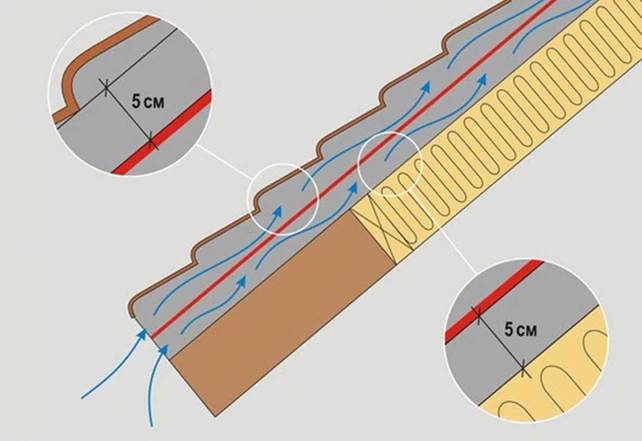

In an insulated roof with a slope angle of more than 35°, you can use the Izospan A diffusion membrane. It is mounted on the rafters with a slight sag, but so that it does not touch the inside of the insulation. As a result, there should be two air gaps under the roof measuring 3-5 cm:

- between the insulation and the membrane;

- between the membrane and the roof covering.

The peculiarity of this material is that on one side it has a rough surface that can hold condensation until conditions are created for its weathering. And this side is placed inside the roof.

Such a device (with two ventilated gaps) is recommended if a large amount of condensation forms on the inside of the coating:

In this case, a gap is left near the waterproofing in the area of the ridge to allow condensation to erode.

Important! If Izospan A lies on the insulation, it will lose part of its waterproofing properties.

On roofs with a slope angle of less than 35°, Izospan superdiffusion membranes of AM, AS or AQ brands are used. They can also be laid on slopes with any slope angle. These materials are laid directly on the thermal insulation. They are suitable for all types of roofing, including profiled metal coverings: corrugated roofing sheets and metal tiles.

Vapor barrier

Izospan grades RS, B, DM or C are used as a vapor barrier for insulation. These are materials with a rough surface that can retain moisture vapor until conditions for its weathering appear.

This is what the side with the anti-condensation function looks like

Important! You need to remember which side the vapor barrier is laid on - the rough side facing the attic room (used attic).

The rules for laying Izospan RS (B, DM, C) in the roof are as follows:

- installation is carried out in horizontal stripes;

- start from the bottom, the next sheet is overlapped on the bottom one (the overlap size is at least 15 cm);

- fastening is carried out to the rafters or counter-battens of an additional layer of insulation, using a stapler or nails with an anti-corrosion coating and wide heads;

- joints of canvases and abutments to other surfaces are glued with Izospan tapes - the vapor barrier layer must be continuous and without breaks.

Modern building material

the most frequently used products of the Izospan brand is Izospan, marked with the letter indices A and M. This material belongs to the class of waterproofing windproof, vapor-permeable membranes, protects the insulation and structural elements of the building from the effects of condensation and atmospheric moisture and significantly increases their service life.

Main technical characteristics

Izospan AM is a three-layer diffusion membrane with a density of 90 g/m2, vapor permeability of at least 1000 g/m2/day, and water resistance of at least 1000 mm of water. Art. UV stability is 3-4 months. An important characteristic of the material is also the longitudinal and transverse breaking load, amounting to 125 and 95 N/5 cm, respectively.

After analyzing the above technical characteristics, we can conclude that Izospan with the AM index has:

- water permeability;

- high elasticity;

- resistance to ultraviolet radiation;

- resistance to negative atmospheric phenomena.

In addition, the structure of the material ensures air circulation between its layers and moisture removal; it is safe for humans and the environment, capable of stable operation over a wide temperature range (from - 60 °C to + 80 °C) and, importantly, is affordable .

Izospan AM is produced in rolls 1.6 m wide and 35 and 75 m long. It is used for the installation of waterproofing of pitched roofs, the construction of frame walls, insulated external facades, as well as for the installation of ventilated facades and attic floors.

