Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of different grades is used in production, but it is not corrosion resistant. Such rolled metal products require additional protection - painting, for example;

- galvanized steel pipes - products are coated with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. Obviously, the service life according to SNiP and GOST for such a model is much longer;

- stainless steel – alloys with the addition of nickel and chromium. Depending on the size of the alloying additive, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows use in sea water, for example, and also does not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rare, but used in domestic conditions. They are distinguished not only by their resistance to corrosion, but also by their disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will vary.

Corrugated stainless steel pipe

The main document establishing the standard service life of utilities in a residential building is VSN (departmental building codes) number 58-88, adopted in 1988. They regulate the timing of maintenance, reconstruction and repair of buildings.

Corrosion. Rusting of the pipe is accelerated by a damaged outer layer of paint, frequent shutdowns of the water supply (in this case, the unpainted inner surface of the pipe is in contact with air with high humidity) and poor ventilation in the bathroom (read: consistently high humidity).

The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion.

The service life of a pipeline can be calculated taking into account operating conditions, parameters of pipes, waterproofing and thermal insulation coatings. For example, such calculations are given in GOST 24723-81 “Galvanized steel sea water pipelines. Calculation of the durability of elements."

Water supply steel pipes are still successfully used to create water supply networks. To find out exactly in what situations it can be used, you will have to understand in detail all the pros and cons of its operation.

Black steel for water pipe

Alas, this option is not particularly durable. Even with the most careful painting and care, they will rust over time. The fact is that after the construction of communications, individual fragments turn out to be inaccessible, and it turns out to be impossible to update the paint, for example.

In addition, black steel loses its smoothness quite quickly. And this leads to the fact that the water-gas or heating pipe “overgrows” quite quickly: first very small debris and salt deposits are retained on the unsmooth surface, and then increasingly larger particles of rust, fibers, and lime deposits. The rate of sediment accumulation is directly proportional to water hardness.

Constant contact with moisture - in the bathroom, for example, in the toilet, leads to faster destruction of the material, which is reflected in SNiP standards. Here the weak link is often the seams: the first fistulas appear precisely on the welds and threads, where the wall thickness decreases.

Standard operating times are:

Cink Steel

This material is much more resistant to corrosion, which significantly extends the standard time. The most significant destructive factor here is only the welded connection, if for some unknown reason the installation is carried out by welding. The photo shows water and gas steel pipes.

In fact, this installation method is prohibited: the zinc completely burns out during welding, and accordingly, the seams remain completely defenseless against rust.

Galvanized steel products overgrow much more slowly. Firstly, the smoothness of the wall is much higher, and secondly, there is much less “garbage” itself - particles of rust, scale, sand. But if the taps in the plumbing system are not fully opened and there is not a sufficiently dense flow of water, scale and sand can accumulate.

The service life of the product according to GOST is as follows:

- risers and connections in cold water supply systems are in use for 30 years;

- the service life of steel heating pipes in a house with a closed system is 20 years;

- an open heating system will last 30 years.

It is allowed to construct a gas pipeline from galvanized pipes. But there is still a nuance: unlike plumbing systems, the gas pipeline must be one-piece, which requires welding. And the connection destroys zinc at the junction. On the other hand, gas pipelines, like water pipelines, are coated with polymer paint, which prevents corrosion.

In fact, galvanized steel pipes for both water supply and heating last 50–70 years.

Service life of steel heating pipes

Any material wears out over time, but this time can be very different and depends on the load, on additional factors and, of course, on the quality of the product itself. The standard service life of steel water pipes largely determines their purpose. Types of pipelines Several types of metal products are used in heating and water supply systems: black steel pipes - steel of different grades is used in production, but it does not have corrosion resistance.

How to convince residents to pay contributions for major repairs and what to do if there is no money for it? In the article we will talk about the types of metal pipes, their features and service life - both those prescribed in regulatory documents and real ones. To help the Criminal Code, we also provide a list of mandatory work that must be carried out as part of the maintenance of water pipelines in multi-storey buildings. Previously, during construction, exclusively metal communications were used, which continue to be used in a significant part of the apartment complex. As the resource is exhausted, they are replaced with modern materials. This is a long process that will continue in the public utilities sector for many more decades.

