Features of different types of fuel

Let's consider the two main, most common types of solid fuel raw materials - firewood and coal. Firewood contains a significant amount of moisture, so the moisture first evaporates, which will require a certain amount of energy. After the moisture evaporates, intense combustion of the wood begins, but, unfortunately, the process does not last long.

Therefore, to maintain it, regular addition of firewood to the firebox is required. The ignition temperature of wood is about 300°C.

In terms of the amount of heat generated and the duration of combustion, coal is superior to wood . Depending on the age of the fossil material, the mineral is divided into types:

- brown;

- stone;

- anthracite.

Composition of different types of fuel

Brown coal is a young deposit, so it contains the largest amount of moisture (from 20% to 40%), volatile substances (up to 50%) and a small amount of carbon (from 50% to 70%). Its combustion temperature is higher than wood and is 350°C. Heat of combustion - 3500 kcal/kg.

The most common type of fuel is coal. It contains a small amount of moisture (13-15%), and the content of the combustible element carbon exceeds 75%, depending on the variety.

The average combustion temperature is 470°C. Volatile gases in coal are 40%. When burned, 7000 kcal/kg is released.

The oldest solid fuel deposits include anthracite, which occurs at considerable depth. It contains virtually no volatile gases (5-10%), and the amount of carbon varies between 93-97%. The heat of combustion ranges from 8100 to 8350 kcal/kg.

Special mention should be made of charcoal. It is obtained from wood by pyrolysis - combustion at high temperatures without oxygen. The finished product has a high carbon content (from 70% to 90%). When burning wood fuel, about 7000 kcal/kg is released.

You can read about the features of using peat briquettes in this article: https://teplo.guru/kotly/torfyanyie-briketyi.html

Types of coal

There are several types of this fuel; the temperature of coal during combustion will be different for each type. Based on their origin, they distinguish between coal obtained from wood and fossil specimens.

Fossil fuels were created by nature itself. It consists of plant components that have undergone changes while located under the thickness of the earth.

The following types of coal fall into this category::

- anthracite;

- brown;

- stone.

There are 3 types of coal

Natural resources

The youngest type of fossil is brown coal. This type of fuel consists of a large number of impurities and has a high level of moisture (up to 40%). In this case, the carbon content can reach up to 70%.

Due to high humidity, this coal has a low combustion temperature and low heat transfer . The combustion temperature is 1900 degrees, and combustion occurs at 250 degrees. The brown variety is rarely used for stoves in private homes, since it is much inferior in quality to firewood.

However, brown coal in the form of briquettes is in high demand. This coolant undergoes special modification. Its humidity decreases, and therefore the fuel becomes more efficient.

Stone minerals are older than brown ones. In nature they are found very deep underground. This coolant can contain up to 95% carbon and up to 30% volatile impurities. At the same time, the fossil has a low moisture content - a maximum of 12%.

While in the furnace, the combustion temperature of coal is 1000 degrees , and under ideal conditions it can reach 2100 degrees. It is quite difficult to ignite; to do this, you need to heat the fossil to 400 degrees. Stone coolant is the most popular type of fuel for heating buildings and private homes.

Anthracite is the oldest fossil, practically free of impurities and moisture. The amount of carbon in the fuel is more than 95%. The combustion temperature is 2250 degrees under suitable conditions. For ignition it is necessary to create a temperature of at least 600 degrees. It is necessary to use firewood in order to create the necessary heating.

Interesting: the temperature of burning wood in the stove.

This coal has no moisture

Production products

Charcoal is not a natural resource, so it is classified in a separate category. This product is obtained by processing wood. Excess moisture is removed from it and the structure is changed. When properly stored, the moisture content of wood fuel is 15%.

In order for the fuel to ignite, it must be heated to 200 degrees. It should be taken into account that the combustion temperature of charcoal may differ depending on the conditions and type of wood, for example :

- Birch coals are suitable for forging metal - with a high-quality air supply, they will burn at 1200-1300 degrees;

- in a heating boiler or stove, the temperature of charcoal during combustion will be 800-900 degrees;

- in a barbecue outdoors the indicator will be 700 degrees.

Fuel obtained from wood is very economical. It requires much less than firewood. This industrial product is ideal for cooking meat on the grill.

In this video you will learn the difference between coal and charcoal:

GOST 7657-84 Charcoal. Specifications

1 file 106.78 KB Download

Coal: varieties and characteristics

Coals first of all differ in their origin. Coke, which is obtained by burning wood, and also fossil fuels are used as an energy source.

Fossil coals are fuels created by nature. They consist of the remains of ancient plants and bitumen masses, which underwent a number of transformations in the process of sinking underground to great depths. The transformation of the initial substances into effective fuel took place at high temperatures and in conditions of oxygen deficiency under the earth. Fossil fuels include brown and hard coals, as well as coal.

Brown coals

Among fossil coals, the youngest are brown coals. The fuel got its name from its brown color. This type of fuel is distinguished by a sufficient amount of volatile impurities and a high moisture content - up to 40%. In this case, the amount of pure carbon reaches 70%.

