22.05.2018

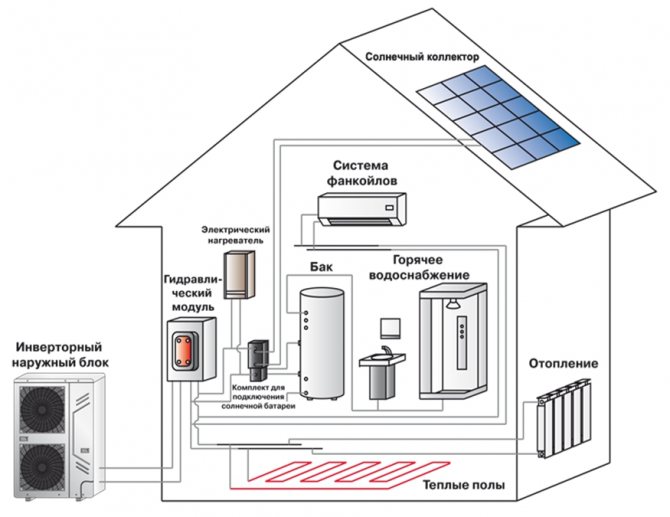

Heating / hot water supply / air conditioning operates from energy from many sources: electricity, solid and liquid fuels, as well as soil, water and air. Geothermal systems are of interest to consumers. No less in demand are analogues, the main element of which is an air heat pump. This unit is superior to traditional heating equipment in many respects, and in some respects it is superior to geothermal installations. It is used both in industry and in everyday life.

Heat pump. House heating design

In a home heating system, a heat pump (HP) plays the same role as a boiler, that is, it is a heat generator.

The only difference is that the boiler burns fuel, and the heat pump “pumps out” thermal energy from sources that, at first glance, are not rich in it at all.

Soil and river water with a temperature of 5 - 7 degrees, or even frosty winter air, the temperature of which was generally below zero.

Such sources are called low-potential, and although they are in no way associated with the concept of heat, TN manages to “squeeze” an impressive amount of life-giving energy out of them. To this should be added the heat generated by the electric motor of the HP compressor: here, unlike a refrigerator and air conditioner, it is not wasted.

Otherwise, a heating system based on a heat pump is no different from a conventional one: a coolant is used - water or air, which is heated by flowing through a heat exchanger, and then distributes heat throughout the house. Circulation is provided by a pump (for water heating) or a fan (for air heating). Just like a traditional heat generator, a HP can be simultaneously connected to a hot water supply (DHW) circuit with or without a storage tank (boiler).

Did you know that you can heat your home for next to nothing? Geothermal heating: operating principle, advantages and disadvantages of technology, read carefully.

Read about how to independently install a double-circuit gas boiler for heating a private home.

In Russia, steam heating appeared earlier than water heating, but now such a system is rarely used. Here https://microklimat.pro/sistemy-otopleniya/montazh-sistem-otopleniya/parovoe-otoplenie-v-chastnom-dome-sxema.html you will find an overview of the main types of boilers and methods of steam heating.

Pump manufacturers

The name of the manufacturer plays an important role in choosing a unit. Prices for products from well-known companies are always a little high, but the quality is worth it. There are not so many worthy companies that have earned the trust of users. Some of the best brands are Mammoth, Chofu, Buderus, Viessmann.

Mammoth Corporation, whose history began in 1935, is located in Minnesota (USA). It is part of the CES Group of companies, which, in turn, is part of the Nortek corporation. The American manufacturer is a world-famous company for the production of advanced cooling, ventilation and heating systems. Air source heat pumps for heating homes and businesses are one of the main products sold. Production sites, in addition to the USA, are located in Europe and China. The official representative in Russia since 2007 is the Geopumps company.

Chofu is the undisputed leader in Japan in the production and sale of heating systems. It uses only advanced technologies in the manufacture of products, and as a result, it exports equipment not only in its region: the company’s products are known in 50 countries around the world. High production standards, strict adherence to technological processes, strict quality control are factors that allow you to buy heat pumps with your eyes closed. The manufacturer is distinguished by its individual characteristics: one of them is that almost all products are created on the territory of the Land of the Rising Sun.

