A solid fuel boiler is a non-volatile source of home heating. With its help, you can ensure a comfortable temperature in the room; the main thing is to correctly calculate the required power of the unit depending on the area of the house and select the equipment accordingly.

Installation of the device does not require special knowledge and tools, so even a person without technical skills can cope with such a task as installing a solid fuel heating boiler with his own hands. Moreover, this procedure does not require complex approval.

It is only necessary to responsibly approach each stage of installation and observe their correct order.

A solid fuel boiler is capable of heating a large house.

In total, there are 7 main stages of installation, the first of which is preparation of the base. The site must be absolutely solid and level. It is optimal to mount household boilers on a concrete screed with a thickness of 70 mm or more, and any gaps between the bottom of the appliance and the base must be removed using a heat-resistant sealant.

Next steps:

- Combustion product removal system equipment.

- Boiler installation.

- Design and installation of heating system pipes.

- Installation of safety system devices, expansion tank.

- Strapping.

- Checking the heating system.

Selecting a room and constructing a base site for the boiler

You should think in advance where you will install the solid fuel boiler.

Before installing a solid fuel heating boiler with your own hands, you need to equip a special, well-ventilated room for the device. Living spaces - kitchen, bathroom or living room - are not suitable for this purpose, since the operation of the heat generator is accompanied by the release of combustion products harmful to the body.

The boiler room has certain requirements for installing a gas boiler:

- It is necessary to install a solid fuel heating boiler at a distance of 50 cm or more.

- A distance of 1 meter is required from the walls of the room to the combustion door.

- Flammable items must not be stored in the boiler room.

- Ventilation ducts must be located strictly at a certain distance: from the floor no higher than 50 cm and from the ceiling no lower than 40 cm.

The base platform on which the boiler will be installed must additionally be protected with a steel plate or asbestos. It is also necessary to provide fire protection for the space under the loading door. A metal sheet measuring 500*700 mm is placed here.

Nuances and requirements for installation

Installation of boiler room equipment in a private house must be carried out taking into account technological nuances and requirements of the regulatory and technical framework. The main ones:

- If gas boiler houses are being installed, then it is necessary to obtain permission from the gas trust to connect to the main gas pipeline

- When installing a floor-standing boiler, it is recommended to lay a concrete screed underneath it. Solid fuel boilers with a power of more than 50 kW are installed on a concrete foundation that is not connected to the foundation of the house

- It is prohibited to store explosive and fire hazardous compounds in the boiler room. The exception is fuel, the storage conditions of which are regulated

- In boiler rooms there must be free access to the boiler from all sides. The minimum permissible distance between the front panel of the boiler and the far wall is 1 meter

- If a gas, diesel or solid fuel boiler room is located directly in the house, the door to it must be made of fire-resistant material or trimmed with it

- The minimum permissible area of the boiler room allocated for the installation of a gas boiler is 6 square meters. meters. For solid fuel - 8 sq. meters

- In boiler rooms where a coal-fired boiler is installed, only hidden electrical wiring is allowed. This is due to the high explosiveness of coal dust.

- When installing a diesel boiler room, a thick-walled metal tank is placed underground. Its volume must be at least 1.5 cubic meters. meters. It stores fuel, which is supplied to the boiler through underground pipes.

- When installing a smoke exhaust system, the chimney should not have more than three elbows. It is necessary to provide a technological hole (revision) for cleaning inside the pipe

- The chimney deflector must be located above the level of the roof ridge. This condition is necessary to avoid the draft tipping over.

- The section of the chimney located outside must be securely fixed (for example, using clamps attached with anchors to the outer wall)

- If you are installing boiler equipment that runs on gas, diesel or solid fuel, then it is necessary to install a ventilation system, the frequency of which is at least 3 in 1 hour. To organize the inflow, as a rule, a hole with a diameter of 13-17 cm is cut. It is recommended to force exhaust

- In the room where the electric boiler is installed, all terminals must be grounded

The turnkey boiler room, completed by our engineering staff, takes into account these requirements and nuances. Specialists are certified by most of the popular manufacturers of boiler units in Moscow and the Moscow region.

If a boiler room that runs on gas is being installed on a turnkey basis, then we are responsible for signing the Act on Delineation of Responsibilities. The act is signed by the Customer, the local gas trust and us.

For the Customer, one of the advantages of working with us is that we do not impose any brands of equipment, but offer the entire range available on the market. Our experienced specialists will help you choose the most suitable option.

The chimney is an important element of the heating system

To understand how to install a solid fuel heating boiler with your own hands and avoid the penetration of flue gases into the living space, you need to carefully study the design of the combustion product exhaust system. The configuration of the chimney - its length and diameter - must be selected based on the recommendations of the heat generator manufacturer. The chimney must meet the following requirements:

- Provide good traction.

- Remove smoke and gases from the combustion chamber.

The chimney must be vented outside. All joints must be treated with heat-resistant sealant. A modern chimney must have holes to clean the pipe from soot, as well as a condensate collector.

Pipeline system - installation features

Before installing a solid fuel heating boiler with your own hands, you need to calculate the parameters of the pipelines - their length, diameter, required slopes and the total number of radiators. It is important that the return inlet to the boiler is located below the heating radiators - this is necessary to ensure normal natural circulation of the coolant.