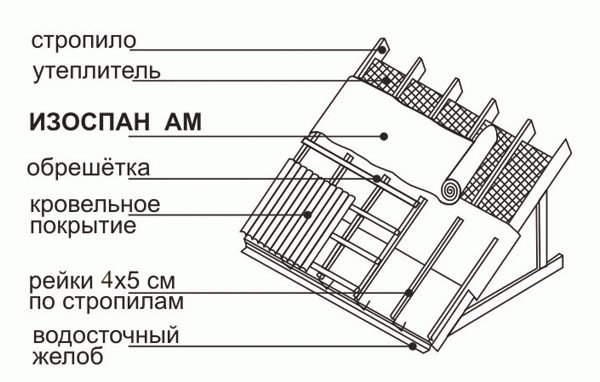

Stages of installation work for the roof

We emphasize once again that when installing the roof, protective material must be used to protect the insulation and structural elements from wind, precipitation and condensation formed under the roof. This type of Izospan successfully copes with this function. The structure of the membrane does not prevent moisture from escaping from the insulation and does not require the organization of additional air space, which reduces the cost of construction. It is important to note that this type of material is not used as a temporary or permanent roofing covering.

The main stages of work on installing roof waterproofing:

- Izospan AM is rolled out with the white side facing the insulation, cut and placed directly on it without creating an additional air gap.

- Installation is carried out from the lower edge of the roof. The panels of material are laid without tension horizontally, overlapping with an overlap of at least 15 cm at the joints (horizontal and vertical) and fixed to the rafters with a construction stapler. The lower edge of the film in the area of the eaves overhang is glued to the drip edge with connecting tape. The overlaps of the laid panels are also fastened together.

- Those places where the film adjoins pipes and roof windows are additionally taped with adhesive tape.

- Izospan AM is fixed to the rafters with vertical counter-battens 4-5 cm thick, impregnated with antiseptic, using nails or self-tapping screws. In this case, the places where the two panels vertically overlap are tightly pressed against the rafters with counter-battens and sealed.

- Next, depending on the type of roof, a continuous plank flooring or sheathing is mounted along the counter slats and the main decorative covering is laid. The resulting gap between the sheathing and the film serves to ventilate water vapor and the resulting under-roof condensate.

- To ensure ventilation of the space under the roof and air circulation, special openings are provided both in the lower part of the roof and in the ridge area.

Installation of walls and facades

Izospan AM is widely used in the construction of country houses when installing frame walls and insulated facades, providing the necessary hydro- and vapor barrier. The material is laid with the white side directly on the outer surface of the heat-insulating material. Installation is carried out from bottom to top. The canvases are laid horizontally with an overlap of at least 10 cm. The film is attached to the frame using a construction stapler and vertical counter-battens. Siding, lining or other finishing material is laid directly on the counter slats. When installing walls, care must be taken to drain moisture from the bottom edge of the membrane into the drain.

When constructing ventilated facades and attic floors, both Izospan AM brand and other materials of the Izospan brand are used. When carrying out work using other Izospan products, you should follow the operating instructions supplied with them.

Thus, having analyzed in detail the use of Izospan with AM marking for waterproofing roofs and walls of buildings, we can conclude that working with this material does not require special skills or specialized equipment; it is easy to use . All of the above, as well as relatively low installation costs, make this material popular and widely used in construction work.

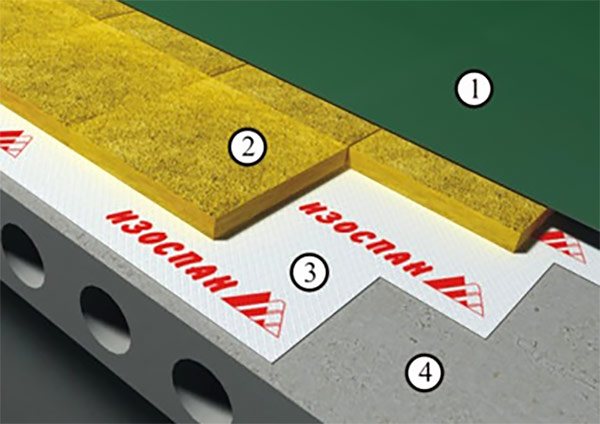

Insulated flat roof

Regardless of the flooring material, the insulation of a flat roof is protected from vapors from the room. For these purposes, one of the types of vapor barrier is used: Izospan D, RM, C, RS.

Installation of vapor barrier is carried out according to the following scheme:

- the film is rolled out over the slab (the side of installation does not matter);

- the canvases are overlapped, the amount of horizontal and vertical overlap of the strips is 15-20 cm;

- overlaps are taped with Izospan tape;

- Insulation and covering are installed on top according to the roof design.