Due to very high humidity, brown coal has a low combustion temperature and low heat transfer. Fuel ignites at 250°C, and the combustion temperature of brown coals can reach 1900°C. The heat of combustion is approximately 3600 kcal/kg.

As an energy carrier, brown coal in its natural form is inferior to firewood, which is why it is less often used for stoves and solid fuel units in private homes. But briquetted fuel is in strong demand.

Brown coals

Brown coal in briquettes is a combustible, special preparation. By reducing moisture, its energy efficiency increases. The heat release of briquetted fuel can reach 5000 kcal/kg.

Stone coals

Hard coals are older than brown coals; their deposits are located at a depth of up to three kilometers. In this type of fuel, the content of pure carbon reaches 95%, and volatile impurities - up to 30%. This energy carrier contains no more than 12% moisture, which has a beneficial effect on the thermal efficiency of the mineral.

The combustion temperature of coal under optimal conditions can reach 2100°C, but in a heating furnace the fuel is burned at a maximum of 1000°C. The heat output of coal fuel is 7000 kcal/kg. It is harder to ignite - it requires heating up to 400°C to ignite.

Coal energy carrier is most often used for heating residential buildings and houses for other purposes.

Stone wall

The oldest solid fossil fuel, which has almost no moisture and volatile impurities. The carbon content in coal exceeds 95%.

The specific heat output of the fuel can reach 8500 kcal/kg - this is the highest indicator among coals. Under optimal conditions, coal burns at 2250°C. It lights up at a temperature of at least 600°C - this is an indicator for the lowest calorie types. For ignition it is necessary to use firewood to create the necessary heat.

Characteristics of coal

Coal is primarily an industrial fuel. Its use in a furnace or boiler is impractical and expensive. In addition to high heat transfer, the positive qualities of coal include low ash content and low smoke.

What is coal made of? What is the chemical formula of coal

Coal is one of the oldest fuels known to man. And even today it occupies a leading position in terms of volume of use. The reason for this is its prevalence, ease of extraction, processing and use. But what is he? What is the chemical formula of coal?

In fact, this question is not entirely correct. Coal is not a substance, it is a mixture of different substances. There are a lot of them, so it is impossible to completely determine the composition of coal. Therefore, by the chemical formula of coal in this article we will rather mean its elemental composition and some other features.

But what can we learn about the state of this substance? Coal is formed from plant remains over many years due to exposure to high temperature and pressure. And since plants are organic in nature, organic substances will predominate in the composition of coal.

Depending on the age and other conditions of origin of coal, it is divided into several types. Each type differs in its elementary composition, the presence of impurities and other important characteristics.

Brown coal

It is the youngest type of coal. It even exhibits a plant-like woody structure. It is formed directly from peat at a depth of about 1 kilometer.

This type of coal contains a fairly large amount of moisture: from 20 to 40%. When exposed to air, it evaporates and the coal crumbles into powder. Next we will talk about the chemical composition of this particular dry residue. The amount of inorganic impurities in brown coal is also large and amounts to 20-45%. These impurities include silicon dioxide, aluminum, calcium and iron oxides. It may also contain alkali metal oxides.

This coal contains a lot of volatile organic and inorganic substances. They can make up up to half the mass of this type of coal. The elemental composition excluding inorganic and volatile substances is as follows:

- Carbon 50-75%.

- Oxygen 26-37%.

- Hydrogen 3-5%.

- Nitrogen 0-2%.

- Sulfur 0.5-3%.

Coal

In terms of formation time, this type of coal comes next after brown coal. It has a black or gray-black color, as well as a resinous, sometimes metallic sheen.

The moisture content of hard coal is significantly less than brown coal: only 1-12%. The content of volatile substances in coal varies greatly depending on the location of mining. It can be minimal (from 2%), but can reach values similar to brown coal (up to 48%). The elemental composition is as follows:

- Carbon 75-92%.

- Hydrogen 2.5-5.7%.

- Oxygen 1.5-15%.

- Nitrogen up to 2.7%.

- Sulfur 0-4%.

From this we can conclude that the chemical formula of hard coal consists of more carbon than that of brown coal. This makes this type of coal a higher quality fuel.

Brown coal

It is the youngest type of coal. It even exhibits a plant-like woody structure. It is formed directly from peat at a depth of about 1 kilometer.

This type of coal contains a fairly large amount of moisture: from 20 to 40%. When exposed to air, it evaporates and the coal crumbles into powder. Next we will talk about the chemical composition of this particular dry residue. The amount of inorganic impurities in brown coal is also large and amounts to 20-45%. These impurities include silicon dioxide, aluminum, calcium and iron oxides. It may also contain alkali metal oxides.

This coal contains a lot of volatile organic and inorganic substances. They can make up up to half the mass of this type of coal. The elemental composition excluding inorganic and volatile substances is as follows:

- Carbon 50-75%.

- Oxygen 26-37%.

- Hydrogen 3-5%.

