What is an inverter?

An inverter is a transformer that converts direct electric current (on average 12 V) from batteries into alternating current and changes the voltage depending on the situation. If electricity is supplied normally, it begins to charge the batteries. If the voltage drops or is turned off, the power from the home network goes to the battery, turning their 12 V DC voltage into an alternating voltage - 220 V/50 Hz.

Compact car inverter

To keep your inverter running properly, you need the best materials and parts. How well the inverter is installed determines how long other components, especially the battery, can operate. The quality of the inverter determines the life of the battery - it will last for 2 years or for as long as 12 years.

Better battery life can be achieved through the use of different components, for example, wind generators or solar panels.

Working principle of VIN

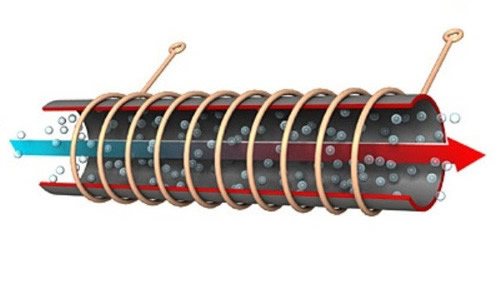

The principle of induction heating The operating algorithm of a vortex induction heater consists of the following sequential actions:

- the generator generates a high-frequency current and supplies it to the inductor;

- the inductor, receiving this current, creates an electromagnetic field near the cylindrical coil;

- the heating element, which is located inside a coil of copper wire, is heated by eddy currents that are created by an electromagnetic field;

- The coolant, which is located inside the heating element, is simultaneously heated up and is directly supplied to the heating radiators.

An important fact: the entire VIN operation process occurs with virtually no energy losses.

Why is it needed for a gas boiler?

If you do not focus on energy independence, then a fully functional modern gas boiler requires a connection to the electrical network to power a control board with a controller, a circulation pump and a group of control units that can be distributed throughout the house. Such a set of equipment allows you to completely and accurately control the heating of the house, raising the heating to a higher level, ensuring high comfort of life in the house. If this is the case, then when the power goes out, the heating, unfortunately, stops completely.

In order not to be left without heating, you should provide in advance a backup power source for the gas boiler and all auxiliary equipment. Options include: gas or diesel (gasoline) generator, uninterruptible power supply (UPS) or inverter.

Installing a generator requires large capital investments, which is why UPSs and inverters have become more widespread. In them, electricity is stored for future use in batteries and, if necessary, given to the load, the boiler. More often than not, if the electricity goes out, it’s not for long, so the energy stored in the batteries is quite enough to keep the boiler from stopping and the coolant from cooling down.

The main requirement for any backup power source for a gas boiler is a stable sinusoid and output voltage amplitude. The gas boiler does not have any converters or stabilizers of its own, so any surges or deviations will affect the quality of the controller and sensor readings. The shape of the sine wave is critical for the circulation pump. The more regular the sinusoid shape, the more stable the current frequency. The better the pump works.

Household and computer UPSs produce a signal only partially similar to a sine wave, more like alternating rectangular pulses. For the intended purposes, this is enough; computer and office equipment have their own power supplies that convert the input voltage.

Putting all of the above together, it becomes clear why uninterruptible power supply units and inverters for heating boilers are designed and manufactured separately and with increased requirements for the characteristics of the output signal.

TOP 8 electric boilers for 60 square meters

Each electric boiler is the product of painstaking work of professional engineers and craftsmen. The following are popular models from global manufacturers. They were able to prove their effectiveness in a work environment.

EVAN Warmos-IV-9.45 9.45 kW

Wall-mounted model in a compact case. The boiler is designed for operation in residential premises and industrial areas. Equipped with wear-resistant heating elements with three-stage power adjustment.

Peculiarities:

- maintaining optimal temperature;

- single-circuit design;

- possibility of functioning in tandem with non-freezing liquids;

- quiet operation;

- presence of a self-diagnosis system.

Characteristics:

- belongs to the single-circuit type;

- Max. power - 9.45 kW;

- Max. area - 94.5 sq. m;

- Efficiency - 99%;

- equipped with electronic control, display, auto-diagnosis, protection against freezing and overheating, connection of a heated floor, power-on indication, thermometer;

- mains voltage is three-phase with a rated current of the circuit breaker of 25 A;

- temperature of heating elements - 5-85°C;

- service life - 10 years;

- manufacturer's warranty - 2 years;

- dimensions - 380x640x245 mm;

- weight - 27 kg.

Advantages:

- the boiler independently selects the number of power stages to maintain the set temperature. It is also possible to adjust the power manually;

- maintaining operability if a sharp decrease or increase in voltage is observed;

- if the unit overheats too much, the auto-shutdown system is triggered;

- the ability to connect the unit to remote control via Wi-Fi or GSM channel;

- heat loss is minimized;

- durability, strength and attractive design;

- cost - from 18,000 rubles.

Flaws:

- The boiler requires the installation of an additional water heater to produce hot water.

EVAN Next 7 7 kW

It looks like a monoblock, the design of which consists of a boiler and a control panel . The wall-mounted model with three-stage power adjustment is designed for installation in any type of room.

It can be used as a stand-alone unit or acts as an addition to heat-solid equipment.

Characteristics:

- belongs to the single-circuit type;

- power - 2.33-7 kW;

- heated max. area - 70 sq. m;

- Efficiency - 99%;

- control - mechanical;

- mains voltage - single-phase or three-phase;

- coolant temperature - 30-85°C;

- presence of an overheating protection system;

- service life - 10 years;

- warranty - 2 years;

- dimensions - 205x600x105 mm;

- weight - 8 kg.

