Due to its durability, appearance and ease of installation, laminate is one of the most common floor coverings.

With the growing popularity of equipping houses and apartments with electric heated floors, the issue of proper installation of an electric heater under laminate flooring has become one of the most pressing.

general information

Therefore, laying heated floors under this floor covering is extremely important, especially for owners of frame houses.

Electric floor heating systems for laminate flooring have extremely high efficiency, which makes the choice in their favor completely justified. Thanks to the thermostat, you can control the heating temperature in each individual room, which reduces energy costs and ensures comfort in the home.

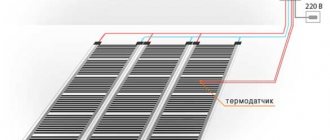

Film infrared heated floor

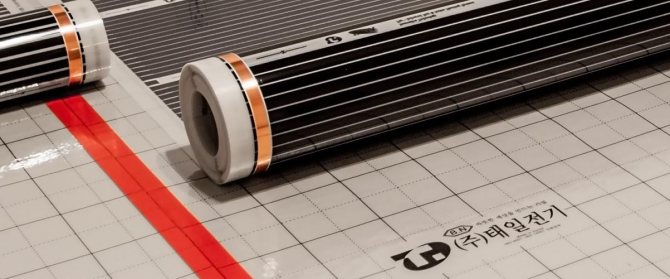

This floor heating system is based on the effect of infrared radiation, and the floor itself? it is a thin film with strips of material that conducts current.

This floor is best suited for installation under laminate, as it has a number of advantages:

- The film heated floor is installed without screed and glue;

- It is quite economical and also effective for heating floor coverings with low thermal conductivity;

- It is not dangerous to human health, and also does not have a negative effect on the laminate, since it maintains a certain level of heating.

For reference! The optimal heating temperature for laminate is 28–30 degrees, since higher temperatures cause its deformation. In addition, when heated strongly, the laminate begins to emit formaldehyde vapors? substance hazardous to health.

So, the most suitable heating system for laminate flooring is infrared film flooring.

Some Western companies producing laminate began to produce this coating with a built-in heating system. But unfortunately, its cost is too high.

Application

However, you must remember that this coating contains a dangerous substance - formaldehyde , which, if released into the air, can cause diseases of the respiratory system.

When heated above 27 °C, this substance begins to release more strongly.

For this reason, when laying heated floors under laminate in a nursery, you should very carefully monitor the thermostat readings and prevent overheating of the floor surface.

Important! In addition to the release of harmful substances, the increased temperature of the laminate can lead to deformation of its surface.

Installation features

Let's look at several options for laying a water-heated floor under a laminate and the features of its installation.

Cement-sand screed

- On a pre-leveled floor, on which there are no differences of more than 3 mm, polystyrene foam (foamed polystyrene) with a thickness of 2.5 cm to 10 cm is laid as insulation.

- The next layer should be plastic film, but it is better if it is foil penofol.

- The third layer is a special reinforcing mesh with a cell size of up to 150 mm and a wire thickness of 2-4 mm.

- A system of polyethylene, aluminum-reinforced or metal-plastic pipes is laid on top of the mesh, which are attached to the mesh with plastic clamps.

- A damper tape made of elastic material, preferably foamed polyethylene (isolon), is laid around the perimeter of the room.

- Next, the floor is filled with cement-sand mortar with a layer thickness of 5-7 cm. The distance from the floor surface, taking into account the thickness of the laminated panels, should not be more than 3 cm.

- A warm water floor under laminate will be ready for use in 3-4 weeks. In this case, the surface of the screed should be moderately moistened once a day for the first week. It is not recommended to turn on the heating until the solution has completely dried.

- The floor covering is laid on top of the screed, and the technology for laying the laminate does not differ from the standard one.

Dry screed

It should be said right away that a heated floor under a laminate, mounted in a dry screed, is ineffective. However, this installation method has one undeniable advantage: simplicity and minimum time required for installation.

How is dry screed, warm water flooring and laminate laid?

