Double-circuit gas boiler Viessmann Vitopend 100-W

Double-circuit gas boiler Viessmann Vitopend 100-WThe Vitopend 100-W double-circuit gas boiler from the German ]Viessmann[/anchor] is an excellent solution for organizing heating and supplying hot water to both small rooms (small apartments, small offices) and individual houses with an area of up to 300 square meters. Due to the fact that the boiler is mounted on the wall, usable space is saved (especially in small apartments), and its simple and attractive appearance will allow it to fit into any interior.

The advantages of this boiler include its compact size - I am still surprised by the fact that a unit with such small dimensions is capable of efficiently heating a room and uninterruptedly providing hot water. Another advantage is the control system - simple and intuitive, not requiring special skills from the user. In addition, the boiler is equipped with a self-diagnosis system, which greatly simplifies its operation and monitoring of its proper operation.

Viessmann specifically coordinates the technical characteristics of its gas boilers, which are intended for use in Russia, with the peculiarities of the local gas supply.

Naturally, there are also disadvantages - high sensitivity to voltage changes in the electrical network and some operating features, which we will discuss below.

General view and technical characteristics

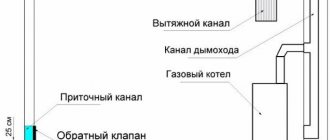

Viessmann Vitopend 100-W double-circuit gas boilers come in two types: chimney and turbocharged. The first will be connected to a stationary chimney designed for the installation of boilers of this type (it provides natural draft and removal of combustion products). Turbocharged boilers are installed in rooms where there are no special exhaust systems for exhaust gases: combustion products are removed using a special fan outside the room, which makes it possible to install such a boiler in almost any apartment. We will consider the chimney model.

In addition to the boiler, the delivery set includes a mounting frame and a pipeline for exhaust gases. The installation of the boiler and installation of the chimney system is carried out by qualified craftsmen, so in this matter you will have to rely only on the level of their professionalism.

The first start-up of the boiler and its setup is carried out by a representative of the Viessmann service center in your region, and he also puts the boiler under warranty.

Technical characteristics of the Viessmann Vitopend 100-W boiler:

- minimum and rated power - 10.7-23 kW;

- power of the hot water supply system - 23 kW (this boiler has priority for hot water supply, so when this circuit is turned on, all boiler resources are directed to heating water);

- maximum water pressure in the system is 3 bar;

- expansion tank - volume 6 l;

- maximum permissible temperature - 85 ° C;

- water temperature range in the heating circuit is 40-80 °C;

- temperature range in the hot water supply circuit - 30-57 ° C;

- minimum and maximum productivity in the hot water supply circuit at an average water temperature of 30 °C - 2.4-11 liters per minute;

- smoke formation temperature - up to 117 °C;

- electrical protection class - IPX4D;

- overall dimensions (width, height, depth) - 40x72.5x34 cm;

- weight - 36 kg.

Control Panel

From left to right: pressure gauge, display, hot water temperature regulator, heating water temperature regulator, switch

The pressure gauge shows the water pressure in the heating circuit. After the heating system is installed (radiators, heated towel rails, heated floors are installed), the circuit must be filled with water. For these purposes, a special key is used that opens the water intake into the boiler heating system.

When filling the system with water, you need to look at the pressure gauge so that the water pressure does not exceed 1.5 bar: this is what the manufacturer recommends. But, for example, I brought the pressure in the system to 2 bar, and after some time (the boiler did not turn on for two weeks - I connected the gas, agreed on service) it dropped to the recommended 1.5 bar - air came out of the system through special valves on batteries and in the boiler itself. When the heating circuit operates, the water will heat up and the pressure will rise to the normal operating value of 1.8-2.5 bar.

The display shows the temperature of the water in the heating system, the temperature of the hot water, the intensity of the burner, and can also show fault or error codes that are deciphered in the user manual.

The illustration above shows that hot water heating is turned off; on the left, at the bottom of the display, the “light” shows that the water in the heating system is being heated (in the “house” the battery icon is lit) and its current temperature.

With the help of temperature regulators, you set the required level as you wish - everything is very individual here. You just have to try several options and settle on the one that suits you. In any case, the regulator should be between o and “5” - in the lower position there will not be sufficient heating, and in a position greater than “5” there is a risk of overheating. You should pay attention to the fact that in order to warm the room to the desired temperature, you must set the water temperature in the system above 60 °C (the regulator position is above o).