What is the service life of steel pipes for water supply and heating - material characteristics

Steel pipe products are used both in everyday life and in many areas of activity - they are used in the construction of oil pipelines, heating mains, water supply systems, heating mains, etc. In many ways, the service life of metal pipes depends on the conditions in which they are used.

Currently, manufacturers produce pipes from various materials, which are successfully used when laying heating and water supply systems. They are environmentally safe and of the highest quality; their use in houses and apartments creates an atmosphere of coziness and comfort.

Areas of use of metal pipes

For decades, steel pipes have been in great demand on the domestic building materials market. It should be noted that in most apartments, pipelines are still laid from them. These products differ in that, despite their affordable price, the costs of their installation are quite high.

Experts recommend using black steel pipe products for heating systems, and galvanized products for water supply structures. And, despite such a disadvantage as susceptibility to corrosion processes, the service life of steel pipes is quite long. To slow down corrosion, manufacturers coat them with zinc on the inside and outside.

When purchasing pipe products for metal communications, you should pay attention to the method of their manufacture. This circumstance affects the service life of water pipes made of steel pipes.

They are:

- electric welded products that are used for laying gas and water pipelines, as well as heating systems;

- seamless pipes.

Their throughput with an equal internal cross-section is lower than that of copper or polymer products. This is explained by the fact that the surface of steel pipes is rough on the inside, which prevents the free movement of liquids due to the formation of turbulence.

Features of steel pipeline communications

Products for laying steel pipelines can easily withstand hydraulic loads, so they do not affect their durability, which means that the service life of steel water supply pipes is not reduced.

This pipe product is characterized by good thermal conductivity, and the insignificant expansion coefficient due to temperature changes makes it possible to lay water pipes in the wall. Steel pipes, in addition, are excellent for arranging radiant types of water heating.

In addition to the advantages, metal communications made of steel also have disadvantages. So they have a significant weight, which causes inconvenience during their operation. Laying steel pipelines is impossible without the use of gas welding equipment and this circumstance increases the cost of installation work.

The service life of heating pipes made from steel is more than 20 years. They are laid both underground and in the basements of multi-story buildings, where very hot coolant moves along them with an internal pressure exceeding 6 atmospheres.

In case of water hammer it reaches even 12 – 15 atmospheres. Under such operating conditions, metal-plastic pipes are not able to withstand even a 15-minute operating mode. This is precisely the main advantage of engineering heating communications made of metal.

In multi-story buildings in cities, steel pipes for water supply are laid either open or placed in walls, which are then plastered. Provided that the pressure in the pipeline is about 6 - 7 atmospheres, and the temperature of the working environment reaches 90 degrees, only steel products can serve reliably.

When creating water supply and heat supply systems in urban high-rise buildings, steel pipes today have no competitors, since they are characterized by mechanical strength and a low expansion coefficient.

But specialists are in no hurry to work with such pipe products, since the products are heavy, straight - the length can reach 12 meters and are difficult to transport. The most negative point is that the installation of steel pipelines requires gas welding.

Some advantages of pipes that affect service life

Steel pipes in so-called “Stalinist” houses are used in heating systems at a coolant temperature not exceeding 60 degrees. Heat supply structures that are equipped with cast iron batteries can last more than 100 years, which is what actually happens.

There is another advantage of steel - the lowest coefficient of thermal expansion compared to pipe products made from other materials. For example, for copper this figure is 2 times higher, and for plastic it is almost 20 times higher. Thus, it is not recommended to hide plastic and other pipes, except steel ones, in the floor and walls due to the instability of their parameters, especially for heating structures.

Reducing or enlarging products leads to destruction of the integrity of the coating in which they are mounted. Therefore, when laying non-metallic communications, it is customary to use compensating materials - for example, soft thermal insulation. Metal pipe products are best suited for installing radiant water heating systems.

As for the shortcomings that affect the service life of metal heating pipes, experts consider the main ones to be:

- High degree of susceptibility to corrosion processes and damage of various types.

- Rapid clogging of pipe products used in heating systems by deposits.

The best solution to eliminate the above problems is to use products with a larger cross-section and use galvanizing technology. But the latter method has a significant drawback - antifreeze cannot be used in such a system.

