- Foundation - standard size of the structure

- With analysis of floors

- Mounting tank assembly

- Advantages of the prototype with a remote channel

- Installation

Steam room stoves are very popular among many homeowners. The market offers a large list of various modifications with different characteristics and sizes. But before installing a metal stove in a bathhouse, you need to know all the fire safety provisions in order to prevent a fire. Let's consider the main points of choosing and installing a heating unit with all the requirements and nuances.

Varieties

The model should not only warm the room, but also not pose a danger to people who will visit the bathhouse. There are several design options that differ in the location of the heating chamber door:

- The firebox opens directly in the steam room - this is the most common scheme. You can not only regulate the burning of wood, but also admire the flame if the prototype is equipped with fire-resistant glass. There are also negative characteristics - dirt, debris, and wood debris accumulate on the floor.

- Installing a stove in a bathhouse with a firebox in the dressing room is the safest option: it saves space, eliminates litter in the washroom, and allows you to warm up all rooms at once.

- The firebox is vented outside - an excellent solution for buildings with a minimum area, but not entirely comfortable - to maintain the desired temperature you will have to run out of the room and systematically add firewood.

There are several design options for devices:

- horizontal;

- vertical;

- oval;

- square.

Modern models have a water tank and a compartment for stones.

Installing a stove in a bathhouse - step-by-step instructions

To save energy and time, you should divide the work into phases. Installation is carried out in five main stages:

- choice of location;

- pouring the base or laying the podium;

- heater device;

- chimney outlet;

- securing a screen that will protect from temperature.

Let's consider each point in detail.

How to choose the right location for assembly

Traditionally, steam rooms are a wooden structure with appropriate finishing. Before you begin installing an iron stove in a wooden bathhouse, it is important to choose the right zone.

Criteria for choosing a fulcrum during construction

You will have to take into account the material of manufacture of the heating device, its power, the design of the combustion chamber and the exit point of the chimney (the usual height is up to 1 meter from the roof to the end point of the chimney). It should be remembered that the heater must be located in a place that is safe for visitors so that no one gets injured. Also key is the proximity of the device to flammable surfaces.

There are rules that must be taken into account during installation.

SNiP requirements for installation

- distance to flammable surfaces – at least 80 cm;

- parameters to the ceiling from the heater - at least 80 cm when it is plastered and 1.2 m if it is made of wood;

- the wooden flooring is protected with a screen, but the height of the firebox is at least 13-15 cm from the floor;

- from the door to the opposite surface – up to 1.25 m.

Stove base

Before correctly installing the stove in the bathhouse, you need to decide which base to mount under the heating device, taking into account the features of a particular model and the type of soil at the construction site. You cannot build shallow foundations if the soil is prone to swelling in winter; it can simply be squeezed out in cold weather.

Foundation - standard size of the structure

Everything will depend on the specific gravity of the heater and the type of soil on which the bathhouse is built. There are several varieties:

- monolithic, deep;

- pile-grillage;

- shallow slab.

Each type has its own positive characteristics and different arrangement methods.

Pouring a monolithic slab base

The algorithm of actions is as follows:

- dig a pit with a height of vertical walls of 50 cm. Compact the bottom, leveling the horizon;

- arrange a cushion of crushed stone and sand, in a layer of 25-30 cm. Sprinkle with water, level and compact well;

- to make a concrete base, for this purpose a liquid solution is mixed. Pour over crushed stone and allow to harden;

- lay a layer of waterproofing - roofing felt glued with bitumen or mastic;

- install formwork from old boards or panels so that the walls are strictly vertical and the angles are 90 degrees. Secure a plastic film on the inside of it so that the plywood does not deform from moisture;

- make reinforcement - the frame should be 10 cm smaller than the formwork on each edge, install a reinforced frame;

- distribution of the solution - you can prepare it yourself or order ready-made. All layers of the mixture are well compacted by piercing them with a sharp iron rod.

After pouring the concrete mixture to the level of the finished floor and allow it to harden for 3 weeks. After this time, the formwork is dismantled and backfilling is carried out - the distance between the base and the walls of the pit is filled.

If you plan to install a brick sauna stove with a firebox from a dressing room, then the installation of the base occurs by deepening it to the freezing line of the soil.

Pile-grillage

This method of arranging the foundation is much simpler and not as labor-intensive compared to the one described above. But it is ideal for unstable, water-logged soil. The execution technology consists of the following stages:

- make markings on the surface, first removing the turf layer;

- in the corners of the future foundation for installing a metal stove in the bathhouse, dig pits 10-15 cm deep;

- screw in piles with a diameter of 10 cm. Be sure to check the vertical;

- cut the posts with a grinder along the bottom line of the subfloor;

- weld a corner channel of the optimal size, arranging a place for pouring the solution;

- place a steel sheet on the beam and secure it with a weld;

- dilute the concrete mixture and pour it into the prepared frame.

Once the concrete has gained the required strength, installation can begin.

Shallow base

This is a simple foundation option for installing an iron stove in a wooden bathhouse.

