Types of heat exchangers

When choosing the device being described, you can find products of various types. The most commonly used heat exchangers are coil-shaped. Corrugated devices are also popular. In addition, many use products in which air is the coolant.

Based on the type of coolant, almost all devices can be divided into those that use air and products that heat water. Devices of the first type have a simpler structure, but are less efficient.

If you wish, you can create a heat exchanger for installation on the chimney with your own hands. To do this, you will need tools such as a grinder and a welding machine.

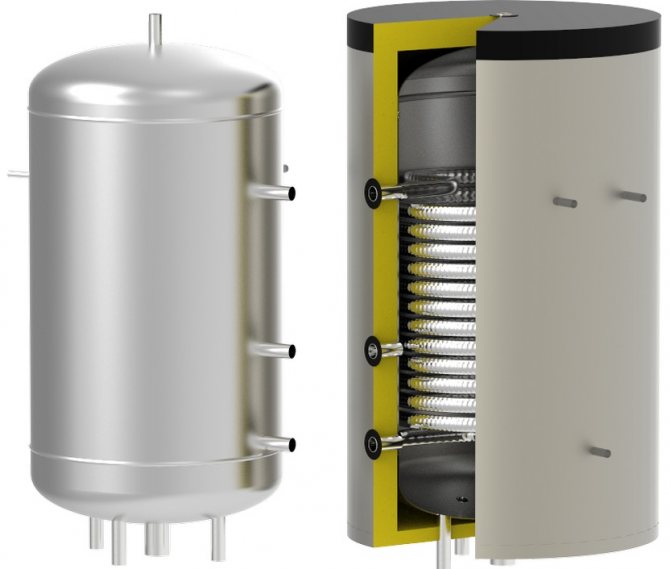

Liquid devices

During the manufacture of liquid heat exchangers, in order to make them safer, the core is placed in a metal casing. At the same time, insulation is placed in it. Often, when creating the described devices, basalt wool is used.

Such products are fixed to the chimney, which helps to heat the coolant. If a coil is used, its ends are connected to the heating system. If you create the product yourself, you should make a coil from copper. This is due to the fact that this material has high thermal conductivity.

Some homeowners use metal products, but to increase efficiency they have to significantly increase the size of the structure.

Coolant circulation is carried out as follows:

- first, the liquid heats up, resulting in an increase in its volume;

- after that it rises along the coil;

- after this, the liquid is sent to the radiator;

- the cooled coolant is displaced and directed to the heating element.

In order for the system to work efficiently, it is necessary to calculate in advance such parameters as the length of the heating element and the diameter of the pipes used to create the system. If these parameters are not taken into account, the system will not work effectively. In some cases, due to errors made during the creation of the system, water hammer occurs.

When installing a heat exchanger on a chimney pipe, you should remember that the design must be safe. Its heated parts must not come into contact with materials that could catch fire.

Coils bellows pipes screw type

You can somehow limit the power using dampers, but then the draft and the adjusted operation of the stove itself will suffer. The bypass path, actually a bypass, significantly complicates the design of the chimney and makes it excessively voluminous.

Solid or liquid fuel stoves produce a large amount of heat, but a lot of it goes unhindered into the chimney. A heat exchanger for the chimney pipe will help you avoid losing useful energy and stop heating the street.

It all comes down to a simple idea. There is no need to put up with the loss of heat that goes into the pipe.

Disadvantages of liquid heat exchangers

The disadvantages of the described devices include:

- Complexity of manufacturing and calculations. Before carrying out work on creating a device, it is important to take into account the area of the house and other parameters that may affect the efficiency of the system.

- The need for constant monitoring of system parameters such as coolant pressure and temperature.

- Increased fluid consumption associated with its evaporation from the expansion tank. Moreover, in winter, if the house is empty, the liquid must be completely drained.

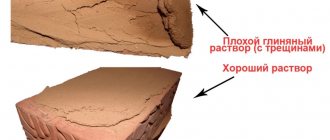

But it should be noted that almost anyone with knowledge of physics at school level can make a liquid heat exchanger. But before manufacturing the device, it is important to draw up a drawing of the entire structure, which will display the dimensions of all elements.

