Dual-circuit

These are models KS TVM 16/20, TV 31.5/40, TV 20 and others. A number of dual-circuit heaters can be easily converted from gas to coal/wood and vice versa. Designed for heating areas up to 300 m². Simultaneously with heating, they heat water for domestic needs.

The secondary circuit is a copper coil; if necessary, it can be changed, thereby prolonging the operation of the equipment.

A double-circuit boiler has characteristics almost similar to those of a single-circuit boiler. Also made of steel, but more powerful than single circuit versions. 20, 30 and 50 kW options are available. Their weight is 150–200 kg.

Advantages of the Don 16 boiler

Let's look at the main advantages of domestic Don 16 boilers:

Versatility

In cases where heating is needed now, and the gas main is already on the way, it is very convenient to install a solid fuel boiler, and then convert it to gas without any special costs.

Economical

The huge dimensions of the combustion chamber allow the solid fuel boiler to operate on one load for up to 8 hours, which is very good in comparison with analogues. The use of an American Honeywell draft regulator can reduce fuel consumption by 30%.

Electronically independent

The boiler is designed in such a way that no power supply is required during its operation. This parameter is especially important for owners of houses or cottages in new villages that are not yet equipped with power lines.

Resistant to hard water

For central Russia, hard water is a common occurrence. It forms scale on the walls of the heat exchanger, heating system pipes and the hot water heating coil, which significantly reduces their service life. The materials used in Don 16 significantly reduce the effect of hard water.

Photo 5: Trimming of a floor-standing wood- and coal-fired boiler Don 16

A few words need to be said about the shortcomings. The main disadvantage is the relatively low efficiency, similar in values to home-made long-burning pyrolysis boilers. With the exception of working with a pellet burner connection, working on one load is also not great.

Model range of boilers Don

Don solid fuel boilers are produced with a power from 11 to 40 kW. All of them are universal and can work on wood, coal, briquettes and pellets. Does not depend on the power grid. They are marked with letters and numbers, for example, KS-T-1R or KS-T-11P, where:

- K – boiler;

- C – steel;

- T – solid fuel;

- numbers – rated thermal power;

- P – draft regulator;

- P – plate.

The efficiency of all units is 80%. A gas heater can be inserted into each boiler, then it can operate on natural or liquefied gas.

One of the most popular models is the Don 16 boiler with a gas burner. The technical characteristics of this unit allow it to be used for operation in open and closed heating systems (see Horizontal heating system: general information and recommendations).

The line also includes solid fuel heaters that can operate in automatic mode. Pellets are used as fuel. To automate the process, a pellet hopper is attached to the boiler. A pellet burner is inserted into the firebox. It operates from the mains, consumes 300 W when igniting, and 70 W/hour to maintain combustion. The burner weighs 18 kg.

How to choose

Thermal power. When choosing it, you need to know not only the area that is supposed to be heated. If a device is selected for heating a private home, you must also take into account what material it is made of and how insulated it is.

In apartments, the location is important - central or corner. It’s always colder in the latter, so the power needs to be chosen with reserve

The approximate power of the device is determined by the ratio - 1000 W for every 10 square meters of area. And for every cubic meter - 40–60 W. But it is recommended for cold houses and apartments to take boilers with a heating capacity reserve of 30%. Firstly, there will be no problems with heating in the most severe frosts, and secondly, the equipment will not wear out and will last longer.

Dependence on power grids. This parameter is more important for reliability and stability than for efficiency. If boilers require electricity consumption, for example for ignition, it is insignificant.

Number of circuits. The capabilities and cost of the heater depend on the choice of this parameter. Single-circuit ones are chosen for heating; double-circuit ones, in addition to heating rooms, can heat water for domestic use.

Installation method. Wall or floor. The choice depends on the area of the room. Wall-mounted versions are more compact.

Heat exchanger material - steel or cast iron. Cast iron ones are more reliable, they are not afraid of corrosion.