The algorithm of actions is as follows:

- mark boundaries;

- dig a ditch 50 cm deep;

- fill the pillow with 20-25 cm;

- make a footing;

- arrange waterproofing;

- install formwork;

- pour 30 cm of concrete mixture and compact.

As soon as the concrete sets and dries, you can remove the formwork and lay a layer of insulation - the foundation is ready.

Note: if the base is below the planned level, you can lay 2 rows of brickwork on top of the roofing material. Such a podium will serve as additional thermal protection for the floor covering.

The location of the stove in the bathhouse, sauna - recommendations, photos, videos

A wood stove is a heating unit that runs on solid fuel. The operation of any such unit is largely determined by the correctness of its installation. It is important to remember that the stove is also a rather fire hazardous device.

In this regard, the installation of a stove requires strict adherence to appropriate fire safety measures.

Ventilation and chimney should be given special attention.

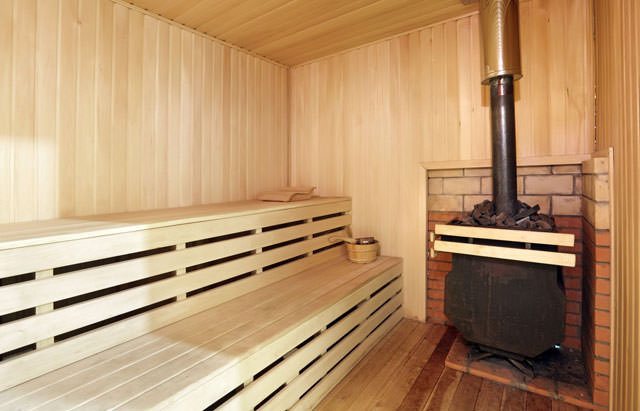

A sauna stove is a continuous convection type heating device. You can install a solid fuel stove using one of several options:

- installation directly in the steam room,

- installation in the wall between the relaxation room and the steam room,

- with a built-in, remote or hanging tank for heating water (or without it),

- with left or right hot water tap.

Fireproof foundation for the furnace

The stove must be installed on a fireproof foundation, the thickness of which is at least 200 mm. If the floor in the room in which the stove is located is wooden, it must be protected from fire. To do this, use at least two layers of brickwork (flat), made with clay mortar.

A layer of basalt cardboard must be laid between the bricks and the floor (the thickness of the cardboard must be at least 10 mm). The dimensions of the brick platform or foundation must be such that these elements protrude beyond the stove from the sides and rear by 10 cm, and from the front by 50 cm.

Where is the best place to install the stove?

The stove must not be located in close proximity to walls made of combustible materials. The minimum distance between them should be 50 cm.

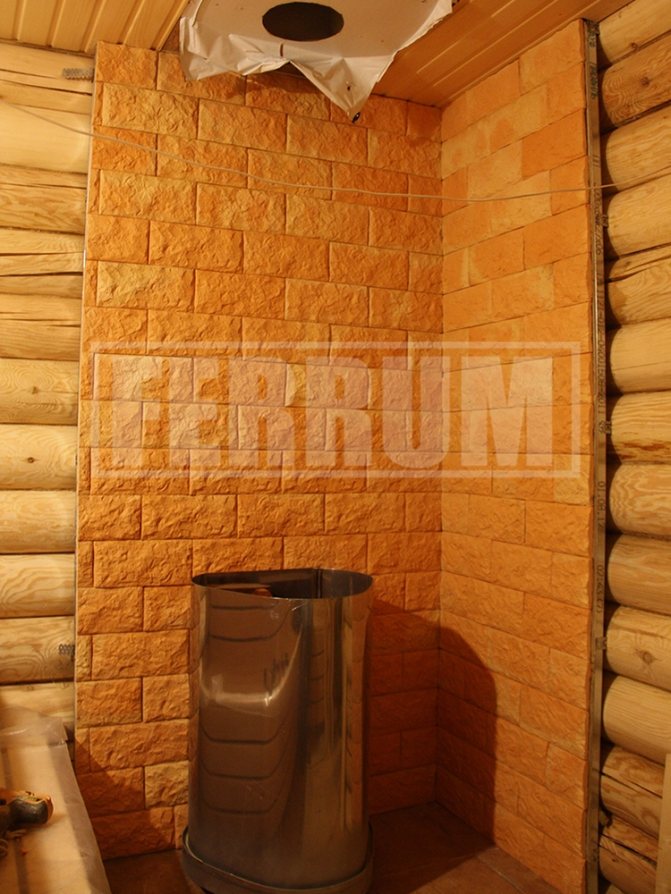

If the walls adjacent to the stove, made of flammable materials, are protected by a sheet of metal over a layer of basalt cardboard or brickwork, then the distance from such walls to the stove can be reduced to 20 cm.

In this case, it is necessary that the walls be protected to a height of at least 100 cm to the top of the stove. The distance can also be reduced if fireproof building materials are used (for example, mineralite LV slabs).