Since the boiler has priority for preparing hot water, it is equipped with a special relay that is activated when the hot water tap is opened: the burner turns on, and a special three-way valve switches to the hot water preparation mode.

Attention! If you do not use hot water regularly (you do not live in an apartment or are away for a long time), from time to time you should turn on the hot water circuit and release a few liters - to prevent the three-way valve from working properly (so that it does not “sour”).

Optional equipment

The Viessmann Vitopend 100-W boiler can be equipped with additional devices that will greatly simplify its operation.

Vitotrol 100 RT is a room thermostat on which you set the desired temperature in the room, and it takes over all control of the boiler.

Vitotrol 100 UTA is a more complex thermostat model that allows you to program temperature conditions throughout the day. For example, you can program it so that at night the temperature will be maintained at, say, 17 °C, and by the time you wake up at 7 am it will already be 21 °C. In the same way, during the working day, when there is no one in the apartment, the air temperature can be lowered, and when you arrive from work, the thermostat will raise it to the most comfortable level.

Vitotrol 100 RT (left) and Vitotrol 100 UTA (right)

Vitotrol 100 UTDB is an even more sophisticated device, equipped with a liquid crystal display to indicate operating modes.

Vitotrol 100 UTDB-RF - this gadget has a device for receiving and transmitting radio signals, with its help the temperature in the room can be set remotely.

Vitotrol 100 UTDB (left) and Vitotrol 100 UTDB-RF (right)

Tips for use

It is imperative to check that the gas hose is connected to the boiler without distortions or mechanical stress. It goes without saying that there should be no gas leaks.

When the technician from the service center was preparing for the first start-up of the boiler, he used a special highly sensitive device to check for gas leaks. And it turned out that almost all the connection points were leaking - a little, insignificantly, but they were leaking (when checked with a soap solution, no leaks were visible). We had to call the gas workers, who re-packed all the connections.

In order to promptly respond to possible gas leaks, I recommend purchasing a household gas analyzer (without one, they may not even supply gas to your apartment). Issue price $20. The device is installed at a height of 20-30 centimeters above the boiler and if there is a gas leak, it will give a rather unpleasant sound signal, which will be very difficult not to hear (you can check it using gas from a simple lighter).

In order to extend the life of the boiler and its combustion chamber, it is necessary to install a gas filter - there may be small abrasive particles (sand and other debris) in the gas pipeline that can clog the combustion chamber, which will certainly affect its normal operation. Such a filter costs up to $10, and you can clean it yourself - remove the front cover and clean the foam filter, which is located between two metal mesh. After cleaning, make sure the cap is screwed on tightly and there is no gas leakage.

The electronics in the Viessmann Vitopend 100-W boiler are very sensitive to voltage drops, so I strongly recommend purchasing a voltage stabilizer. Firstly, it will ensure normal and uninterrupted operation of the equipment, and secondly, it will save your nerves and money - the warranty does not cover the failure of the boiler due to a power outage (you can only sue the energy supply company, but how will that end? in our realities, you know yourself).

I purchased such a voltage stabilizer for $40, which, you see, is not much compared to the cost of the boiler or how much it might cost to replace the electronics. The output stabilizer “iron” provides 220 V and works normally when the input is from 140 to 250 V. It is designed for a power of 500 W, which is quite enough for one boiler.

If you have a coarse water filter installed and water enters the boiler through it, then it is better to choose a mesh (mesh size from 5 to 50 microns) as the filter cleaning element. You should avoid using a thread filter or any other filter, the smallest parts of which over time can get into the heater and impair its performance.

After the first start-up (let the boiler run for a day and turn it off), I also recommend cleaning the return filter. To do this, turn off two taps (upper and lower), unscrew the lid and clean the filter mesh from possible debris that got into the heating system during its installation.

An important point - when turning off the boiler, first turn the temperature controls to the extreme left position, let the boiler run for several minutes (so that the temperature in the heater drops) and only then turn off the power supply.

If you are going to close the boiler in a cabinet or build it into furniture, then you should take into account that its body can be removed “upwards”. Therefore, it is necessary to leave a distance of about 20 centimeters between the top of the boiler and the furniture elements so that servicing can be carried out.

For normal operation of the boiler, an air flow is necessary, so it is strictly forbidden to close the special openings intended for this.

The room where the boiler is installed should not have high humidity for a long time - do not dry clothes in the same room as this device.