Type of combustion chamber. It is more convenient with a closed firebox: they are safer, do not waste the internal air of the premises, they are preferred today by owners of houses and apartments that are not equipped with traditional chimneys.

How much do they cost

Equipment from domestic brands is a priori cheaper than imported ones, and products are no exception.

The price of Don boilers depends on the model and its power. An inexpensive single-circuit device KS-T-16, designed to heat 160 m², costs about 17,000 rubles. The cost of a powerful double-circuit device designed to heat 300 m² is 37,000 rubles.

Installation and installation of the Don KST-16 boiler

___________________________________________________________________________

- Solid fuel boiler Don KST-16 – Design and service

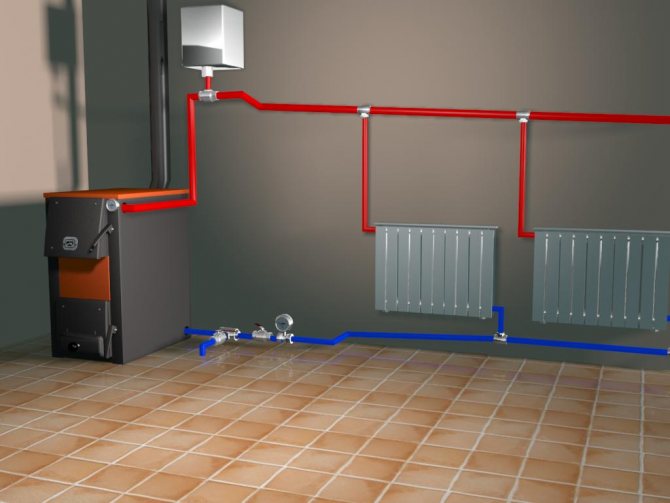

Installation work on solid fuel boilers Don KS-T-16 When installing on combustible building structures, 0.5 m below the unit and in front of its front, it is necessary to install a steel sheet gasket over asbestos cardboard or felt soaked in a clay solution. In order to improve the conditions of water circulation in the heating system, the Don KST-16 boiler must be installed in such a way that its lower pipe is lower than the radiators of the heating system of the building (structure). Pipelines are made from water pipes. Pipes can be connected using threaded fittings and/or welding.

When installing pipelines using welding, it is recommended to leave threaded connections to ensure disassembly of the system during repairs. Recommended installation dimensions for radiators when installing residential heating: - at least 3 cm from the radiator wall; — from the floor to the bottom of the radiator – 10 cm; - from the top of the radiator to the window sill - at least 10 cm. - When installing the radiator in a niche, the distance from the radiator to the side wall of the niche is at least 10 cm on each side. When bending pipes, it is necessary to observe a minimum radius, which must be at least 2 outer diameters of the pipe. When laying pipes, risers must be installed strictly vertically. The permissible deviation from verticality is 3 mm over 3 meters of pipe length. Horizontal pipelines must be laid with a slope to allow air to escape from the system. The slope must be at least 10 mm per 1 linear meter. pipeline.

In this case, the slopes of the branches to the heating device must have a slope of at least 10 mm along the entire length of the supply towards the heating device. When installing 2 or more KST Don boilers on 1 system, it is necessary to install a plug valve or valve on the return line to each boiler.

The diameters of the heating system pipelines are selected using a special calculation. In typical heating system designs, the most common values are: - main riser from the boiler - 1ѕ - 2″ - distribution and collection lines 1ј - 1Ѕ" - connection of devices * - 1 The chimney structure must meet the following requirements: - The chimney to which it is connected the KS-T-16 Don boiler must be located in the internal main wall of the building. — Smoke exhaust pipes laid through unheated rooms must, if necessary, be covered with thermal insulation. — It is allowed to connect heating boilers to chimneys made of asbestos-cement pipes. The cross-sectional area of the chimney should not be equal to or less than the area of the boiler pipe connected to the chimney. Chimneys must be vertical, without ledges. Cold running water is connected to the lower pipe of the water heater of the Don KS-T-16 boiler, and the hot water supply is connected to the upper pipe. A safety valve adjusted to a pressure of 0.15 MPa must be installed on the supply line (no further than 500 mm from the upper branch pipe of the device). If the heating system involves filling and feeding the boiler from the water supply network, it is necessary to install a check valve in front of the tap.