The distance from the firebox to the opposite wall, regardless of the material, must be at least 125 cm.

The section of the ceiling that is located above the connecting pipe and the stove must be made of non-combustible materials. If the ceiling is combustible, then it must be protected with a sheet of metal over a layer of asbestos. The area of the metal sheet should be one third greater than the area occupied by the stove. Or the dimensions of the sheet should be 30 cm larger than the dimensions of the stove in plan.

Oven on the border of two rooms

If the stove is located on the border of two rooms, then the partition where the tunnel is mounted must be made of non-combustible materials to a height of at least 200 cm.

Between the brickwork and the tunnel it is necessary to lay basalt cardboard, the thickness of which is at least 10mm, as well as a basalt slab, the thickness of which is at least 40mm (it will prevent temperature deformation of the brick).

The wall on the side of the stove must be protected with a metal sheet with a thickness of at least 0.5 mm, as well as 20 cm across the width of the stove on each side and the height to the ceiling (instead of metal, you can use a fireproof mineralite plate of the same size). The floor in front of the firebox must be protected by a sheet of metal measuring 70 cm x 50 cm.

Installation of railings

In order to prevent possible contact between a person and a hot stove, railings can be installed along the perimeter of the fireproof foundation.

To reduce the level of harshness of radiation from metal, it is recommended to line the stove with natural stone or refractory brick.

In order for the air flow to pass freely to the firebox, openings must be left at the base of the masonry.

The dimensions of these openings must be no less than the area in terms of the space around the firebox (it is better if the openings are twice as large as this area). The length of the firebox contour in plan is multiplied by three centimeters of the gap.

The result is an area (in centimeters), no less than which the windows at the base of the masonry should be.

- back to the section “Building a house with your own hands”

- Bath brooms

- Bath and sauna in the house

- Ventilation holes in the bath

- Bath ventilation system

- Internal structure of the bath

- Interior decoration of the bath

- Construction of a chopped bathhouse

- Construction of bath walls

- Auxiliary materials for the construction of a bathhouse

- Choosing a place for a bath

- Choosing a stove for a bath

- We make furniture for a bath

- Reducing humidity on the walls of the bathhouse

- Which sauna should you choose?

- Choosing stones for a bath

- Installation of a sewerage system for a bathhouse

- Caulk of a wooden bath

- Operation of hatches and chimneys

- Materials for building a bathhouse

- Installation of a concrete floor in a bathhouse

- Installation of bath doors and windows

- Installation of a wooden floor in a bathhouse

- Bathroom ceiling installation

- Lighting in the bath

- Features of choosing tiles for a bath

- Finishing of sauna log houses

- Bath heating

- Cleaning the ash pan

- How to choose the right stove for a sauna

- How to take a steam bath correctly

- Heaters for solid fuels

- Steam room ceiling

- Rules for lighting the stove

- Types of sauna stoves

- Bathhouse repair

- Chimney pipe repair

- Repairing the crown of the chimney

- Bath walls

- Arrangement of the roof of the bathhouse

- Thermal insulation of the bath

- Bathhouse foundation

- Cleaning chimney bricks

- Choosing an electric heater for a sauna

What are the pros and cons of Uralochka polycarbonate greenhouses?

To lay a wooden floor in a bathhouse, you need boards 150 mm wide and 50 mm thick. Before laying the floorboards, it is necessary to lay logs from beams with a cross-section of 150 mm x 150 mm or from logs with a diameter of 14 mm - 18 mm.

Building a bathhouse from a log house with your own hands

Building bathhouses from a log frame is not a difficult task; this technology is, in principle, no different from conventional bathhouse construction, the technology of which we recently described on our resource

Bath brooms: evening, morning, oak

Oak broom has an anti-inflammatory effect and makes the skin elastic. Due to the fact that oak lowers blood pressure, it is well suited for hypertensive patients.

Log baths are built from pine logs, the diameter of which is about 22 cm. The good thing about pine here is that the aromatic substances contained in its wood begin to be released into the atmosphere at elevated temperatures and humidity

Reducing humidity on the walls of the bathhouse - instructions

During the operation of the bathhouse, moisture may settle on its rough (logs or bricks) walls, as well as on finishing boards (lining), which is subsequently absorbed into the wood

Types of baths: Finnish sauna, Russian steam room, hammam, ofuro

To make it easier for you to make a choice, we will introduce you to the main types of baths, their characteristics and parameters

Preparing a Wooden Floor

Installation is not an easy process, especially if the floor is already covered. There are 2 options for solving this problem, let's consider them in detail.

Without disassembling the boards:

- mark lines along the dimensions of the structure directly on the surface. Back off 5 cm and draw an outer quadrangle;

- take a sheet of steel and fit it to the outlined square;

- prepare a layer of mineral wool;

- install a heat insulator on the floor (for example, a mineralite slab or non-flammable drywall), then metal and screw it on;

- soak a brick (preferably fireclay) in water and lay a podium out of it using fireproof mortar strictly horizontally.