- A waterproofing film is laid on the base of the floor.

- Dry sand or expanded clay screenings are poured over the film.

- Beacons are placed around the perimeter, the screed is leveled with a simple strip or rule.

- Next, special aluminum plates are laid out, which are designed to distribute heat from the pipes over the flooring area.

- Pipes are laid in the recesses of the aluminum plates, after which the evenness of the floor is checked again.

Take the time to check the levelness of the floor after laying the pipe system. There should be no depressions or bumps. To avoid their appearance, you can use a small sheet of thick plywood to move around the room.

- A damper tape is laid around the perimeter of the room, which will serve as additional sound insulation.

- The floor is then covered with two layers of OSB, plywood or plasterboard with overlapping seams.

- The seams are fastened with self-tapping screws. For plasterboard, the fastening step is 5 cm, for OSB and plywood – 15 cm.

- Next, the standard substrate and laminated coating are laid.

Kinds

By system type

Convection

The convection type of electrical system can be made from individual heating cables or from cable mats. Each type has its own characteristics of installation and use.

Heating cable

One of the most common and inexpensive types of electric underfloor heating is the cable system. The heating cable can be single- or double-core, which affects the cost and some installation features.

The cable is laid in a thick concrete screed in a snake pattern over the entire surface of the room. This process is quite expensive and labor-intensive.

In addition, there are a number of disadvantages of this type of heater:

- high consumption of electrical energy, most of which is spent on heating the screed;

- difficulty in regulating temperature conditions due to heat accumulation by the structure;

- the impossibility of rearranging furniture due to the danger of overheating the surface underneath it.

Conclusion: It is not advisable to use cable flooring under laminate.

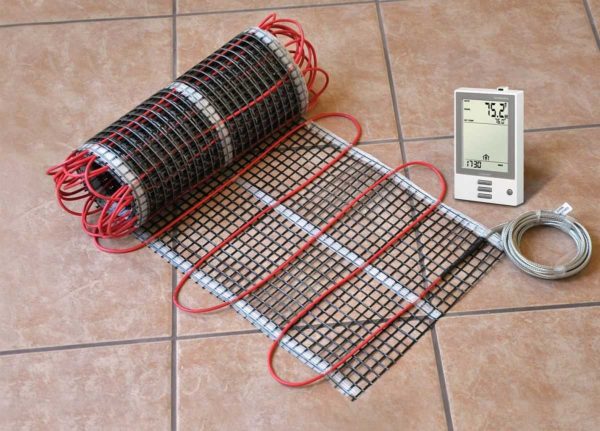

Mats

In such a system, the cable is already fixed with a snake with an optimal pitch on the canvas and has a significantly smaller thickness.

Due to this, the screed requires a much smaller thickness and installation is somewhat simplified.

Despite this, the disadvantages of such a system are the same as those of a conventional cable system.

Conclusion: such a system is preferable to cable installation, however, it is not economically viable.

Read more about cable mats in this article.

Infrared

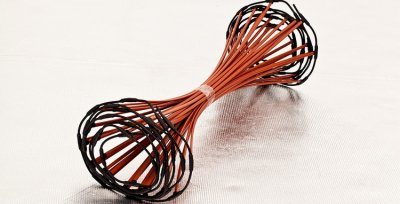

Rod

Heating these rods results in the emission of infrared waves, which heat the room. This type of electric floor is the most expensive, but at the same time economical to use.

However, it is not recommended to use it for installation under laminate due to its unreliability. In this system, contact is often broken at the point where the rod is connected to the cable. Considering the fire hazard of laminate, such a proximity is not desirable. Conclusion: the system is unreliable and is not recommended for use under laminate.

Read more about infrared rod heated floors in this article.

Film

An infrared film heater has the largest number of advantages for laying under laminate:

- does not require installation of a screed;

- ensures uniform heating, which eliminates cracking of the lamellas due to temperature changes;

- economical to use.

Conclusion: IR film flooring under laminate is the most suitable option.