- Nitrogen 0-2%.

- Sulfur 0.5-3%.

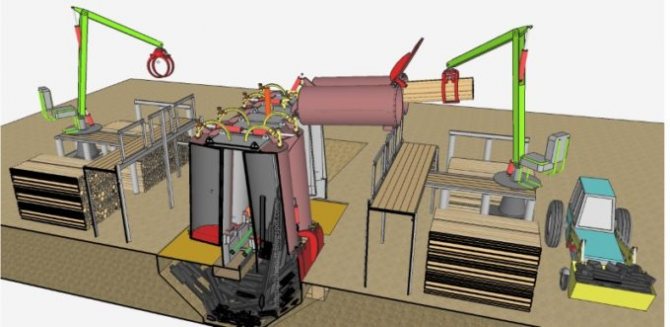

Production process technology

In ancient times, people used charcoal technology to produce coal fuel. They placed firewood in special pits and covered them with earth, leaving small holes. After the industrial revolution, the charcoal charring procedure began to be carried out using automated equipment capable of controlling the carbonization reactions of substances and heating the material to combustion temperature.

In industrial conditions, this material is produced in small quantities. Before producing charcoal, you need to choose the right raw materials, purchase specialized equipment and determine the manufacturing technology. The industry uses 3 main methods for producing charcoal:

- drying;

- pyrolysis;

- calcination

The resulting products are packaged in bags, briquetted and labeled. GOST 7657-84 describes how charcoal is made in production. It describes the process flow diagrams and provides precise information about the amount of temperature required to heat the raw materials.

Charcoal can be produced at home, forming a cottage industry. Most often, a personal plot is chosen as a place for the production of these raw materials. Before making charcoal, you need to arrange the premises in accordance with safety rules, choose a manufacturing technology and evaluate the prospects for the development of a business project.

Selection of raw materials

According to GOST 24260-80 “Raw materials for pyrolysis and charcoalization”, when creating charcoal, hardwood is required. This group includes birch, ash, beech, maple, elm and oak. Coniferous trees are also used in production: spruce, pine, fir, larch and cedar. The least used softwoods are pear, apple, plum and poplar.

GOST 24260-80 Wood raw materials for pyrolysis and charcoalization. Specifications

The raw materials must have the following dimensions: thickness - up to 18 cm, length - up to 125 cm. The wood should not have a large amount of sap rot (up to 3% of the total area of the workpiece). Its presence reduces the hardness of the material and increases its ash content. Large amounts of water are not allowed. This substance leads to the appearance of cracks on the surface of the workpieces.

Drying wood

During the drying process, the raw materials are placed in a charcoal burning block. Wood is affected by flue gas. As a result of heat treatment, the temperature of the workpieces increases to 160 °C. The amount of water contained in wood affects the duration of the technological process. As a result of drying, a material with a moisture level of 4-5% is obtained.

Pyrolysis

Pyrolysis is a chemical decomposition reaction that involves heating a substance with a lack of oxygen. During combustion, dry distillation of wood occurs. The workpieces are heated to 300 °C. Pyrolysis removes H2O from the raw material, which leads to charring of the material. With further heat treatment, the wood is converted into fuel, the percentage of carbon is 75%.

Calcination

After pyrolysis is completed, the product is calcined. This procedure is necessary to separate resins and unnecessary gases. Calcination occurs at a temperature of 550 °C. After this, the substance is cooled to 80 °C. Cooling is necessary to prevent the product from spontaneous combustion upon contact with oxygen.

Advantages

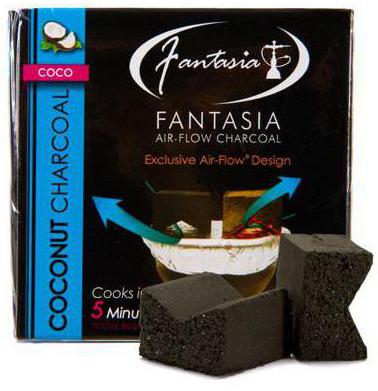

The choice of consumers in favor of coconut charcoal is obvious, as it has numerous advantages:

- heating time is 5-7 minutes;

- longer combustion process, about 1.5 hours;

- high combustion temperature;

- does not spark during ignition;

- there is no foreign smell or taste;

- environmentally friendly product.

A special technology for processing coconut shells makes it possible to achieve excellent performance in terms of heat transfer intensity and, as a result, the duration of smoldering. Coconut coals are made in the form of a pillow, which is very practical - it simplifies the lighting process and does not roll off the cup, and most importantly, does not leave a lot of ash behind.

Only a real product can satisfy the high demands of avid hookah lovers. This coal is practically odorless and smokeless, and only the process of smoking tobacco gives it a subtle aroma of exoticism.

It is also worth mentioning the cost-effectiveness of this product - its combustion, compared to other types of hookah coals, lasts several times longer. It does not spark when ignited, which is very important for enclosed spaces.

We suggest you read: Which thin cigarettes are the lightest?