Advantages:

- compact dimensions;

- high build quality;

- The heating elements are made of stainless steel, which affects their durability;

- ease of installation and maintenance. A 1″ pipe is required for connection;

- quick heating of rooms with long-term maintenance of the set temperature;

- attractive price - from 8,000 rubles.

Flaws:

- not detected.

EVAN EPO 6 6 kW

This is the most budget-friendly electric boiler, perfect for floor installation in the house or country house . A distinctive feature is the absence of a case, but the preservation of all basic characteristics and capabilities.

Additionally, it is possible to connect an external thermostat to regulate the temperature. For example, the GSM-Climate remote control module.

Characteristics:

- type - single-circuit;

- Max. power - 6 kW;

- Max. area - 60 sq. m;

- Efficiency - 99%;

- availability of electronic control, remote control, power-on indication, overheating protection, connection of external control;

- mains voltage - single-phase;

- coolant temperature - 30-85°C;

- service life - 10 years;

- warranty - 2 years;

- dimensions - 160x500x200 mm;

- weight - 7 kg.

Advantages:

- durability of the heat exchanger, thanks to its manufacture from stainless steel;

- light weight and compact dimensions make it easy to install and maintain the unit;

- highest level of safety in case of boiler overheating;

- possibility of connecting a “warm floor” system;

- affordable price - from 9,000 rubles.

Flaws:

- not found.

ZOTA 9 Lux 9 kW

Wall-mounted model with three-stage power helps reduce heating costs by maintaining a minimum safe temperature.

At the same time, the room heats up quickly and evenly. This is the third generation of electric boilers, which are equipped with control unit protection against power surges.

They are also suitable for connection to a “warm floor” system.

Characteristics:

- belongs to the single-circuit type;

- power - 3-9 kW;

- area - 90 sq. m;

- the presence of electronic control, outdoor temperature sensor, room thermostat display, auto diagnostics, protection against freezing and overheating;

- network voltage - single-phase and three-phase;

- heating element temperature - 30-90°C;

- Max. water pressure - 6 bar;

- dimensions - 290x730x160 mm;

- weight - 18 kg;

- warranty - 1 year;

- cost - from 19,000 rubles.

Advantages:

- simplified access to the heating element block;

- the heaters are made of a stainless tube with a diameter of 7.4 mm, which allows you to quickly replace them using a regular wrench;

- the presence of ultra-precise sensors;

- ease of management of functions and capabilities;

- emergency situations are accompanied by characteristic sounds;

- ability to save individual settings.

Flaws:

- Requires professional installation.

EVAN Next 3 3 kW

The wall-mounted design with three-stage power is ideal for heating any type of room . Used as a main or backup heat source.

This is an economical, ergonomic, easy to install and operate model . The combination of reliability and low price makes the unit the best in its class.

Characteristics:

- type - single-circuit;

- power - 1-3 kW;

- area - 30 sq. m;

- Efficiency - 99%;

- equipped with mechanical control, overheating protection;

- mains voltage - single-phase or three-phase, with a rated current of the automatic switch 16 A or 6 A;

- coolant temperature - 30-85°C;

- service life - 10 years;

- warranty - 2 years;

- dimensions - 205x600x105 mm;

- weight - 8 kg.

Advantages:

- silent operation;

- high level of reliability and quality, efficiency in completing assigned tasks;

- The heating elements are made of stainless steel, which makes them durable and economical;

- ease of installation, replacement of main components;

- affordable price - from 7,000 rubles.

Flaws:

- there are no negative sides.

Vaillant eloBLOCK VE 9 9 kW

Wall-mounted model with two-stage power with more advanced features . It features a modern design, microprocessor control and eBus, simple and convenient controls, smooth power changes with moderate load.

Characteristics:

- type - single-circuit;

- power - 3-9 kW;

- Efficiency - 99%;

- has electronic control, a built-in circulation pump and a 10-liter expansion water tank, a display, autodiagnostics, protection against freezing and overheating, a thermometer, a pressure gauge, a power-on indication, and protection against pump blocking;

- mains voltage - single-phase or three-phase (14 A or 16 A);

- coolant temperature - 25-85°C;

- dimensions - 410x740x310 mm;

- weight - 32.9 kg;

- service life - 10 years;

- warranty - 2 years.

Advantages:

- the ability to connect external control;

- ease of installation due to the presence of a 3/4″ pipe;

- durability and strength;

- rapid heating of rooms with long-term maintenance of the set temperature;

- the model provides for the connection of a “warm floor” system;

- there is an air vent.

Flaws:

- high price - from 37,000 rubles. However, it is justified by the highest quality.

Reko 6P 6 kW

Wall-mounted, attractive model with three-stage power . It is distinguished by the presence of functions: protection against freezing and overheating, connection to a “warm floor”, programmer, power-on indication, thermometer.

It is possible to connect external control for better comfort.

Characteristics:

- single-circuit type;

- power - 2-6 kW;

- area - 60 sq. m;

- mains voltage - single-phase or three-phase;

- carrier temperature - 10-85°C;

- connection - 1″ pipe;

- dimensions - 300x500x195 mm;

- weight - 12 kg;

- service life - 5 years;

- warranty - 2 years.

Advantages:

- convenient and simple functionality;

- silent operation of the unit;

- the ability to use individual settings;

- durable heating elements;

- uniform and rapid heating of rooms;

- low price - from 18,000 rubles.

Flaws:

- not identified.

