The queen of the sauna stove loves it when it is heated with good, not rotten wood. Then the heat in the bath is excellent! Is it possible to heat a stove in a bathhouse with coal?

It is impossible to answer such a question in one word. For this reason, I decided to write a separate article in which I will try to answer this question.

They heat the bathhouse with coal where firewood is very rare and in short supply...

In central Russia there are practically no forests suitable for felling. Gardens, groves, plantings, lindens, oaks, apple trees, cherries, pears, only an unruly person would use such beauty of nature as firewood!

Moreover, it will not be possible to heat a bathhouse perfectly with just an armful of firewood...

This is where the well-known fuel material coal comes to the rescue. After all, burning coal is an economical, effective way to heat any premises.

Living in the Far North, we didn’t know what it was to burn stoves with coal. But for example, in the Belgorod region (where my mother is from), coal in the stove was commonplace. Now, of course, gas has been installed in the houses, and this tradition is becoming a thing of the past.

But, my story about how to heat a stove with coal will be based on my memories and the stories of my grandmother. So…

In order to melt coal in the stove, a small amount of firewood is needed. Without firewood it is impossible to light coal; matches are indispensable. I personally tried to light a coal stove with a match - it was a futile effort.

Wood chips are essential! When the wood is hot and the flame is dancing in the stove, it’s time to add coal. But, of course, not a whole bucket at once, but only a little, and when the coal flares up, add a new portion.

Firing a stove with coal is different from heating it with wood. In order to speed up the combustion process of coal, it is necessary to stir it with a poker, this way we give a new portion of air to the fire. Everyone knows that without air, fire will not dance.

Remember that you need to start stirring the coal after it is well lit, after about 15-20 minutes. Otherwise you risk putting out the fire.

As a portion of coal burns out in the stove, you need to add a new one. As far as I remember, a bucket of coal was enough to heat a small room in the house.

It is also worth noting that the heat in your stove depends on the quality of the coal. Unfortunately, coal is not always of high quality. Fine coal and coal dust not only do not provide any heat, but can also extinguish the stove.

Therefore, before putting coal into the oven, it is always sifted. This is done through a special device - a sieve. Pebbles that remain after sifting and are suitable for filling in the oven.

Choosing fuel and firewood for the sauna

Please note that in our country the most popular are heater stoves that burn wood. That is, the insides are filled with stones. The main fuel raw material is firewood. It is best to use birch wood because they have a pleasant aroma, burn quickly, and have a high calorific value and calorie content. At the same time, they do not smoke and are distinguished by a small amount of resin.

Sauna fuel options:

- The best option, as mentioned above, is birch. Coniferous species are not very suitable, as they release a lot of essential oils when burned and smoke heavily. Wet wood, as well as freshly cut wood, are not suitable for heating the stove.

- It must be chopped and allowed to dry in a well-ventilated place. Wood whose moisture content does not exceed 20% is considered ideal. At the same time, you cannot use old boards, rotten wood chips, or wood coated with some kind of varnish or paint to heat the stove. When burned, they release substances that are toxic to the body and can cause poisoning.

- Many will ask what about the use of coal, peat or waste oils. To light a stove at home, you can use such energy sources. This kind of fuel is actually used to heat the house.

- But such energy resources are not suitable for heating a bath. The fact is that coal flares up quickly, immediately gives off heat, and then smolders. What is not suitable for a bath. During combustion, waste oil can form an explosive mixture, so it is not used when melting the bath.

- It is not entirely advisable to use peat, which also takes a long time to smolder and has a high content of combustion products and volatile gases. The best option is wood; pellets are also often used. This is a product that is formed in sawmills in the wood processing industry. Simply put, these are pressed shavings characterized by high thermal conductivity, so they can be used to melt a bath.

Bath fuel

How to properly heat a sauna: instructions

Instructions for heating the oven:

- First you need to make a seed. To do this, pour some chips and small twigs under the grate, which have dried well.

- A ball of paper is made and chips are poured on top. Two logs are placed on top of the grate, that is, two pieces of fresh firewood. The seed is ignited and they wait for these logs to light up. If they are damp, they will light up reluctantly.

- Under no circumstances should you use ignition substances or organic solvents. The only thing you can use is a dry alcohol tablet. After the seed ignites, it is necessary to close the furnace door and open the pipe halfway to remove combustion products.

- When the seed burns well, you can fill the stove two-thirds with wood and close it again. In about an hour and a half, everything will flare up. Add wood from time to time if necessary.

- On average, in winter, it will take 5-6 hours to light the stove. In summer, the period is reduced to 3-4 hours. Only after this can you carry out bath procedures, that is, directly take a steam bath.

- Please note that 2 hours before bathing procedures, you must open the window and ventilate the bathhouse. This is necessary in order to remove combustion residues and unpleasant odors. Then you can close the window and steam. The bath will not cool down during ventilation. This way the heat will be soft and not hot.

