In apartments and private houses, designers often use zoning. The living room and kitchen combine well. Two rooms connected to each other look spacious, and this layout will make the space cozy.

You can update the design, implement interesting ideas, or repeat a design seen in a magazine, TV show, or photo on the Internet. The style in the living room-kitchen can be different, and choosing it can turn into a fun experience.

Before combining rooms, designers advise taking into account the basic rules, creating a project, and choosing colors.

Zoning

Designers do not advise giving in to fashion trends and copying design ideas without taking into account dimensions, location and other nuances. Before planning and arranging furniture, every detail is thought through.

There are several simple rules that experts advise you to follow:

- Let the room have natural light. To do this, remove excess walls (except for load-bearing ones).

- If the rooms in the apartment are small (12 sq. m or 16 sq. m), the layout of the kitchen combined with the dining room will be the right solution.

- If the ventilation system is not designed correctly, the smell of food will spread throughout the apartment.

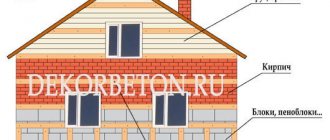

Methods for wall insulation of panel houses

To improve the indoor climate, residents can use one or two insulation methods:

The implementation of the first method is often complicated by two factors:

- apartment location on the top floor;

- layout of the living space, in which a large number of walls border on the walls of adjacent rooms (it happens that only a balcony can be sheathed from the outside).

The second method is not without a number of disadvantages:

- certainly reduce the usable area of the room;

- for high-quality insulation inside, you will have to seriously prepare the walls, destroying ordinary life;

- temporary relocation of residents is required, especially if work is carried out with materials containing harmful impurities;

- Insulation work from the inside reduces the service life of the panel structure, because during winter the wall penetrates into the territory of negative temperatures.

Still, insulation inside the walls is better than thermal insulation on the outside in terms of savings - residents will not have to spend money on work at heights. They will also spend less on thermal insulation.

Partitions

The interior of the kitchen and living room begins to be thought out from the junction of the two zones.

- Here are some of the ways and objects that delimit space:

- installation of a bar counter;

- kitchen island;

- big table;

- installation of a low partition.

Designers advise installing a wide counter, since you can sit at it like at a regular table, and high chairs are quite suitable for the whole family.

However, in small rooms (16 sq m), narrow counters are installed. Kitchen islands are convenient to use, but are only suitable for large kitchen-dining rooms (25 sq m or 30 sq m). Capital low partitions are installed only if it has been decided in advance what they will be used for (for example, as a TV stand).

Finishing

If the kitchen combined with the living room has the same floor covering, then there are no special rules for carrying out the work. When combining different materials, take into account in advance where they will be joined.

For example, laminate flooring creates unsightly joints with tiles. The main thing is that the floor is flat without curved joints, as they will be noticeable.

Kitchen cabinets that are mounted on the walls should reach the ceilings. In some cases, craftsmen “lower” the ceiling with plasterboard.

Methods for wall insulation of panel houses

To improve the indoor climate, residents can use one or two insulation methods:

The implementation of the first method is often complicated by two factors:

The second method is not without a number of disadvantages:

- certainly reduce the usable area of the room;

- for high-quality insulation inside, you will have to seriously prepare the walls, destroying ordinary life;

- temporary relocation of residents is required, especially if work is carried out with materials containing harmful impurities;

- Insulation work from the inside reduces the service life of the panel structure, because during winter the wall penetrates into the territory of negative temperatures.

Still, insulation inside the walls is better than thermal insulation on the outside in terms of savings - residents will not have to spend money on work at heights. They will also spend less on thermal insulation.

Furniture items

A few examples of furnishing a kitchen combined with a living room:

- 1. Sofa. It becomes an object that zones space. The sofa is placed with its back facing the place where food is prepared. In small rooms (less than 20 sq m) a corner is placed, which is placed against a wall installed perpendicular or parallel to the kitchen.