Once everything is dry, you can begin further work. The platform can be left open or plastered. After this, you should begin installing a wood-burning sauna stove in a bathhouse with an external firebox on a wooden floor.

On the side of the door you need to screw a steel sheet, part of which will extend onto the brickwork.

With analysis of floors

This is a very labor-intensive process in which the podium for the device and the floor will not be interconnected. If the covering is already laid, it will have to be dismantled or a quadrangle cut to fit the size of the future pedestal.

Masonry is built on the foundation, 2-3 bricks above the floor. Next, actions are taken to isolate from overheating.

How does a sauna stove differ from a heating stove?

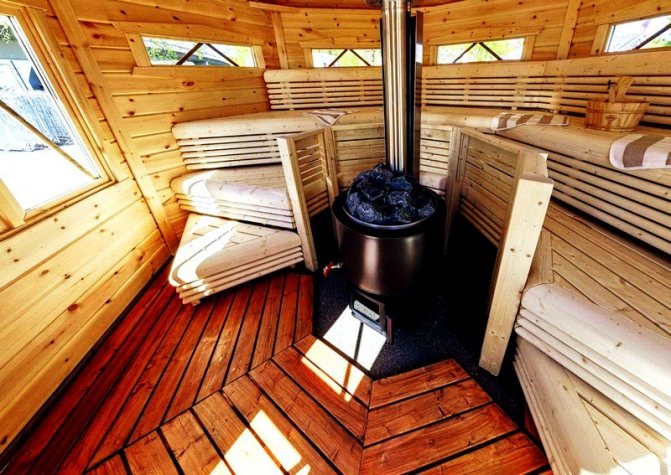

In addition to their purpose, bath stoves have their own design features. Unlike heating systems, they do not work constantly, but from time to time. Their task is to warm up a small washing room as quickly as possible, accumulate a sufficient amount of heat to generate steam and maintain the desired temperature for one to two hours.

An important feature is the ability to provide different heating modes, which allows you to organize dry superheated steam of a Finnish steam room or a traditional Russian steam room with clouds of wet saturated steam in a steam room. All this is easily ensured by the correct installation of a metal stove in a wooden bathhouse.

Installation of a furnace in a bathhouse with a remote firebox

In this case, it is not so much the “gluttony” of the design that is important, but the ease of use and safety of operation. It is the safety of the design that makes it necessary to move the furnace door to the next room. In addition, part of the room is freed up for washing. And firewood, which traditionally serves as fuel for such stoves, will not absorb much moisture.

Walls - preparation

If the load-bearing fence is made of wood, then the distance will be at least 50 cm. For a unit with an external firebox, you will have to cut out a niche.

How to protect partitions from fire:

- apply the plaster composition to a metal mesh previously screwed to the surface;

- install an iron screen with a non-combustible insulator;

- clad with artificial stone or porcelain stoneware;

- make a brick layout;

- adjust factory thermal insulation.

The best option is to lay the masonry on the side of the adjacent surfaces; it will not only protect them from fire, but also accumulate heat.

How to install a heating device

Many home craftsmen ask how to properly install a sauna stove on an already poured foundation.

There is no need to attach the heater to the foundation, but sometimes experts advise attaching the legs to anchor bolts.

If you are installing a model with a protruding channel, then it is important to well insulate the portal from fire - this can be done using polyurethane foam or other material that does not ignite.

Heating a bathhouse from a stove, stove heating

Having installed the bathhouse box and covered the roof, the owner begins to arrange the heating system. Traditionally, many bath attendants believe that soft steam and high-quality heating of the room can only be provided with the help of a stove. However, its advantages do not end with the organization of the surroundings.

How to choose

Not only the safety of the bathhouse owner and his guests, but also the steaming process depends on the choice of stove. Therefore, when installing a stove, you need to consider the following points:

- area of the heated room;

- the material from which the oven is made.

Bath dimensions

Every bathhouse attendant dreams of a stove that is compactly located in the room, consumes little fuel, is environmentally friendly, and heats a lot of adjacent rooms. It is impossible to meet all these conditions at the same time.

If the bathhouse is small in size, then one stove will be enough for it. If in the bathhouse, in addition to the washing room and steam room, there is also a relaxation room, a veranda, and a toilet, then one device will not be enough. In this case, you will have to additionally install a boiler.

It should also be remembered that there are two types of furnaces: periodic and continuous. The first ones do not require that a person does not leave the firebox; it is enough to heat the devices once before starting the rest. In the second case, fuel must be added to the stove as needed.