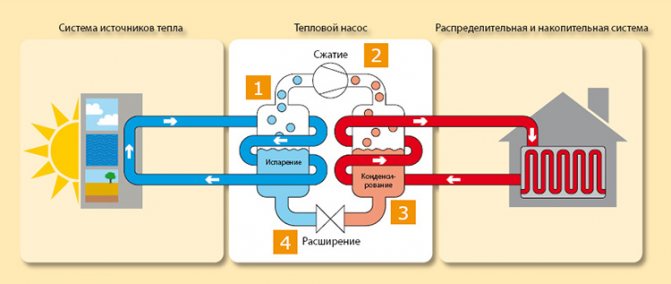

Operating principle of heat pumps

Any HP contains a working medium called refrigerant. Usually freon acts in this capacity, less often ammonia. The device itself consists of only three components:

- evaporator;

- compressor;

- capacitor.

The evaporator and condenser are two reservoirs that look like long curved tubes - coils. The condenser is connected at one end to the outlet pipe of the compressor, and the evaporator is connected to the inlet pipe. The ends of the coils are joined and a pressure reducing valve is installed at the junction between them. The evaporator is in contact – directly or indirectly – with the source medium, and the condenser is in contact with the heating or hot water system.

Working principle of a heat pump

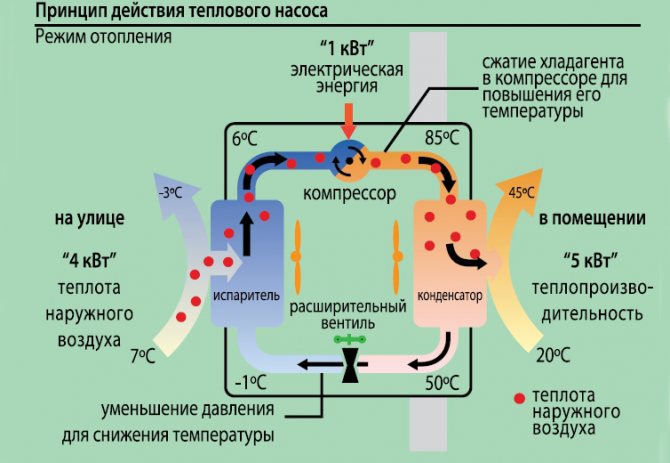

The operation of HP is based on the interdependence of gas volume, pressure and temperature. Here's what happens inside the unit:

- Ammonia, freon or other refrigerant, moving through the evaporator, is heated from the source medium, say, to a temperature of +5 degrees.

- After passing through the evaporator, the gas reaches the compressor, which pumps it into the condenser.

- The refrigerant pumped by the compressor is held in the condenser by a pressure reducing valve, so its pressure here is higher than in the evaporator. As is known, with increasing pressure the temperature of any gas increases. This is exactly what happens to the refrigerant - it heats up to 60 - 70 degrees. Since the condenser is washed by the coolant circulating in the heating system, the latter also heats up.

- Through the pressure reducing valve, the refrigerant is discharged in small portions into the evaporator, where its pressure drops again. The gas expands and cools, and since part of the internal energy was lost by it as a result of heat exchange at the previous stage, its temperature drops below the original +5 degrees. Following the evaporator, it is heated again, then pumped into the condenser by the compressor - and so on in a circle. Scientifically, this process is called the Carnot cycle.

The main feature of HP is that thermal energy is taken from the environment literally for nothing. True, to produce it, you need to spend a certain amount of electricity (for the compressor and circulation pump/fan). But HP still remains very profitable: for every kWh of electricity spent, you can get from 3 to 5 kWh of heat.

Does it make sense to install a water-to-water heat pump?

As a result of the operation of water-water thermal systems in our country, a number of strengths and weaknesses of such installations have already been identified. Users of such systems mainly complain about decreased efficiency in severe frosts and high prices. As for efficient operation in cold weather, with qualified installation of the system it works down to minus 30 without problems. In terms of price, as manufacturers say, no reduction in price is expected in the near future.

As for payback, in most cases a heat pump of this type pays off in about 3-5 years. So the costs are high only at first. But, of course, widespread use of such systems can only be expected after a rise in prices for energy extracted from traditional energy sources. The main advantage of a water-to-water pump is its cost-effectiveness. In particular, this is a high COP coefficient, by which the energy efficiency of heating installations is assessed.

COP shows how much thermal energy is generated using one kilowatt of energy. In most modern installations this indicator is at the level of 3-5. This means that from one kilowatt spent, 3-5 times more thermal energy is obtained. In general, we can conclude that heat pumps are energy efficient and economically feasible. But at the current level of energy prices, they will not become widespread. If you found this article useful, please share the link to it on social networks. This will help the development of the site. Vote in the poll below and rate the material! Please leave corrections and additions in the comments.