ZOTA 6 Economy 6 kW

The wall-mounted model with three-stage power is popular due to its low cost, but the presence of impressive functionality.

It has electronic control, connection to a “warm floor”, power indicator and overheating protection. The durability of the heating elements is achieved by making them from stainless steel.

Characteristics:

- single-circuit tee;

- power - 2-6 kW;

- area - 60 sq. m;

- mains voltage - single-phase or three-phase;

- coolant temperature - 40-90°C;

- Max. water pressure - 6 bar;

- connection pipe - 1 ¼";

- dimensions - 185x460x120 mm;

- weight - 5.5 kg;

- warranty - 1 year.

Advantages:

- good value for money. The buyer receives a powerful product for only 9,000 rubles;

- compact dimensions and low weight allow you to install the boiler without much effort;

- the unit does not spoil the wall finish;

- uniform supply of hot air into the room, with efficient heating.

Flaws:

- The boiler can be connected using the EVT-I1 PU panel, which is not included in the kit.

Electric boilers for heating a house of 60 sq. m - modern and multifunctional designs .

They not only cope with the assigned tasks, but also harmoniously adapt to the overall interior of the room. Affordable prices and attractive service life make such units a profitable purchase.

Device and principle of operation

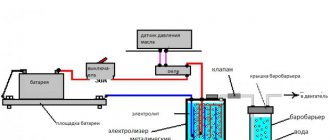

Regardless of which of the three schemes a particular uninterruptible power supply is designed according to, its key elements are the battery and the inverter . The battery (in the most powerful models - a battery) is an energy storage device; when the power is turned off from the external network, it powers an inverter - an electronic converter that generates alternating current at the output with a given voltage and frequency. Uninterruptible power supply systems use gel or AGM batteries with a nominal voltage of 12 V.

It is in the output stage of the inverter that a number of features that are extremely important in our case:

- All equipment designed to operate from a 220 V household network is designed based on the sinusoidal shape of the supply voltage (the so-called “pure sine”). At the same time, the generation of a signal of this shape by the output stage of the inverter is quite complex, and the oscillogram from cheap inverters will be very different from a pure sine wave - they use simple pulse converters. First of all, this can cause malfunctions in the control electronics of the gas boiler, and secondly, it will significantly increase inductive losses in the windings of electric motors of circulation pumps. A characteristic signal of improper operation of the inverter will be a noticeable hum of the electric motors. Long-term operation of an imperfect inverter with an inductive load can cause overheating and breakdown of the power transistors of the output stage and, as a result, complete failure of the uninterruptible power supply.

- To protect the inverter output stage from overload, it includes protective circuits that completely disconnect the load when the current consumption is exceeded. Since circulation pumps, like any device that contains an electric motor, when turned on, consume power several times more than the rated power, if you connect them to an inverter without sufficient power reserve, it will go into protection mode, leaving your heating system without power.

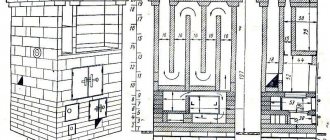

Boiler design

An inverter boiler consists of two main parts: a magnetic circuit and a heat exchanger. The circuit's tasks include creating an alternating magnetic field.

A heat exchanger is needed to transfer energy from the induction current to the coolant, increasing the temperature of the latter to the level necessary for effective heating.

Boiler control system

As a rule, manufacturers supply a control system with the boiler. Essentially this is an assembled electrical cabinet with the following equipment.

- Start relay;

- Thermostat (electronic);

- Thermocouple (temperature sensor);

- Automatic circuit breakers;

- Reactive power saving unit

- Surge protection

For boilers from 7 kW

- Start relay heatsink with fan

- Thermal overload relay.

Equipment Features

An inverter boiler, like every type of heating device, has its advantages. Thanks to this, the equipment is quite popular among consumers and is gradually being used more and more often. At the same time, of course, one cannot do without disadvantages, although for such boilers they are not very significant.

Pros and cons of an inverter boiler

There are a number of advantages that inverter installations have, including:

- increase in operational parameters as a result of the absence of heating elements;

- slight inertia when heating, thus, if there is a centrifugal pump, the coolant will heat up faster;

- the operation of the system is not affected by the chemical composition of the coolant;

- the ability to install the device anywhere.

We recommend: Installing an instantaneous water heater with your own hands: step-by-step instructions

Like other heating systems, an inverter boiler has several disadvantages :

- the rather high cost of inverter equipment compared to similar devices operating on heating elements;

- has impressive dimensions and weight, and therefore requires strengthening of the base on which the boiler will be located;

- The device requires an electronic control system for subsequent power adjustment.

Despite minor shortcomings, inverter boilers are still very popular among consumers and the demand for them is constantly increasing.

Inverter equipment design

Specifications of voltage converters for gas and electric boilers

The voltage converter is part of an uninterruptible power supply (UPS) for volatile systems. IBNs duplicate electrical power, which significantly improves the reliability of heating equipment. These emergency power supply devices turn on quickly when the voltage level drops or when there is no voltage at all.

In heating systems of private homes, the following uninterruptible power supply options are used:

- backup IBNs, which are turned on only when the 220 V network voltage disappears or decreases below a specific threshold;

- linear-interactive devices contain an electrical voltage stabilizer for good and safe operation of the boiler’s electronic equipment;

- Double change systems operate regularly online.

When selecting an IBN, it should be taken into account that the voltage converter for a gas water heater must provide power sufficient for the good functioning of all consumers of electrical energy - a circulation pump, an automatic unit. In fact, this power is usually no more than 300 W, taking into account the required margin.