Fill the system with a pressure not exceeding the operating pressure of the unit. Fill the heating system with tap water. Testing (pressure testing) of the heating system (pipes, radiators) should be carried out with the heating boiler disconnected, because the pressure in it should not exceed the working pressure specified in the passport. The volume of the expansion tank depends on the volume of the heating system and is calculated when developing a heating project. To prevent freezing of the expansion tank and drain pipe in winter, they must be installed in rooms with a temperature not lower than +5°C. There should be shut-off valves at the inlet and outlet of the coil.

___________________________________________________________________________

___________________________________________________________________________

- Malfunctions of the AOGV-23 ZhMZ boiler

- Parameters and design of gas boilers AOGV and AKGV

- Boiler automation Baxi Luna-3 Comfort

- Installation and installation of the Baxi Slim boiler

- Adjustments and maintenance of the Beretta Chao boiler

- Determination of error codes and malfunctions of Rinnai boilers

- Errors and malfunctions of the Termet gas boiler

- The meaning of error codes and malfunctions of Vailant boilers

- Determination of malfunctions and errors of Visman boilers

- Questions about servicing Navien boilers

- Questions about malfunctions of Kiturami diesel boilers

- Junkers boilers - Experts answer user questions

- Experts answer questions about Electrolux boilers

- Answers from Nova boiler repair experts

- Questions about Hermann boiler service

- Answers from Daewoo boiler service technicians

- Questions about servicing Ferroli boilers

- Questions from users regarding the repair of electric boilers Evan

- What causes an AKGV gas boiler to light up and immediately go out?

- What is wrong with the Alpha Color boiler if it shows error code E01

- Why does the AOGV boiler light up and go out quickly?

- How to eliminate error E01 on the Baltgaz boiler

- What is the problem if Dani’s boiler lights up but immediately goes out?

- Why does a Danko boiler light up but quickly go out?

- The Demrad boiler has stopped holding pressure, what is the problem?

- Why did the Gaslux boiler start to get hot and make noise?

- What is the reason if the Keber gas boiler lights up but quickly goes out?

- How to eliminate error code 01 on the Kiturami boiler

- What causes a Conord boiler to light up but immediately go out?

- What is the reason if the Lemax boiler lights up and goes out quickly

- Why does a Mimax boiler light up but suddenly go out?

- Why does the Hearth boiler light up but immediately go out?

- Why does a Ross gas boiler light up but go out quickly?

- What is the problem if the Siberia boiler lights up and goes out suddenly?

- Why does the boiler Signal light up and suddenly go out?

- What can cause a Termet boiler to make noise and get hot?

- Why does the Termotechnik gas boiler light up but suddenly go out?

- How can you eliminate error E01 on a Thermon boiler?

- For this reason, the Electrolux double-circuit boiler began to hum and heat up

- For what reasons does a Ferroli gas boiler display an error code A01?

- For what reason does the Immergaz boiler not operate on hot water supply?

- Why does the Navien gas boiler constantly turn off when heating and then turn on immediately?

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

- Heating boiler piping

- STS boilers

- KVT boilers for solid fuel

- Pellet boiler Peresvet

- Steel floor standing boiler Raton

- Solid fuel boiler Thermology

- Errors and malfunctions of the Termet gas boiler

- Termona boiler repair

- Boiler repair Nova

- Hermann boiler service

- Comparison of gas boilers Lemax Premium-20 and Danko-20s

___________________________________________________________________________

- Daewoo boiler maintenance

- Demrad boiler malfunctions

- Mora boiler malfunctions

- Westen boiler repair

- Malfunctions of Immergaz boilers

- Types of solid fuel boilers

- Models and design of combination boilers

- Liquid fuel and double-circuit boilers

- Cast iron boilers on coal

- Boilers with modeling burners

- Imported boilers for heating systems

Features of operation

Each model is accompanied by instructions in which the user can familiarize themselves with the rules for operating the heater, its connection diagram, design features, settings and adjustments.