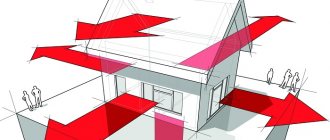

It is very important to properly ventilate rooms when the boiler is running. To do this, before opening the window, completely close the thermostatic valves on the radiator. Such actions will save gas and electricity.

When ventilating, set the regulator to “snowflake”

Another serious point is that batteries and thermostatic valves for normal operation should not be closed or cluttered (with heavy curtains or foreign objects).

Also, to save money, you should maintain the room temperature at the same level (20 ° C is considered optimal) - the boiler will operate stably, consuming gas and electricity evenly.

If you have blinds or shutters, you can close the windows at night to reduce heat loss.

Viessmann gas boilers with an open combustion chamber

A gas boiler is an economical household equipment that runs on inexpensive fuel. Heating equipment is produced by companies in Russia and Europe. On the Russian market you can find brands of boilers from world-class companies. The gas boiler is designed for the heating system and hot water supply.

Types and functions of gas boilers

The gas boiler is produced in different configurations depending on the design features. Boiler installation for heating is:

- wall and floor;

- condensation;

- with different efficiency (from 90 to 98%);

- low fuel;

- with open and closed combustion chamber;

- with different power;

- with different types of burners (atmospheric, liquid fuel, gas);

- double-circuit and single-circuit.

These are just some of the important characteristics of gas heating boilers. Systems intended only for heating are single-circuit. To connect DHW, two circuits are required. Most modern boilers are automatic. Automation opens up wide opportunities for using equipment in everyday life.

The automatic boiler is set up once. After that, it operates in the specified mode until the settings are changed. Manufacturers went further and made the control system for the heating boiler simpler. The automatic boiler is now easy to operate.

An economical and efficient system is created from a boiler that has a margin of safety and power. However, the power of the heating equipment should not be too high for a room with a specific area. If there are not enough classic models of wall-mounted and floor-standing boilers, a cascade is used to create heating systems - installing several boilers together. Companies produce systems that are convenient for side-by-side installation and have additional functionality.

Heating wall-mounted and floor-standing boilers can be purchased at an affordable price in the online store. Sales are carried out with home delivery. We supply products to individuals and organizations. Store managers will help you choose the optimal model for creating a heating system at your facility.

Advantages of gas models: high efficiency, long service life, easy operation. Maintenance is required quite rarely; the level of breakdowns in modern devices is extremely low. You can use the system for many years and it will not let you down. We supply devices with a manufacturer's warranty.

Condensing boilers, like other Viesmann products, are a convenient, compact and economical solution, optimally suited both for the modernization of existing boiler rooms and for the installation of such systems in private and apartment buildings.

A significant warranty period of up to 20 years, established by the manufacturer, and the constant increase in gas costs make the economic benefits of purchasing a condensing boiler obvious.

Viessmann gas condensing wall-mounted boilers are a modern system that has a simple and intuitive control system and a compact design, which allows you to rationally solve the issue of heat and water supply and not think about allocating a separate room for the boiler room. After all, such a boiler can even be installed on a wall in an ordinary living space.

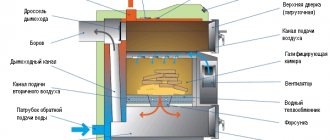

Let's take a closer look at condensing boilers: The whole point of condensing heating technology comes down to cooling the combustion products below the dew point and making good use of the heat of condensation. But, unlike pure water vapor, water vapor in flue gases has slightly different properties, since they are mixed with other gases. As a consequence, the temperature at which condensation begins depends on the composition of the flue gases. And they, in turn, are determined by the type of fuel and the degree of air saturation of the burned gas-air mixture. For example, when burning methane, the dew point (beginning of condensation) will be 55 °C, and for diesel fuel - 45 °C.

Despite the fact that methane is the most efficient type of fuel, gas condensing boilers can also be used with other gases, namely propane and butane, a mixture of which fills the gas tanks. Since regular filling and maintenance of a gas tank requires constant costs, the consumer subconsciously (or not) always tries to save gas. In this situation, a condensing boiler is convenient not only as a generator of albeit small, but additionally produced heat, but also as a device with a wide range of power modulation (regardless of the manufacturer). This saves gas because the consumer does not overheat the house. In addition, reconfiguring the burner to liquefied gas is carried out by switching the boiler settings without interfering with its design.