Types of heat pump designs

The type of heat pump is usually denoted by a phrase indicating the source medium and coolant of the heating system.

The following varieties exist:

- TN “air-to-air”;

- HP "air - water";

- TN “soil - water”;

- TN "water - water".

The very first option is a conventional split system operating in heating mode. The evaporator is mounted outside, and a unit with a condenser is installed inside the house. The latter is blown by a fan, due to which warm air mass is supplied to the room.

If such a system is equipped with a special heat exchanger with pipes, the result is an air-water heat exchanger. It is connected to a water heating system.

A HP evaporator of the “air-to-air” or “air-to-water” type can be placed not on the street, but in the exhaust ventilation duct (it must be forced). In this case, the efficiency of the HP will be increased several times.

Heat pumps of the “water-to-water” and “ground-to-water” types use a so-called external heat exchanger or, as it is also called, a collector, to extract heat.

Schematic diagram of the operation of a heat pump

This is a long looped pipe, usually plastic, through which a liquid circulates, washing the evaporator. Both types of HP represent the same device: in one case, the collector is immersed in the bottom of a surface reservoir, and in the second - in the ground. The condenser of such a heat pump is located in a heat exchanger connected to the water heating system.

Connecting a VT according to the “water-water” scheme is much less labor-intensive than “ground-water”, since there is no need for excavation work. The pipe is laid in a spiral at the bottom of the reservoir. Of course, only a reservoir that does not freeze to the bottom in winter is suitable for this scheme.

Learn more about renewable energy sources

If atmospheric or ventilation air is chosen as a heat source, heat pumps operating according to the air-water scheme are used. The pump can be located indoors or outdoors, with a built-in or remote condenser. Air is blown through the heat exchanger (evaporator) using a fan.

Groundwater with a relatively low temperature or soil from the surface layers of the earth can be used as a source of low-potential thermal energy. The heat content of the soil mass is generally higher. The thermal regime of the soil in the surface layers of the earth is formed under the influence of two main factors - solar radiation incident on the surface and the flow of radiogenic heat from the bowels of the earth. Seasonal and daily changes in the intensity of solar radiation and outside air temperature cause fluctuations in the temperature of the upper layers of the soil. The penetration depth of daily fluctuations in outside air temperature and the intensity of incident solar radiation, depending on specific soil and climatic conditions, ranges from several tens of centimeters to one and a half meters. The depth of penetration of seasonal fluctuations in outside air temperature and the intensity of incident solar radiation does not, as a rule, exceed 15–20 m.

Types of horizontal heat exchangers:

- heat exchanger made of series-connected pipes;

- heat exchanger made of parallel connected pipes;

- horizontal collector laid in a trench;

- loop-shaped heat exchanger;

- a heat exchanger in the shape of a spiral located horizontally (the so-called “slinky” collector);

- heat exchanger in the form of a spiral located vertically.

Water accumulates solar heat well. Even in the cold winter period, groundwater has a constant temperature of +7 to +12°C. This is the advantage of this heat source. Due to the constant temperature level, this heat source has a high conversion rate through the heat pump throughout the year. Unfortunately, groundwater is not available in sufficient quantities everywhere. When using groundwater as a source, supply is carried out from a well using a submersible pump to the entrance to the heat exchanger (evaporator) of a heat pump operating according to the “water-water/open system” scheme; from the output of the heat exchanger, water is either pumped into another well, or dumped into a reservoir. The advantage of open systems is the ability to obtain large amounts of thermal energy at relatively low costs. However, wells require maintenance. In addition, the use of such systems is not possible in all areas. The main requirements for soil and groundwater are as follows: - sufficient permeability of the soil, allowing water reserves to be replenished; - good chemical composition of groundwater (for example, low iron content), which avoids problems associated with the formation of deposits on pipe walls and corrosion.

Open systems are more often used to supply heating or cooling to large buildings. The world's largest geothermal heat transfer system uses groundwater as a source of low-grade thermal energy. This system is located in the USA in Louisville, Kentucky. The system is used for heat and cold supply of a hotel and office complex; its power is approximately 10 MW.