For electric boilers of various types, when selecting an IBN, it is necessary to add the power consumed by the boiler to the power used by the automation unit and circular pumps.

Simple and accessible information about the types of voltage converters

The type of inverter is the main criterion when choosing, which you need to decide on first. Each type has certain properties, operating algorithm and characteristics.

Off-line

Off-line inverters are also called backup inverters; they have the simplest design and operating algorithm:

- At normal voltage in the electrical network, the inverter is inactive, and the boiler operates in normal mode, exclusively from the electrical network.

- As soon as the voltage in the electrical network drops below a critical level (usually 175-190 V) or disappears altogether, the inverter instantly switches the power to the boiler to the battery connected to the converter. The switching occurs imperceptibly, in modern models it takes 4-8 ms, which is enough for the uninterrupted operation of the boiler unit.

- As soon as the voltage in the electrical network is restored, the inverter switches power to the main network and goes into standby mode.

We recommend: Do-it-yourself hood over a barbecue in a gazebo: how to make a chimney from metal or brick, distance and height, materials and tools

Also, most devices are designed for excess voltage, they usually operate at values above 260-300 V. Off-line inverters the simplest and most inexpensive, their prices start from 4 thousand rubles.

However, it is better not to use them if the power supply voltage fluctuates too often or constantly. With such instability, the converter switches from the main power source to the backup one too often, which leads to very rapid wear of the batteries.

Line-interactive

Line-interactive voltage converters are the most optimal and universal for a modern heating boiler. In addition to the converter and switching relay, as in Off-line devices, linear-interactive models use a voltage stabilizer.

In standard mode, the boiler still consumes electricity from the main network, but the voltage is equalized by a built-in stabilizer; some more technologically advanced models are equipped with additional filters that smooth out noise, eliminate interference in the network, etc. With this type of operation, the battery is used less frequently and the energy efficiency (efficiency) is much higher.

Linear-interactive models often have a built-in battery that can ensure the boiler operates for 20-120 minutes, while it is also possible to connect external additional batteries that can extend autonomy to several days.

A Line-interactive inverter will always be sufficient for any gas, solid fuel or low-power electric boiler. However, such equipment also has disadvantages - poor smoothing of the sinusoid during interference, disruption of its uniformity during deep drawdowns or drops (switching time of 4-6 ms does not protect overly sensitive modules).

On-line

The most technologically advanced and expensive double conversion inverters. A simplified operating algorithm looks like this:

- At the input, the inverter converts the alternating voltage of the electrical network into a constant voltage of 12 V.

- At the output, the inverter converts 12 V to 220 V with a perfectly pure sine wave with a frequency of 50 Hz.

The batteries in such a device act as a buffer capacity necessary to equalize the current parameters. The advantage of the technology is that the boiler does not contact the electrical network directly and, at any current parameters in the network, receives an ideal, pure sine wave produced by the inverter. However, due to double conversion, the efficiency of such equipment is lower, up to 90%.

Inverter electric heating boilers

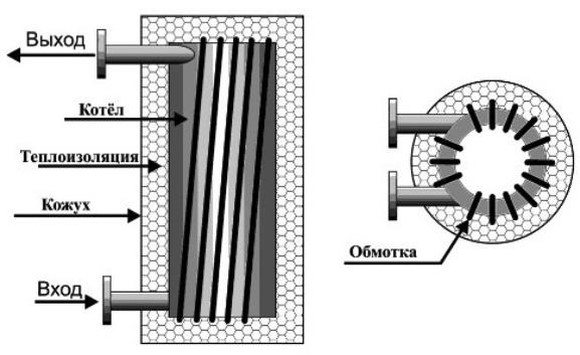

If we strictly approach the term - inverter heating boiler, then this name corresponds to a device whose power is supplied through a double-change voltage converter. The 220 volt network voltage is rectified and supplied to a voltage converter, which converts stable voltage into high frequency voltage in the range of 15 - 40 kHz to power the inductor (winding) of an electric induction boiler.

Several types of induction boilers are known:

- electromechanical heating boilers SAV;

- electromechanical vortex boilers VIN.

SAV electric boilers are connected directly to the electrical network, single-phase or three-phase, depending on the power and connection diagram. If a cascade connection is used to increase power, then each device is connected to an individual phase.

Vortex electromechanical boilers of the VIN type were developed as inverter heating boilers with high-frequency voltage supply to the inductor.

The use of high frequency made it possible to reduce the dimensions of the boiler, the number of turns of the inductor winding and reduce its weight.

Most manufacturers recommend VIN vortex boilers, which, for some reason, require a power supply of 220 v 50 Hz, i.e. such a home heating boiler turns out to be a modernized SAV type boiler. It cannot be called an inverter vortex device of the VIN type, since the very principle - the use of high-frequency voltage - has been lost. There is a lot of confusion on the Internet regarding the use of terms and concepts. It even goes as far as outright deception. For example, an induction electric boiler A006 is offered. Let's look at its technical data:

- total power of TENOV – 6 kW;

- step power adjustment – 3/6.

Only such parameters clearly determine that the boiler belongs to the heating element heating devices.

Despite the fact that induction equipment is one of the most economical, safe and reliable, its widespread adoption is hampered by the price of electrical energy. The use of IBN, which includes voltage converters for heating, is fully justified in conditions of an unstable network, because increase the reliability of the circuit and provide operation without interruptions. The term inverter heat supply can be used exclusively for vortex induction boilers of the VIN type, the inductor of which does not stop operating from the high-frequency voltage generated by the voltage converter.