By installation method

Concrete (screed)

The installation method depends on the type of electrical coating. So, for cable heated floors it is necessary to make a concrete screed, and for infrared and cable mats it is enough to level the final coating.

Floor-standing (on a wooden floor)

Without a good reason, there is no need to install an electric heating coating on a wooden flooring for a number of reasons:

- wood conducts heat poorly, so heat loss is higher, and the cable will have to be chosen more powerful;

- since an electric heated floor cannot cope with the role of the main heating source, you will also have to use standard radiators;

- wood is extremely fire hazardous, which can cause a fire if there is a short circuit;

- Wood contracts and expands under the influence of temperature differences, which can cause cracks and a decrease in thermal conductivity.

Description of technology

Today, the most widely used are three main technologies of warm electric floors , which can be easily laid under laminate:

- Cable floor.

- Heating mats.

- Infrared film technology.

If initially cable flooring and heating mats were the most popular, today an increasing number of homeowners are choosing infrared film technology , which is easy to install, providing efficient and fast heating, reducing the homeowner's costs.

Cable heated floor

For heating, a resistive cable is used, which is laid under the floor covering and, when voltage is applied to it, begins to actively emit heat . Installation of a cable floor will require the installation of a screed, the minimum height of which will be 40 millimeters.

The disadvantages of cable heated floors include the following:

- Significant consumption of electricity for heating.

- The complexity of installation work and the need to fill a four-centimeter screed.

- Impossibility of subsequent adjustment of heating intensity.

In recent years, cable heated floors have become less and less common, which is explained by the complexity of repairs and the complexity of the subsequent operation of the floor covering.

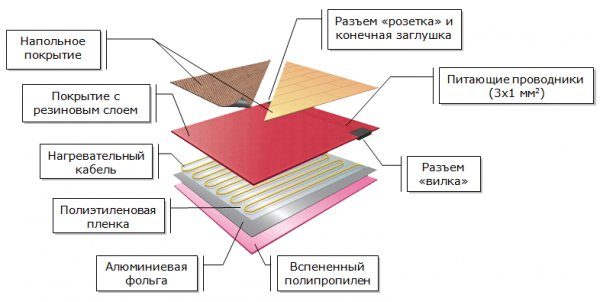

Heating mats for laminate flooring

A distinctive feature of this technology is the use of small mats , inside of which a thin heating cable is located. According to the technology, the mats are laid on the completed screed, and subsequently they are connected to the control unit. The minimum thickness of the screed is 10 millimeters, which simplifies installation work, eliminating the need for the homeowner to raise the floor level.

Infrared heated floor

This technology appeared in the early nineties and today is popular in the market. Installing a film heater under a laminate flooring is not particularly difficult ; there is no need to fill in a screed, cracking of the floor material along the seam is eliminated, and the homeowner gets the opportunity to significantly save electricity on heating the room.

Electric infrared floor heating under laminate is the most economical heating option today. The ability to smoothly adjust the power allows you to quickly solve problems with cold in the room, maintaining a comfortable temperature in the room.

The operating principle of this technology is extremely simple. The film is made of bimetals, which, when voltage is applied to them, begin to emit heat, quickly heating the floor and the entire room. It is only necessary to properly plan the installation work, using high-quality heat insulators and special foil material , on top of which the heating elements are laid.

How to choose?

The choice of the type of electrical underfloor heating system is determined by the design features of the house itself and the financial capabilities of the owners. The heating cable is most often used because its price is the lowest and its heat transfer is the highest. But at the same time, heat loss due to heating the screed is very high.

It is best to use an infrared film heater for installation under laminate, as it is more economical and efficient. In addition, installation is much simpler and the floor height increases slightly. This coating does not produce electromagnetic radiation, so it can even be used in children's rooms.

Types of laminate

This material changes its shape under the influence of temperature during the operation of a heated floor. However, laminate manufacturers decided to increase its positive qualities and make it suitable for laying on a heating surface.