Let’s take another source - a reservoir; loops of plastic pipe can be laid on its bottom, a “water-water/closed system” scheme. An ethylene glycol solution (antifreeze) circulates through the pipeline, which transfers heat to the refrigerant through the heat exchanger (evaporator) of the heat pump. The soil has the ability to accumulate solar energy over a long period of time, which ensures a relatively uniform temperature of the heat source throughout the year and, thus, a high conversion coefficient of the heat pump. The temperature in the upper layers of the soil varies depending on the season. Below the freezing line, these temperature fluctuations are significantly reduced. The heat accumulated in the ground is extracted through horizontally laid sealed heat exchangers, also called ground collectors, or through vertically laid heat exchangers, so-called geothermal probes. The ambient heat is transferred by a mixture of water and ethylene glycol (brine or medium), the freezing point of which should be approximately -13°C (take into account the manufacturer's data). Thanks to this, the brine does not freeze during operation. This means that there are two possible options for obtaining low-grade heat from the ground. Horizontal laying of plastic pipes in trenches with a depth of 1.3–1.7 m, depending on the climatic conditions of the area, or vertical wells with a depth of 20–100 m. Laying of pipes in trenches can also be done in the form of spirals, but with a laying depth of 2– 4 m, this will significantly reduce the total length of the trenches. The maximum heat transfer of surface soil is from 7 to 25 W per m.p., from geothermal 20-50 W per m.p. According to manufacturing companies, the service life of trenches and wells is more than 100 years.

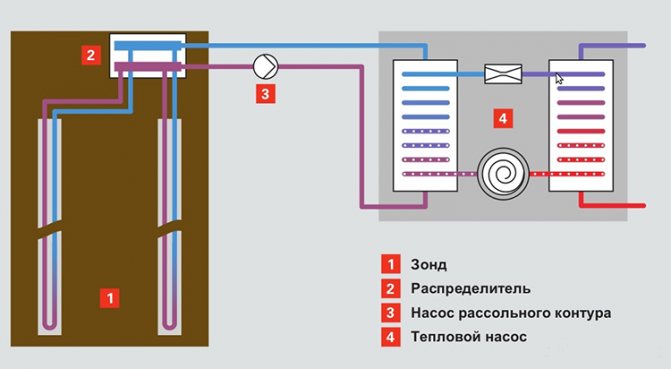

Heat pump operation when operating according to the “ground-water” scheme

The collector can be installed in the ground in three ways.

Horizontal option

The pipes are laid in trenches in a “snake” pattern to a depth exceeding the freezing depth of the soil (on average, from 1 to 1.5 m).

Such a collector will require a fairly large plot of land, but any homeowner can build it - no skills other than the ability to work with a shovel will be required.

It should, however, be taken into account that constructing a heat exchanger manually is a rather labor-intensive process.

Vertical option

Collector pipes in the form of loops shaped like the letter “U” are immersed in wells with a depth of 20 to 100 m. If necessary, several such wells can be built. After installing the pipes, the wells are filled with cement mortar.

The advantage of a vertical collector is that its construction requires a very small area. However, there is no way to drill wells more than 20 m deep on your own - you will have to hire a team of drillers.

Combined option

This collector can be considered a type of horizontal, but its construction will require much less space.

A round well with a depth of 2 m is dug on the site.

The heat exchanger pipes are laid in a spiral, so that the circuit looks like a vertically installed spring.

Upon completion of installation work, the well is backfilled. As in the case of a horizontal heat exchanger, all the necessary work can be done with your own hands.

The collector is filled with antifreeze - antifreeze or ethylene glycol solution. To ensure its circulation, a special pump is inserted into the circuit. Having absorbed the heat of the soil, the antifreeze enters the evaporator, where heat exchange occurs between it and the refrigerant.

It should be taken into account that unlimited heat extraction from the ground, especially when the collector is located vertically, can lead to undesirable consequences for the geology and ecology of the site. Therefore, in the summer, it is highly desirable to operate HPs of the “soil-water” type in reverse mode - air conditioning.

A gas heating system has a lot of advantages and one of the main ones is the low cost of gas. The heating diagram for a private house with a gas boiler will tell you how to arrange heating of your home with gas. Let's consider the heating system design and replacement requirements.

Read about the features of choosing solar panels for heating your home in this topic.