When using a liquid device, remember that if the house is not used in the winter, the liquid must be completely drained. If this is not done, it will turn into ice, which can lead to the destruction of pipes and radiators. If the heat exchanger is installed in a house that is used all year round, you can forget about this drawback.

Features of air heat exchangers

Devices of the described type consist of a metal casing, inside of which there are several pipes. During operation of the system, cold air is heated and flows into the room.

If you wish, you can make and install an air heat exchanger on the chimney with your own hands. To do this, you need to have several metal pipes of different diameters, a grinder and a welding machine.

Before starting work, you must purchase the following materials:

- a piece of pipe having a diameter of 50 mm;

- a pipe 2.4 m long and 3.175 cm in diameter;

- metal sheet 350x350x1 mm;

- 2-liter metal container.

The manufacture of a heat exchanger begins with cutting out metal circles. After this, in the center of the created circles it is necessary to cut holes for a 5-centimeter pipe. Around the holes, you need to mark the points at which 8 openings will be cut for a pipe with a diameter of 3.175 cm. This pipe must be cut into 8 pieces. The result will be 8 tubes 30 cm long.

The next step is to attach a pipe with a diameter of 50 mm to the central hole. Sections 30 cm long are welded to the side holes. As a result of the work carried out, a heat exchanger core will be created. After this, you can begin creating the device body.

After the described actions, you need to cut off the bottom of the previously prepared metal tank using a grinder. It is necessary to cut a hole on the sides that is equal to the diameter of the chimney.

Then you need to connect the pipes. The created heat exchanger body must be placed on the core and then welded to it. After carrying out such work, the structures should be coated with heat-resistant paint. When it dries, you can install the heat exchanger on the chimney.

Air heat exchanger

In the case where the primary heat exchanger is a firebox (steel stoves, long-burning stoves - PDG, waste oil stoves - POM), the following measures can be taken to increase the efficiency of “dry” heat transfer.

Through vertical and horizontal straight channels (pipes)

Steel pipes are welded directly onto the firebox. It is better to install them vertically - this will improve air flow. Suitable if you have available material - pipe scraps (the cross-sectional shape does not matter). Diameter 50–200 mm. The original solution for the firebox would be to weld the walls from equal sections of pipe.

Curved and rounded channels

The ideal option is to “wrap” the entire firebox in 1-2 turns. This will require skill and time, but the effect will be much higher than from simple direct channels. The greater the difference between the levels of air intake and outlet, the better the channel will work. If you take the fence outside, the effect will be maximum, because when the firebox is heated, due to the temperature difference, a draft will arise, which will ensure a constant flow in “automatic” mode.

Labyrinths with bulkheads in containers

To implement such a heat exchanger, you need to install an additional steel box on the top wall with a height of about 100 mm and thick walls. In this box, steel 5–8 mm bulkheads should be placed in such a way as to create a “labyrinth”. At the beginning and end of it there should be inlet openings for the cross-section of the air duct. The top of the “labyrinth” is also covered with a lid. In this embodiment, the heat exchanger is the space between the firebox wall and the walls of the box. Such heat exchangers can also be installed on the side walls of a steel reactor.

Through channels in the reactor, integrated into the furnace

Such channels are included in the design when creating the furnace, then welded into the walls. They can be located side by side at the top of the firebox. Diameter from 50 mm.

In any type of VT, the phenomenon of convection* is used, but in most cases, due to the high temperature in the reactor, the natural movement of air is not enough and it is forced in by fans. This method is also called injection.

* Convection is a method of transferring heat by flows or jets.

Injection can be done in any available way - by building an air pump into the channel or simply directing it to the heat exchanger. “Dry” heat exchangers are the simplest and most affordable heating devices.