Variety of heaters. What to choose from?

There are two main types of these devices:

- Single-phase

- Three-phase

The significant difference between them is that the first are designed to work in a 220V network, the second - 380V.

Oddly enough, the most reliable boilers are made in the countries of the former CIS. The most common are TENG heaters, induction heaters and ion heaters. Each of them can be attached to both floors and walls due to their lightness (new generation induction boilers reach 30 - 40 kilograms).

You can also connect a water heating system to supply hot water to the bathroom and kitchen.

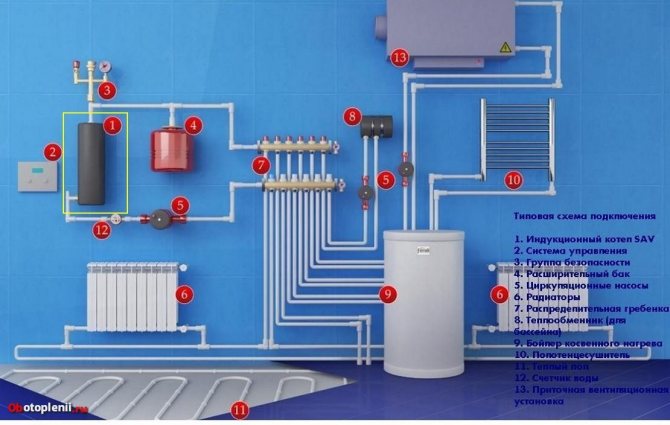

Conventional heating system, excluding boiler

For almost every induction model, you can adapt a special pump, which will make it possible to carry out heating in two- to three-story houses. But for this it is necessary to spend a lot of effort to insulate the walls, otherwise the work of vortex induction boilers will be wasted. In this case, it is necessary to purchase more “strong” models, and they, in turn, are more expensive.

To purchase this heating system, you need to know the area of the room, possible ventilation and overall thermal insulation. This knowledge will help you when purchasing an induction system. Also, do not forget about calculating the dimensions and choosing the installation location.

Which inverter to choose

Russian inverters are, of course, cheaper than American ones, but in them you cannot change how the batteries will be connected: with what charging algorithm, the threshold for starting work, how third-party sources will be controlled.

Setting these parameters helps to use the battery more safely, smoothly switch to the mode, and allows the use of inverters in parallel. American systems are more reliable, they last longer, and they will last longer for the benefit of your home.

There are two types of inverters: online and offline. In online inverters, a discharged battery begins to simultaneously work and be recharged from an external power source (for example, a similar operating principle is characteristic of a car battery).

However, such a compound mode actually has a very bad effect on the batteries, causing them to wear out and quickly expire. An offline inverter is much safer for batteries - here the battery is either charged or discharged at the same time. This is a more gentle operating mode.

Offline inverter

Therefore, when making calculations in order to identify a more reliable option, turn your attention to offline inverters.

Don't forget to also consider the quality of the voltage. Imported models produce a voltage of 230 V. Typically, one battery has a voltage of 12 V. Their distortion coefficient is quite low - from two to three percent. To achieve this, such models use a special algorithm that generates a sinusoidal voltage output, high-quality transformers and matched filters.

How to choose?

When choosing, you should take into account the power and type of unit . So a house with an area of 60 sq. m are capable of heating devices with a power of 4 to 18 kW. The more powerful they are, the faster the rooms warm up, and the higher their cost.

Today, manufacturers offer 3 types of electric heating boilers.

They differ from each other in design, advantages, additional features:

- Heating element boilers . The heating element in the form of plates or tubes acts as a heating element. It is housed in a heat exchanger. One device can be equipped with 8 2 kW elements. Adjustment occurs automatically or manually. Such models are presented on the market in the form of single-circuit and double-circuit products. They operate on water, antifreeze or oil. Double-circuit ones additionally heat a container of water for its subsequent use in domestic needs. But heating element boilers have low efficiency due to the stepped water heating system - 80-93%.

- Electrode boilers . Heating elements - electrodes. Water acts as an excellent electrolyte with a given resistance. When it passes through a salty environment, heating occurs. They are characterized by simple, high efficiency - 94-95%, simplicity and safety. Disadvantage - they require frequent replacement of electrodes due to their rapid dissolution in a salty environment.

- Induction boilers . Complex systems involve induction coils in the form of wire wound around a dielectric. Electric current passes through the coil, forming electromagnetic induction. After its influence on the potential difference, the core is heated. The efficiency is 99%, energy savings are observed, and a comfortable temperature in the room is maintained for a long time.

The buyer decides which type of boiler to choose. The main thing is to pay attention to power consumption and output .

How long does the inverter work?

The inverter does not have internal batteries, but instead uses external ones. Thanks to this, it becomes possible to select a volume of batteries that will ensure the required period of independent operation of the uninterruptible power supply device.

Let's talk in more detail about the time of independent operation of the system. To calculate charge time, you need to divide the volume of the battery by the current it produces (in amps).

To determine the battery current (IAB), we rely on the law of conservation of energy, in which case the efficiency of the inverter will be one hundred percent. The required result is that the multiplied volts and amperes of the Inverter Battery equals the multiplied volts and amperes at the output.

Calculation of battery voltage = 12 V (in stronger models there are 24 V and 48 V), let's call it UAB. Volt*amps output is the power connected to the load inverter Pload.

We recommend: Calculation of an expansion tank for closed and open heating

As a result, we have the calculation Pload = U battery * I battery, as well as I battery = P load / U battery.