Installation rules and recommendations

You can install the equipment yourself (it will be cheaper), but before you begin installation, you need to understand that this work is not easy. It is always possible to break one or another part, even to the point of disabling the entire system. During installation work, you should adhere to the following rules and recommendations:

- depending on the design, the external unit can be mounted in different ways: on the wall, on the roof, in the boiler room, near the object (at a distance from 2 to 20 m);

- when installed outdoors, a metal foundation and a canopy must be installed to protect from rain and snow;

- if possible, it is better to combine an air heat pump with a “warm floor”: this combination is the most pragmatic;

- the boiler room, if used, should be minimally distant from the house (enterprise): among the system equipment there should be circulation pumps and a storage tank;

- the thermal unit and the heating circuit are connected by flexible hoses: thanks to this fixation, vibrations emanating from the power units are eliminated.

The recommendations given will help, but will not save you in unforeseen situations.

Therefore, it’s better not to take risks and contact us, the professionals from Geopumps. Return to list

Calculation of a horizontal heat pump collector

The efficiency of a horizontal collector depends on the temperature of the medium in which it is immersed, its thermal conductivity, and the area of contact with the surface of the pipe. The calculation method is quite complex, so in most cases averaged data is used.

It is believed that each meter of heat exchanger provides the HP with the following thermal power:

- 10 W – when buried in dry sandy or rocky soil;

- 20 W – in dry clay soil;

- 25 W – in wet clay soil;

- 35 W – in very damp clay soil.

Thus, to calculate the length of the collector (L), the required thermal power (Q) should be divided by the calorific value of the soil (p):

L = Q/p.

The values given can only be considered valid if the following conditions are met:

- The area of land above the sewer is not developed, shaded or planted with trees or bushes.

- The distance between adjacent turns of the spiral or sections of the “snake” is at least 0.7 m.

When calculating the collector, it should be taken into account that the soil temperature after the first year of operation drops by several degrees.

Installation rules

- The evaporator and compressor must have a power reserve of at least 20%, otherwise the pump may not cope with the heating.

- The choice of freon should be taken very seriously. The best option is R-22 freon, but there are forecasts that in a few years it will disappear from production. Therefore, it is better to give preference to the R-422 brand.

- All connections must be tight, and the lines through which freon will circulate must be clean. Moreover, when refueling, a vacuum must be created inside the system, which is hardly possible without special equipment.

Important! Pipe cutting should be done exclusively by rolling, because if even small chips get into the system, the compressor will become unusable in one or two weeks.

Example of heat pump calculation

We will select a heating element for the heating system of a one-story house with a total area of 70 square meters. m with a standard ceiling height (2.5 m), rational architecture and thermal insulation of enclosing structures that meet the requirements of modern building codes. For heating the 1st sq. m of such an object, according to generally accepted standards, it is necessary to spend 100 W of heat. Thus, to heat the entire house you will need:

Q = 70 x 100 = 7000 W = 7 kW of thermal energy.

We choose a heat pump of the TeploDarom brand (model L-024-WLC) with a thermal power W = 7.7 kW. The compressor of the unit consumes N = 2.5 kW of electricity.

Reservoir calculation

The soil in the area allocated for the construction of the collector is clayey, the groundwater level is high (we assume the calorific value p = 35 W/m).

The collector power is determined by the formula:

Qk = W – N = 7.7 – 2.5 = 5.2 kW.

Determine the length of the collector pipe:

L = 5200 / 35 = 148.5 m (approx.).

Based on the fact that laying a circuit longer than 100 m is irrational due to excessively high hydraulic resistance, we accept the following: the heat pump collector will consist of two circuits - 100 m and 50 m long.

The area of the site that will need to be allocated for the collector will be determined using the formula:

S = L x A,

Where A is the step between adjacent sections of the contour. We accept: A = 0.8 m.

Then S = 150 x 0.8 = 120 sq. m.

DIY heat pumps - why not? ↑

Despite all the “progressiveness” of heat pump technology, the unit can be installed with your own hands.

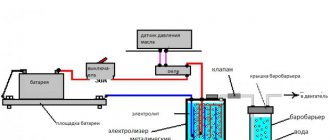

Do-it-yourself heat pump: one of the options for its appearance

Before you start “creating”, objectively assess the condition of the house.

Thermal insulation, if necessary, should be improved - modern building materials will help you. The schematic diagram of a heat pump “includes” several components: a compressor, an evaporator, a condenser and a thermostatic valve. Safety devices such as a receiver, a filter-drier and an inspection window may not be used here - by assembling the system manually, you are unlikely to be able to provide for all the “factory stuff” and create a unit “as if from the factory.”