Coconut charcoal for hookah is completely natural, made from coconut shells. It contains no sulfur or chemical additives. Such coal burns for a long time, maintains a stable high combustion temperature, and does not tend to emit specific odors.

In addition, to make coconut charcoal, precious rare wood species are not cut down. Coconut charcoal production is an innovative development and cost-effective. Coconut shells increase the intensity of heat produced when coals burn. The special formula of the pads allows you to light coconut charcoal very simply and quickly.

Coconut charcoal has numerous benefits. Thanks to a special technology for processing raw materials, the heat transfer rate is excellent, as a result of which the coal smolders for a very long time. Coconut charcoal has a practical pillow shape, which simplifies the ignition process, and does not leave a large amount of ash, and does not roll off the cup.

Coconut charcoal produces virtually no smoke or odor, and during smoking it produces a barely noticeable exotic aroma. Another advantage is efficiency. The combustion process, compared to other types of coal, takes several times longer. When ignited, no sparks are formed, which makes it absolutely safe for use indoors.

You should choose coal only from a well-known, trusted manufacturer, with high-quality characteristics and a long shelf life. Coconut charcoal allows you to fully enjoy the wonderful taste and aroma of a hookah.

This type of coal has excellent filtering properties. It perfectly purifies water. To convert coconut shells into a sorbent, they are first burned and then processed, resulting in a change in the structure of the material. As a result, coconut charcoal traps harmful substances, such as chlorine compounds contained in tap water, foreign tastes and odors.

Charcoal is also a completely natural product. The material used to make charcoal is lemon tree particles. It is also made from other shrubs, olive pits and other exotic trees or hardwoods that contain virtually no resin.

Since ancient times, charcoal has been most popular in Eastern countries. No foreign odor is generated during smoking. The production technology is based on the combustion of natural wood. The most popular charcoal is made from citrus and fruit woods. This is a grape, lemon or olive tree.

The only drawback of charcoal is that it burns out quite quickly, so it has to be changed quite often. Coal production technology does not involve the use of chemical elements. The duration of coal combustion is individual and depends on the manufacturer. Charcoal is the oldest type of hookah coal. It began to be produced back in the 16th-17th centuries in African countries - Syria, Egypt, Lebanon.

This coal is ideal for lovers of recreation in the wild and active pastime, as it can be ignited with the help of a fire. The tobacco layers in the bowl burn slowly and steadily; the coal does not produce too much heat. Every year, charcoal production technology is improved, resulting in an increase in its quality.

What coal to choose for the fire?

What is coal? This is a product of plant origin, which contains carbons and non-flammable impurities. It is they who form ash and slag-like substances after burning. The ratio of the two components is different everywhere. It is this, as well as the “age” of natural fuel, that determines the grade of coal. Experts distinguish several varieties.

The “youngest” type of coal is lingite. It has a rather loose structure. If you pick up a lump of lingite, it will quickly crumble and lose its shape. This type of coal is most often used in thermal power plants, but lingite is not suitable for heating a home.

In addition to lingite, brown coal, hard coal, and anthracite are also mined - the most ancient carbon deposits. All varieties have different humidity levels. In brown coal, for example, humidity is 50%; in anthracite its threshold does not exceed 7%. Therefore, anthracite has the highest specific heat. Its indicators are 9 thousand kcal/kg.

Material for coal-fired stoves is the main criterion for choosing fuel and stove. Let's look at these qualities in more detail.

When the heating of the stove is successfully completed and the firewood is happily blazing in the firebox, all that remains is to monitor the thermal operating conditions and add new logs in time. As for the mode, it is recommended to maintain it constantly at the same level, avoiding overheating

This is important because alternating intense heating and cooling often causes the furnace body to expand and contract, causing cracks to occur.

Maintaining optimal thermal conditions and timely adding logs is the best way to properly heat a stove with wood, although it is not very convenient at night. No one wants to get up in the middle of the night, although if there is severe frost outside, this cannot be avoided, otherwise the house will be cold by morning. During continuous burning for several days, the ash pan has to be cleaned

Coal for hookah

- Only the required temperature of 180 - 250 degrees is achieved;

- Does not produce carbon monoxide;

- The cost of operation is an order of magnitude cheaper than conventional coal - 50-75 watts per hour of electricity for the city is about 15 kopecks per hour;

- No smoke;

- No smell;

- No need to change coal

- No need to shake off the ashes

In general, everything is rosy except for one thing - you need an outlet and a power cord.

Electric coals have nothing in common with them. This is a spiral that runs on electricity. Let's classify them as a separate type as an innovation in the hookah industry.

It has a pleasant smell and maintains a high temperature for a long time. There are three types, which differ in composition, temperature characteristics, taste and smell:

- coconut: “Crown”, “Panda”, “Cocobrico”, “Coconara”, “Coco Loco” etc.;

Coconut charcoal “Cocobrico”

Coconut charcoal “Panda”

- woody: “Suzanna”, etc.;

Charcoal “Suzanna”

- bamboo: “Aladin Bamboocha”, etc.;

Bamboo charcoal “Aladin Bamboocha”

Coconut charcoal is made from coconut shells and is considered harmless to health.