- 2. Set. According to designers, minimalist models without elaborate details look modern. The service, vases or glasses are placed on an open shelf. You can buy a fashionable display case for them. Furniture is placed near the wall. If the space is large (20 sq. m, 25 sq. m or 30 sq. m), then in the central part you can install an island, which also has sections for kitchen appliances.

- 3. Furniture set. The style should be combined with the design of both rooms. In small rooms, a compact table and chairs made of transparent material or painted in light colors look good. You can add a table with a round top to your living room interior. In spacious rooms, the kit is installed near the wall or in the central part. An elongated rectangular dining table would look good here.

Heat-saving materials for house walls made of panels

The operation of the apartment is accompanied by a periodic increase and decrease in the ambient temperature in the middle of the premises.

Therefore, the material must not only be an excellent heat insulator, but also have optimal moisture-resistant characteristics.

This requirement is fully met by the two most popular materials for insulation, which we will consider. Nowadays, liquid heat insulators are also becoming very popular, but these are already topics for our other publications.

Artificial latex

Thermal insulator supplied in the form of foam that hardens after application. It has a low thermal conductivity, thanks to which it perfectly retains the air that has heated up in the house. For uniform application and crystallization, formwork must be used. Its role is usually played by bars with a cross-section of 25×25 mm or slightly larger, placed vertically and horizontally along the surface of the wall. The resulting cells (parts) will be equally filled with artificial latex.

Thermal insulation of house walls made of panels using polyurethane foam has a couple more properties:

- after hardening of the polyurethane foam, an additional waterproofing layer is required (to reduce the amount of condensate formed);

- impossibility of finishing and finishing (you will have to build a second plasterboard wall on top of the PPU, on which you can apply wallpaper, plaster, etc.);

- if the previously listed conditions are met, a minimum of condensation will appear, after which it will be diverted to the wall joint using insulation.

The cost of work on wall thermal insulation of a house from panels on the outside or in the middle using polyurethane foam is high - you will need the necessary equipment, as well as professional workers. Thanks to this, consumers prefer the second good material.

Foamed polystyrene extrusion (foamed polymer)

The most serious difficulties when working with a material appear at the stage of its installation process. The foamed polymer is supplied in ideal slabs of 100×50 cm or more, due to this, when covering walls that need to be leveled, its distortion is inevitable. Therefore, it is necessary to carefully prepare the initial surface, otherwise layers of air will appear where condensation will penetrate.

The boards are attached to the wall surface with a special glue, applied equally to the entire sheet, and the joints are lubricated with sealant. The use of anchor connections is excluded - leaky transitions may appear throughout the entire layer of foamed polymer. It is better to use a T-shaped profile fixed to the floor and ceiling.

Multi-level floor

To zone the space, craftsmen install floors at different levels. They advise installing a podium to separate the kitchen and dining room. This option is considered one of the most practical because, among other things, the owners have additional free space where they can hide something.

It is convenient to use boxes or crates for this. Wicker baskets will look good. But such space can remain free.

For podiums, reliable materials are selected that can withstand heavy loads. Usually builders make wooden or metal podiums.

However, such a design should not be made if there are small children in the family, since the podium can become an obstacle for him. In addition, various floor coverings can be used.

They will zone the space between the living room and the kitchen and protect the podium from damage. For example, tiles are laid in the kitchen area, and laminate flooring in the dining room. The main thing is to choose colors and textures and combine the finishes correctly.

Work methodology

When insulating, you must adhere to the working steps described below.

- Selection of thermal insulation method (outside/inside; the second is easier to implement).

- Calculation of insulated area, purchase of materials; transition to the preliminary stage.

- Drying the surface (heat guns and heating devices are used). The walls are insulated strictly during hot periods!

- Old coverings (wallpaper, paint, decor) are removed, the plaster is removed down to the concrete base.

- The surface is cleaned of dirt and dust (use a broom or vacuum cleaner).

- Treating the walls inside with an antiseptic.