- It is best to “give” the role of the compressor to the most silent equipment: you can take, for example, a compressor from an imported air conditioner. Using L-300mm brackets it is attached to the wall;

Installing the compressor on the brackets

- The condenser requires a special tank (volume - 120 l), made of stainless steel. It is cut into 2 parts; a coil of copper pipe is inserted through which the freon will move. Then the tank must be welded back, not forgetting to weld several technical threaded connections;

- As a heat exchanger pipe, you can use a copper refrigeration pipe or a regular plumbing pipe (clean);

- The pipe must be rolled into a coil (wound around a cylinder). The edges of the turns should be fixed (aluminum slats) to increase the equal pitch of the loops. Bring out its ends using plumbing passages;

- Freon guide of the coil: inlet to the condenser from above - outlet from below. This will prevent bubbles from forming;

- The evaporator does not require high temperature, so a plastic container “a la” barrel (capacity about 100 l) is ideal for this purpose;

- The drainage and supply of water can be “carried out” by ordinary sewer pipes with seals;

- Secure the evaporator using L-400mm brackets;

A plastic container of suitable volume can be used as an evaporator; it must be installed on a stand secured with brackets

- Thermostatic valve must be purchased separately (consider compatibility with your “work of art”);

The process of soldering, refilling with freon, etc., we still recommend trusting the hands of professionals (safety first); and in general, an “experienced look” before putting the unit into operation will not harm anyone. Don’t forget about automation issues - you will need a single-phase starting relay, fuses, and a temperature relay.

Attention! Creating such equipment without certain skills and deep knowledge of physics is a risk. If you doubt your strengths and competence, do not improvise! A superficial acquaintance with the operating principle and structure of a heat pump is not enough to construct a unit with your own hands!

Vertical collector calculation

At a depth of over 15 m, the ground temperature remains stable at +10 degrees all year round. Therefore, the efficiency of a vertical collector is higher - on average, up to 50 W of heat can be removed from a meter-long area. To calculate the length of the heat exchanger, the type of medium must also be taken into account. So, from 1 meter of pipe it is possible to obtain the following thermal power:

- 20 W – when immersed in sedimentary soil (dry);

- 50 W – in rocky or wet sedimentary soil;

- 70 W – hard rocks (stone);

- 80 W – groundwater.

Application of vertical probe for heat pump

When constructing wells, the following condition must be observed: the distance between them must be at least 5 m.

To operate the heat pump from the above example, you will need a collector with a length of L = 5200 / 50 = 140 m.

Consequently, to equip the reservoir, it will be necessary to drill two wells with a depth of 70 m. In each of them, two U-shaped loops will need to be installed, for which it will be necessary to purchase 4x140 = 560 m of pipes.

Pump operating principle

There are 3 types of equipment:

- "soil - water";

- "water - water";

- "air - water".

The first word here means the medium from which energy is taken, the second means the coolant in the heating system.

For Russia, the most practical can be considered the first type of heat pump, which you can make yourself. Already at a depth of five meters below the surface of the earth, the temperature levels out and remains unchanged all year round. The circuit is assembled from plastic tubes, and the coolant is a special technical liquid called brine. The external pipeline itself is placed in the ground either horizontally or vertically.

When installed horizontally, large areas are required for work, from 25 to 50 m2 for each kW of installation.

These areas cannot be occupied for growing garden crops, only for decorative plantings or lawns.

To install a vertical heat pump, several wells up to 150 m deep will be required. Since at such levels the soil temperature is more stable and higher, the structure is considered more reliable.

The “water-water” system is no less effective: in the lower layers, the degree of water heating is constant all the time. The energy source is:

- lakes, rivers, ponds located near the house;

- wells and wells.

The easiest way is to install the device in an open natural or artificial reservoir.

The principles of energy generation for ground-water and water-water pumps are basically the same:

- The coolant of the external circuit, flowing through the pipes, heats up and enters the heat exchanger or evaporator.

- There it transfers the accumulated energy to the refrigerant of the inner circle.

- The refrigerant evaporates and enters the compressor, where it is compressed under high pressure, becoming even hotter.

- The heated steam enters the condenser and transfers its energy to the coolant of the internal circuit, which is responsible for heating residential premises.

- The refrigerant that has given off heat becomes liquid again and returns for the next round.

The air-water pump is somewhat inferior in terms of extraction efficiency to previous models, since its power decreases in winter. We have to think about additional ways to obtain energy. But its installation is the easiest. It is enough to install the equipment on the roof.

You can learn more about the operation of heat pumps from this video.