The system is filled gradually, at a rate of no more than 8 l/min. The water is fresh. Filling is continued until liquid appears in the overflow tube of the expansion tank.

Description of the ignition process:

- ventilate the combustion chamber for 5–10 minutes, the main valve must be closed;

- checking traction by bringing a paper strip closer to the viewing window;

- opening the air supply gate and igniting the flame;

- closing the door;

- temperature control by coil valve.

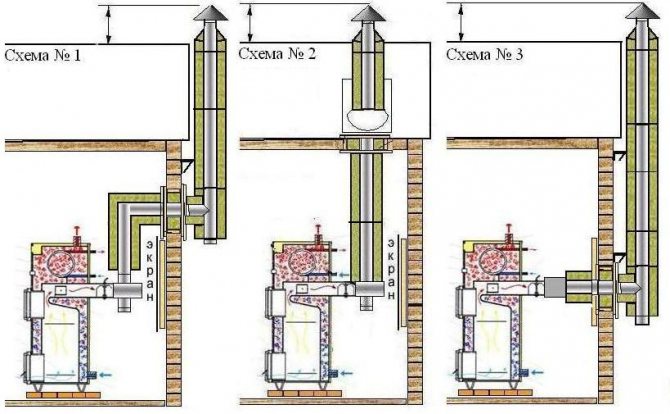

Installation and strapping

The installation of boilers should be carried out by specialists, but even users benefit from knowing the installation rules. If the piping is carried out according to the gravity scheme, the heater is placed lower than the return pipes - this improves the movement of the coolant. The chimney is located inside the structure.

If the chimney passes through unheated rooms, it must be insulated.

Connecting additional equipment

All products are easy to use, but it would be a good idea to equip the device with a thermostat - this device will make the equipment operate as efficiently as possible. You can also purchase an additional coil in advance in case of breakdown. As standard, the heaters are equipped with an adjustable front damper.

Main features of boilers

The Don gas boiler has a number of design features that must be mentioned in this article so that the potential buyer has an idea of what he is paying money for when choosing equipment from the Rostov brand. Among the advantages we note the following:

- The equipment is equipped with a highly reliable gas burner and thermo-hydraulic automation, ensuring its stable operation.

- Possibility of operation on various types of fuel.

- High efficiency when heating large areas.

- Excellent efficiency and high efficiency. This result was achieved by engineers with a special water jacket device. During operation of the unit, the coolant is distributed throughout the entire body of the device. At the same time, the outside of the boiler is covered with a special heat-insulating material designed to reduce thermal energy losses.

- High structural strength achieved through the use of thick high-quality steel as the body material. In addition, the equipment is able to withstand serious pressure drops, which is also a definite advantage and relevant for Russia.

- The boiler is equipped with a 3-turn exhaust gas passage system, which increases its efficiency.

- Small dimensions and light weight, which simplifies installation and transportation.

- Easy maintenance and cleaning of the boiler, thanks to the horizontal arrangement of the doors and chimneys.

- The ability to clearly regulate the temperature in the room using convenient and stable built-in automation.

- High power and reliability of the units, as well as safety.

Let's take a closer look at several variations of the Don gas boiler.

Operating principle of the regulator

The functionality of the device is based on controlling the air flow that enters the combustion chamber under the influence of chimney draft. The process looks like this:

- When solid fuel burns and the temperature of the heating element increases, the thermostatic liquid naturally increases in volume.

- The liquid puts pressure on the spring of the actuator, and it puts pressure on the lever, which overcomes the elastic force and begins to rotate.