Flat roof vapor barrier

In a flat roof, a vapor barrier is placed on the base under the insulation to prevent moist air and condensation from rising above:

- Roof covering

- Insulation

- Steam-waterproofing Izospan D, RM

- Floor slab

When installing a flat roof, to protect the insulation from moisture from inside the room, Izospan D or Izospan RM . The material is rolled out onto floor slabs or another base with overlapping panels of at least 15-20 cm. In this case, the side of laying does not matter. The joints of the panels must be fastened together with Izospan KL, KL+ or Izospan SL tape. Insulation and roofing are mounted on top of the material.

In flat roof construction, instead of Izospan D or Izospan RM Izospan C and Izospan RS can be used . The only difference is that Izospan D is a two-layer material, and Izospan RM is three-layer and more durable and dense.

The places where Izospan joins a concrete or wooden surface are glued with Izospan ML proff .

How to properly lay Izospan on the roof?

The roof is a necessary element of any building. It protects from direct sunlight, rain and snow. In order to improve the performance characteristics of the roof structure, a vapor barrier is used. There is a wide selection of materials of this type on the market today. One of the most popular is Izospan - this is the type that fully meets vapor barrier standards, and it is also affordable. Izospan has been used successfully for roofing for several years now, because with the right approach to its installation, it helps to reliably protect the insulation layer from premature destruction.

Why Izospan is needed: advantages

The function of this type of insulation is to protect the roof insulation from condensation, which is formed due to air flows coming from inside the premises. Since condensation tends to accumulate, sooner or later the insulation system will be destroyed, which, in turn, will lead to the formation of cold bridges and the need to replace the insulation.

Materials of this brand contribute to the creation of an excellent insulation system and prevent the penetration of vapors from the interior of the building, and also protect against external adverse factors. These varieties are produced on the basis of modern technologies, and therefore have many advantages, such as:

- High tensile strength;

- Environmental Safety;

- Resistance to direct sunlight;

- Resistance to sudden temperature changes;

- Versatility of use;

- Affordable price;

- Ease of installation.

Izospan A is a type that is successfully used to protect roofing insulation. It is produced in the form of a special membrane that prevents the penetration of moisture and wind. This type is able to protect both the roof and various elements of internal walls, as well as provide reliable protection to the thermal insulation system from atmospheric phenomena and drafts. This type of vapor barrier, moreover, is able to ventilate water vapor and helps maintain a favorable microclimate in the building.

It should also be noted that some types of vapor barrier of this brand can be resistant to fire, since fire-resistant particles are added to their composition. Absolutely all types of Izospan are resistant to ultraviolet radiation and can withstand frost (up to -60 degrees Celsius) and extreme heat (up to +80 degrees).

Such material is marked, depending on the type, with letters and each of these varieties has its own special functions and characteristics.

Izospan rs which side to the insulation

Vapor barrier Izospan: instructions for installing membranes

Vapor barrier membranes are used for house cladding, roofing, flooring, partitions, and bath insulation. The use of such films protects thermal insulation from the destructive effects of moisture, facilitating the release of moist air, preventing its retention in the thermal insulation layer. The dew point shifts - condensation does not fall out, the insulation retains its thermal efficiency. In addition, they protect the interior of the building from the penetration of fiber insulation particles.

The peculiarity of the structure of vapor barrier films is that they have two layers: on one side there is a smooth layer, and on the other there is a fleecy side, which is designed to absorb condensation and prevent it from flowing onto the finish.

Varieties of Izospan

- Izospan A. This is a special vapor-permeable but moisture-protecting membrane. It is this type that is most often used to protect insulation and roofing structures from condensation and wind. The outer side of this membrane is smooth and can repel moisture, while the inner side has roughness. This protection does an excellent job of removing water vapor from the insulation system, which prevents the formation of condensation. The use of this variety helps to significantly extend the life of the entire roofing structure.

- Izospan B. It is used to protect structural elements from absorption of internal vapors. This variety consists of two layers: rough and smooth. In addition, this material prevents the accumulation of condensation, and also prevents the formation of fungus and prevents insulation particles from penetrating into the premises.

- Izospan C. Made from high density propylene. It is mainly used as a means of additional protection against vapors and moisture in roof structures that are not equipped with insulation. It is often used as a vapor barrier layer when installing parquet and laminate flooring, and in wet rooms when installing concrete screed.