Fuel savings that justify the cost of the equipment are especially noticeable with gas condensing boilers. For liquid fuel boilers, the savings are almost half as much and very small for biofuel boilers. However, in condensation mode they can achieve up to 15% additional useful heat and up to 97% efficiency. This happens due to the fact that in such boilers the energy of steam condensation obtained as a result of the reaction is supplemented by the energy of condensation of moisture evaporated from the fuel.

From 50 m² to ∞

Let's again take a certain traditional boiler with a useful thermal power of 24 kW. The minimum power it can produce is 11 kW. But for a small house with an area of 80 m2, this amount of heat is excessive. As a result, the house overheats, the consumer feels uncomfortable, he opens the windows, but at the same time continues to waste gas. The condensing boiler can be set to operate between 4-12 kW. And the point here is the heat exchanger used in such a heat generator. The design of heat exchangers from different manufacturers, of course, is different, but their common “ideological” difference from steel and cast iron used in traditional technology is resistance to condensate. The lower the power, the lower the temperature. And where the temperature is low, there is condensation, which traditional steel and cast iron are afraid of. For a small house, the most common and simple solution is suitable - a condensing wall-mounted boiler with a “full package”, including a pump, expansion tank, safety and control elements. The power of such boilers is usually up to 35 kW. For one or two DHW points in the house, a built-in heat exchanger is sufficient. If more hot water is required, you can install an external boiler, the volume of which is selected according to flow rate.

If you take a house with a larger area. For example, 300 m2, with a swimming pool, sauna and other structures where more thermal power is required, and where 35 kW will no longer be enough. In this case, the boilers can be combined in a cascade or you can choose a wall-mounted boiler of higher power - from 50 to 100 kW.

An alternative to a cascade is a floor-standing condensing boiler. The power can be selected in the range from 110 kW to several megawatts (when combined in a cascade). Until recently, such condensing offers were rare, but now they are in the lineup of almost all manufacturers.

Naturally, such economical heat generators as condensing boilers can also be easily combined with other “green” generation sources - heat pumps, solar collectors or boilers using other types of fuel.

A wide selection of automation and applications makes it possible to assemble all this and control the boiler room remotely from a smartphone or tablet.

Other advantages of condensing boilers:

The condensing model is much more compact and lighter. It is also worth considering that a floor-standing traditional boiler will require more space for maintenance.

Condensing boilers, by improving the combustion process and lowering the temperature in the furnace, have significantly lower emissions: carbon dioxide (CO2) by 40%, and nitrogen oxides (NOx) by 90% less than a standard boiler. Acid vapors are removed and disposed of along with the condensate.

As already mentioned, the idea of using condensation arose from the desire to make an economical and efficient heat generator, which, as experience in using equipment at finished facilities shows, can reduce gas costs by up to 15% (with correct calculation and proper operation). And if you compare a condensing boiler not with a modern model of a conventional boiler, but with a gas appliance produced several decades ago, the savings will reach 30%.

Condensing boilers are not recommended for use with non-freezing liquids. Water for the heating system must be used in advance. If the boiler has a make-up unit, it is important that water also gets there after water treatment.

Condensing boilers, like traditional ones, require annual technical inspection. Unfortunately, we treat this serious aspect formally and often skip the work required by regulations. This usually leads to trouble at the most inconvenient moment. December 31st, for example. If there are doubts about the competence of a specialist, a list of routine maintenance can be found in the instructions or on the manufacturer’s website. Despite the simplicity of its function, the gas apparatus is quite complex and requires attention.

The condensing boiler needs air. Manufacturers offer a huge selection of options for arranging air supply and, accordingly, removing flue gases.

Condensate, as already mentioned, must be drained. To do this, a separate sewer outlet should be provided. If the pipeline is removed from a heated room, the pipe should be protected from freezing.

To ensure the correct operation of all systems, the boiler has a control board. This part is important and therefore expensive. In order to protect it from unstable voltage of the electrical network, it is better to immediately provide a voltage stabilizer. Which stabilizer is better is a topic for a separate article.

Any condensing boiler allows you to change settings depending on the gas pressure in the system, the configuration of the heating system, and additional remote control and monitoring devices. All these parameters can be adjusted before starting work to achieve maximum efficiency.

And don’t forget, in order to correctly make a thermal calculation of a house and design the necessary utility networks, you need the help of a specialist. You should not neglect the services of professionals when starting up the boiler for the first time, as well as during maintenance.

You can order all this from our company; we have been dealing with German heating equipment for many years and know almost everything about it.