- The chain tension is released.

- The ash pan flap is partially closed - the flow area decreases, the fuel burns more slowly, and there is less incoming air

- The temperature of the coolant decreases, the volume of thermostatic fluid decreases, forcing the lever to open the sash again.

The cycle is repeated until the fuel burns out completely. Then the spring opens the ash pan flap to the maximum.

The functionality of the draft regulator is based on controlling the air flow entering the combustion chamber.

There is a handle on the end surface of the device, which is used to regulate the amount of stroke of the lever and, as a result, the position of the sash.

This is done to limit the maximum temperature from fuel combustion.

Design features and main characteristics

Like most solid fuel models, the Don 16 boiler is a steel device with a water jacket. Its main part is the firebox. Manufacturers deliberately increased its size so that it could hold more fuel, thereby ensuring longer combustion. The fuel chamber is made of a special alloy, which makes it resistant to corrosion.

Photo 1: Steel universal solid fuel boiler Don 16

The second significant part of the Don 16 hot water boiler is the heat exchanger. Its task is to ensure maximum heat removal and transfer it to the coolant. To ensure maximum heat removal, the heat exchanger is designed in such a way that smoke pipes pass through it. For even better heat transfer, turbolizers are installed inside them. The heated coolant is supplied to the heating system through the upper pipe. The water is returned to the solid fuel boiler through the return line pipe. The temperature of the coolant is controlled by a temperature sensor.

Photo 2: Ash pan of the Don 16 boiler of the old modification

In Don 16 double-circuit boilers, a coil is installed inside the heat exchanger around the smoke pipes. Due to its proximity to the heat source, the water in it quickly heats up, uninterruptedly providing the home owner with hot water for sanitary needs. The flow rate is controlled by a valve or mixer.

The front panel contains the screwing and loading doors. They serve for loading and removing ash, as well as cleaning internal surfaces. The draft, and therefore the combustion intensity, is adjusted using the damper handle.

Photo 3: Gas burner for a solid fuel boiler with a water circuit Don 16

In addition to the universal boiler with a power of 16 kW, 30 kW models are also available. The line also includes devices capable of operating only on solid fuel. Here are some technical characteristics provided by the manufacturer on the official website:

| Model | KS-TG-16/20S | KS-TG-30/40S |

| Power (coal/gas), kW | 16/20 | 30/40 |

| Room area (coal/gas), m² | 160/200 | 300/400 |

| Efficiency (coal/gas), % | 86/90 | 86/90 |

| Gas consumption, m³/h | 1,3 | 2,5 |

| Price, rub | 19 800 | 45 000 |

To ensure operation on gas, the screw door and grate are dismantled, and an automatically controlled gas burner is mounted in the lower hole of the front panel. The upper part of the firebox is covered with a firebox sheet close to the front wall.

Don 16 by installing a pellet burner and a hopper with a control unit can easily be converted into a Russian-made pellet heating boiler. Unlike gas equipment, connecting equipment for working with pellets does not require registration. Pellets are much more efficient than firewood and coal and will help you save significantly on heating your country house or cottage.

What does the manufacturer offer?

- Models KS T 16 (16 kW) and KS TV 31.5 (31.5 kW) are designed to operate exclusively on solid fuel . Accordingly, they can heat rooms and buildings with an area of up to 160 m2 and up to 310 m2.

- The universal model KS TGV 16-20 includes a gas burner and a coil . It is capable of operating on solid fuel and gas; in the latter case, the power of the device reaches 20 kW, which allows heating an area of up to 200 m2.

Using solid fuel, the efficiency of the equipment reaches 75-76%, which is a good result. It is possible to achieve this thanks to a specially designed firebox and a unique water jacket.

Heating boiler Don connected to the home heating system

In the latter, water is evenly distributed throughout the boiler body, and an 8 mm layer of heat-insulating material retains its heat for the heating system. Therefore, the coolant does not waste extra energy on heating the environment and heating the surface of the device.