Temperature: Maintains optimal temperature for a long time, ignites in about 10-15 minutes.

Taste and smell: none. The coals do not spoil the taste of tobacco.

Charcoal – made from wood and shrubs: lemon tree and olive pits.

Temperature: Takes a long time to light up, but burns quickly.

Taste and smell: gives the smoke an aroma that is distinguished by its lightness and tenderness.

Bamboo charcoal is made from bamboo wood. A good substitute for wood analogue.

Temperature: Maintains optimal temperature for a long time. The burning time is longer than that of wood.

Taste and smell: has a special taste and aroma.

Usually made from either saltpeter or dry alcohol. Saltpeter coals have an unpleasant odor. The dry alcohol analogue is relatively better than saltpeter, but in terms of properties, both are very far from coconut and wood ones.

Temperature: ignites quickly – 1-2 minutes. The combustion process lasts from 20 to 40 minutes.

Taste and smell: pungent, chemical smell. It is felt both when lighting the coals and while smoking.

Coal is an excellent absorber of viruses and various organic substances. It also absorbs chlorine, foreign odors and clarifies the liquid.

This type of coal is usually presented in 2 versions: compressed and in the form of granules. Granulated coconut charcoal is made from special varieties of coconut shells. Thanks to this, it is not only an excellent absorbent, but also has a high density and does not wear out over time.

Its also distinctive quality is regeneration, which means that it can be used more than once, washing as necessary. After washing, the coal fully returns to its quality and is ready for further work.

Without a doubt, hookah charcoal is important for the quality and taste of inhaled smoke when smoking. Manufacturers today offer a fairly wide range of hookah coals - wood, saltpeter, tablet, coconut.

Each of these types has its own characteristics. For example, charcoal in tablets can be easily lit with a regular lighter, but the taste of the smoke is not very pleasant. Coconut coals take longer to light and require a higher temperature, but they do not have an unpleasant odor and smolder much longer.

Hookah fans have recently increasingly given preference to coconut coals. This is a natural product that does not require sacrifice from nature. Their production does not require cutting down precious wood.

Coconut charcoal has excellent filtering properties. It is characterized by a number of properties that make this product one of the leaders in terms of water purification.

In order for coconut shells to turn into a sorbent, they are burned first and then processed. As a result of such manipulations, the structure of the material changes. Its installation in the filter will allow you to retain harmful substances in the coconut charcoal material. It perfectly retains chlorine compounds, which is important when filtering tap water.

Purification with coconut charcoal allows you to remove both organochlorine elements and foreign tastes and odors from water. For this reason, such coal is used for additional processing of high-purity process water.

The final product obtained from coconut shells is characterized by high purity, low dust formation, activity and high mechanical strength.

Combustion process

Depending on the type and grade, fuel is divided into short-flame and long-flame. Short-flame coals include anthracite and coke, and charcoal.

When burned, anthracite produces a lot of heat, but to ignite it it is necessary to provide a high temperature with a more easily flammable fuel, such as wood. Anthracite does not emit smoke, burns odorless, and has a low flame.

Long-flame fuels burn in two stages. First, volatile gases are released, which burn above the coal layer in the furnace space.

After the gases burn out, the remaining fuel begins to burn, which has meanwhile turned into coke. The coke burns on the grates with a short flame. After carbon burns out, ash and slag remain.

Combustion Features

Coolants differ in flame type. Lignite and lithium are characterized by long flames, while anthracite and wood fuels are energy carriers with short flames. The latter release a lot of thermal energy and burn almost without a residue.

Long flame fuel burns in two stages. First, the volatile fractions evaporate, the combustible gas burns and moves to the upper region of the combustion chamber. During the evolution of gas, the coal cokes, and after the impurities are completely burned out, coke combustion begins. A short flame appears. Finally, the carbon burns, leaving ash and waste behind.

Grill temperature

The ideal fuel temperature for frying meat is 600-700 degrees. In this case, the kebab will turn out to be as juicy and cooked as possible.

Professionals advise determining the temperature by the type of coolant. It is optimal when the coals begin to “grey”, that is, white ash forms on them.

It is important not to confuse the combustion temperatures of coal and wood. If you place birch wood in the grill and light it, the temperature will reach 1070-1570 degrees . This indicator is not suitable for frying barbecue. The meat will simply burn.

Measuring indicators

In order to determine the temperature in the grill, beginners can use a pyrometer. This device is inexpensive and will make life easier for those who love summer holidays. However, it is possible to measure the indicator without using special tools. All you need is your hand. It must be raised above the grill at a height of 7-8 cm from the fuel. In the process , you need to calculate after what time it will become as hot as possible :

- after 1 second - temperature level of 350 degrees or more;

- 2 seconds - about 280 degrees;

- 3 seconds - 250 degrees;

- 4 seconds - 200 degree mark;

- 5 seconds or more is less than 150 degrees.