- Priming the original surface (it is better to use a good penetration primer and apply it in several layers).

- Allow the walls to dry thoroughly.

- Leveling using specialized mixtures (those used for tiling bathrooms are acceptable). When drying the plaster, do not use heating devices - this way it will acquire normal reliability.

- Installation of foamed polymer. Unlike artificial latex, it does not require formwork - the slabs are attached with glue directly to the dry surface. When using polyurethane foam, the heat insulator is applied a little later after creating the wooden frame.

- After the glue has completely dried, the joints of the plates are sealed with sealant.

- A second wall with the final cladding is applied on top of the resulting structure.

If all steps are completed correctly, the temperature increase in the middle of the panel house is guaranteed. If the work does not produce results, you will also have to insulate the floor of the apartment.

The range of good thermal insulators is very large, but few of them are suitable for panel buildings. Due to the impossibility of insulating the living space from the outside, residents need to carry out work inside that is not incredibly complex, productive and does not require specialized abilities or knowledge. Even residents of irreparably freezing panel buildings can achieve an increase in room comfort if they use the heat insulators proposed above.

Styles

There are many current trends and design ideas. The kitchen-living room in a modern style looks simple and minimalistic.

At the same time, it is not necessary to strictly adhere to any style; you can take its main idea as a basis and cleverly play with it with accessories and other details.

Methods for repairing joints

When choosing a method for sealing joints between slabs, you need to take into account the degree of damage to the joint. If you follow the basic rules and instructions, you can complete the repair yourself.

Caulking seams

The method is used for minor damage to the sealing layer and minimal displacement of the panels relative to each other. The insulated surface must be sealed with a sealant that penetrates tightly into all holes and restores the integrity of the coating. In most cases, putty is included in the complex of cosmetic repairs.

Seam putty is used for minor damage.

Waterproofing works

Waterproofing work requires the involvement of specialists, because... accompanied by some difficulties. The joints must be completely cleaned of old sealant, and then applied with a new layer, after drying and degreasing the slabs.

The method does not provide for insulation of seams, so polyurethane-based compounds are used for sealing. They are suitable for use in temperatures ranging from -45 to +75 °C for 10 years.

Combined insulation

The first stage of combined insulation is to remove dirt. Then the polyurethane foam is poured, and at the final stage the seams are treated with mastic.

If the insulation is done efficiently, moisture will not penetrate the seams, and the problem of freezing, dampness and the appearance of fungus will disappear.

Scandinavian

This style came into fashion several years ago, but still does not lose its relevance. Its practicality and European elegance are well suited for a living room in a city apartment or house. You can add bright accents, for example, textiles of different shades.

The basis for the Scandinavian style is white and gray finishing, wooden details. To decorate the space, pink, blue or ocher elements are suitable.

How and with what to seal the joints (seams) between the panels in the apartment on the ceiling and walls with your own hands

WITH

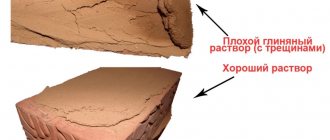

The construction of panel houses involves joints between these panels, that is, seams. The slight mobility of the entire structure of the house and various types of vibrations suggest that the panels, albeit by millimeters or even fractions of millimeters, will be movable, and the panel house will also settle after construction for about 2-5 years. These small movements will provoke the appearance of cracks at the joints of the panels, that is, in the mortars sealing them.

To protect your finishing from the appearance of cracks at the joints of house panels, there are several ways to reinforce them and seal them with special ones. compositions. We will talk about how and with what to seal the joints between the panels of the house so that the finish does not crack at the seams between the panels. In addition, the panels are often blown through, and there is draft from them, but you need to contact the management company so that they can deal with this issue.

Loft

This year the style remains in demand. It is often used to equip kitchens combined with a living room. This combination gives more free space, which will only emphasize all the details of the loft.

Today, such a definition as “classic style” is used less and less by designers. Loft - any interior design in which various technical elements are not hidden, but emphasized.