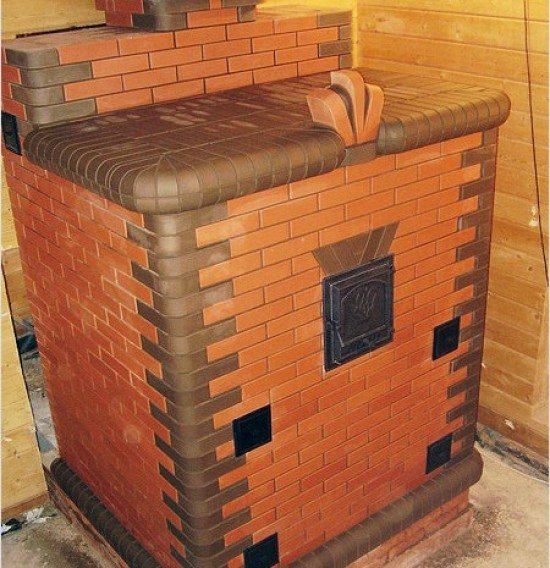

Material

Today you can order a stove from almost any material. If desired, the owner can order decorative finishing for the device and decorate the structure with tiles that imitate the appearance of a heater stove. However, brick and steel are the most popular among bath attendants. Moreover, the demand for these furnaces is much higher than for steel devices.

This user choice is justified by the fact that brick stoves are able to retain heat for a long time. However, warming up the structure is a tedious task that can take several hours.

However, the most significant drawback of the stove is its high cost. The matter is not limited to the purchase of building materials. The stove is a complex structure, and not every lover of soft steam can do the masonry on their own. Only a skilled stove maker is suitable for this work, and his services today are not cheap. The foundation that is necessary for the construction of the furnace will also require serious financial investments.

If brick structures come in two types (intermittent and continuous), then a steel furnace is only a continuous-operating device due to the fact that its walls are quite thin and it cools quickly. Because of this, to ensure a stable temperature, it is necessary to frequently add firewood to the firebox. The main advantage of a steel stove is its rapid heating. If the bathhouse is small in size and installed on a light foundation, then this design is ideal.

Heating system

When choosing a stove, you must remember that this is the only device responsible for heating the entire bath. To make your vacation enjoyable, you should think about placing the stove indoors. Initially, the design was intended to heat the steam room, but the economical owner will strive to ensure its end-to-end arrangement, i.e. It will be possible to add fuel in the dressing room, the water tank will be in the washing room, and the stove itself will be in the steam room.

Installation of a steel furnace

The operation and installation of a metal structure differs from the laying of a brick oven:

- a foundation is not required, but the base of the device must be made of materials that are not subject to fire;

- the firebox door should be located in the opposite direction from the bathhouse attendants;

- the floor is covered with non-flammable materials;

- a metal stove can be lined with bricks not only to add aesthetic appeal to the structure, but also to protect against burns.

Features of masonry and use of a brick kiln

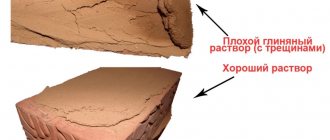

Laying a furnace begins with arranging a reliable foundation. If the owner decides to build a stove himself, then he should remember that when laying bricks, he should not pour a lot of mortar between the rows. If you spread it in more quantities than required, then when the oven heats up it will collapse, and, as a result, the tightness of the structure will be compromised.

In order to prevent damage to the brick, do not lay the material with the cut side towards the base of the structure. Finally, cast iron elements are installed, between which there should be gaps. When installing the fire door, it is necessary to secure its upper part using a clamp.

Installing a stove requires a significant investment of money and effort, but a room equipped with such a design will undoubtedly appeal to any bath attendant.

Setting up a chimney

You need to understand how to build a chimney so that carbon monoxide does not enter the steam room.

The furnace pipeline gets very hot and can cause a fire, so the place is prepared especially carefully:

- make markings in the ceiling and cut a window measuring at least 50x50 cm;

- install a passage unit with mineralite into it with a hole equal to the diameter of the pipe + 3-5 mm;

- secure the polyurethane foam with special fasteners and attach it to the ceiling;

- insert a pipe into the protective box and cover it with kaolin wool to a depth of 5-7 cm, no more, so as not to create the opposite effect of overheating;

- After completing the work, use a stainless steel protective screen to increase fire safety, as well as for decorative purposes.

Advice: no matter how well the installation is done, you need to know how to properly ventilate the bathhouse, otherwise the balance of air exchange will be disrupted.

Below is a link to a video where you can learn more about this system:

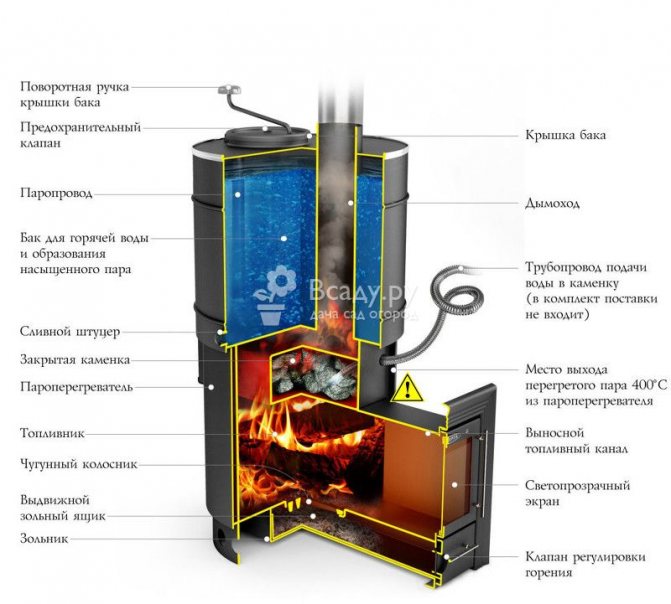

Mounting tank assembly

This mandatory element can be attached as follows:

- fixed on the side wall of the stove;

- placed on top of a single-wall chimney;

- at the end, the heat exchanger is connected to the tank for uniform circulation of liquid.