Bath

Features of heating a coal bath

Coal does not have a special aroma, the specific smell of burnt logs. You will never see the amazing dance of the flame as it jumps from log to log. The charm of the process of heating a bathhouse is somehow simplified and becomes a purely mechanical procedure.

It should also be noted that coal ash is much more toxic than wood ash. The oven should only be cleaned after it has cooled down. In this case, the ash will not smoke and will not pollute the air you have to breathe.

When a sauna is heated with coal, the sauna steam and its quality change. Coal steam is heavy and wet. Most often, a dry bath heated with coal does not work. But, even if the result is a dry bathhouse kingdom, it will in many ways be inferior to the one heated with firewood. But this is purely my personal opinion...

However, all the shortcomings of a coal stove are more than compensated for by the unprecedented heat! Such heat in the bath lasts for a very, very long time.

There is also such an important point as the fact that coal never burns completely in a stove. Therefore, after cleaning the stove, the combustion products are sifted through a sieve. That's what my grandfather did. Unburned coal was again used to fill the furnace.

Never heat a sauna with black coal! This is harmful to health, carbon monoxide and coal soot must escape into the chimney! After the sauna is heated and the stove mouth is free of fire, rake the coals with a poker from the heater, and after finishing the sauna ceremony, be sure to clean the stove.

In conclusion, I want to say that the stove in a bathhouse is often used to burn a wide variety of garbage and rubbish. Remember: you cannot burn anything that has served its purpose in a sauna stove. The stove turns into a source of toxic emissions, then the benefits of the bath and the therapeutic effect are out of the question.

The bath cleanses the body and pleases the soul. I don’t know about you, but after a good bath I feel light and calm in my soul. The heat of the bath and some water relieve sadness and take away worries. It’s not for nothing that they say: “After the bath I was born again!”

How to light a sauna: tips

In order to properly heat a sauna, it is not enough to fill the stove with wood and set it on fire. Remember that a blue-yellow flame indicates carbon monoxide is being released.

Adviсe:

- In this case, do not rush to close the damper completely, leave it completely open at the beginning, and as the wood burns, close the damper halfway and continue heating the stove. If everything is done correctly, there should be no smoke or unpleasant odor in the steam room itself, as well as in the bathhouse.

- The room should be dry and warm. This is evidenced by the color and condition of the stones. They should turn crimson in color. To create steam, you need to pour water on the stones in small portions, about 50 or 100 ml.

- In this case, the movements should be fan-shaped, the water should not fall into one place, but should be evenly distributed over the stones. The stones should not be wet; as soon as water gets on them, it should instantly evaporate, and the stone should again become crimson in color.

- It is also necessary to arrange the firewood correctly. They must be laid on top of each other so that there is a minimum number of gaps between them. It is necessary to leave 20 cm to the upper arch of the stove. There is no need to lay firewood all the way to the top so that normal conditions for ignition are created and combustion products exit through the pipe.

- The quality of the selected stones plays a huge role in how long your wood will burn and your stove will be heated. Here you can learn how to choose stones for a bath.

Heater stove

How to properly heat a stove with wood and coal

It would seem that there is nothing easier - to light the stove.

Put some wood in the firebox and that's it. But after some communication with the stove, it turns out that this is far from true. She is a wayward unit, knows the laws of combustion and demands the same from the consumer of her services.

To paraphrase the words of a famous movie character, we can say: baking is a delicate matter.

Years of experience with stoves have taught me a thing or two. In my youth, I had the opportunity to work as a fireman on ocean-going ships; I know that maintaining a fire of the required intensity in the firebox is an art that must be mastered.

A household stove, as you know, is designed for cooking and heating a room. In terms of the way the fire is maintained, these are two different processes. Each of them is characterized by its own characteristics. What they have in common is the kindling and the completion phase (before closing the pipe).

Kindling is a simple operation. However, the speed of ignition and development of fire depends on the correctness of its organization. If done incorrectly, this stage can last for a long time. In principle, the technique of its execution is simple: first, flammable materials are set on fire, the fire engulfs small chips, spreads to larger ones, and finally ignites real firewood.

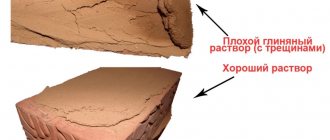

After many tests, the following became clear. Everyone, of course, knows that without air (oxygen) combustion is impossible. But at the same time, oxygen is not perceived as a material fuel component that needs free space for placement. Therefore, the amateur stacks the firewood closely and literally fills the firebox with it. There is no room left for the main participant in the combustion. So the stove is suffocating, Instead of a cheerful and bright fire there is black-brown smoke.

The following scheme for organizing normal combustion turned out to be optimal.