If we know the volume of the battery of the battery, then we can find out how long it will work autonomously: tАВТ = SAKB/(Pload/UAKB) = SAKB*UAKB/Pload.

So, let's say we have an inverter connected to a 55 Amp*Hr battery with a 300 W load. Let's calculate how long it will work independently.

- UAKB = 12 V

- Pload = 300 W

- SACB = 55 Amp*hours

We make the calculation: tАВТ = SAKB*UAB/Pload = 55*12/300 = 2.2 hours.

And another question is what kind of battery is needed to ensure a certain operating time: SAKB = Pload*tAVT/UAB.

Twelve battery pack

For example, let's calculate what kind of battery we need for a given inverter in order to provide 2.2 hours of independent operation with a load of 300 W: SACB = 00*2.2/12 = 55 Ampere*hours.

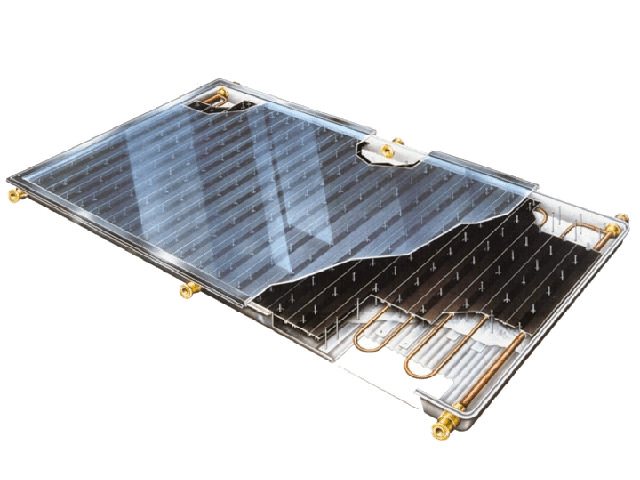

Solar collectors

The essence of solar collectors is to collect, store and transfer heat from the sun. Solar energy can be used freely and endlessly; it does not require extraction or transportation. There are two main types of collectors - flat and vacuum.

Flat-plate collectors

Flat solar collector

The design of flat-plate solar collectors is a heat-insulated panel located under glass, inside of which there is an absorbing plate. It is she who accumulates the energy of the sun. However, even taking into account the thermal insulation of the bottom and side walls, in winter the charge level is much lower due to heat loss. Flat-plate collectors are less suitable for temperature changes, but are more widespread due to their low cost.

Vacuum manifolds

The structure of vacuum solar collectors involves several vacuum tubes converting sunlight into thermal energy. The tubes themselves are similar to a regular thermos and consist of several glass tubes built into each other. The outside of the tubes is translucent, and inside there is a material that collects sunlight.

Vacuum manifolds

Collectors are located on the roof and/or walls of the house. Vacuum solar collectors are much better protected from temperature changes and absorb heat better, which is why they are suitable for operation in cold weather.

Comparing an induction boiler and a heating element boiler

Induction and heating element boilers are the same type, electric heating boilers, that is, boilers in which electrical energy is converted into heat. Comparing them we can say:

- Both boilers have high efficiency tending to 100%;

- The cost of heating the coolant is the same;

- Heating element boilers are cheaper;

- Induction boilers are easier to use and more reliable.

However, the induction boiler has significant advantages:

- Scale does not form on the heating element;

- You can use almost any coolant, not just water;

- They operate silently and do not require a specially equipped room.

Types of inverter heater

The devices can operate on liquefied gas and are suitable for country houses.

The inverter is capable of changing the characteristics of the heater if the latter is electronically controlled. The actual design of the heater does not matter. But since the technology is expensive, the unit is installed on high-end models.

By type of fastening

These units can be floor-mounted, wall-mounted or baseboard-mounted.

- Floor-standing ones are distinguished by the presence of wheels, which allows you to transport the unit from one room to another. This suggests that floor-standing options are mobile. For example, when heating one room, you can then warm up another. And given the low power consumption, this device has even more advantages.

- Wall-mounted devices are mounted on vertical surfaces. Less mobile than floor or baseboard ones.

- Due to their special structure, baseboard They have the principle of operation of a water baseboard, when the entire area is heated at once. Another advantage is that the presence of any cold places is suppressed by the heat created, various changes in the room temperature are prevented, and rooms do not fog up. This type of equipment can also be easily moved and transported, just like floor-mounted equipment.

By type of heating element

Presented in 3 types:

- electric;

- gas;

- energy saving.

Electric ones operate from the mains. Such devices are popular among those who purchase them for an apartment.

Gas models operate using gas. The main function is to maintain heat in small areas or even in some unheated rooms. The advantage is that with low fuel costs, the device effectively heats the entire room.

Ergonomics, simplicity and high mobility make them an ideal option for their price.

Energy saving is suitable for those people who do not have a particularly powerful electrical system. Considering the increased efficiency (compared to other equipment of this type), this feature makes this type of equipment even more preferable. If you look at statistical calculations, you can see that the total amount of electricity saved is up to 60%. Very serious numbers, especially with high efficiency.

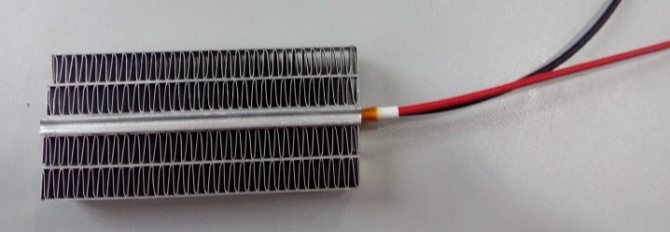

Also, the elements themselves can be of different types.