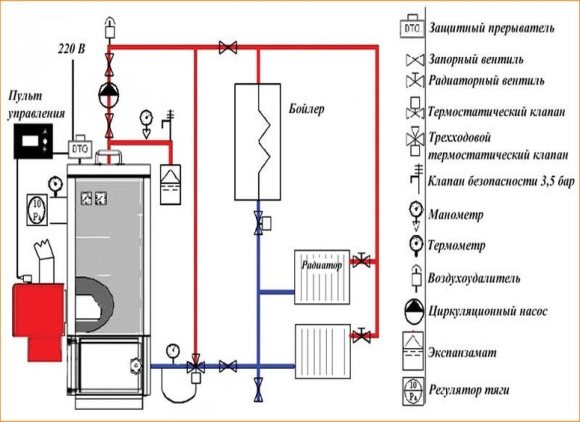

Wiring diagram for a solid fuel heating boiler

When installing a solid fuel boiler, it is recommended to install a combined heating system - capable of operating with forced and natural circulation. This is necessary to ensure safety: in the event of a power outage, a solid fuel boiler cannot be stopped immediately. If the water continues to heat up without forced circulation, it will boil, which can cause damage to the entire device. Therefore, a bypass must be additionally included in the natural heating system. This is a special device for switching circulation modes.

Heating installation in a private house

It should be noted that all manufactured boilers that run on solid fuel can function with the direct participation of humans. After all, it is the person who must load fuel into the boiler and ensure that it does not go out.

Therefore, before installing this device, it is necessary to carefully consider the place where the boiler is supposed to be placed. Typically, experts recommend installing the unit in a specially equipped room, in which access to the device by unauthorized persons will be limited.

Heating boilers should be installed with the help of qualified specialists who can correctly calculate the output parameters of the unit depending on the cubic capacity of the living space.

Our company carries out installation work and connection to the heating system of boilers that run on solid fuel. All work is carried out by qualified specialists with extensive experience. Also, at the client’s request, they can repair the heating in a private house.

We follow safety measures. When installing equipment, the company guarantees not only the quality of work, but also the reliability of the heating system in the subsequent period.

Checking the heating system - the final stage

After installing a solid fuel heating boiler with your own hands is completed, you need to check the correctness of each connection and connection. To do this, you should first conduct a visual inspection for integrity, and then run cold water into the system. If leaks are detected, they must be repaired.

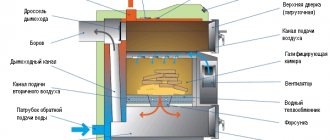

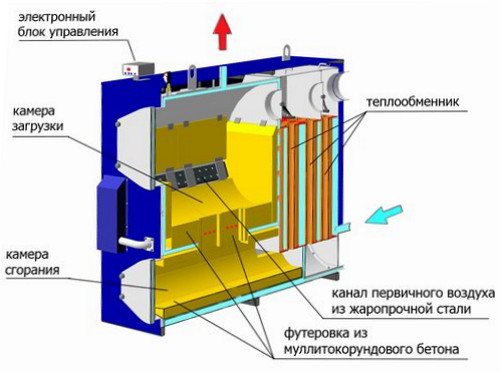

The operating principle of a solid fuel heating boiler.

When the system is operating under pressure, it is checked for operation by monitoring the readings of the pressure gauges for 15 minutes. The final test is to check the equipment under operating conditions. At this stage, all key aspects are controlled:

- Operation of a solid fuel boiler.

- Coolant circulation.

- Operation of safety devices.

- Return temperature value.

- Uniform heating of all rooms.

Types of boilers

Steel is a versatile metal from which many different products are made. It is moderately strong, elastic, resistant to damage from the external environment and has an acceptable weight. It was these characteristics that spurred various manufacturers to use steel parts in the production of heating boilers. Based on the type of fuel used in the process of heating water, such boilers are divided into:

- Electrical;

- Gas;

- Liquid;

- Solid fuel.

However, no less important is the presence of an additional circuit into which heated water flows. In single-circuit boilers there is only one circuit; such boilers can only be used as heating; the heated water along the circuit enters the radiators, which then release heat into the surrounding air. Double-circuit models have 2 circuits in which water circulates. These circuits are not connected to each other, as they are responsible for different engineering systems. In the first, water goes to heating radiators, in the second - to the house water supply system. Such a boiler replaces a boiler, although it usually produces a much smaller volume of hot water and is only suitable for households with low hot water consumption.

Installation cost

Our company has a democratic approach to pricing. We can install this type of boiler both in Moscow and in the Moscow region at an affordable cost.

So, for example, specialists will be able to install basic boiler equipment for an average of 4,900 rubles, and installation of heating pipes will cost our clients approximately 3,900 rubles.

As you can see, the services of the masters are acceptable for people with different income levels. More detailed information about options and prices for heating country houses can be found on our website.

Our company is a leader in the installation of solid fuel boilers in the region. Our specialists perform all work at a high professional level, which allows you to organize efficient heating of your home.

The heating system for a private home based on a solid fuel boiler, created by our specialists, will ensure a comfortable temperature in the living room for many years.

| Work performed | Price |

| Installation of a floor-standing solid fuel boiler | from 18,000 rub. |

| Installation of an indirect heating boiler | from 12,000 rub. |

| Installation of a boiler safety group | from 1100 rub. |

| Installation of a circulation pump | from 1400 rub. |

| Installation of expansion tank | from 1400 rub. |

| Installation of the main mixture collector | from 1500 rub. |

| Installation of thermohydraulic distributor | from 1700 rub. |

| Installation of the pump group | from 2000 rub. |

| Installation of a radiator, floor convector, etc. | from 1800 rub. |

| Installation of an in-floor convector | from 2500 rub. |

| Installation of a collector with underfloor heating flow meters | from 2500 rub. |

| Installation of risers made of polypropylene, polyethylene, metal plastic | from 800 rub./ linear meter |

| Routing heating pipes to radiators | from 2500 rub. |

| Pressure testing of the heating system | from 4000 rub. |

| Installation of the mixing group | from 2800 rub. |