Characteristics

Thermal resistance coefficient

Laminate for covering a heated floor must have a thermal resistance value of no higher than 0.15 sq. m. * K/W. The higher the porosity of the material, the lower the resistance to thermal conductivity.

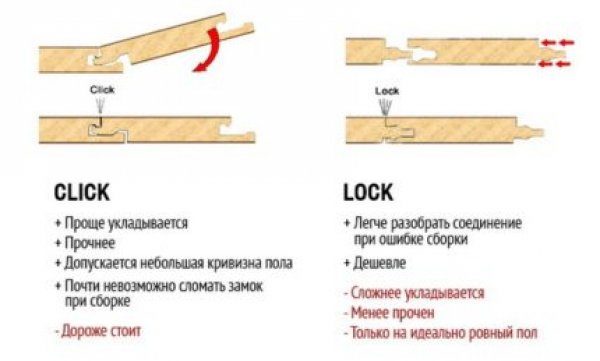

Method of connecting lamellas

Modern laminate lamellas are secured with a locking type. There are two types of slat locks, lock and click, which are best used simultaneously. Click connects the lamellas along the length, and lock closes the end parts. This fastening provides increased reliability.

Maximum temperature

The critical temperature to which laminate can be heated is 27-30 °C. When heated to higher levels, formaldehyde is released from the laminate and the surface is distorted.

It is important to pay attention to the labeling indicated on the packaging.

Thickness

The thickness of the laminate boards is one of the key indicators that affects the ability of the coating to warm up. In this case, the thickness should be selected optimally not only for heating, but also for the expected load on the coating. You will not only need to walk on it, but also install furniture on the surface. The optimal laminate thickness is considered to be 8 mm.

Class

This characteristic affects the wear of the floor surface, but not the thermal conductivity. Therefore, you need to select the class of laminate depending on the financial capabilities of the owners.

Marking

There is a special marking on the packaging of the laminate, which means that this type of material can be used with heated floors.

Important! The temperature of use does not mean the temperature of the front surface, but the bottom one, which is in direct contact with the heating surface.

Device

On a concrete base

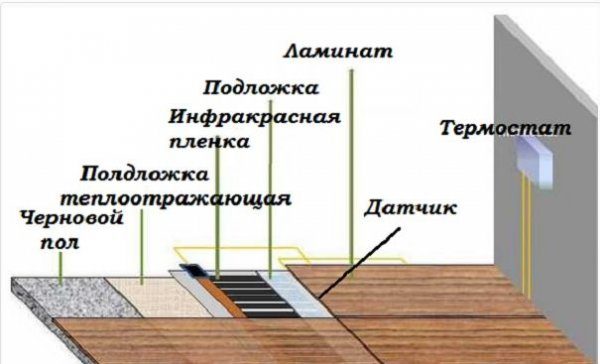

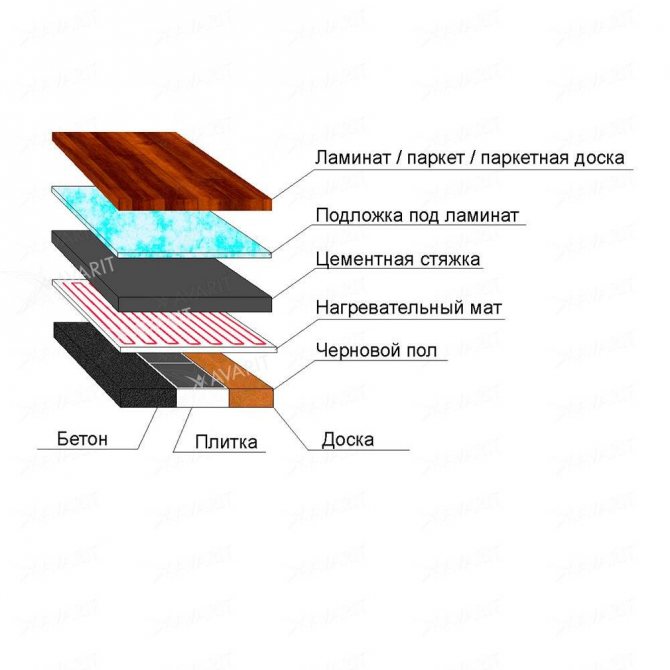

The installation of an electric floor under a laminate consists of the following layers:

- finishing coating or screed;

- waterproofing;

- thermal insulation;

- heating layer;

- screed or sheets of plywood;

- finishing floor covering.