- A heating element in the form of a tape or needle. The loops are located on the sides of the plate, and these loops are frangible. Due to the fact that the design does not include fins, the air heats up rather slowly. Nowadays it is rare to find such equipment, since it has not been produced for a long time.

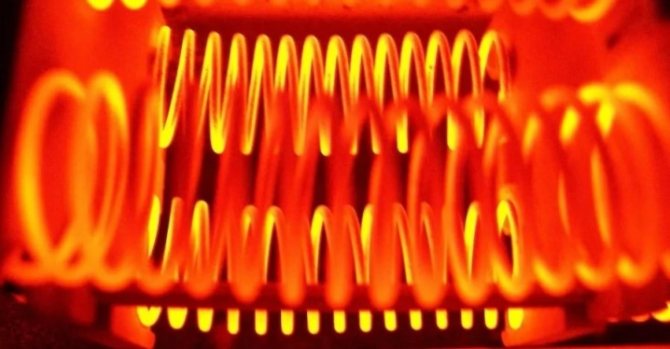

- A heating element (tubular electric heater) can also heat. The tube consists of ribs. The greater their number, the more heat the room will receive. The heating element can heat up to a high temperature, so the efficiency of this device is higher than that of a tape or needle.

- The monolithic type has a special design. The nichrome thread is housed in a ribbed housing made of aluminum. Thanks to this, the likelihood of losing heat is extremely low. Low noise level.

Gas

Such heaters operate on natural or liquefied gas. Since it is a cheap fuel, heating a room costs only slightly more than using hydronic heating. It is designed for heating large areas and is perfect for a summer residence.

Inverter technology increases the efficiency of the device. The burning intensity of the burner changes smoothly, which eliminates the risk of extinguishing the flame. Fuel is consumed even more economically. Inverter units are more compact than conventional gas heaters.

Infrared

The principle of IR heaters is to heat objects in the room, which will then emit heat.

Heating elements emit infrared radiation - this is a plus. In this case, it is not the air in the room that heats up, but surfaces, objects and people. This makes it possible to provide comfort at an actually lower temperature.

We recommend: How to make a bio-fireplace with your own hands: assembly instructions

The heater works the same way as the others: it turns on when the temperature drops and turns off when it rises. An inverter electric infrared heater works without switching off, only reducing the heating intensity. The device consumes much less electricity with high heat transfer. This is important because electricity is expensive.

With heat pumps

This refers to air conditioners that can operate in reverse mode - not only for cooling, but also for heating. The fan blows cold air from the outside, but since the temperature of the refrigerant is still much lower, the latter boils and condenses at the compression stage, releasing heat. The heat is transferred to the air in the room through the heat exchanger. Thus, an air conditioner with a heat pump receives heat from air with a temperature of up to 0 C.

Such a system turns out to be cheaper than an electric heater. An inverter unit makes the air conditioner even more economical. When the desired temperature is reached, it does not completely turn off the installation, but switches it to minimum power mode. Without peak loads, the device operates longer and consumes less electricity.

Convectors

The inverter operating circuit has been introduced into convection-type heaters.

An inverter is also installed in electric convectors. Such models are presented by Electrolux and Bally. The principle is the same: the unit does not turn off the device, but reduces the power. The heater operates in maintenance mode most of the time. At the same time, it consumes less electricity and wears out less.

In this mode, heating elements heat up to a lesser extent and less oxygen is burned. Inverter convectors are safer for health.

What is an induction boiler

When considering heating devices powered by electrical energy, you should first of all pay attention to the heater. For example, in infrared heating installations, halogen, carbon or quartz lamps can act as a heat emitter, directly heating the room.

If the system or heating circuit is of a closed type, then a heating element (tubular electric heater) is most often installed as an electric heating element. Induction devices differ from others in that the component of the device that directly generates heat is not included in the electrical circuit.

Device

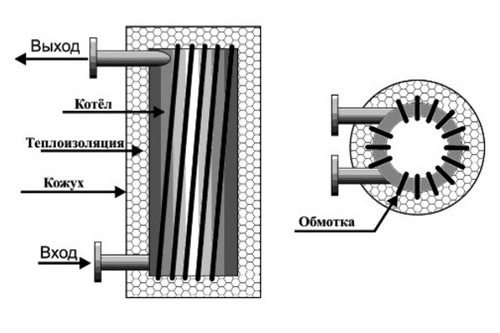

Schematically, an induction heat source can be represented as a piece of dielectric pipe with a steel core inside, on top of which a multi-turn cylindrical coil (inductor) is located. In order for the device to operate and generate heat, the inductor is connected to an alternating current network.

Induction heat generators for a private home have a more complex design and consist of the following main parts:

- housings with inlet and outlet pipes;

- inductor;

- heat exchanger;

- cabinet with control equipment.

Induction devices are installed into the system or heating circuit in the same way as other electric boilers.

The installation kit also includes:

- Control block;

- pump;

- security group;

- shut-off valves and flow sensor.

Principle of operation

The principle of induction heating is quite simple and is known to everyone from a school physics course. When an alternating electric current passes through an inductor, an electric field is formed around the coil.

Under its influence, Foucault eddy currents arise on the surface of the ferromagnetic core. They heat the metal core, which transfers heat to the surrounding coolant due to the thermal conductivity of the materials. When the heat generator is integrated into the heating complex, it is turned on and off by the control unit when the required temperature of the coolant fluid is reached.