The zinc coating method increases resistance to corrosion processes and thus affects the service life of galvanized pipes.

Features of the galvanizing process of steel products

Zinc coating is applied in several ways. When using the hot-dip galvanizing method, steel pipes are completely placed in liquid zinc at a temperature of about 450 degrees. This process is labor intensive.

Service life of steel structures

And she really wanted to get a link to some official document. We actually managed to find something. The only point is that this order concerns the organization of major repairs of residential buildings in the city. This regulatory act establishes the following service life of steel structures: 1. For central heating pipelines - 30 years. For water supply and sewer steel pipelines - 15 years. The same galvanized steel pipes will last twice as long as 30 years.

For steel enameled bathtubs and sinks - 15 years. For drainpipes made of galvanized steel - 15 years, for drainpipes made of black steel - 5 years. For roofing: and from black roofing steel - 15 years. As we can see, according to this document, the average service life of steel residential building structures is 15 years. In the case of water pipes, during the first years of operation, the inner surface of the pipe becomes overgrown, and wet condensation forms on the surface.

Moreover, this type of pipe can withstand strong dynamic loads. The service life of galvanized steel structures is much longer, thanks to the anti-corrosion coating.

WATCH THE VIDEO ON THE TOPIC: Plastic Heating Pipes from 1963. What happened to them after 55 years?

Service life of heating pipes

What factors limit the service life of VGP pipes without anti-corrosion coating: Image Description Steel water supply risers. The first fistula that caused the ceiling to become wet appeared in the Corrosion ceiling. Rusting of the pipe is accelerated by a damaged outer layer of paint, frequent shutdowns of the water supply in this case, the unpainted inner surface of the pipe is in contact with air with high humidity, and poor ventilation in the bathroom (read: consistently high humidity). The first fistulas appear on the longitudinal welds of VGP pipes GOST - electric welded, on threads where the thickness of the pipe walls is minimal, and in ceilings where the surface of the pipes is not ventilated and, in the case of cold water risers, is continuously wetted by the condensate falling on them. The rate of overgrowing is directly proportional to the hardness of water in the region: where it erodes sediment on the way to the consumer, the clearance in the water supply decreases much faster.

Black steel

Steel rusts. It rusts especially quickly with prolonged contact with water. That is why the service life of steel risers and connections laid down in the regulatory documents, frankly speaking, is not amazingly long.

Standard service life

The main document establishing the standard service life of utilities in a residential building is VSN (departmental building codes) number 58-88, adopted in 1988. They regulate the timing of maintenance, reconstruction and repair of buildings.

The document regulates the procedure for repair and reconstruction of buildings

Appendix No. 3 to the document provides the following figures:

| Engineering system element | Standard service life, years |

| Riser or cold water supply from gas pipes | 15 |

| A riser or hot water supply from gas pipes in a building with a closed heating system (without taking hot water from the heating system) | 10 |

| The same, in a building with an open heating system (DHW is taken from the heating circuit) | 15 |

| Heated towel rails in the DHW system | 15 |

Destructive factors

What factors limit the service life of VGP pipes without anti-corrosion coating:

| Image | Description |

Steel water supply risers. The first fistula that caused the ceiling to become wet appeared in the ceiling | Corrosion. Rusting of the pipe is accelerated by a damaged outer layer of paint, frequent shutdowns of the water supply (in this case, the unpainted inner surface of the pipe is in contact with air with high humidity) and poor ventilation in the bathroom (read: consistently high humidity). The first fistulas appear on longitudinal welds (VGP pipes GOST 3262 are electric welded), on threads where the thickness of the pipe walls is minimal, and in ceilings where the surface of the pipes is not ventilated and (in the case of cold water risers) is continuously wetted by the condensate falling on them. |

Lime deposits and rust have almost completely blocked the gap in the water pipe | Overgrowing of pipes with deposits (primarily lime salts) and rust. The rate of overgrowing is directly proportional to the hardness of water in the region: where it erodes sediment on the way to the consumer, the clearance in the water supply decreases much faster. The narrowing of the lumen leads to a drop in water pressure on plumbing fixtures connected to the water supply. |