You can study the issue in more detail and visually examine the process in the video:

How to install a stove in a bathhouse

This process is a little more complicated than installing a conventional heating device - creating a niche in the wall to access another room.

It will be easier to purchase a ready-made design, for example, the Atmosphere sauna stove, made of high-quality cast iron.

Advantages of the prototype with a remote channel

Models with take-away fireboxes are becoming more popular, as they have many more advantages:

- safety - there is no risk of gas poisoning from burning wood;

- comfort – two rooms are heated at once;

- cleanliness - there will be no chips, sawdust or dirt from the firewood. This is very important, since people usually wear it without shoes;

- space saving - as a rule, the oven takes up 1 m2 of space, and if the washing room is small, then this is significant;

- good, saturated steam - the firebox burns out oxygen, which makes the air dry, which has an adverse effect on health;

- there is no need to install a special ventilation system, which saves money and time.

Question answer

The main thing is the creation and preservation of a steam cake, heat retention, good ventilation.

It depends on it:

- how comfortable the microclimate will be;

- how long the warm-up will take;

- how much energy will be spent on heating.

Ceiling

The optimal height is calculated using a simple formula. Its application is as follows:

- measure the height of the tallest person in the family with their hands raised, and add half a meter to the resulting number. The resulting amount will be the standard value - it often varies 220-260 cm.

It turns out that the larger the air space of the area for taking procedures with a broom, the thicker and richer the cake from the steam masses at the top will be.

Floor

The floor in the steam room should be 20 cm higher than the dressing room and shower. This can help avoid rapid cooling of the air in the room.

Door

height, wooden door.

Shelves

Now about the shelves - this is one of the important points when arranging a steam room in a Russian steam bath.

Number of regiments 3

lower - temperature, distance from the floor. Purpose

Medium - for steaming from brooms, temperature, distance from the floor

Comfortable location for the steamer and the bathhouse attendant. It is important not only to get warm steam, but also to distribute it evenly throughout the body.

The upper one is for the initial stage of vaping and warming up. When steaming with a broom, the temperature is too high. Distance from floor

Ventilation:

To organize proper air circulation in the steam room, it is recommended to supply natural supply air so that it is heated by the stove and rises upward along with the steam.

Insulation

Particular attention should be paid to insulation and sealing of the ceiling. It is near the ceiling that the most heated air and steam are concentrated, the so-called “steam cake”. The quality of sealing of a steam room due to foil is significantly influenced by the quality of gluing joints and places where foil is attached.

To insulate a steam room, it is necessary to use only environmentally friendly heat-insulating and heat-reflecting materials. The minimum thermal protection of the enclosing structures inside the steam room includes a mineral plate (50 mm thick) + foil glued with special tape + a tightly fitted wooden strip.

Requirements for insulating a steam room:

- SNiP 23-02-2003 “Thermal protection of buildings”;

- SP 23-101-2004 “Code of rules for design and construction. Design of thermal protection of buildings"

Good luck to you and have fun!

Safety rules when designing a bathhouse

When organizing a plan for the construction of a steam room, it is important to immediately take into account the placement of the heater, using all recommendations and protective measures that prevent fire.

If the building is made of non-flammable material, then the partitions do not need to be thermally insulated; it is enough to protect the floor with a metal sheet.

If a metal heater is installed in a wooden structure, then carefully insulate the niche without fail - it is better to lay out the brick.

Installing a home-made system requires special attention - the distance from adjacent structures is at least 50 cm, if high-quality insulation from heat is provided, for example, with brickwork. Otherwise, the distance is increased to 1 meter.

It is important to understand that the distance from the firebox door to the opposite plane must be at least one and a half meters.

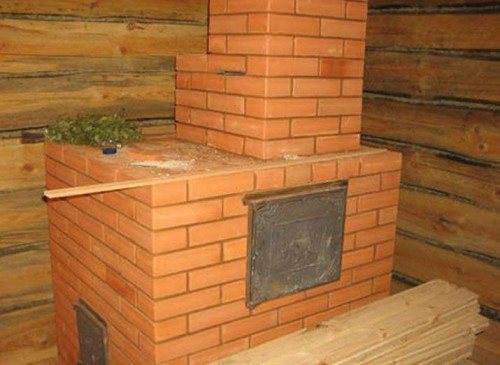

Installation

The main feature of installing a wood-burning stove for a bathhouse with an external firebox is the presence of a through hole in the wall between the steam room and the dressing room. A capital brick structure will require a lot of labor and expenses for the purchase of material. In addition, it is quite difficult to install such heating yourself - you need to have certain skills. Let's look at the step-by-step preparation instructions developed by experts:

