Heating

Author Anton

Date

Jan 29, 2016

0

1 218

Share

A garage is not only a place to store a car, but also a workshop where you sometimes have to spend quite a lot of time. Therefore, at sub-zero temperatures outside, it is necessary to provide heating.

- LiveJournal

- Blogger

A potbelly stove using waste oil is easy to make with your own hands

- The process of making a potbelly stove

- Nuances of operation

In order to save money, craftsmen and car enthusiasts build a potbelly stove with their own hands to heat a garage or workshop.

The operating principle of a waste oil furnace is quite simple. The exhaust furnace consists of two chambers. The lower one is the fuel tank in which the oil poured in is burned. Fuel vapors generated during combustion rise into the upper chamber, mixing with oxygen along the way, and this mixture burns in the second chamber.

In the fuel tank, the waste burns at a moderate temperature, and oil vapor mixed with air burns at temperatures up to 800 degrees. It is this process that mainly provides the heating capacity of the furnace.

The air necessary for combustion enters the furnace through a perforated pipe that connects both chambers.

The chimney pipe is also a kind of heater, giving off heat from the combustion products removed outside.

The fuel consumption of a potbelly stove is 0.5 – 2.5 liters. diesel per hour, depending on the volume of the fuel tank.

- Cheapness. Used oils can be collected from fellow motorists or purchased at a service station.

- The steel body heats up quickly and the room warms up in a short time.

- High efficiency.

- Does not consume gas or electricity.

- It's easy to make a potbelly stove with your own hands.

- Easy to use.

What tools and materials will you need to make a potbelly stove from scratch with your own hands:

welding machine, supply of electrodes, gas cutter, grinder, circles for cutting metal, hammer, chisel, pliers, drill, drills for working with metal, extension cord, chalk for marking.

Protective equipment: glasses for working with an angle grinder, a shield for welding work, overalls, gloves.

- LiveJournal

- Blogger

When performing work, follow safety precautions

Potbelly stove with oil: operating principle and advantages of the device

Heating at work makes it possible to have a good source of heat completely free of charge. The principle of operation of such a device is as follows: the required amount of waste oil is poured into the opening of the fuel tank, the fuel is ignited and heat is emitted. From 12 to 30 liters of waste are consumed per day of work. The exact volume depends on the furnace tank itself. When oil burns, a small percentage of heat is released, but this is not enough to sufficiently heat the room. Therefore, to increase efficiency, the unit is also equipped with an additional combustion chamber.

During the combustion of oil, an oil-air mixture is released. It burns at very high temperatures, ranging from 800 to 900 degrees. This combustion occurs in the upper chamber.

To form the mixture and its combustion process, air leaks are achieved through openings in the transition pipe. This results in increased heating of the room. A small amount of heat also comes from the chimney pipe, which leads the combustion product outside. In order for the heating of the premises to take place more actively and with better quality, labyrinths with pipes coming out of it can be installed above the upper chamber. Moreover, the hot air will be directed in the required direction.

Advantages of a potbelly stove operating in mining:

- No need to purchase fuel;

- The room heats up quickly;

- Device security;

- Not tied to electricity.

This type of heating can be used not only for the garage. Country houses can also be heated using such a stove.

Features of work

The principle of operation of a potbelly stove in mining is based on the pyrolysis reaction (thermal destruction of waste with oxygen limitation and the resulting carbon residue and pyrolysis gas with high heat transfer).

In 40-60 minutes, a drip stove consumes from 0.5 to 2.5 liters of waste oil (depending on the size of the tank). During fuel processing, an oil-air mixture of moderate temperature (less than 100 degrees) is formed in the lower chamber, and heat of up to 800 degrees is created in the upper part.

The thermal power of a potbelly stove is limited to 16 kW (ready-made modified models, such as the GeKKon dripper stove, have increased power - up to 100 kW). The principle of operation of the stove using waste oil makes it possible to obtain a high efficiency coefficient of 75-80%. A small potbelly stove is suitable for heating rooms with an area of 60-100 square meters.