- Izospan D. This type is a polypropylene base, on one side of which it is laminated. This type is often used in various construction works to provide a protective layer against moisture. It is able to withstand high loads, including snow. It is often used when constructing concrete screeds as a waterproofing layer.

There are also subtypes of Izospan, used in certain areas of construction:

- AM. A two-layer membrane used to protect insulation from condensation and various types of moisture. This variety has a high water resistance, which helps with installation in any weather.

- AS. It can protect not only insulation from moisture, but also internal wall structures and roof elements. It differs from the previous version in the number of layers - in this version there are three.

- DM. This type is distinguished by the fact that it can be mounted directly on the roof, but its service life will be up to 4 months.

- FB. It is based on kraft paper, which is laminated with a special metallized lavsan. This variety, in addition to vapor barrier properties, is able to reflect the sun's rays. Helps reduce heat loss.

- F.D. Used as an additional layer. Capable of reflecting infrared radiation, which helps save thermal resources.

- F.S. Used as a protective layer against moisture and steam. Also capable of reflecting infrared radiation. Capable of significantly extending the service life of internal structural elements.

- FX. This is a foam material with a metal-reinforced film on one side. It has the ability to reflect heat and is also resistant to significant loads.

Roof installation instructions

So, how to install the material correctly? The first, and most important, question that arises for those who are faced with the installation of Izospan for the first time is which side is laid to the insulation.

It is better to start the installation itself from the bottom of the roof structure. Following the instructions for use, you should not allow it to come into direct contact with the insulation itself, as this will greatly worsen its vapor barrier properties. The amount of overlap at the joint should not be less than 15 centimeters.

Care should be taken to ensure that during installation, various swellings do not occur or, on the contrary, sagging parts of the layer are formed. Such installation errors can lead to a variety of unpleasant noises inside the building in windy weather.

During installation, it is possible to temporarily secure the panel structure using a construction stapler, but subsequently a lath is placed on it.

To secure the Izospan A layer to the roof, you should use slats and nails. The membrane is mounted so that there is a ventilation gap of about 4-5 centimeters. This is done so that steam and condensate have the opportunity to ventilate. As a rule, this requires additional slats that are attached to the rafter system. They are pre-treated well with special protective and antiseptic compounds for wood.

During operation, moisture may accumulate on the surface of the vapor barrier, which, as it accumulates, will roll down the material. Accordingly, the first sheet should be laid in such a way that this water enters the drainage system.

After completing these steps, you can begin installing the sheathing for roofing materials. It is advisable to complete the final roofing as soon as possible, since this type of Izospan cannot serve as a temporary replacement for the roof.

In order to ensure good ventilation of the space directly under the roof, it is advisable to provide special openings both in the area of the ridge part and in the lower part of the roof.

Izospan AM: instructions for use

Now you can move from theory to practice. Another important advantage of Izospan AM is its ease of installation. Anyone can cope with this task if they follow the safety rules and instructions. The first thing you need to do is prepare all the appropriate tools and materials for the work. We will need:

- self-tapping screws;

- wooden slats;

- construction stapler;

- metallic profile;

- scissors to cut material;

- construction tape for joints;

- roulette;

- Izospan AM itself in the required quantity.

Advice! When buying products, it is better to take them with a reserve of 10%. This way it will be calmer and you won’t have to go to the store again.

Now you can get to work. According to the instructions, Izospan AM must be laid directly on the insulation. This ensures proper removal of moisture. It is better to lay the membrane with the red side inward. The white layer of Izospan AM is a little stronger and will protect the material from external factors.

The roll is laid horizontally, gradually moving from bottom to top. The weak point is the joints. That is why, in order to ensure high-quality waterproofing, the canvases need to be laid on top of each other with an overlap of 15 cm on each side. The film is fixed to the rafters using a construction stapler. And to make the joints even more airtight, they are glued using construction tape.

Note! When laying Izospan AM, you need to ensure that the sheets do not sag, but are slightly stretched, and that no defects form on the surface.

Once the membrane is secured, it can be further secured with wooden or plastic slats. They need to be secured to the wall surface or rafters with nails. The spacing of the slats is 30 cm. These slats will act as a ventilation gap.

When Izospan AM is laid, roofing material can be laid on top of it. As for the work inside, all that remains is to cover the insulation with a vapor barrier material using the same technology and, if necessary, finish the inside of the attic. That's it, job done.