- a niche is cut out, which should be 26 cm larger than the combustion channel;

- the floor is covered with a fireproof slab - this is done in the steam room and in the dressing room in front of the chamber door;

- lay metal sheets on top and screw them with self-tapping screws;

- the firebox is installed flush with the wall or with a small recess (it all depends on the thickness of the partition);

- insulate surfaces adjacent to the heating unit with metal screens;

- After the structure is completely installed, the distance between the heating chamber and the wall must be tightly sealed with any fire-resistant material. The ideal solution would be brickwork - it not only protects well from heat, but also has a beautiful appearance that does not require further processing;

- small gaps between the layout and the walls can be filled with polyurethane foam or basalt fiber.

Once the main work is completed, the metal screens should be decorated in accordance with the overall interior of the room.

Chimney installation

This is the last stage in assembling the structure by a professional; for this you need:

- Prepare the pass-through unit.

- Arrange holes for the pipe; they should be 25 cm wider than the chimney.

- For maximum insulation, take polyurethane foam with mineralite produced by FERRUM and fill it inside to 5-7 cm with kaolin wool, leaving the distance between the pipe and the sheet empty.

- Insert the assembly into the box, having previously protected it with mineralite sheets, fix it to the ceiling from above, and attach the base of the assembly to the lining only after finishing.

- When installing, make sure that the hole coincides with the pipe, because it is strictly forbidden to tilt the system (the maximum permissible error is 1 mm).

- To prevent the pipe from being covered with snow in winter and rain from getting into it in summer, a cap is attached.

Installing a stove in a bathhouse with an external firebox is not difficult; the main thing is to strictly follow the instructions and observe all safety measures, especially for a model made of metal. And if you have no experience in construction at all, then you can watch detailed video instructions.

Location of the stove in the bathhouse: layout features, installation procedure | Heat monster

The Russian bath is one of the favorite ways to spend leisure time.

Therefore, a suburban or dacha plot often becomes the place that is used for its construction, and the owner of the land often begins building a bathhouse almost immediately after the completion of the residential building.

This is not surprising, because a bathhouse is not only an opportunity to wash off dirt and sweat after a hard day on the site, but also a way to relax with friends, improve your health and well-being, and experience a surge of strength and energy.

https://www.youtube.com/watch?v=Fbk0mmOimzQ

When building a bathhouse, you need to pay attention to the correct location of the stove.

Bathhouse layout and its main features

However, when making plans for the future use of the bathhouse, it is necessary to carefully approach the process of its construction. It is the quality of the design of this building and its subsequent implementation that determines whether a bathhouse on an existing site will be a source of positive emotions or constant problems and disappointments.

Is the sun greenhouse so good?

During the construction planning process, special attention should be paid to the key elements of the bathhouse. One of these, without a doubt, is a stove, which serves as a source of heat, which means it performs several functions simultaneously: it heats the room, provides the possibility of generating steam, and provides the necessary water temperature.

Sauna stove: installation procedure and factors influencing the choice of location inside the sauna

Diagram of the approximate placement of a heater stove in a bathhouse: 1. a, b, c – direction of thermal radiation from the stove; 2. d – heating of the steam room using steam.

Today there are a large number of manufacturers on the market that offer sauna stoves designed to satisfy both standard and very specific needs.

They can be made of different materials, have different sizes of main compartments, different prices and delivery times.

Therefore, it is quite difficult to give unambiguous recommendations for choice: each future owner of a bathhouse must make his own informed decision based on the number of family members, the planned intensity of use of the bathhouse, the nature of its use and other factors.

Once the stove for the future bathhouse has been selected, you need to think about how to fit it into the design of the planned premises. This decision, in turn, will be influenced by several groups of main factors, which will become the basis for the future safe and durable use of the structure.

Requirements for the placement of a sauna stove, determined by considerations of fire safety of the room

Since private baths in Russia are a fairly common phenomenon, the long-term practice of their existence led to the development of general requirements for the location of the stove. Compliance with these requirements, as many years of practice have proven, is a necessary condition for the safe operation of a bathhouse.

Minimum permissible distances between the wooden parts of the bathhouse and the heating surfaces of the stove.

One of the key points in this regard is the formation of the furnace base. Typically, to provide fire protection, the furnace requires a self-supporting foundation, usually made from a non-combustible building material such as brick or concrete.

In addition, to ensure insulation of the furnace from the floor, which is often made from fire-hazardous materials, such as wood, additional elements are used.

For example, one of the common solutions to this problem is edging the floor around the perimeter of the furnace with sheets of steel or asbestos, the width of which is usually chosen in the range of 400-500 millimeters.

The minimum distance from the stove to any structure in the bathhouse, including walls, beams, railings and others, must be at least 260 millimeters.