Potbelly stove in production: types of devices

A metal stove that has a chimney and is installed indoors is popularly called a potbelly stove. It gained its popularity at the beginning of the last century. But it was immediately replaced by the central heating system, as well as the proliferation of gas stoves.

The potbelly stove was given a second life by soldiers who actively installed it during the war in dugouts and heated buildings, as well as by civilians in dilapidated houses. In peacetime in the mid-20th century, such stoves heated garden houses. Today they are also used for seasonal heating of small utility rooms with an area of up to 15 m2.

Such stoves can be made of cast iron or steel. The finished device is a kind of bunker with a door in the firebox, a small ash pan, and a special pipe from the chimney.

What types of potbelly stoves can there be:

- Oven with hob for cooking;

- Appliance with oven and burners;

- Heater;

- Gas generator furnace.

The heater furnace is enveloped in an air casing throughout the entire body. This device is capable of very effectively enhancing heat transfer. Due to the clever design, air is sucked into the gap between the casing and the wall of the river in the lower zone, and then rises, where it is heated against the furnace walls. After that, it exits in the upper zone through the holes. The casing is made of ceramic or steel.

Select a drawing

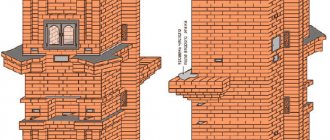

Drawing of the most efficient potbelly stove using waste oil.

Let's look at the details - before us is a stove consisting of three main parts. Part one, the lowest, is a container with a small hole for pouring fuel and ignition. This container plays two roles - it acts as a tank and works as the primary combustion chamber. The container lid also serves as a kind of combustion intensity regulator.

The next part is a tube with holes that is welded to the lower container. The holes are used to take in secondary air. It mixes with the evaporating waste, resulting in the formation of a combustible mixture that burns to form a high-temperature flame. When the potbelly stove warms up and reaches operating mode, the pipe will literally hum under the pressure of the fire. The final combustion occurs in the upper chamber.

The upper chamber of our potbelly stove is round. But nothing prevents you from making it rectangular (like the bottom one). By increasing the area of the upper surface, you can create a kind of hob so that you can boil a kettle and warm up with a cup of warm drink. In the upper part of the second chamber of the potbelly stove we see a small pipe - it serves to connect the chimney. That's the whole scheme - simple and unpretentious.

How to make a potbelly stove at work with your own hands

Those who have potbelly stoves operating during mining should stock up on fuel in advance. To do this, they usually place a container in the garage into which all the used oil is poured over and over again. Thus, by winter a certain amount of reserves accumulates. For pennies, or maybe even free, you can get work done at service stations and auto repair shops. You can try your luck at large transport enterprises.

If you decide to make a potbelly stove to heat your own garage, you should keep in mind that the operation of the device largely depends on good, sufficiently powerful draft in the stove, and the size of the device itself.

Based on this, craftsmen do not recommend assembling the stove carelessly. For its proper operation, it is necessary to develop accurate drawings, manufacture the device directly according to them, and comply with certain dimensions. You need to remember that the larger the capacity of the fuel tank of the furnace, the faster the oil burns, and, consequently, its consumption will increase. To ensure that used oil does not stink, does not hiss, does not bubble, but burns normally, it is necessary to use only waste oil that has settled. In addition, it is not advisable to fill the fuel tank more than two-thirds full.

We make a potbelly stove from a regular stove:

- Weld a container for waste oil from sheet iron.;

- Cut holes in the stove to supply air;

- Install a valve to regulate the flow of air into the tank;

- Instead of a chimney, install a pipe with holes for the exhaust of air and smoke gases;

- You do an afterburner (a chamber in which the gas will burn a second time), with a removable top part;

- Connect the recombustion chamber to the main pipe with holes;

- Install the chimney pipe.

Make sure that the vent in your new oven is tightly closed. If necessary, brew it. If you are not sure what you can do, you need to know that converting the stove into a potbelly stove is completely optional. You should know that you can buy a ready-made design in stores. One of these models is the Teplon-603 oven.