Advantages

Marketers often present their induction devices as devices that operate on new principles and using innovative technologies. This statement is quite controversial, considering that steel and other metals have been successfully melted industrially in induction furnaces since the second half of the 20th century.

However, for domestic use these are truly new devices that have a number of advantages, including:

- efficiency;

- durability;

- consistency of performance characteristics;

- noiselessness;

- compactness;

- high degree of electrical safety;

- no need for off-season maintenance.

Manufacturers point out their ability to save up to 20-30% of electrical energy compared to heating elements as the main argument for using induction units. This statement causes some skepticism among experts. It is known that any electric heater, provided that it does not perform mechanical work, converts 100% of electricity into heat. According to the immutable law of conservation of energy, to get 1 kW of heat, you need to spend 1 kW of electricity.

In this case, losses can only occur due to heating of the copper wire of the inductor and heat dissipation around the device. If the entire complex is installed indoors, then the heat naturally goes to heating it, and does not fly out into the chimney. In comparison with solid fuel installations, induction technical equipment clearly wins in terms of efficiency in using the energy source.

The ferromagnetic core, even if it is destroyed by corrosion and heating, does so very slowly.

A breakdown of the copper wire of the coil rarely happens, and this is most likely due to the failure of the automation. The main factor determining the service life of the induction unit is the quality of the transistors used in the control unit. If the electrical and electronic parts are of high quality, then the entire system can last 10 years or more without failure.

The almost complete absence of noise and the compact dimensions of this type of system fully meet the requirements in private construction. If the operation of the boiler is based only on the natural circulation of convection currents, then in the absence of acoustic vibrations it can be comfortably operated even next to the bedroom. If forced circulation of the coolant is required, the problem can be easily resolved by installing a silent circulation pump.

Flaws

The main disadvantage of induction units compared to heating element analogues remains their almost twice the price.

In addition, experts note such negative aspects as:

- the need for installation only in a vertical position;

- automatic operation control initially based on flow temperature;

- turning on the unit at maximum power regardless of the selected stage, which leads to sudden surges in the mains voltage;

- quite heavy weight, requiring special fastenings on load-bearing surfaces;

- impossibility of repair without complete disassembly with damage to the housing, for example, if the winding burns out.

When choosing electric heating equipment, homeowners first of all pay attention to its cost. According to this criterion, induction systems are still seriously inferior to other types of heat generators. Despite the advertising, people are also deterred from buying by the large costs of the proposed repairs, which are quite difficult to do with your own hands.

What is the effectiveness

Experts are still arguing about the increased efficiency of induction heating circuits. Considering that they use electricity to generate heat, they are usually compared with their heating element counterparts. In a closed circuit, unlike a hot water supply system, there is no large amount of scale on the heating element and on the steel core.

In both cases, heat exchange occurs, and thermal energy is transferred to the coolant. Otherwise there would have been an explosion. If we compare two models of the same power, which are assembled at a high level, then the efficiency of both types of boilers in a closed circuit is the same.

According to master installers, the higher efficiency of induction systems is only a marketing ploy by manufacturers and has nothing to do with reality.

Organization of the heating system

Depending on the power, all inverter boilers can be divided into the following types:

- Industrial. They have large dimensions, a rather complex current conversion system (carried out by an inverter for a heating boiler), and volumetric heat exchangers.

- Household. This type of model is characterized by relatively small dimensions, as well as the ability to operate on mains power or batteries.

To organize an inverter-type heating system, you should carefully pre-design it.

When the boiler is operating, the overall load in the electrical network of the premises will increase, so the wiring will need to be laid with a larger cross-section.

An important aspect is the safety of the boiler. And this nuance must be properly ensured. So, you will need to install a protective electrical unit that will automatically de-energize the boiler if there are voltage drops in the network.

What are induction devices?

Induction boilers consist of three layers:

- Outer layer, which is made of metal

- Insulating middle layer (heat and light insulation at the same time)

- The inner layer or "core". It is a ferrimagnetic pipe made of steel. The thickness of each pipe is equal to ten millimeters. These pipes are “inserted” into each other and have a toroidal winding.

Heating boiler design

All these indicators are necessary to increase the performance of the boiler itself, reducing its overall dimensions, which makes it suitable for use in residential premises.

For the boiler to operate, liquids are required, namely any coolant, water or antifreeze. The operating diagram of the device is as follows. Any of the above liquids enters the inside of the device. In the “core” the water is heated, heating and releasing up to 98 - 99% of the heat. This process is facilitated by a toroidal winding in the inner layer. The main current passes through it, passes through all structures, and is then directed through pipes to the heating sections. This procedure requires a time of 5 to 10 minutes.

Two outer layers protect against liquid leakage and various electrical problems.

The operating principle is based on heating the coolant

The advantage of such boilers over industrial ones is that for operation there is no need to strengthen the wiring of the house and install additional generators. Vortex induction boilers operate under a direct current of 20 kHz, which is an advantage of conventional home appliances.

The presence of internal sensors allows you to regulate differences in the network and monitor heating indicators.

Operating rules

In order for the device to serve for a long time, it is necessary to adhere to certain rules during operation:

- The distance from the heater to any object must be at least 500 mm.

- The unit cannot be placed under a window opening.

- Experts do not recommend leaving the device turned on overnight; this can only be done if there is a thermostat inside it that regulates the frequency of operation.

- You should not dry things on a heater.

Energy efficiency is now considered one of the most important criteria when choosing heating devices, so you should carefully approach the purchase of heaters. Unlike convective heating (central heating, oil radiators), inverter devices allow you to warm up that part of the air mass where people are, which is very convenient and profitable.