Steel – the body and combustion chamber are 3 mm thick, which ensures long-lasting operation of the equipment, even with intensive operation. The service life of the device declared by the manufacturer is 15 years.

Thanks to its large firebox, the DON solid fuel boiler is capable of operating autonomously on one load of firewood for up to 8 hours. You no longer need to be distracted from your work to add firewood. The equipment has all certificates of compliance with safety standards.

Advantages

Let's take a closer look at the capabilities of the heating device:

| Hot water | In addition to single-circuit heating boilers, the equipment line also includes double-circuit ones. They are capable of providing residents with hot water with a volume of 390-740 l/h. |

| Versatility |

|

| Energy independence | Don heating boilers of the entire model range do not require electricity. Therefore, power outages cannot in any way affect their performance. You can be sure that even if the power goes out in the house, heat will be supplied to it at the same rate. |

| Additionally | The undeniable advantage of floor-standing boilers:

|

The dimensions of the firebox allow the boiler to be operated for up to 8 hours without changing fuel

Cost-effectiveness and reliability of equipment

One of the main parameters influencing the choice of a heating device is its efficiency. In our case, it approaches the 75% mark, and in some cases exceeds it, which is considered an excellent indicator. This reduces the operating cost of the device.

When determining the efficiency of the heating equipment in question, we recommend paying attention to the following features:

- the presence of thermal insulation between the lining and the heat exchanger, which prevents unproductive losses of heat energy;

- how large is the surface area that heats the coolant by combustion products.

Advice: heating devices are more economical if the sum of the heat exchanger surface areas is greater.

In the photo - a non-volatile heating system

Reliability should be understood as the ability of equipment to function without failure in our special conditions, which include:

- fluctuations in gas pressure within the range of 0.6-2.0 kPa, alas, are not uncommon;

- lack of electrical energy. Typically, domestic devices of this type do not require connection to an electrical network, while imported ones in most cases do not work without it. For them you need to purchase an additional UPS;

- quality of manufacture of the necessary controls.

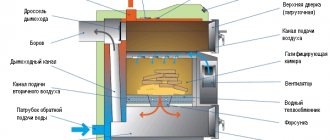

Solid fuel boiler diagram

The following parameters are accepted as boiler safety criteria:

- to what temperature do the outer surfaces heat up? Up to 50˚C is considered safe, which can only be facilitated by a layer of thermal insulation between the casing and the body;

- how the automation is protected from mechanical damage during operation of the equipment, due to which its settings may be lost or it may completely fail;

- Is it possible to diagnose the device?

- reliability of controls.

Advice: we recommend purchasing only devices where the controls have maximum protection from various damages.

Gas heating boiler Don in section

When choosing, pay attention to the presence of a thermometer, which indicates the temperature of the coolant inside the boiler. If gas is used as fuel, the heating device must have an automatic system that will prevent the water from boiling and turn off the gas supply in the absence of draft or when the pilot burner goes out.

Connecting a solid fuel boiler to the chimney

Convenience and safety of operation

In this case, we mean the possibility of unhindered execution:

- ignition - in most cases it is carried out using a torch and does not cause difficulties;

- diagnostics - visual control of the temperature of the water inside the stake must be provided;

- settings - clear instructions for operating the automation are required, and the controls must be conveniently located;

- prevention - inspecting the gas burner device, cleaning the smoke pipes, convenient access to various components and their unhindered removal if necessary.

Solid fuel boiler with installed gas burner

Boiler Don 50

This energy-independent universal heating unit is highly reliable and efficient. This is confirmed by technical tests and relevant certificates. The rated power of the equipment is 50 kW. At the same time, the Don 50 boiler consumes only 3 cubic meters of gas per hour, providing heat to living spaces up to 500 square meters.

The efficiency of this device reaches 85%, and the dimensions are 850x700x1430 millimeters. Installation of the system is quite quick and easy, and daily correct operation does not require special skills or scrupulousness.