Advantages of air heat exchangers:

Disadvantages of air heat exchangers (HE):

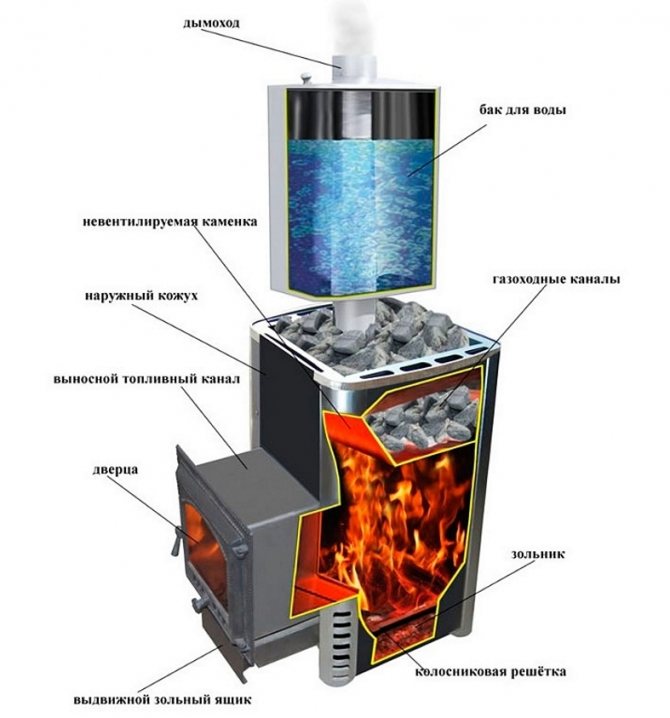

Features of devices used in the bath

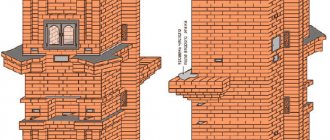

By design, the described devices can be divided into those that are built-in and attached to the chimney. Products of the second type are often called samovar-type devices.

Built-in structures consist of a small tank with a capacity of up to 5 liters. It is installed between the firebox and the heat generator casing.

A container with a volume of up to 100 liters is connected to the heat exchanger using pipes. After heating the heating installation, hot water rises through the pipe. The cooled coolant flows back into the heat exchanger. Thanks to this, the required coolant temperature is maintained in the external container.

Samovar-type devices are a sealed container surrounding a chimney. In the process of heating the liquid, in this case, the heat from the combustion products moving through the pipe is used.

Sauna stoves with heat exchanger

The advantages of the described structures include:

- Simultaneous solution of two problems - heating the steam room and dressing room, as well as heating water.

- Possibility of installing the tank in a room located closer to the steam room.

- Long period of use. This is due to the use of high quality materials.

- No need to maintain the structure.

- Small oven size. This allows you to save space in the steam room.

- The power of the stove with a heat exchanger is enough to quickly warm up the room.

When installing a heat exchanger, you should remember some rules. For example, it is necessary to connect the pipes in the system in such a way that they are not rigidly fixed near the walls. This is due to changes in their linear parameters during heating of the coolant.

It should also be remembered that to seal the threads it is necessary to use materials that are resistant to high temperatures. The choice of the volume of the container installed in the bath should be made taking into account the fact that heating is carried out for two hours.

How to safely operate a sauna stove with a heat exchanger

Probably, safety comes first for every person, so you need to be able to operate the system correctly:

- Pipes connecting parts of the system to the tank cannot be fixedly attached to the wall surface, as they change linear parameters during the heating process.

- The heat exchanger power characteristics should not be more than 10% of the furnace power.

- The choice of the volume of the water tank should be carried out in accordance with the fact that the heating time of the latter should occur within 2 hours after ignition of the fuel in the firebox. Otherwise, the water will turn into steam.

- Do not fill the system with water when it is heated to high temperatures.

- To seal the threaded connections of the system, you need to use gaskets that can withstand high temperatures.

On the construction market there is a huge range of heating systems for baths with and without a heat exchanger. However, you can build a heat exchanger for a sauna stove yourself if you have the necessary tools and welding skills.