Work on other types of fuel

There is no need to bother with exact adherence to the millimeter - many craftsmen assemble potbelly stoves by eye, obtaining excellent results.

In our reviews, we have repeatedly published diagrams of conventional wood-burning stoves, including the pyrolysis type. They are made from sheet iron or old gas cylinders. Being equipped with large fireboxes, they allow you to burn almost any type of solid fuel. If you try, you can make a universal heating device - this is a wood-burning stove.

To do this, you will need an exhaust burner, shown in the figure below. Here we see the same primary combustion chamber with a perforated vertical tube connected to it. Only the final combustion will take place not in the secondary chamber, but in the chamber of the wood-burning stove. Your task is to arrange a removable door on it so that you can turn on the presented burner instead.

Converting a potbelly stove for mining is not particularly difficult - just use the diagrams and tips published in our review.

Materials for making a potbelly stove using waste oil for a bath

These days, establishments such as saunas and steam baths are very popular. People have been coming here for a long time to receive physical healing and cleansing.

Of course, the heart of any bathhouse can only be called the stove. The quality of the procedures taken, the temperature in the room, air humidity and steam intensity depend on it.

A potbelly stove, operating on waste, can be classified as the simplest and cheapest type of small stove. You can easily make it yourself. They come with closed or open heaters. In shape it can be round, it can be square, located both vertically and horizontally.

To make a working stove-stove you will need:

- 8 mm sheet steel;

- 500th metal pipe, with a wall thickness of at least 1 cm;

- Grate bars;

- Bulgarian,

- Chimney pipe;

- Rod, 10mm thick;

- Welding machine;

- Diodes.

Cut a hole in the pipe measuring 20x5 cm. Weld a mount for the grate on the inside of the pipe, install the firebox door and make rods for the heater. On the other side, cut holes for water in the heater. Cut out a cover from a metal sheet where there will be a hole for the chimney pipe. Then you weld it to the heater.

Making a potbelly stove from a gas cylinder

Another design option for a waste furnace is a self-made potbelly stove based on a 50-liter gas cylinder. In addition to this main element, you need to prepare 2 steel pipes with a wall of about 4 mm and a diameter of 10 cm. One of them will remove burning gases, and the second will act as a heat exchanger.

To this should be added a 4 mm steel sheet for the hood above the heat exchanger and the partition separating the evaporator and the combustion chamber. For the evaporation chamber itself, you will need a brake disc from a car with such a diameter that it fits into the cylinder without effort. A piece of 0.5-inch pipe is needed to transport oil to the combustion chamber.

In addition, you should have in stock an equilateral steel angle with a shelf of 50 mm and a length of more than 1 m, a 0.5-inch valve, clamps for sealing - 2 pcs., a hose, any cylinder equipped with a needle valve.

The work of creating a potbelly stove is carried out in a certain order. First, the container is turned upside down and a small hole is drilled in it. A measure such as wetting the drill and the drilling site with oil will prevent sparking.

Empty the container from gas condensate. Drain it carefully away from your home, because... its unpleasant odor lingers for a long time. Then the workpiece is filled with water, after which it is drained again, thus removing any remaining gas. Since the mixture is explosive, there should be no open flame nearby.

How to make a potbelly stove during testing (video)

Among the huge variety of options for homemade stoves that are made at home, the potbelly stove is the easiest to make, as well as easy to use and safe. An important condition that must be met when constructing a potbelly stove operating in mining is the access of air masses to both combustion chambers. You need to make a not very large hole in the lower tank to allow fuel to be poured in and the air supply to be regulated. The hole is closed with a special valve. Secondary air enters the upper chamber through small holes.

Features of operation

Used oil is poured into the opening of the fuel tank (do not pour too much, a third of the fuel from the total volume of the chamber is enough). Then they set fire to a rag soaked in kerosene or a strip of compressed newspaper and bring it to the oil surface.

Complete ignition of all the liquid occurs in about 3-5 minutes, after which you should close the damper (leaving a gap of a couple of centimeters in it). The door cannot be closed completely, otherwise the flame will not burn.