Measuring degrees in this way is very arbitrary and not very suitable for beginners. Only an experienced barbecue maker can accurately determine the temperature in the barbecue using his hand.

The use of a variety of fuels is very popular. Coal, peat and wood are used not only in everyday life, but also for industrial purposes. In today's market, everyone will find a suitable coolant based on the purpose and desired requirements.

Determining the type of fuel needed for a furnace depends on many factors.

One of them is the amount of heat released during combustion.

Coal, wood, peat, and fuel briquettes are used as combustible materials.

Combustion formulas

Ignition temperatures of different types of fuel (click to enlarge)

When fuel (wood, coal) ignites, a chemical reaction occurs and heat is released.

Carbon dioxide reacts with the carbon in the fuel in the upper layers to form carbon monoxide.

The combustion process does not end there, because rising up in the combustion space, carbon monoxide reacts with oxygen from the air, the influx of which occurs through the vent or the open firebox door.

Its combustion is accompanied by a blue flame and the release of heat. The resulting carbon monoxide (carbon dioxide) enters the chimney and escapes through the pipe.

Smoldering with minimal oxygen will produce non-poisonous carbon monoxide, producing even heat.

Application

The main use of fuel is to burn it to produce heat. Heat is used not only for heating a private home and cooking, but also in industry to support technological processes that occur at high temperatures.

Unlike a conventional stove, where the process of oxygen supply and combustion intensity is poorly regulated, in industrial stoves special attention is paid to controlling the supply of oxygen and maintaining a uniform combustion temperature.

Let's consider the basic scheme of coal combustion.

- The fuel heats up and moisture evaporates.

- As the temperature rises, the coking process begins with the release of volatile coke gases. When burned, it provides the main heat.

- Coal turns into coke.

- The coke combustion process is accompanied by the release of heat sufficient to initiate coking of the next portion of the fuel.

In industrial boilers, the combustion of coke is separated into different chambers from the combustion of coke oven gas. This allows the flow of oxygen for coke and gas at different intensities, achieving the required combustion rate and maintaining the required temperature.

Using Charcoal

In everyday life, charcoal is used to cook meat on the grill.

Thanks to the high combustion temperature (about 700°C) and the absence of flame, uniform heat is provided, sufficient for cooking meat without charring.

It is also used as fuel for fireplaces and cooking on small stoves.

In industry, it is used as a reducing agent in metal production. Charcoal is indispensable in the production of glass, plastics, and aluminum.

It is possible to make charcoal yourself. Details: https://teplo.guru/eko/drevesnyiy-ugol-svoimi-rukami.html

Production technology

Coconut charcoal for hookah is a truly innovative find. In terms of its properties, it is an order of magnitude higher than its competitors. This product is produced from coconut shells using a special technology, which results in achieving such cost-effective characteristics as long-lasting smoldering and high combustion temperatures.

The use of coconut shells in the production process helps to increase the intensity of the heat generated by burning coal. Thanks to the unique pillow shape, coconut coals can be lit without much effort.

Use of brown coal

Although the combustion temperature and heat transfer of brown fossils is lower than that of stone, it is also used for heating and cooking.

This is due to its low cost.

But brown coal is more widely used for processing and producing various chemicals: semi-coke, rock wax, soot, gasoline.

The operating principle and advantages of coal boilers are discussed here: https://teplo.guru/kotly/tverdotoplivnye/ugolnye-kotly-otopleniya.html

Watch the following video about burning brown coal:

Charcoal burning temperature

Regular charcoal, produced by burning dry wood, has surprisingly high performance. Its specific calorific value reaches 7400 kcal/kg, humidity is a maximum of 15% (depending on storage conditions) and the ash content is so low that almost nothing remains after combustion. As for the combustion temperature of birch coals, in practice it is enough to soften and forge metal in a forge. This is approximately 1200-1300 ºС.

This simple type of fuel is also used for cooking on various outdoor stoves. And, although the conditions for burning charcoal in a barbecue are far from ideal, its consumption is much less than that of ordinary firewood. This is due to decent heat generation and the absence of ash inclusions.

Properties of charcoal

Charcoal is placed in a separate category because it is not a fossil fuel, but a manufactured product. To obtain it, wood is processed in a special way to change the structure and remove excess moisture. The technology for producing an effective and easy-to-use energy carrier has been known since ancient times - previously, wood was burned in deep pits, blocking access to oxygen, and today special charcoal kilns are used.

Burning wood in a charcoal kiln

Under normal storage conditions, the moisture content of charcoal is about 15%. The fuel ignites when heated to 200°C. The specific calorific value of the energy carrier is high - it reaches 7400 kcal/kg.

The burning temperature of charcoal varies depending on the type of wood and combustion conditions. For example, birch coals can be used to heat up a forge and forge metal - with an intensive air supply they will burn at 1200-1300°C. In a stove or heating boiler, the temperature during combustion will reach 800-900°C, and when using coal in a barbecue outside - 700°C.