Important! When laying laminate flooring on a warm electric floor, it is important to leave a small distance from the covering to the wall. This distance will allow the laminate to expand when heated and provide ventilation to the layers.

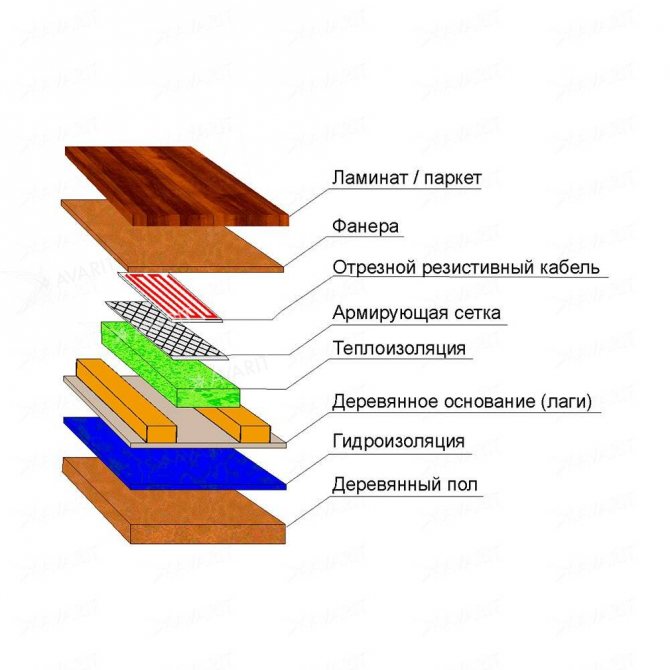

On a wooden base

Warm floor layers:

- wooden logs;

- waterproofing;

- thermal insulation;

- heating layer;

- plywood sheets;

- finishing floor covering.

Important! When installing on wooden flooring, the main thing is to follow technology and ensure fire safety.

Installation

On the screed

To properly lay an electric floor under a laminate flooring, you must follow the following sequence:

- Leveling the rough surface. If necessary, perform a floor screed to seal cracks and strengthen the base.

- Laying an insulating layer to reduce heat loss and ensure the efficiency of the finished system. To do this, use foil thermal insulation, which is fastened together with foil tape.

- Draw a layout for laying the heated floor, taking into account the locations of furniture or household appliances where heaters will not be installed.

- Next, proceed to the installation of heating sections. Pre-check the resistance of the cables and record it.

- If heating cables are laid, then a reinforcing mesh or metal plates are fixed to the thermal insulation layer to secure the cable. If mats are being laid, they can be laid out directly onto the thermal insulation.

- Before laying out the heating layer, a groove is made on the wall for mounting the thermostat and outputting the floor temperature sensor. This is where you should start laying out cables or mats.

- The installation of heated floors is carried out strictly according to the previously prepared scheme. In this case, it is important to ensure that the cables are laid in step and that the cables do not touch each other or intersect. This may cause the elements to overheat and cause a fire.

- After the heating layer is completely laid, the installation of the thermostat and temperature sensor begins. The sensor is installed at a distance of 40 cm from the wall in a corrugated pipe, the end of which is isolated from the ingress of solution. It is important to secure the temperature sensor in the middle between the turns of the cable.

- The power supply cable, temperature sensor and thermostat are connected to the junction box. Check cable resistance and system performance in all modes.

- The final stage is the installation of the screed over the cable and heating mats. In the case of IR film, sheets of plywood are laid instead of screed.

- After the solution has completely dried, the laminate is laid.