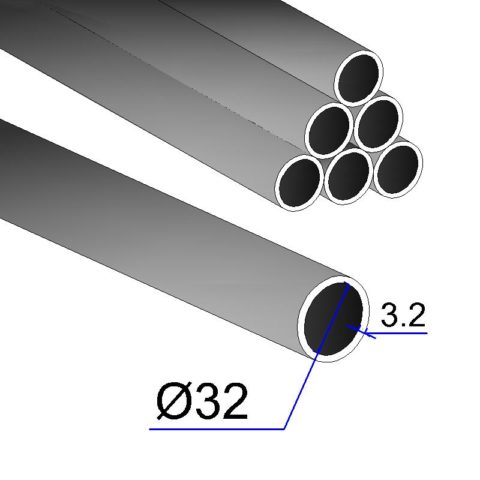

The diameter of steel risers is selected taking into account the reduction in pipe capacity due to deposits | Pipeline diameter. The larger the internal cross-section of the pipe, the longer it maintains acceptable throughput. |

The thicker the wall, the longer the pipe can resist corrosion. | Wall thickness. According to GOST 3262, ordinary, reinforced and lightweight pipes are produced. It is clear that those reinforced before the first through fistulas appear will last longer. |

Chemical flushing can transform old plumbing

Standard service life of steel pipes according to GOST

These materials are susceptible to corrosion. This is their main problem. In order for the pipe to serve faithfully for a long time, it is necessary to apply anti-corrosion materials to its surface. This requires additional financial costs. In addition, they are exposed to aggressive environments, which destroy their structure and make it fragile. This leads to rapid failure of the entire system. Modern heating pipes are made of polypropylene or polyethylene. Modern pipes for heating and water supply are made of metal-plastic, polypropylene and polyethylene. These materials do not corrode, and aggressive environments have virtually no harmful effects on them. They are ideal for organizing a heating system and water supply system in the house.

Odnoklassniki It is very difficult to name those areas in which steel pipes are not used. They are used in oil pipelines, heating mains, main water pipelines, heating systems and many others.

Service life of steel pipes

It is very difficult to name those areas in which steel pipes are not used. They are used in oil pipelines, heating mains, main water pipelines, heating systems and many others. Many people are interested in how long a steel pipe can last. Their service life depends greatly on operating conditions.

How long can steel heating pipes last?

A heating system that uses steel pipes has always been considered durable and reliable, capable of withstanding fairly heavy loads. The service life of steel heating pipes is thirty years. But why do some owners of newly built houses refuse steel pipes and prefer to make heating from plastic? The whole point is that the pipes are chosen incorrectly. There are two types of steel pipes:

- suture. This is the cheapest type of steel pipe. The choice of this type of pipe for heating is doomed to failure in advance, since its service life is only a few years and they will not live up to thirty years. This is because when installing a heating system, it is very difficult to bend such a pipe and the seam simply bursts at the bend. Also, the inside of the seam cannot be properly processed; a leak may appear and the pipe will need to be replaced. Therefore, it is not suitable for heating systems;

- seamless. Such pipes are much more reliable. For individual heating, such pipes with a diameter of 25 mm are recommended; when tested, they can withstand loads of up to 20 atmospheres. Therefore, for at least twenty years, such pipes will last without problems.

Remember that previously only steel pipes were installed for the heating system. And often, when installing autonomous heating and replacing steel pipes with plastic ones, it turned out that they could serve for a long time, despite the fact that they were installed twenty years ago.

How long can steel water pipes last?

Also read: Standard diameters of steel pipes

The service life of steel water pipes and sewer pipes made of the same metal is fifteen years. The same galvanized steel pipes can last for thirty years. During the first five years of operation, the inner surface of the water supply pipes becomes overgrown, and wet condensation appears on the surface, not to mention the fact that they withstand high dynamic loads. And galvanized steel pipes are coated with an anti-corrosion coating, so they can last much longer.

Advantages and disadvantages of steel pipes

Advantages:

- low cost, however, this is compensated by the high cost of installation work;

- strength;

— with increasing temperatures there is slight deformation;

- durability.

Flaws:

— corrosion. However, to delay it, a zinc coating is used, which is found on galvanized pipes, which can last the longest;

— to work with pipes, welding is required;

- do not bend well;

— with a sharp increase in pressure, the pipe may rupture.