First, birch bark or paper, most often newspaper, is placed on the grate for kindling. Glamor magazines are not suitable for this because they contain more chalk than pulp. Newspaper quarters are not stacked anyhow, but in a certain order. As you know, combustion requires oxygen. If the quarters are simply placed on top of each other, proper combustion will not work, since air will not be able to leak under them.

Pieces of newspaper need to be crumpled in the form of tubes and placed on the grates, but not close together, but with discharge, leaving passages for air.

Then come the wood chips. If these are not available, thin thin sticks are used. They are also placed in a discharge and across the tubes. If placed lengthwise, they will close the air passages, leaving numerous windows. The edges of the tubes extend 2-3 cm beyond this layer, which facilitates combustion. Larger chips are then placed across, leaving passages. After this, it’s the turn of the firewood.

The reader has already guessed that the firewood should be stacked according to the same principle - leaving windows for the passage of air. Firewood is placed in layers along and across the firebox with intervals between logs, forming a cellular cage with a large number of vertical channels for air supply. Thanks to them, the logs are exposed to fire from all sides. This type of masonry burns well. What comes out of the chimney of a well-heated stove is not black smoke, as usual, but a slightly visible haze, which indicates complete combustion of the fuel. When burning, a light and even hum is heard.

The cage rises so much that there is at least 5-6 cm of free space between it and the burner plate. Here the combustion of gases and combustible suspension occurs, which continues in the afterburning chamber. To activate the fire, you need to move the fireplace with a poker every 10-15 minutes, slightly lifting it by the front edge. This increases the flow of air, and the volume of fire at least doubles.

It turns out that a person who undertakes to service a stove must have certain skills. It is no coincidence that in the days of wood heating there was a special profession - a stoker. An incompetent person's stove will always burn poorly, and it will take much more wood than it should.

It operates in two modes - cooking and heating. During cooking, intense combustion is maintained until the contents of the pans boil. The temperature in the firebox at this moment can reach 1200-1300 “C. It has to be lowered by raking the logs towards the walls of the firebox.

To continue boiling, you need even and not very strong heat. This task will be perfectly accomplished by 2-3 thick logs, including unsplit round logs with a diameter of 10-12 cm. Placed side by side on low heat, almost on bare grates, they will ensure maintaining the required temperature for a long time due to slow burning.

A well-heated oven can finish cooking food for 30-40 minutes without fire with the vents closed. This happens due to the heat accumulated by the brickwork of the firebox. Borscht, porridge, and simmering vegetables work especially well in this mode.

In parallel with cooking, the home is also naturally heated.

When the stove is operating in heating mode, fire control is greatly simplified. The duration of heating depends on the outside temperature. When it’s plus 7-12 °C outside, it’s enough to make a couple of drops to make the house warmer. If it seems as if the riser has not warmed up enough, do not rush to add firewood. Bricks conduct heat slowly. In the firebox and in the afterburning chamber, the masonry on the inside is quite hot. Gradually the riser will warm up. Even slightly warm, it will actively influence the temperature situation in the room due to its significant mass.

In frosty weather, the number of drops naturally increases. But we must remember that heating conventional stoves for too long is contraindicated. Experts believe that the duration of operation of the stove should not exceed 1.5-2 hours. In case of significant frosts, it is usually heated a couple of times.

When the stove has warmed up well and the wood is burning together, it is rational to place the thickest logs in the firebox. Due to their massiveness, they become heated and therefore burn at a higher temperature. Birch firewood also contributes to an increase in combustion temperature. But it is not recommended to heat with birch trees alone. Due to strong and constant overheating, the bricks will begin to crumble prematurely. It is better to use mixed firewood, including aspen. With good fire, the brickwork warms up well in a short time. This allows you to reduce heating time and reduce fuel consumption.

In the final heating phase, it is very important that all logs finish burning at the same time. Then, in the absence of flames above the hot coals, you can safely close the under-pipe view. There will be no fumes, and all the heat from the fiery mass will be absorbed by the brick mass. If such simultaneity cannot be achieved, one has to wait until the last firebrands burn out. During this time, the stove will throw a lot of precious heat calories down the chimney. The flooding effect will be reduced.

Therefore, the logs from the last delivery should be approximately equal in thickness and dryness. In the firebox they will burn at the same speed and finish the process together. It is prudent to select the last delivery in advance, setting aside suitable logs.

When heating is complete, reduce the draft. It is regulated primarily by the blower door. It is gradually being covered up more and more. Oxygen at this stage is needed only to burn out the firebrands. Excess air cools the oven. The exit view also plays an important role during this period, opening the way into the pipe. It is pushed in at the same time as the blower is covered. It should not impede the exit of smoke into the chimney. Too much is immediately noticeable by the smell in the room, especially near the stove. In this case, the view is opened slightly. The ability to close the outlet damper in a timely manner significantly saves heat.