It is prohibited to install a potbelly stove using waste oil in living rooms due to the oxide released. The rooms where the stove is installed must be well ventilated. If you use a potbelly stove frequently, sludge will accumulate inside the tank over time, so the device must be cleaned 1-2 times every six months. To do this, disconnect the pipe and the upper part and remove carbon deposits through the gap using any brush with stiff bristles.

A potbelly stove that works during mining can be made in a couple of hours. If you have experience in welding, this will not be difficult. If you lack confidence in your abilities, it is better to purchase a ready-made model. Both homemade and purchased potbelly stoves have high efficiency. But its main advantage is its efficiency; you don’t need to buy special fuel for it, it’s enough to use residual oil. With proper use, the stove will last for several decades.

How and with what to heat a potbelly stove?

Fuel . Steel stoves are designed for wood heating. You can also use sawdust-based fuel briquettes, which are sold in construction shopping centers. Stoves designed to fire coal are made of cast iron.

Operating modes . Most stoves of this type can operate in one of two modes: intense combustion and temperature maintenance. For intense combustion, after adding firewood and closing the oven door, open the ash pan drawer to ensure that the maximum amount of oxygen enters the firebox. To switch the stove to slow burning mode (maintain temperature), add firewood again and close the ash pan drawer. The slow burning time depends on the design of the stove and can reach 8 hours for models equipped with afterburners.

The draft is adjusted using a damper: if there is excess draft, the damper is partially closed.

Remember : you can use the stove in intensive combustion mode for no more than 2 hours a day!

ADVICE

To extend the service life of the stove, experts recommend heating the stove intensively for 15-20 minutes after the slow burning mode: this is necessary to remove soot formed during the slow combustion of fuel.

How to choose a stove-stove for a summer house

Power is determined at the rate of 1 kW per 10 m3 of room area. If you intend to use the stove only in the warm season (April-October), you can choose a device with a power less than the calculated one.

The dimensions are directly related to the size of the firebox and, therefore, the power of the stove, however, the dimensions of stoves with the same firebox volume may vary due to design features. When choosing, keep in mind that the stove must be installed at a safe distance from surrounding objects: 500 mm on the sides and rear, 1250 mm in front and 1200 mm on top. The maximum length of firewood used also depends on the size of the firebox.

Purpose . To heat several rooms separated by solid partitions, you need a stove with the ability to install heat sinks: flexible hoses are connected to them to remove warm air to adjacent rooms.

Please note : chimney elements are sold separately from the stove, since its configuration is selected individually and depends on the characteristics of the house.

Potbelly stove for a summer residence: pros and cons

Advantages

Fast heating and high efficiency . A metal stove begins to release heat into the room immediately after lighting. Due to the fact that thermal energy is not wasted on heating the furnace itself, high efficiency and fuel savings are ensured.

Compactness . A potbelly stove is the smallest of wood-burning stoves: the lightest models weigh about 30 kg, the weight of the heaviest ones rarely exceeds 80 kg, and overall dimensions are approximately 700x400x800 mm or less. This stove is the best choice for a small garden house.

Easy to install and dismantle . It is easy to install a potbelly stove in an already built house: it will not require significant alterations to the floor, ceiling and roof structures. The small diameter of the chimney (up to 200 mm) eliminates the need to punch wide holes. Due to its light weight, it can be installed on light floors without pre-strengthening them. Dismantling the stove is also not particularly difficult.

Low price , especially in comparison with “mainstream” brick kilns.

Low operating costs . A potbelly stove is an economical way to heat a house in comparison with electric and gas heating and brick stoves. And if in a holiday village there are periodic power outages and there is no connection to the main gas pipeline, it becomes no alternative.

Flaws

Risk of burns from the hot oven body. Safety rules prohibit the construction of protective and decorative screens around the stove that could protect against accidental contact with the stove.

Quick cooling after heating. If the stove is not switched to slow burning mode, then after the wood burns out it cools down almost immediately.