Grazing

When installing heated floors on wooden flooring, you must:

- Lay waterproofing and thermal insulation between the joists.

- Nail chipboard or boards onto the base at a pitch equal to the cable pitch, so that there is a small distance between the boards.

- After this, thin metal sheets with grooves are mounted so that the grooves fit between the boards.

- A cable is inserted into the grooves, a thermostat is mounted in the wall, as well as a temperature sensor.

- Another layer of waterproofing is laid on top and plywood sheets are laid.

- A laminate is installed on top of all layers.

Read about the installation of all electrical systems for any type of surface in this article.

And if you do not follow the installation procedure, over time, malfunctions may appear that require repair.

Installation of infrared electric heater

Work always begins the same way: with preparing the room and surface, with the calculation and purchase of the necessary material and tools. But some deviations from the usual process allow us to achieve the desired effect: to end up with a warm floor that is beautiful and safe.

- Make sure the temperature is above zero. Experts advise keeping the central heating on for a couple of days and turning it off 3 days before starting work.

- For convenience, it is better to remove the radiators. We remove floor structures that have become unusable.

Laying IR film for floors - Level the surface and clean it.

- Thermal insulation between the ceiling and the base of the floor will be provided by foil. This material is most appropriate because it has a reflective surface. It is necessary that the heat rises up, not down. We cut wide strips of foil and lay them together, connecting them with tape. You can also use foamed cork material.

If the house is old and there is damp soil under the floor, a cellar, lay an additional layer of waterproofing.

- We lay a heating film on top. It is not necessary to place it over the entire surface. It is enough to take 50-80%. But be sure to step back 15 cm from the walls and leave a gap between the electric heater strips.

We cut the film along the white areas without touching the black carbon layer. Experts call the maximum allowable length 8-15 m. We lay it towards the wall with the power source. The side with copper contacts should “look” down. We attach the clamps to the edge and connect all the wires.

We place the wires along the film itself. We fix them where the copper veins are located. The connections should be covered with thermal insulation. For added protection, use silicone sealant to seal the ends of copper wires.

We attach the thermostat to the wall next to the wiring. To do this, install a plastic box and place the regulator in it. You can hide it in the wall, like all the wires.

Place the temperature sensor in the middle of the room. Place it in a corrugated pipe. And run the wire from it to the heat regulator and connect it in the appropriate place. Wrap electrical tape around the pipe where it connects to the film. Connect the wires and power cable.

Floor heating under laminate

Grounding must be done. To do this, the edges of the film along its entire length are attached to the surface with foil tape. And its end must be connected to the wire. There should be no air bubbles under the tape.

We check the operation of the system: connect it to the AC mains, set the thermostat to the middle position, and turn on the toggle switch. After a couple of minutes, turn it off and check the entire surface with your hand. Some parts of the film may not heat up, which means you need to connect them. The tester will help determine where exactly there is no connection.

- Remove debris from the film. For waterproofing, cover with polyethylene film 160 microns thick. So that it extends 10 cm onto the walls.

- The finishing layer is laminate.

- After all work, maintain the same temperature for at least 3 days.

Laying a heated floor under a laminate does not require the use of a screed if you follow the indicated scheme (use heating mats, but more often foil). This method is suitable for rooms located on the ground floor.

Experts do not recommend installing heated floors using dry or cement screed technology at all. This method leads to unnecessary heat loss. Since part of it is spent on heating the screed itself and the additional layer of sound insulation (it is laid so that you cannot hear how the heating system works). And then the floor covering warms up.

Screed technology is usually used in the kitchen, loggia, bathroom and bathroom. And for this, a better choice would be a cable “warm floor”, for example, a model with a reinforced mesh.

If you still prefer this method or choose it forcedly, make sure that the substrate is no thicker than 3 mm, and the heating cable passes under the “wet” screed (or make it thin). It is placed on top of the screed if tiles are used as the floor covering.