This distance is allowed if the furnace is as safe as possible, for example, if it is made of protected material that prevents heat from spreading to nearby structures.

If the oven is made of a material that does not have such protection, the specified distance should be increased to 320 millimeters.

Technical characteristics of sauna stoves.

However, it should be taken into account that the above standards are valid only if the walls and other elements of the bathhouse located in the immediate vicinity of the stove are made of non-combustible material.

Even more stringent requirements for the distance of the stove from other parts of the bathhouse apply if its walls, floor and other components are made of flammable materials.

For example, bathhouses located in gardens or summer cottages are often built of wood or lined with wooden elements on the inside. In this case, the oven must be located at a distance of at least 500 millimeters from such elements.

At the same time, fire safety requirements stipulate that in such a situation, elements of the furnace that are subject to significant heating, for example, its side surfaces, mounted pipes and others, must be separated from flammable structures by non-combustible layers. For example, in this case the stove pipe can be placed in a special channel made of asbestos sheets or other similar material.

Diagram of different types of chimneys for sauna stoves.

Finally, it should be taken into account that the greatest danger from the point of view of a possible fire is the combustion chamber of the furnace.

Therefore, the current regulations establish special requirements for its location.

So, in particular, it is recommended to place the door of this compartment opposite the entrance door, and the distance to the nearest part of the bathhouse in this case should be at least 1500 millimeters.

Options for placing the stove depending on the parameters of the bathhouse and the nature of the premises included in it

Otherwise, the future owner of the bathhouse has a fairly large opportunity to choose the location of the stove. However, the most common places for its installation are only a few basic options. Their choice, in turn, largely depends on the layout parameters of the interior of the bathhouse and their number.

The necessary premises in any, even the smallest bathhouse, designed for rare use by a small family, are a steam room and a dressing room, that is, a place where you can undress, leave things and prepare for bath procedures.

If the resources for building a bathhouse are limited, that is, the construction budget assumes a fairly strict framework, and the plot of land intended for construction is not so large, many combine the functions of a steam room and a washing room in one room.

Foundation diagram for a stove in a bathhouse.

In this case, the location of the stove is determined by the nature of such a layout: as a rule, it is installed in the middle of the room intended for washing and steam generation, ensuring compliance with the fire safety rules listed above.

If the capabilities of the builder of the future bathhouse in relation to the resources available to him are somewhat higher, a reasonable solution would be to provide a separate layout for the steam room and the compartment intended for washing.

This is due to the fact that the functions of these visits partially contradict each other: washing in a bathhouse at the temperature at which people usually steam is not very comfortable, and steaming in a room intended for washing means being satisfied with the mediocre quality of steam, experts say. In this situation, however, one oven is still most often used, so it should be placed partly in the steam room and partly in the soap compartment. Usually this issue is solved in such a way that a hot water tap is available in the room intended for washing, and a heater used to generate steam is available in the steam room.

Finally, if you have even greater freedom in planning the future bathhouse, you can resort to the most convenient option for placing the stove, which involves installing it in a separate room.

Educational program: useful tips when building a house

Scheme of lining a sauna stove with bricks.

Depending on the extent to which the dimensions of the future building allow, a small opening between the individual sections of the bathhouse can be allocated for installing a stove in a bathhouse, or a special room can be allocated for it. In both cases, the operation of the stove, as bathhouse masters admit, will be much more convenient.

In addition, this option of installing a stove in a bathhouse has additional advantages: in this case, the room intended for installing the stove can be finished with maximum compliance with fire safety requirements, which will not interfere with bathhouse visitors from washing or steaming. For example, the walls of such a room can be lined with asbestos sheets, which is impossible if it was supposed to be simultaneously used for washing or steaming, since in such a situation the highly heated sheets would pose a threat to the health of bathhouse visitors.

The optimal way to place a sauna stove

Thus, from the point of view of both ease of use and fire safety, the most suitable option is to place the stove in a separate room. However, one should not think that this installation method is necessarily suitable only for large bathhouse structures that are being built for use by a significant number of people.

https://www.youtube.com/watch?v=Waxg6VSKkXQ

Scheme of installing a stove in a bathhouse.

As already noted, only a small opening or niche located between two independent rooms of the bathhouse, for example, a steam room and a dressing room or a steam room and a washing compartment, can act as such a separate room.

Typically, the choice of this room or niche is made in such a way that the walls of the installed stove are located in accordance with the remaining rooms of the bath - steam room, soap room and dressing room. This arrangement allows you to use one stove to heat the entire interior space of the bathhouse, without resorting to additional heat sources.

This method of placement retains all the advantages of a separate location of the stove, and requires very little space: according to experts, with a competent planning solution, only 0.15 sq.m of floor may be enough to install the stove in this way.

And if the area allows, this value may well be larger, which will provide more convenient access to the stove both during its operation when washing and steaming, and in order to prepare it for use, for example, when laying firewood or coal. Having some space around the stove will make it more convenient to maintain and repair it if necessary, and will also provide greater fire safety.

Most popular blog articles of the week