Fuel made from burnt wood is economical - its consumption is significantly lower compared to using firewood. In addition to high heat transfer, it is characterized by low ash content.

Due to the fact that charcoal burns with a small amount of ash and produces even heat without an open flame, it is ideal for cooking meat and other foods over an open fire. It can also be used for fireplace heating or cooking on a stove.

Final temperature table

| Coal | Temperature | Advantages | Flaws |

| Birch | 600-650°C | Reasonable price, optimal burning time and temperature | Average burning time |

| Briquettes | 650-700°C | Burn for a long time, good heat, minimum smoke | Difficult to light, high price |

| Oak | 620-660°C | Burns long, dense | Difficult to light, high price, rare |

| Pine | 570-620°C | Low price | Burns quickly and smokes |

| Aspen | 570-620°C | Low price | Burns quickly, smokes |

How to store coal

When purchasing a large amount of fuel at once, you need to know how to store it. If you follow storage rules, coal will not lose its original properties.

Shelf life

It is beneficial to purchase solid fuel in large quantities at once. But, like any other combustible material, coal has a shelf life that depends on the deposit and brand.

It is interesting that coal can remain in the bowels of the earth for millions of years without losing its quality. However, once mined, it immediately begins to interact with the environment. The most dangerous thing for it is a meeting with oxygen - that is, oxidation. It destroys the structure of the raw material and renders it unusable.

The larger the coal pieces, the longer it will take to oxidize. For example, coal with a fraction above 100 mm can be stored without loss of quality characteristics for up to 3 years, with pieces with a size of up to 100 mm - about 1 year, and fuel with a fine fraction - less than 24 months. The 20-40 mm fraction, which you can purchase from our company, retains its quality for one season. That is, it makes no sense to store such coal for several winters.

Premises requirements

The ideal storage location is dark, covered and well ventilated. The material can be packaged in bags or wooden boxes. Coal can be placed in the yard. To do this, use a platform into which coal is poured and compacted to reduce the air gap. To extend shelf life, it is advisable to cover the fuel with a lid or polyethylene.

Let's look at a specific example. For the heating season we need 3.5 tons of coal (about 4.5 cubic meters). This means you need a room of 4 m2 and another area for passage. It is advisable that the premises have a reserve area (at least 5% of the area). It will be needed to refresh coal during long-term storage and cooling if it is hot.

It is best if the coal storage room is next to the boiler room. This way you won't have to carry heavy buckets over long distances. It must be equipped with drainage structures to drain melt, rain and groundwater.

The warehouse cannot be equipped with various communications - gas pipelines, heat sources, electrical lines. In addition, it should not be located where underground communications pass - electrical cables, pipelines, and so on.

You should always remember that coal can ignite. That is why this factor must be taken into account during storage. You need to place the fuel, compacting the small pieces well. After all, spontaneous combustion, which occurs due to the penetration of air into the layers of coal, can cause a fire. Spontaneous combustion can occur in places where different types of fuel or different grades of coal come into contact. Also, fresh coal should not be unloaded onto a site that is poorly cleared of old fuel residues.

Storing coal indoors or under a canopy helps preserve the quality characteristics of the fuel for a longer period. But it is not always possible to store it in closed conditions.

Outdoor coal storage

It is best if you find a dry and dark place to store the fuel. This could be a barn, shed or other outbuildings. You can purchase a special bunker - a metal box with a closing hatch. Canvas bags are also suitable (it will be more convenient to transport coal to the boiler in them).

It’s not scary if the coal is stored in the open air. As for precipitation, it is not harmful to fuel. But in order for coal not to lose its properties, you need to follow several recommendations for storing the material.

So, if you are forced to store coal outside:

- Choose a flat, debris-free area for the material. It must be located in a non-flooded, somewhat elevated place (so that during spring floods or rainy times the water does not wet the coal from below). The soil under the material must be dry or frozen.

- It is desirable that the base under the coal be solid. You can lay it out with bricks, tiles, and finally lay down boards or lay wooden pallets.

- When choosing a site, make sure that there are no open sources of fire nearby or expected. Also make sure that there is no equipment that operates at high temperatures (for example, welding) near the coal.

- Before adding material to the site, place a tarp underneath it. This way the coal will be dry, without snow and leaves.

- Periodically pour and stir the material (especially during frosts). This is necessary to ensure that the coal does not freeze in the open air.

As you can see, this material is quite demanding in terms of storage conditions. However, this is compensated by its high efficiency.

Specification of coconut charcoal for hookah

Technical parameters of coconut charcoal for hookah

My name is Grigory Ryabtsev - I specialize in business and export - import of goods in Indonesia.

In this article, I will talk about the specification of coconut hookah charcoal from Indonesia. ★ Business consultation in Indonesia: ☏ +62 811 879 7070 (Whatsapp, Viber, Telegram) @

75% of all coconut shisha charcoal is produced in Indonesia. The basis of production is dried coconut shells.