Advantages and disadvantages

Electric underfloor heating under laminate has many advantages:

- provides the most comfortable room temperature at any time of the year;

- fits perfectly with any interior;

- does not require complex installation and volumetric temperature control design;

- there is no need to obtain permits for the installation of this type of heater;

- Fine control of the room temperature is guaranteed.

There are significantly fewer disadvantages to electric heated floors:

- high energy costs;

- the need for a dedicated power supply line if the existing one cannot cope with the additional load.

Other types of finishing coatings for electric heated floors: tiles, linoleum.

Types of electrical systems: mobile heated floor.

Warm floor under laminate

What kind of warm floor to lay under laminate and parquet

without the risk of deformation of the floor covering?

Electric heating cable and mats in the case of using natural wooden finishing materials should be installed in the screed. This will increase the thickness of the floor. Laminate, due to its high performance and aesthetic qualities, is quite popular. The complexity of installation should also be assessed. Therefore, when choosing a heated floor for parquet and laminate, the price of the product is not a fundamental characteristic. So what should you choose?

Cheat sheet for choosing heated floors (991.86 KB)

Infrared heated floor under laminate

The cheapest heating

– infrared heated floor.

The melting point of the film is high, which is safe for wood coating. The products conduct heat well. An infrared film heated floor with a power of 150 W/sq.m is suitable for laying under a laminate (in an unheated room - with a power of 220 W/sq.m). Or “LamiPol®” - a safe infrared floor with a power of 160 W/sq.m. The price of films varies depending on the manufacturer and model series, and starts from 325 rubles. per linear meter. No screed needed!

Installation diagrams for infrared floors under laminate and parquet

The Avarit store sells self-regulating and striped films Heatus Heating Film, striped film Lavita LH, and 5 more brands for installation as a warm floor under natural wood and laminate. The heated film releases negative ions that have a beneficial effect on human health. Other advantages are heating of the surface in 10 minutes, protection from mechanical damage, fire safety, and small thickness of the multilayer film.

Cable for laminate flooring

Cable on mounting plate.

The Danish manufacturer Devi has developed a product for coating without pouring. The thin cable fits into the mounting grooves on the DEVIcell™ Dry plate, suitable for laminate, parquet boards, linoleum, carpet.

Raychem has a proposal for heated floors for installation on a plate under laminate and tiles - the T2Red R-RF-10M2-LM cable system. This model is designed specifically for floor coverings that are sensitive to temperature increases. The T2Red R-RF-10M2-LM is based on a self-regulating heating cable, which differs from a resistive cable in its high price and operating principle. This electric heated floor never overheats and saves energy.

Cable for installation on joists.

Devi, Nexans, Handy Heat and some other manufacturers produce low power resistive cable (6-10 W/m). The cable is secured between the lags on the reinforcing mesh, observing the laying step and other tips from the installation instructions. This option without a cement screed is convenient for houses with a thermally insulated wooden base and complies with the standards for heating wooden floors (power should not exceed 80 W/sq.m).

Installation diagrams for heating cables for floor heating

Foil and cable mats

All of the above products are installed under the laminate using the “dry” method.

Foil

Heating mats are also installed under the laminate without cement screed or glue. According to European standards, mats on foil are installed only on a concrete base. We recommend budget Russian mats Alumia (Teplolux), Swedish Thermomat TVK-130 LP in rolls and Danish Devidry 100 (like rubberized mats that are easily connected to each other).

Cable heating mats on mesh

differ from foil ones at a low price. But is it worth saving? After all, between the laminate and the cable mesh you will have to lay a layer of cement-sand screed or a thick layer of leveling mixture.

Installation diagrams for heating mats for heated floors with wood covering

Prices and delivery

Sale of heated floors under laminate with delivery to Russian regions. Pickup points in Moscow, St. Petersburg and Orenburg (online store prices).

From us you can order new products in the field of infrared heating, including carbon flooring and heated floors for laminate and cable-based parquet. Delivery time for products and devices for controlling the temperature of underfloor heating, thermostats, sensors, connecting elements - from 1 day

. Call, write, order, managers will answer questions about installation and help make your home cozy and comfortable.