Fire hazard due to improper installation or careless operation. The high temperature of the stove body and chimney structures requires particularly careful attention to safety of use.

Wood-burning stove for a summer house with a glass window

What does Buleryan drown himself with?

To learn how to properly fire a Buleryan stove, you will need quite a bit of practice and following the manufacturer’s recommendations. The operating instructions indicate the length and type of firewood, and the percentage of humidity. If all operating conditions are met, the burning time from one bookmark increases to 6 hours.

What kind of wood to burn with?

Firewood for Buleryan is carefully selected in accordance with the requirements. The strict standards are due to the operating principle used in the operation of the equipment.

For gas generation, it is necessary to create certain conditions in the combustion chamber: high temperature and limited oxygen supply, lack of moisture. Accordingly, if you heat it with raw wood, Buleryan will work like a regular steel stove.

There are certain recommendations regarding the quality and type of firewood:

- Types of firewood that can be used to burn Buleryan - any deciduous varieties will do. Do not use coniferous wood. A high resin content will lead to rapid failure of the stove and clogging of the chimney. If you heat the stove with “fruit” wood (cherry, apple, pear, etc.), the heat transfer will be low, and fuel consumption will increase accordingly. It is optimal to heat the firebox with hard wood: oak, acacia, etc.

- Fuel for special purposes – an attractive property of alder firewood is its ability to remove tar deposits from the inner surface of the chimney. It is enough to heat the stove with alder from time to time to ensure normal draft and performance.

- The maximum moisture content of firewood is no more than 20%.

Firewood is the best fuel for Buleryan, but if necessary, it is possible to heat the stove with alternative types of energy.

Is it possible to heat with coal?

According to the operating instructions, heating with coal alone is strictly prohibited. What is the problem? The stove does not have grates - there are convection pipes at the bottom of the combustion chamber. Coal, when burned, releases a lot of heat, which can cause the metal to burn out.

It is correct to heat the Buleryan stove with brown coal, adding it to the firewood. Some people modify the oven by installing grates. Changes to the design are made at your own risk and will void warranty service.

Is it possible to drown by mining?

An open fire leads to burnout of the lower pipes and failure of the stove. Therefore, waste material cannot be used as fuel.

Is it possible to burn with briquettes?

As practice has shown, using peat briquettes in a stove is the best option of all the types of fuel recommended by the manufacturer. During the processing process, moisture and air are removed from the briquettes, which increases the pernicious ability and heat transfer.

The only drawback of fuel briquettes is their relative rarity. To purchase the required batch, you will need to use the Internet. Various companies offer briquettes, with a minimum batch of several tons.

Is it possible to burn with sawdust, wood chips and tree bark?

The use of wood waste helps to significantly reduce heating costs.

Is it possible to burn with pellets?

Any type of solid wood fuel is suitable for Buleryan, and pellets are no exception. But to use granules you will need to install a special mesh. Otherwise, the kindling is processed in a manner similar to wood waste.

To begin with, firewood is lit in the normal combustion mode. After sufficient burning, pellets are added. The furnace is switched to gas generation mode. For the firebox, it is better to choose high quality pellets made from wood. You should refrain from using granules based on plant waste.

Conversion of a solid fuel stove for testing

When the household already has a potbelly stove, but is not happy with the fact that it runs on solid fuel, you can modernize it and it will become universal. For this purpose, an attachment is made that resembles in its design a stove with processing in its lower part.

There is also a perforated pipe here, but not straight, but bent at a right angle. It is connected to the side wall of the furnace, which serves as the final combustion chamber. If you weld the potbelly stove door and make a hole in it for the pipe to enter, then the stove will only work during exhaust.

To make it possible to use not only industrial oil for heating, but also firewood, two replaceable doors are made. The standard one is hung when it is planned to lay firewood, and the modernized one with the appropriate hole is hung when the stove will operate on waste oil.

We also suggest reading an article on how to assemble a potbelly stove using waste oil from a pipe - to familiarize yourself with the material, follow the link.