For example, stylists play with brickwork, wires or concrete walls. The photographs clearly show how successful it can look like a living room that is combined with a kitchen.

For loft, rough and heterogeneous surfaces and rough materials are selected. In apartments decorated in this style, wall lamps are installed. In this case, the light is directed along the walls.

Due to this, shadows fall so that uneven surfaces look three-dimensional. At first, loft was viewed with caution, but it quickly became popular. Designers do not hide finishing materials and even fake them. To imitate a concrete surface and smudges, decorative plaster is used.

Sealing of interpanel seams

3 year warranty.

Practice shows that all panel buildings have a drawback - interpanel seams in such a building do not last long. That is why sealing panel seams has become a very common service. Destruction and deformation of materials is observed due to temperature changes and the period of use of the building.

The tightness of the seam is important, due to which the walls will not freeze, and noise and moisture will not enter the room. In other words, it is important to perform high-quality waterproofing and thermal insulation of seams. To perform this work, the following actions are relevant:

- Cleaning the old seam from the used sealant, at the same time removing existing dirt and insulation residues.

- Work on thermal insulation of the seam is being carried out.

- The insulation is being waterproofed.

As for the prices for sealing interpanel seams, they depend on the qualifications of specialists, the technology used, and volume. The work in our company is carried out by industrial climbers, since it is inappropriate to erect scaffolding for such specific, narrowly focused work.

During all the time we have been sealing interpanel seams in houses, we have gained a lot of experience by carrying out the following types of work:

- Repair of seams, the old cement mortar was first knocked out of the seam, then waterproofing and insulation were carried out.

- Sealing, which was carried out for the first time in new houses.

- Sealing of interpanel seams of houses, which involved the initial opening of the old seam, replacement of insulation, and secondary sealing. We also worked with the “warm seam” technology.

Sealing can be primary or secondary. Primary involves the use of insulation and covering it with mastic. Secondary sealing includes complete cleaning of the seam, which involves removing previously used insulation and sealant. Next, the seam is resealed, the work is carried out in a manner similar to the primary sealing. In some cases, it is necessary to degrease the seam before using new sealant. If fungus and mold are detected, work is carried out to treat the interpanel space with antifungal solutions.

Practice shows that today the most common technology is the “warm seam”. An increasing number of people prefer this option for performing work.

What are the advantages of working with us?

- To carry out repairs, high-quality materials and technologies are used to guarantee the durability of the resulting seam.

- Work can be carried out in panel houses regardless of the time of year.

- We offer affordable prices for work and materials.

- The “warm seam” technology is used in panel houses.

Sealing panel seams is a very specialized job, so we do not advise you to do it yourself.

Firstly, due to incorrect selection of materials and violation of work technology, you can lose a lot of time, effort and money without achieving the desired result. Secondly, it will not be possible to carry out work at significant heights, where it is necessary to use the help of industrial climbers. This is a big risk to the health and life of the person who is trying to carry out sealing.

All you need is to contact the employees of our company, outline the existing problems, and agree on specific deadlines for completing the order. We always meet our clients halfway, offering optimal conditions for cooperation.

Neoclassical

Even popular music has echoes of ancient motifs. The same can be said about the design, in which classic details are framed in a fashionable design.

This style is characterized by symmetrical lines, framed mirrors, arched openings, and antique accents. All this is complemented by fashionable finishing materials and accessories. Neoclassicism combines sleek modern details with traditional combinations.

Provence

The name of this destination comes from a region in the south of France. Even a small kitchen-living room, the decor of which was inspired by French aesthetics, will be filled with warmth and comfort.

The main thing is that it has a lot of daylight, textiles with romantic prints, and floral patterns. The dining room in the Provence style is designed in pastel shades. Furniture items can be vintage or artificially aged. Plain walls will contrast with large checkered curtains.

The door in the kitchen area set is sometimes replaced with curtains made from the same material as the tablecloth. A good addition would be vases and figurines, clay pots, forged metal parts and ribbons.