Model overview

Let's describe the best models.

KS 16

Of all the models presented by domestic manufacturers, one of the most popular is the “Don” KS 16. Its main advantages: excellent technical characteristics, convenient operation and economical consumption of energy resources.

Having domestic assembly and components, it is ready to work in the most difficult climatic conditions. It is the Russian climate that does not allow many European analogues to compete with domestic developments. This line includes modifications that differ in the number of circuits and a number of smaller differences.

Key technical parameters:

| Heating area, m² | 160 |

| Natural gas consumption, m³/h | 2,0 |

| Thermal power, kW | 16 |

| Efficiency,% | 90 |

| Weight, kg | 139 |

| Dimensions (HxWxD), mm | 1030x470x700 |

| Cost, rub. | 22 000 |

KS-T-11

Steel. Non-volatile. For small objects. Operates on gas or solid fuel - the burner is changed.

Automation installed. Thanks to the Honeywell regulator, energy consumption is reduced by 30%. The firebox material is carbon steel, resistant to corrosion. Adapted to hard water.

| Heating area, m² | 110 |

| Natural gas consumption, m³/h | 2,0 |

| Thermal power, kW | 11 |

| Efficiency,% | 80 |

| Weight, kg | 65 |

| Dimensions (HxWxD), mm | 680x470x580 |

| Cost, rub. | 12 500 |

- Floor installation.

- Steel heat exchanger.

- The exhaust of combustion products is a chimney.

"Don Eco"

An economical version, the main difference of which is its compactness. The small device contains reliable Italian automation and an efficient heat exchanger. It features stable burner operation and high heat transfer.

The boilers are designed for heating small areas; they can be used with a flow-type water heater (“DON” or “CONORD”). In tandem with a water heater, this model will provide a small home with heat and hot water.

As an example, here are the technical characteristics and design features of the Don Eco KS-G-12S:

| Heating area, m² | 120 |

| Natural gas consumption, m³/h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 90 |

| Weight, kg | 34,3 |

| Dimensions (HxWxD), mm | 650x230x573 |

| Cost, rub. | 13 500 |

- Heating system pressure (min/max) - 0.1/1.2 bar.

- The coolant is water.

- One circuit.

- Floor-standing version.

- Open firebox.

- Steel heat exchanger.

- Gas removal is through a vertical chimney.

- Body color: white.

- Warranty - 2 years.

DonStail

New gas equipment from DonStail models with increased performance. Powerful heaters with a strict and stylish design. The white color and decorative perforations on the body create a feeling of lightness; the device fits harmoniously into a modern interior.

Thanks to the special design of the heat exchanger and Sit automation and Polidoro burner, these modifications have high efficiency, low energy consumption and are completely safe.

Characteristics of the single-circuit version of DonStail KS-G-12 S:

| Heating area, m² | 120 |

| Natural gas consumption, m³/h | 1,32 |

| Thermal power, kW | 12 |

| Efficiency,% | 92 |

| Weight, kg | 73 |

| Dimensions (HxWxD), mm | 835x343x515 |

| Cost, rub. | 18 000 |

- Floor-standing version.

- Open firebox.

- Steel heat exchanger.

- White color.

- Warranty - 3 years.

- Piezo ignition.

Powerful boilers "Don"

For heating large cottages, industrial and warehouse buildings, high-power devices are used:

- At 40 kW. Efficiency - 76%. Heats a room up to 400 m². Weight - 290 kg. The dimensions are small - 700x850x1430 mm.

- At 50 kW. Consumption 3 m³/h. Provides heat for cottages up to 50 m². Efficiency - 85%. Dimensions - 850x700x1430 mm.

- At 100 kW. The most powerful option is for 1000 m². Efficiency - 87%. Weight - 560 kg. Dimensions - 1280x900x1090 mm. An ideal solution for large country houses and non-residential premises.