The most valuable charcoal for hookah production is old sun-dried coconuts from the island of Sulawesi. Walnuts from the northern part of the island are especially prized. They produce minimal ash and white color.

Coconuts for the production of hookah charcoal also grow in Java, Sumatra, and Kalimantan. The main production of coconut coal is located on the island. Java in the province of Central Java.

Coconut charcoal production has 2 main parts.

1.The first stage is the collection and preparation of the narrowed coconut shell. Old coconuts are collected by hand and sorted. Fresh - dried in the sun. Then the copra (coconut flesh) and “hair” from the shell are separated. The resulting shell is burned without oxygen (pyrolysis process) in closed ovens.

Some manufacturers, to save money, burn coconut shells in earthen pits. This greatly affects the specification and parameters of coconut charcoal.

In such industries, soil, clay, and wood chips are included with coconut shells. Sometimes rats and small lizards are also burned along with the coconuts. The quality of such production is low.

2. Second stage. Burnt coconut shells are delivered to the production sites. Usually on about. Java to the city of Jepara. Everything is dried on site and excess impurities are removed. Then the coconut shells are ground and mixed with tapioca. Tapioca is used instead of glue to give hardness to coconut charcoal.

3. Third stage. Forming coconut charcoal into cubes measuring 25 by 25 by 25 mm. Sometimes the size 22x22x22 mm is used. The coal is cooled and packaged in 1 kg plastic bags. Then they are packaged in branded boxes of 1 kg and everything is placed in a master box - a cardboard box of 10 kg.

The main characteristics of coconut charcoal for hookah are 3 parameters:

- Ash. The amount and color of ash that will remain after burning/smoking the hookah. The less ash, the better quality the coal. White ash is considered the most valuable. Gray ash (for example from Sumatran coconuts) has less purchasing power.

- Hardness. A cube of coconut charcoal for hookah should not crumble or crumble. What happens if a burning cube disintegrates in front of the visitors of the hookah bar or gets on the visitors’ clothes? Therefore, hardness is an important parameter of coconut charcoal.

- To measure it, a drop test is used. Burning hookah coal is thrown onto the tiled floor from a meter high. A good indicator would be if the charcoal cube does not fall apart or crack after 3 attempts. If a cube of coconut charcoal falls into pieces or a lot of sparks fly from it, this is an indicator of poor quality coal.

- Burning time and organoleptic parameters . The longer the coal burns, the longer and more the hookah will be smoked. The standard is 1.5 to 2.5 hours of coal burning. Also, coconut charcoal should not give off any foreign odor. Coconut charcoal is valued precisely because it does not add any taste or odors when smoking a hookah.

The specification of coconut charcoal for hookah is divided into 3 main categories: premium, standard and economy .

The main difference is the amount of coconut shell in the composition. Almost all manufacturers report using 100% pure coconut shells. In fact, burnt wood is mixed into the coconut shell. The cost of burnt wood is 3-4 times less than coconut shells.

Also, each factory has its own “secret” - the formula for producing coconut charcoal. How much tapioca to add, how much wood and how much coconut to mix to get the desired charcoal.

Main specifications and parameters of coconut charcoal:

| Premium | Standard | Economy | |

| Ash | 1.8 – 2.5% | 2.5 – 3.0% | 3 – 5 % |

| Ash color | white gray | light gray | gray |

| Oxygen | 80% min | 75% min | 75% min |

| Humidity | 4%max | 6%max | 8%max |

| Volatile | 14.5%max | 16%max | 18%max |

| Calories | 7500 Kcal | 7500 Kcal | 7500 Kcal |

| Drop text | 3 x 1 meter | 2 x 1 meter | 1 x 1 meter |

Grigory Ryabtsev

I am Grigory Ryabtsev. I have been living in Indonesia since 2004.

I share my experience of business and life in Indonesia.

How to light coal and how to heat a boiler with it

Even though charcoal burns very well, it is very difficult to light. You can't do this with regular matches.

There is a special ignition technology:

- Place paper and thin wood chips on the grate. You can use any other flammable material (birch bark, sawdust, branches).

- Place firewood on top. You shouldn’t lay them too tightly together – good air circulation is important here.

- Light a fire. At this time, you should not go far from the boiler. It’s better to be nearby and control the process.

- When the wood burns and turns into coals, the boiler will be sufficiently hot. Now you can pour coal into it.

- Place the first portion of coal. The smaller the grains, the better. There is no need to throw in a large amount at once. A handful that will fit in your palms will be enough.

- Periodically stir the pieces of coal and make sure there is space between them.

- When the first batch of coal flares up, you can add the next one. Now you can take larger pieces.

- Next, simply monitor the boiler and add coal as needed.

As you can see, coal alone will not be enough. You will still need firewood. And not just for ignition. It is recommended to periodically heat the boiler with wood. The fact is that coal dust gradually settles on the walls of the chimney. It can clog the pipe, and then it will be impossible to use the stove. To avoid this, heat the boiler with regular wood once every 2-3 months. Aspen ones are good for this, but in fact, you can use any kind.