There is no need to rush, but there is no need to be late either.

When closing a pipe, various pitfalls are possible. For example, in one of the logs of the last delivery there was a massive knot. Its density is much higher than ordinary wood, and therefore the firebrand may lag behind in burning. A knot disguised by a hot mass goes unnoticed. When the valve is closed, it will continue to smoke, that is, release carbon monoxide. Or another case. The log turned out to be damp, burned for a long time and also lingered at the finish line. The effect will be the same.

Therefore, before closing the exit view, you need to thoroughly stir up the heat with a poker and correctly assess the situation. During post-burning, problematic firebrands are masked by a shell of hot coals, which prevent the access of air and inhibit combustion. The shell is broken with a poker, which noticeably revives the flame. It is better to remove the firebrands that stubbornly refuse to burn out from the firebox and extinguish them in a bucket of water.

In conclusion, it remains to say a few words about firewood and ways to restore traction in severe cases.

In the northwestern region, the most popular firewood is birch, aspen and spruce-pine (mainly from dead wood). Birch trees have already been mentioned. Aspen ones are not so hot, but they produce a long flame, which promotes the combustion of gases outside the firebox and “licks” resinous deposits from brick walls. This quality is in great demand when burning resin-saturated coniferous firewood.

Due to its high resin content, widespread use of pine-spruce firewood is not recommended. In a short time they are able to cover the inner walls of the heating riser and pipes with a film of resin mixed with soot. This mixture is prone to spontaneous combustion, which threatens a fire. It is necessary to burn with mixed wood.

When preparing firewood, logs should not be chopped. They should be different, with a predominance of large logs, which provide more heat. If necessary, they can always be split. Small ones burn like brushwood and produce less heat. Long and short logs should be harvested approximately equally.

It is preferable to burn firewood dry. They are stored under a canopy or in a special shed, the walls of which are a ventilated lattice.

Damp firewood, among other things, produces too much smoke and therefore clogs the ducts, which impairs draft. A stove with poor draft is a hassle.

In country houses where the stove is heated irregularly, there are already many problems with draft, especially with vertical chimney channels. It has already been noted that after autumn-winter downtime, damp and heavy air pockets form in them. The smoke from a freshly flooded stove cannot push them out. There is only one way left for him - through the fire doors and cracks - into the room.

This fainting state of the oven can last for hours. As a preventative measure, views should be left slightly open during long periods of inactivity. This will ensure air circulation, even just a little, which will reduce humidity.

– If heating the channels with burning paper does not help, it must be replaced with birch bark or splinters. They provide more heat. Sometimes removing the view from the subpipe socket solves the problem. In the vacated narrow gap, even slightly warm air can flow directly into the pipe. In such a situation, even weak draft can change the situation, discharging the air in the pipe space and thereby pulling out the air plugs.

In the case when all methods turned out to be in vain, they resort to the last thing - they heat the stove in a black way, maintaining a small fire in it. In this case, you will have to open windows and doors in addition to the stove door. Gradually the masonry and the air inside the stove will warm up and it will come to life.

As you can see, you need to handle the stove skillfully.

How to properly heat a stove with wood or coal How to properly heat a stove with wood or coal

Additional heating of the bathhouse and dressing room

If with fuel, in order to get the steam room ready and take a steam bath, everything is clear, then heating the bathhouse in the autumn-winter period is somewhat more complicated. To do this, you should think about how you will carry out heating. Of course, the simplest option is to throw firewood or other selected fuel into the stove and open the door to the dressing room. This will allow it to warm up a bit.

This method requires your constant presence, that is, you need to constantly add firewood to the stove and maintain the temperature, monitor the boiler. To avoid fire, we recommend using electricity or water heating using a double-circuit boiler as permanent heating for the bathhouse. There are options when you can use the boiler both for heating your home and for heating your bathhouse at the same time.

Warm floor in the bath

What to do if the bathhouse is located in the country? An electric heater is not an option, just like water heating. In winter, freezing and rupture of pipes may occur due to a stop in the heating supply. In addition, in winter, the dressing room is quite cold, even if the door to the steam room is often open. But basically, inside the steam room the temperature remains high, and in the waiting room it is quite cold, a strong temperature difference is felt.

We recommend installing heated floors. It will be enough to turn them on 3-4 hours before you are going to relax in the bathhouse or invite guests. This time is enough for the dressing room to warm up well and for the excess moisture to dry out. You can bring an electric heater and thus solve the problem of low temperature and dampness in the dressing room. But most often there is high humidity in this room, which negatively affects the operation of electric heaters and can cause short circuits and breakdowns.

Heating in the bathhouse

Follow the advice, choose the right fuel and follow safety rules. In this case, the stones will be hot for a long time.